UV wrinkled ink capable of forming wrinkles in two modes as well as preparation method and application of UV wrinkle ink

A wrinkle and ink technology, applied in the field of UV wrinkle ink and preparation, can solve the problems of not having wrinkle ink production conditions and restricting the development of UV silk screen wrinkle ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

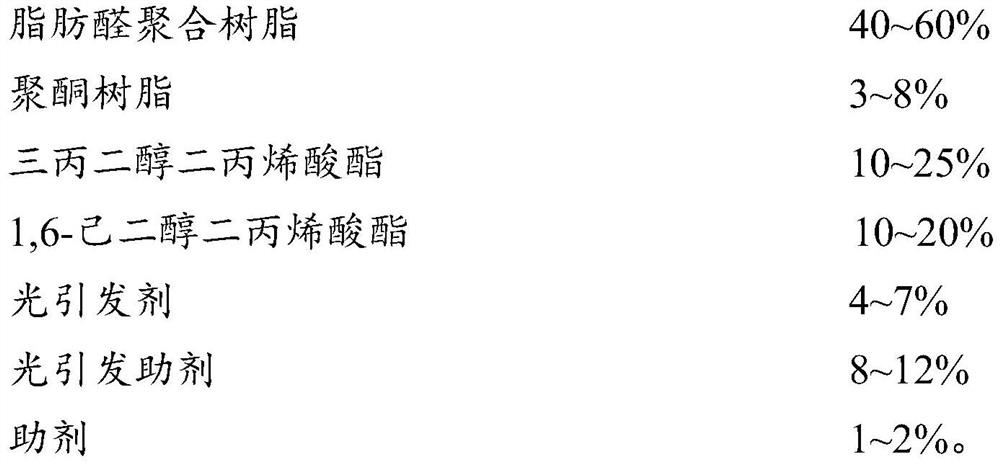

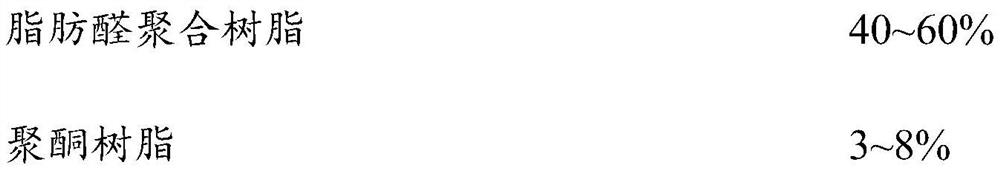

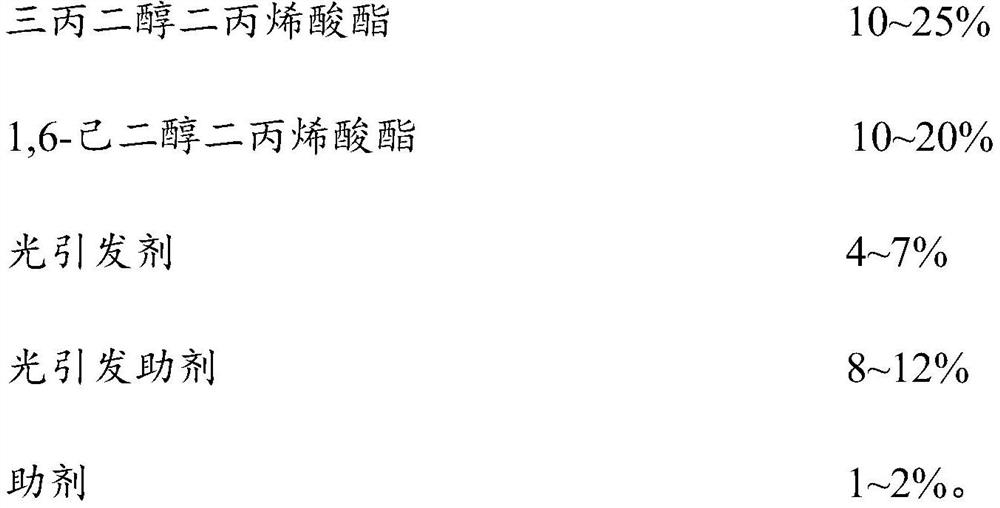

Method used

Image

Examples

preparation example Construction

[0043] Another object of the present invention is to provide a kind of preparation method of the above-mentioned UV wrinkle ink that can adopt two kinds of modes to go out grain, specifically comprise the steps:

[0044] S1, mixing and stirring aliphatic aldehyde polymer resin, polyketone resin and tripropylene glycol diacrylate to obtain an acrylic resin, then adding a photoinitiator and a polymerization inhibitor, and continuing to stir to obtain a semi-finished product;

[0045] S2. Add 1,6-hexanediol diacrylate, defoamer and photoinitiation aid to the semi-finished product, stir and filter to obtain a finished product.

[0046] In the present invention, the aliphatic aldehyde polymer resin, polyketone resin and tripropylene glycol diacrylate in the step S1 are preferably mixed and stirred at a stirring speed of 300 to 500 r / min; a photoinitiator and a polymerization inhibitor are added in the step S1 The stirring speed at which the agent is continuously stirred is preferab...

Embodiment 1

[0050] In parts by weight, mix aliphatic aldehyde polymer resin, polyketone resin, and tripropylene glycol diacrylate in a ratio of 7:1:4 to form 72 parts, control the stirring speed at 300-500r / min, stir and dissolve into acrylic acid without solid particles Resin, then add 6 parts of photoinitiator and 0.1 part of polymerization inhibitor, control the stirring speed to 1000-1500r / min, stir until there are no solid particles, make semi-finished products for later use, then add 11 parts of 1,6-hexanediol diol Acrylate and 1 part of defoaming agent, defoaming and adjusting ink viscosity, stir evenly, finally add 9.9 parts of active amine, use a disperser at a speed of 1000r / min, disperse for 10 minutes, and then filter with a 200-mesh filter to obtain a finished product.

Embodiment 2

[0052] According to parts by weight, aliphatic aldehyde polymer resin, polyketone resin, and tripropylene glycol diacrylate are mixed according to the ratio of 28:3:15 to form 69 parts, and the stirring speed is controlled at 300-500r / min, stirring and dissolving into acrylic acid without solid particles Resin, then add 5 parts of photoinitiator and 0.1 part of polymerization inhibitor, control the stirring speed to 1000-1500r / min, stir until there are no solid particles, make semi-finished products for use, then add 15 parts of 1,6-hexanediol diol Acrylate and 1 part of defoaming agent, defoaming and adjusting ink viscosity, stir evenly, finally add 9.9 parts of active amine, use a disperser at a speed of 1000r / min, disperse for 10 minutes, and then filter with a 200-mesh filter to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com