Electric power unit for vehicle

An electric power and vehicle technology, which is applied to vehicle components, electric scooters, vehicle gearboxes, etc., can solve the problems of increased weight of electric power units, many assembly man-hours, and reduced rigidity of the transmission shell, and achieve the effect of rigidity strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Embodiments of the present invention will be described below based on the drawings.

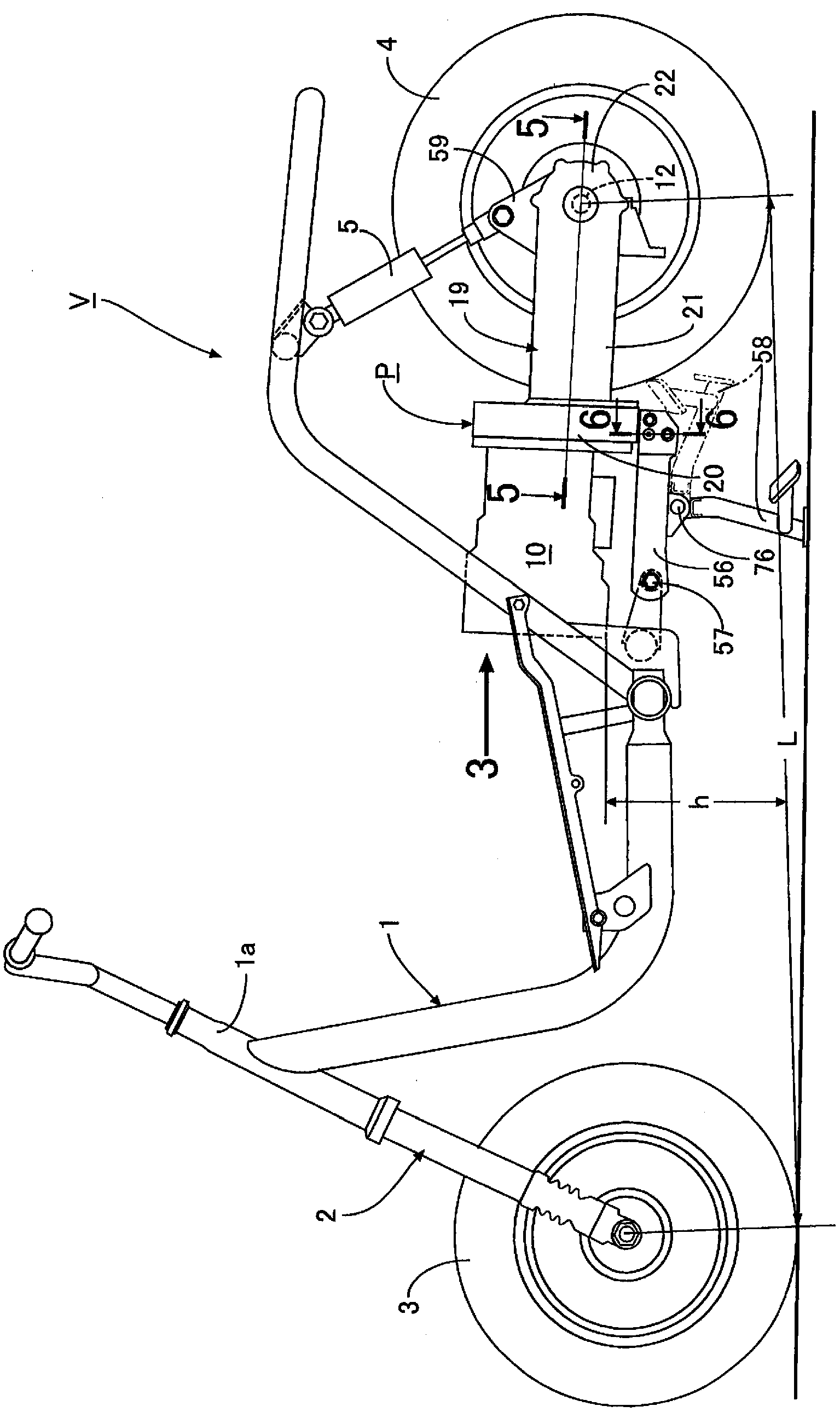

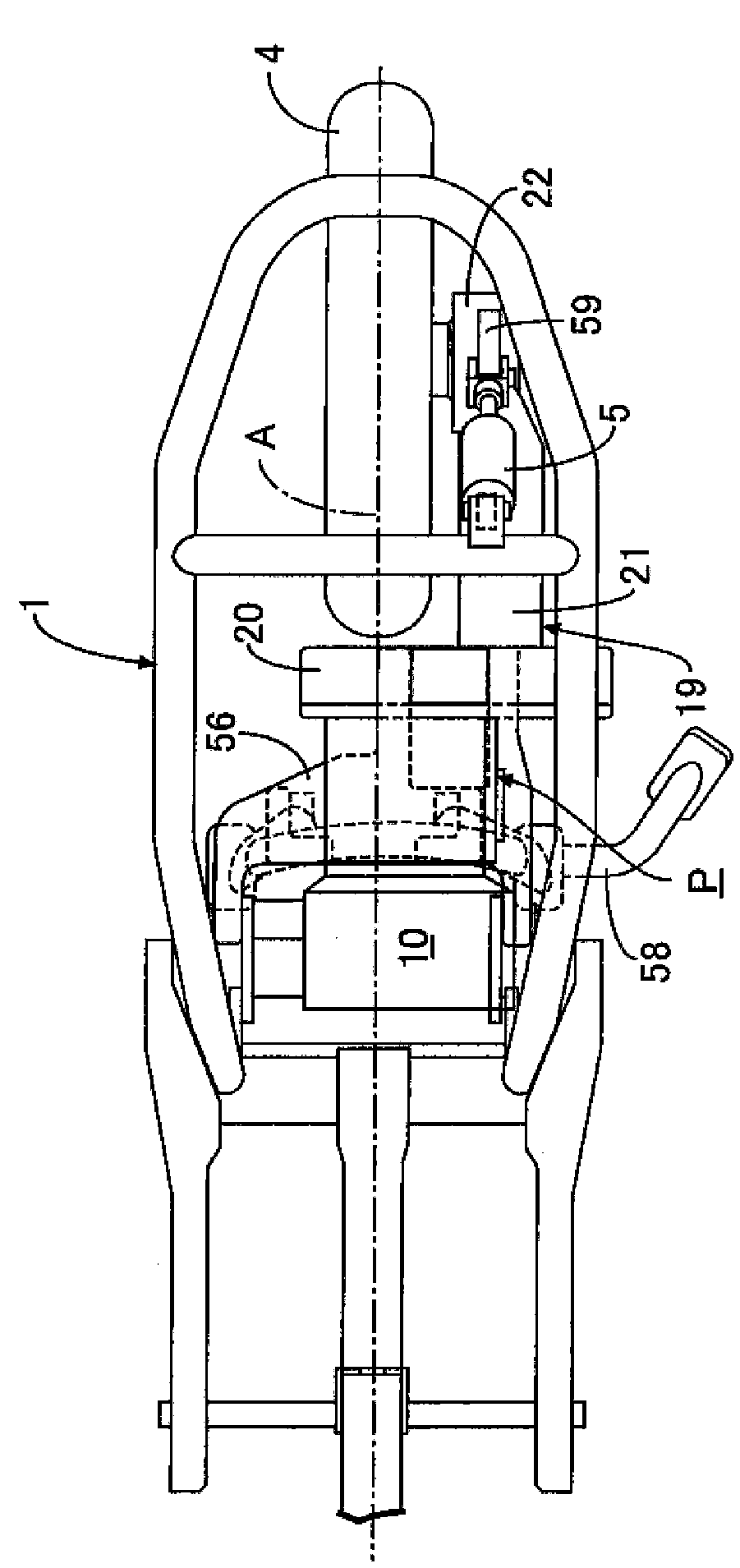

[0084] First, from Figure 1 to Figure 9 The description begins with the first embodiment of the invention shown. exist Figure 1 ~ Figure 4 Among them, a scooter-type motorcycle V as a vehicle includes: a vehicle frame 1; a front fork 2 that is connected to a steering standpipe 1a at the front end of the vehicle frame 1 so as to be able to steer in a direction and supports a front wheel 3; The power unit P is mounted on the rear lower part of the vehicle frame 1 in a manner capable of swinging up and down via the pivot shaft 57 and supports the rear wheels 4, and the electric power unit P drives the rear wheels 4. Between the electric power unit P and the vehicle A buffer unit 5 for buffering the vertical swing of the electric power unit P is interposed between the frames 1 .

