TPEE insulated wire, and preparation method and application thereof

A technology of insulated wires and insulating layers, which is applied in the manufacture of cables/conductors, insulation of conductors/cables, and circuits. It can solve the problems of spark breakdown, poor high and low temperature resistance, and poor wear resistance of TPEE insulated wires To achieve the effect of large market application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

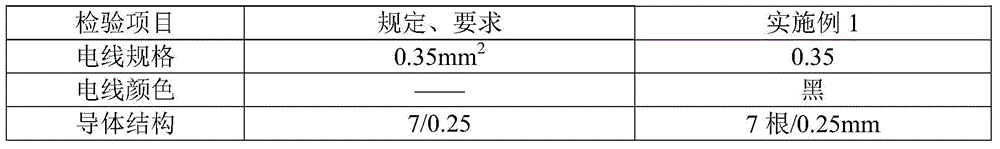

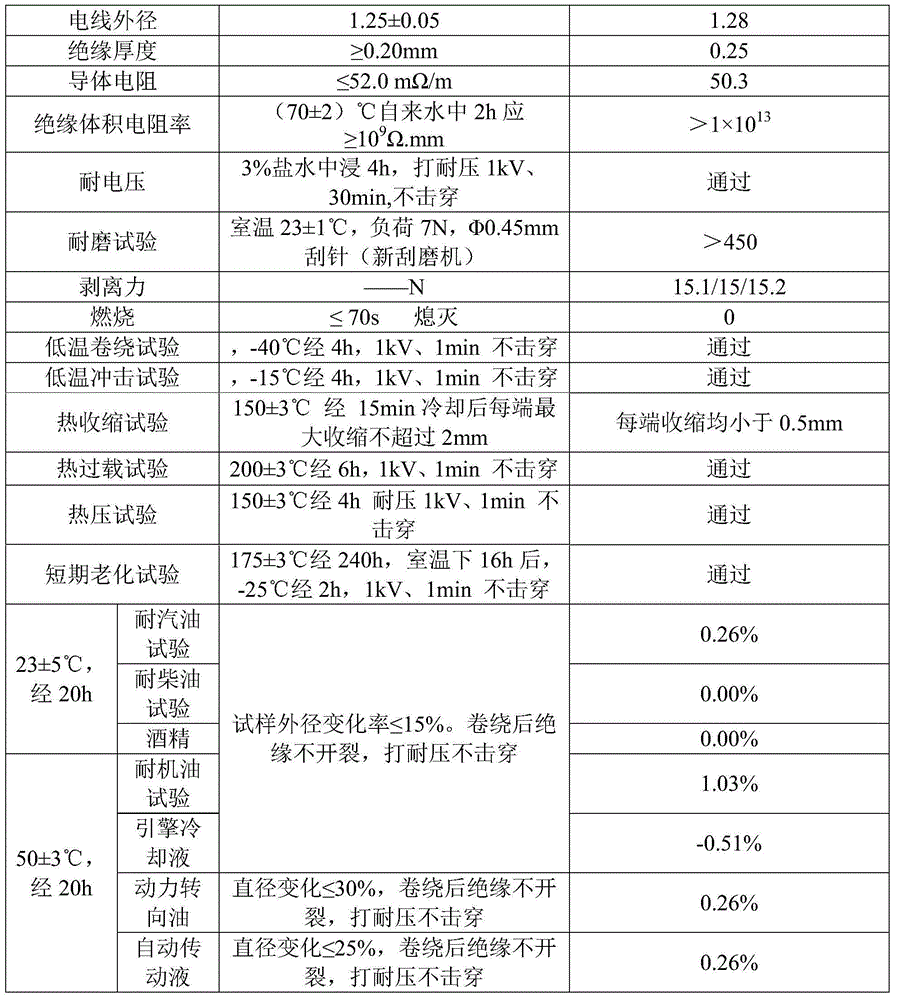

Embodiment 1

[0044] Wire specification: Stranded conductor cross-sectional area 0.35mm 2 , The nominal thickness of the wire insulation layer is 0.25mm; the outer diameter of the wire is 1.28mm.

[0045] Material selection: Melt index 15cm 3 / 10min of TPEE insulation material;

[0046] Stranded conductor: twisted by annealed soft copper wire with a purity of 99.99%. The stranded conductor consists of seven 0.25mm copper monofilaments twisted together.

[0047] The preparation steps of the wire are as follows:

[0048] (1) Preheat the conductor to a temperature of 90°C;

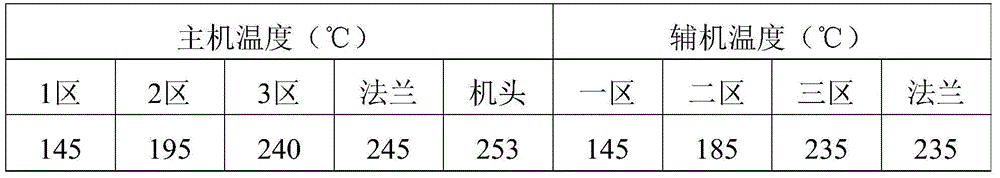

[0049](2) Use Φ45+Φ25 type extruder to extrude the TPEE insulation material on the preheated conductor to obtain the extrudate; the extrusion temperature of the extruder is shown in Table 1;

[0050] (3) The extruded extrudate passes through the cooling zone sequentially from high temperature to low temperature: the first water cooling zone at 65°C; the second air cooling zone at 40°C; the third water cooling zone at ...

Embodiment 2

[0060] Wire specification: Stranded conductor cross-sectional area 2.5mm 2 , the thickness of the wire insulation layer is 0.35mm; the maximum outer diameter of the wire is 2.85mm.

[0061] Material selection: Melt index 15cm 3 / 10min of TPEE insulation material;

[0062] Stranded conductor: twisted by annealed soft copper wire with a purity of 99.99%. The stranded conductor is made of 19 copper monofilaments of 0.41mm.

[0063] The preparation steps of the wire are as follows:

[0064] (1) Preheat the conductor to a temperature of 70°C;

[0065] (2) Use Φ45+Φ25 type extruder to extrude TPEE insulation material on the preheated conductor to obtain the extrudate; the extrusion temperature of the extruder is shown in Table 3;

[0066] (3) The extruded extrudate passes through the cooling zone sequentially from high temperature to low temperature: the first water cooling zone at 65°C; the second air cooling zone at 40°C; the third water cooling zone at 23°C.

[0067] Wherei...

Embodiment 3

[0076] Wire specification: Stranded conductor cross-sectional area 0.35mm 2 , The nominal thickness of the wire insulation layer is 0.25mm; the outer diameter of the wire is 1.28mm.

[0077] Material selection: Melt index 15cm 3 / 10min of TPEE insulation material;

[0078] Stranded conductor: twisted by annealed soft copper wire with a purity of 99.99%. The stranded conductor consists of seven 0.25mm copper monofilaments twisted together.

[0079] The preparation steps of the wire are as follows:

[0080] (1) Preheat the conductor to a temperature of 90°C;

[0081] (2) Use Φ45+Φ25 type extruder to extrude the TPEE insulation material on the preheated conductor to obtain the extrudate; the extrusion temperature of the extruder is shown in Table 1;

[0082] (3) The extruded extrudate passes through the cooling zone sequentially from high temperature to low temperature: the first water cooling zone at 60°C; the second air cooling zone at 30°C; the third water cooling zone at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com