A rotating assembly and steering gear connection mechanism

A technology of rotating components and connecting mechanisms, which is applied in the direction of motor vehicles, mechanical equipment, bearing components, etc., can solve problems such as poor running accuracy, achieve the effects of no loss of torque, avoid deflection, and ensure installation accuracy and working accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

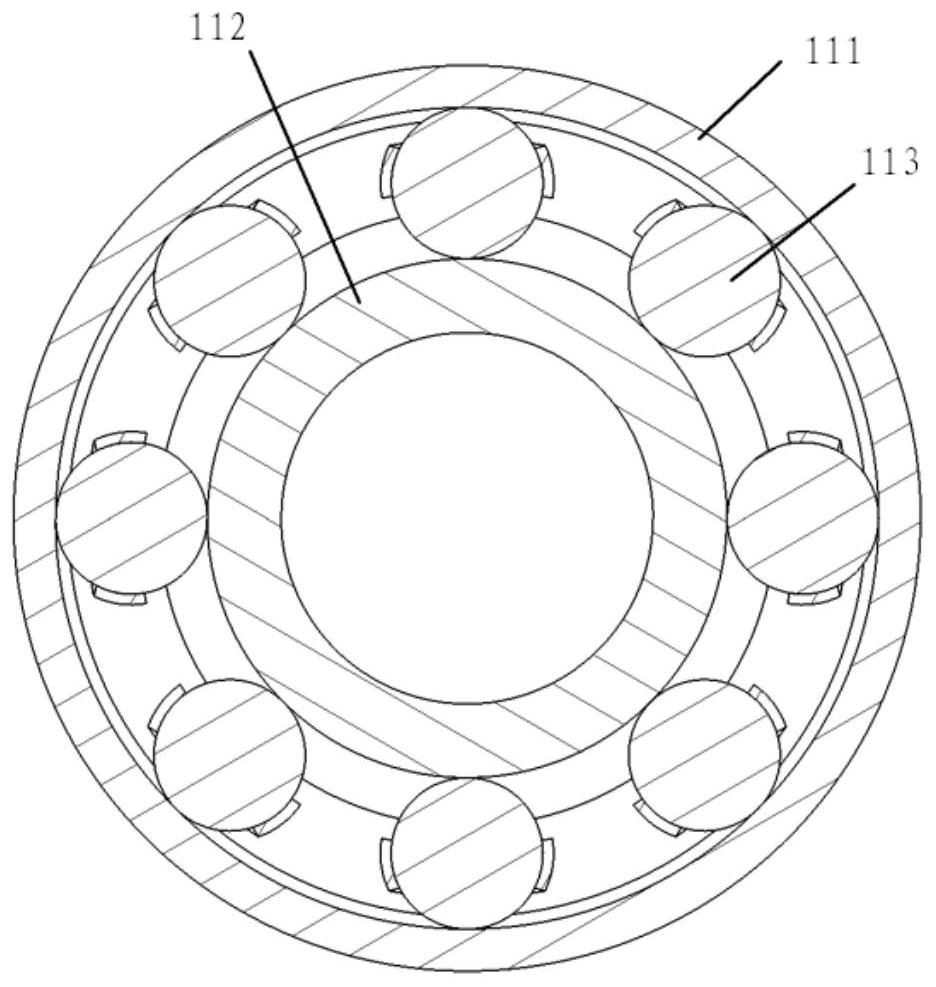

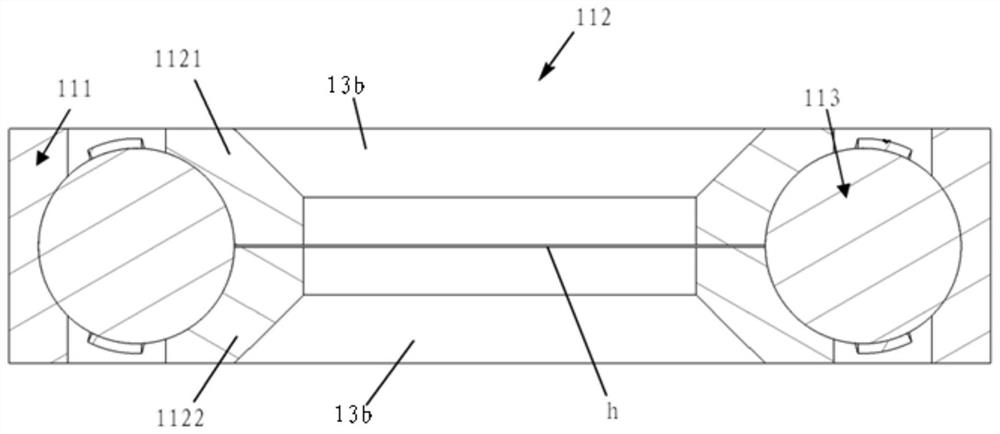

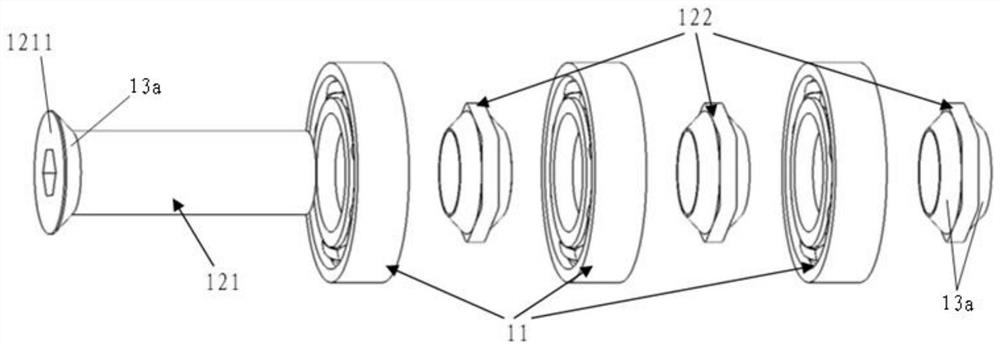

[0035] to combine figure 1 and figure 2 As shown, according to an embodiment of the present invention, a rotating assembly of the present invention includes: a bearing 11 and a locking member 12 . In this embodiment, the locking member 12 and the bearing 11 are coaxially connected to each other. In this embodiment, the bearing 11 includes a rotating outer ring 111 , a rotating inner ring 112 , and a rolling assembly 113 located between the rotating outer ring 111 and the rotating inner ring 112 . The rolling assembly 113 is clamped between the rotating outer ring 111 and the rotating inner ring 112 to ensure the relative rotation of the rotating outer ring 111 and the rotating inner ring 112 . see figure 2 As shown, in this embodiment, the rotating inner ring 112 includes a first inner ring portion 1121 and a second inner ring portion 1122 . The first inner ring portion 1121 and the second inner ring portion 1122 are arranged symmetrically to each other. Groove structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com