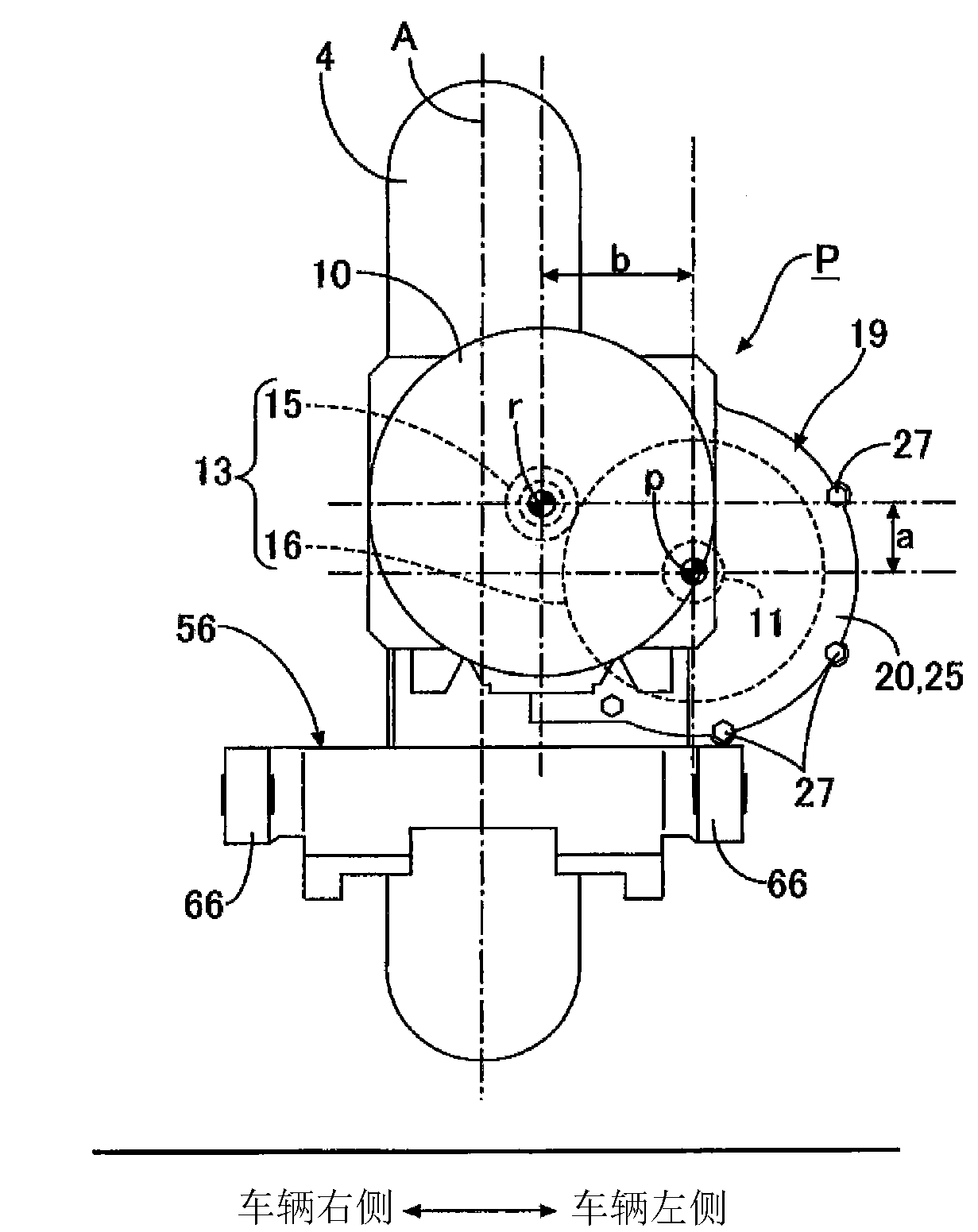

[0085] Such as Figure 5As shown, the electric power unit P includes: an electric motor 10 arranged so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com