Solvent-free cardanol aldehyde amine epoxy resin curing agent containing thiazole structure and preparation method of solvent-free cardanol aldehyde amine epoxy resin curing agent

A phenalkamine epoxy resin, solvent-free technology, applied in the direction of epoxy resin coating, organic chemistry, coating, etc., can solve the problem of single variety, etc., achieve fast drying speed, high adhesion, strong wear resistance and solvent resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Cardanol: 2,6-diamino-4,5,6,7-tetrahydrobenzothiazole: formaldehyde = 1.2: 0.72: 1.8 according to the molar ratio, and the cashew nut phenolic formaldehyde of the present invention is synthesized according to this feeding ratio Amine type epoxy resin curing agent.

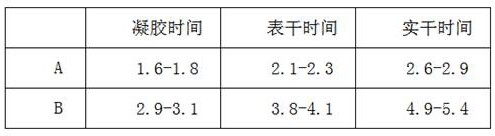

[0022] Steps: first heat 360 g (1.2 mol) of cardanol and 121.85 g (0.72 mol) of 2,6-diamino-4,5,6,7-tetrahydrobenzothiazole to 55 ℃ and stir for 15 minutes, fully dissolve and mix Then, add 54 g (1.8mol) formaldehyde, react at 90°C for 1 h, then raise the temperature to 120°C for 2 h, decompress and vacuum dehydrate at 10 kPa for 1 h after the reaction, then lower the temperature to After reaching 85°C, add 16g of accelerator ethanolamine with a total mass of raw materials of 3% (mass percentages in the following examples are all relative to the total mass of raw materials), and discharge after stirring for 0.5 h to obtain cashew phenalkamine epoxy resin curing agent A. According to the "Determin...

Embodiment 2

[0024] Example 2: Cardanol: 2,6-diamino-4,5,6,7-tetrahydrobenzothiazole: formaldehyde = 1.25: 0.77: 1.85 according to the molar ratio, and the cashew phenalkamine ring was synthesized according to this feeding ratio Oxygen resin curing agent.

[0025] Steps: first heat 375 g (1.25 mol) of cardanol and 130.314 g (0.77 mol) of 2,6-diamino-4,5,6,7-tetrahydrobenzothiazole to 60 ℃ and stir for 15 minutes, fully dissolve and mix Afterwards, 55.5 g (1.85 mol) of formaldehyde was added, reacted at 95 °C for 1 h, and then heated to 120 °C for 2 h. After the reaction was completed, vacuum dehydration was carried out under reduced pressure and vacuum for 1 h under the condition of 11 kPa. After the temperature was lowered to 85 ° C, 19.63 g of 3.5 % accelerator diethanolamine was added, and the material was stirred for 0.5 h to obtain the cashew nut phenalkamine epoxy resin curing agent A . According to the "Determination of Viscosity of Adhesives" GB / T 2794-1995, the viscosity was tes...

Embodiment 3

[0027] Example 3: Cardanol: 2,6-diamino-4,5,6,7-tetrahydrobenzothiazole: formaldehyde = 1.27: 0.75: 1.89 according to the molar ratio, and the cashew phenalkamine ring was synthesized according to this feeding ratio Oxygen resin curing agent.

[0028] Steps: first heat 381 g (1.27 mol) of cardanol and 126.93 g (0.75 mol) of 2,6-diamino-4,5,6,7-tetrahydrobenzothiazole to 60 ℃ and stir for 15 minutes, fully dissolve and mix Afterwards, 56.7 g (1.89 mol) of formaldehyde was added, reacted at 95 °C for 1 h, and then heated to 120 °C for 2 h. After the reaction, vacuum dehydration was carried out at 12 kPa for 1 h. After the temperature was lowered to 85 °C, 19.635 g of 3.5% accelerator ethanolamine was added, and the mixture was stirred for 0.5 h to obtain the cashew phenalkamine epoxy resin curing agent A. According to "Determination of Viscosity of Adhesives" GB / T 2794-1995, the viscosity was tested at 40°C, the viscosity was 15610mPa·S, and the amine value was determined to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Amine value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com