Electric turnover mechanism

A technology of overturning mechanism and transmission mechanism, which is applied in the direction of transmission device, supporting machine, mechanical equipment, etc. It can solve the problems of small impact torque of planetary gear motor, complex structure of electric overturning mechanism, and existence of gaps, etc., and achieve high mechanical efficiency and high efficiency. Mechanical efficiency and mechanical self-locking characteristics, the effect of eliminating free clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

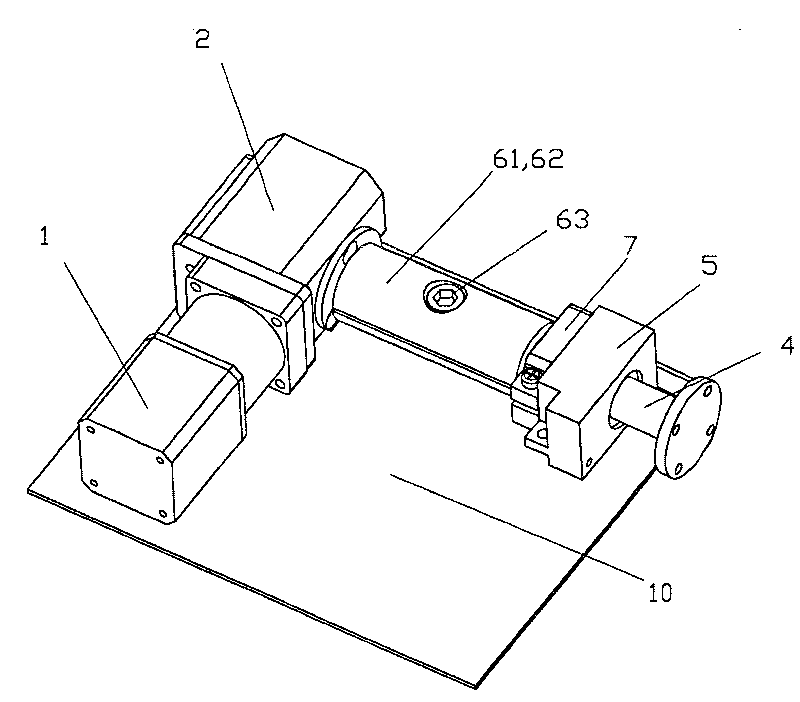

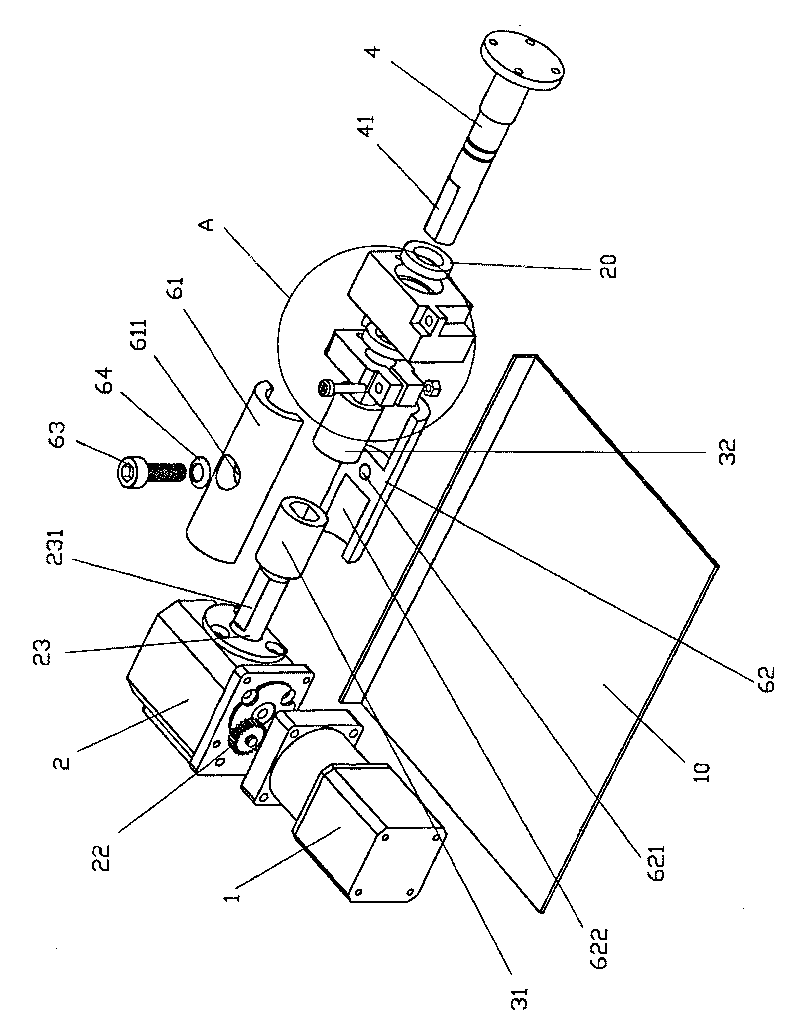

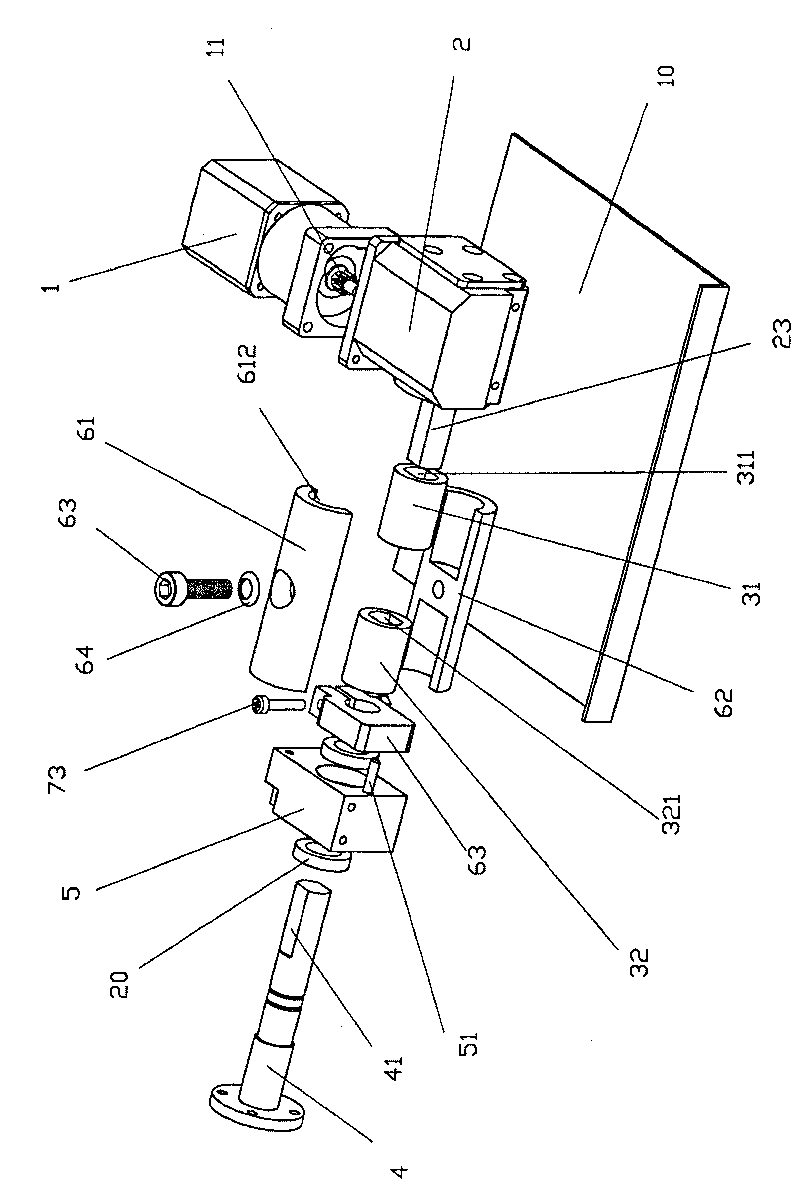

[0027] Referring to the accompanying drawings, an electric turning mechanism of the present invention includes a planetary gear reduction motor 1 driven by a motor, a worm and gear transmission mechanism 2, and a worm gear and worm transmission mechanism 2 installed at a position matched with the worm and gear and worm transmission mechanism through a fixing bracket 5 Mechanism output shaft 4 for flipping objects; the output of planetary gear reduction motor 1 is linked with worm gear and worm transmission mechanism 2 through gears, and the worm gear output shaft of worm gear and worm transmission mechanism 2 and mechanism output shaft 4 are arranged on the same axis; the first The friction member is fixed on the output end of the worm gear output shaft 4 along the circumferential direction, and the second friction member is fixed on the input end of the mechanism output shaft 4 along the circumferential direction; the two ends of the third friction member are respectively on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com