Large-diameter counter bit machining method

A processing method and large-diameter technology, applied in the processing field of large-diameter countersinking, can solve the problems of large machining allowance, waste of machining time, and waste of tool materials, so as to ensure the processing quality, save tool processing materials, and improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

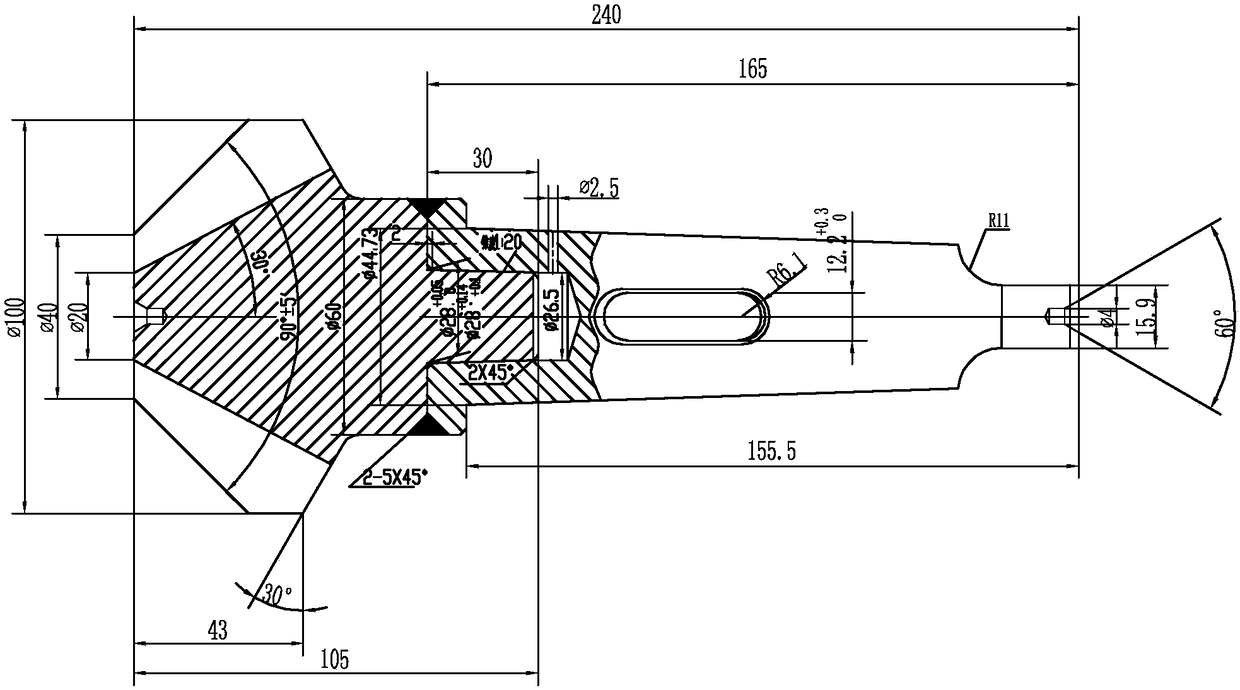

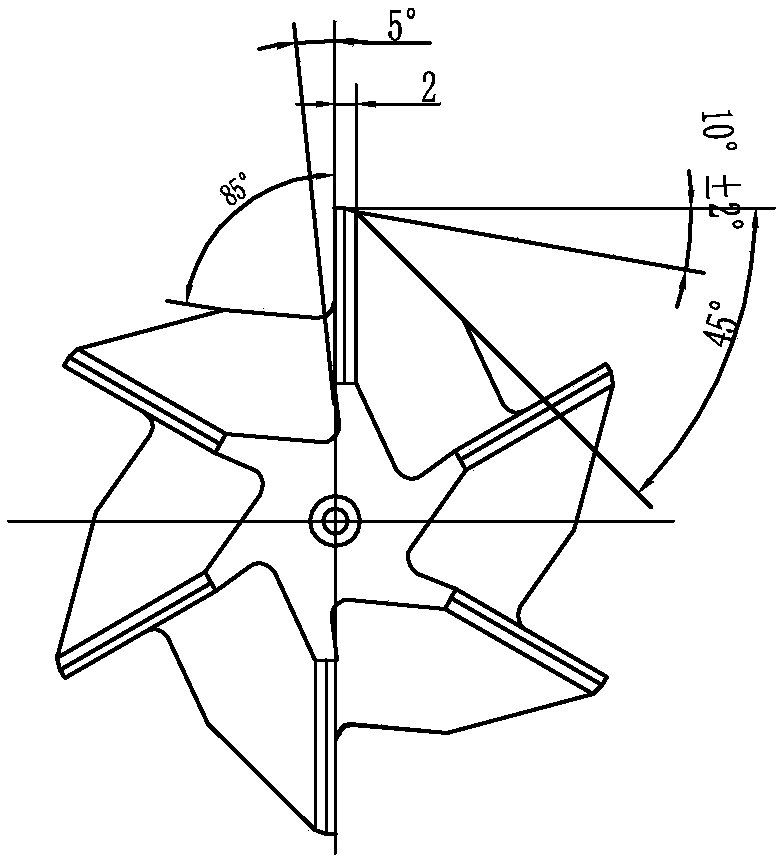

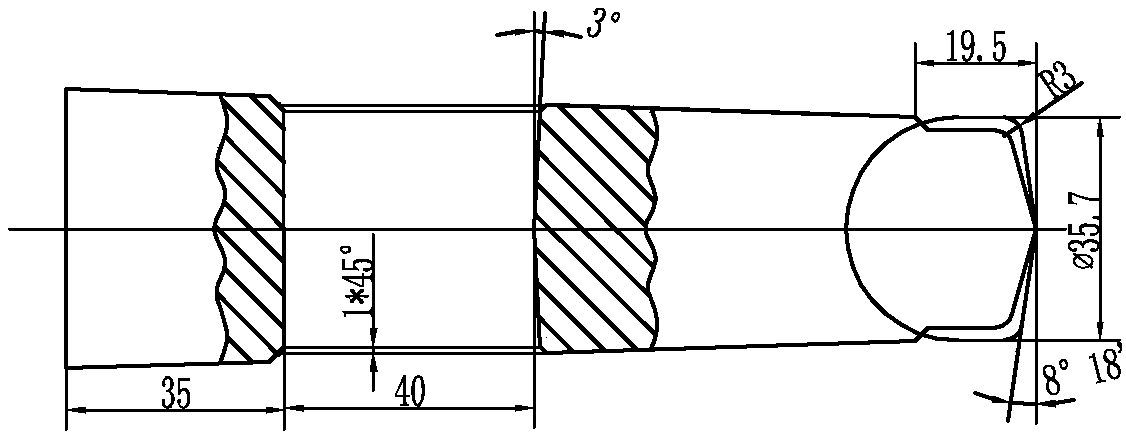

[0032] Specific implementation mode one: as Figure 1~3 As shown, the processing method steps of the large-diameter countersink of the present embodiment are as follows:

[0033] Step 1. Turning the countersink and the tool holder on the lathe: the tool holder adopts Mohs No. 5 taper shank, the taper of the taper shank is 0.6-0.7mm, the small end face of the tool holder is machined along the axial direction to the center hole, and the countersink is processed with a 90° conical surface , the volume of the taper surface is 0.6~0.7mm, the small end of the countersink drills the center hole along the axial direction, the taper of the large end of the countersink drill is turned into a 1:20 taper shank, and the large end of the tool bar is turned into a 1:20 taper hole, the taper The gap between the hole and the countersinking taper shank is 0.1mm, the taper hole is countersinked at 90° chamfering, and the outer circle of the countersinking drill and the tool holder is processed w...

specific Embodiment approach 2

[0045] Specific embodiment two: In this embodiment, the rotating speed is 240r / min, the feed rate is 0.3mm / r, and the cutting depth is 1.5mm. In this way, a small depth of cut of 1.5mm can be used for processing, which can effectively prevent the bending phenomenon of the processed parts and effectively ensure the quality of the processed surface. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0046] Specific implementation mode three: In step one of this implementation mode, the taper of the taper shank is increased to 0.65mm. In this way, a machining allowance is reserved. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com