Clamping jaw corrector

A corrector and claw technology, applied in the directions of clamping, support, positioning device, etc., can solve the problems of cumbersome use, affecting the service life of the claw, and the claw is not concentric. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation, structure, features and functions of a claw corrector proposed according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

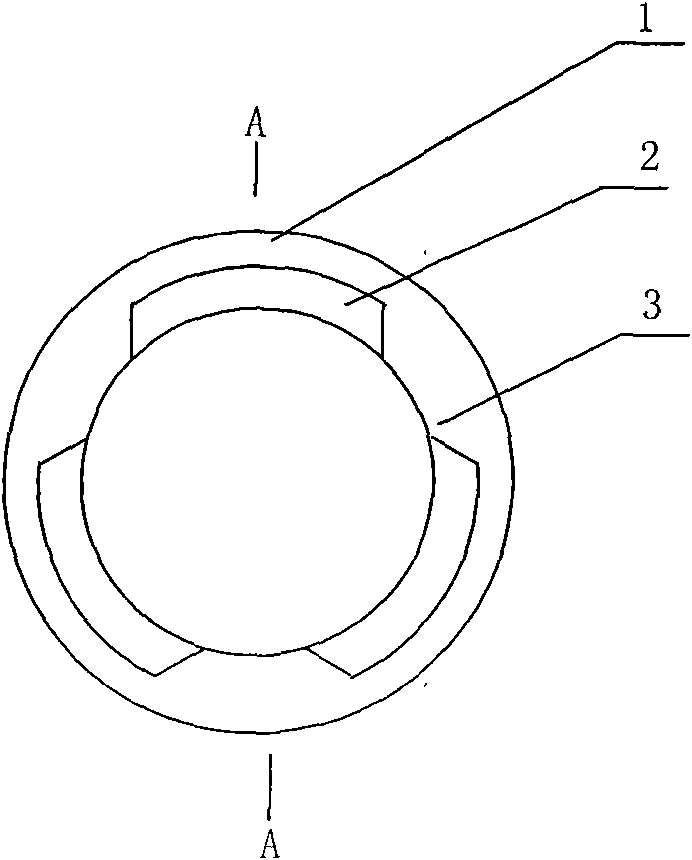

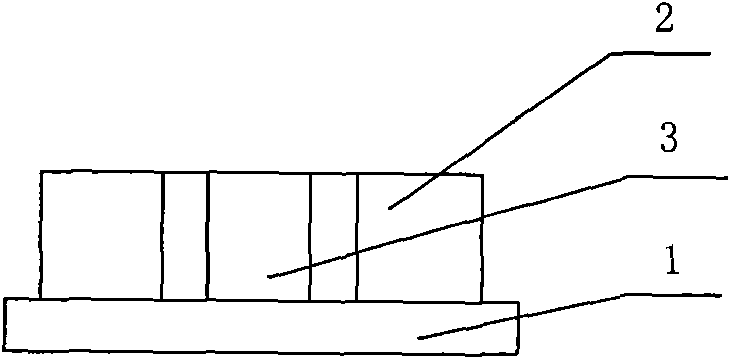

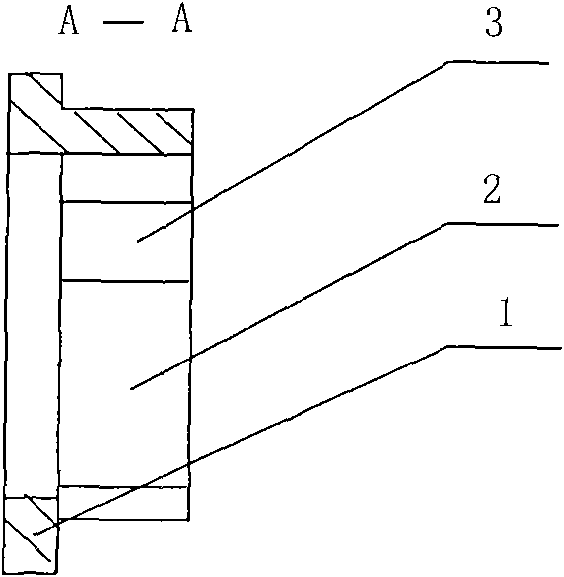

[0016] see Figure 1-5 , The claw corrector is a ring 1, and one side of the ring 1 is evenly provided with three bumps 2, and a bell mouth 3 of 120° is formed between adjacent bumps 2.

[0017] When in use, pass the three claws of the three-jaw chuck through the three bell mouths 3 formed between the adjacent bumps 2, so that the working surface of the claws is exposed in the ring 1, adjust the claws to turn the chuck The claw corrector is clamped on the 120° inclined surface of the claw, and the working surface is corrected with a round knife. It only takes a few minutes to correct and recover.

[0018] The above is only a preferred embodiment of the present invention, and does not limit the present invention in any form. Any simple modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com