Patents

Literature

218results about How to "Guaranteed working accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

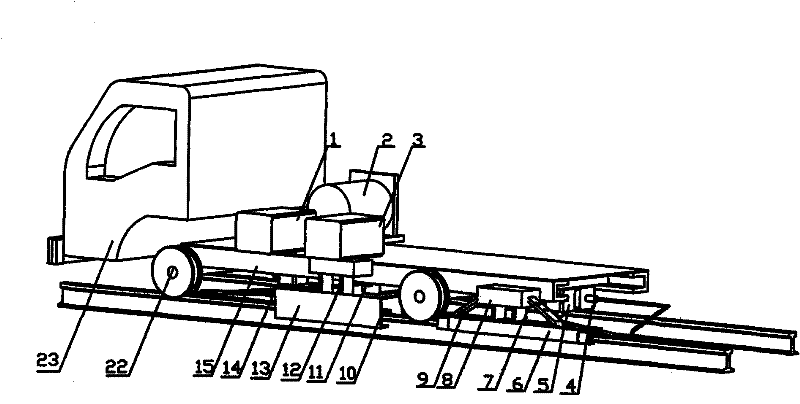

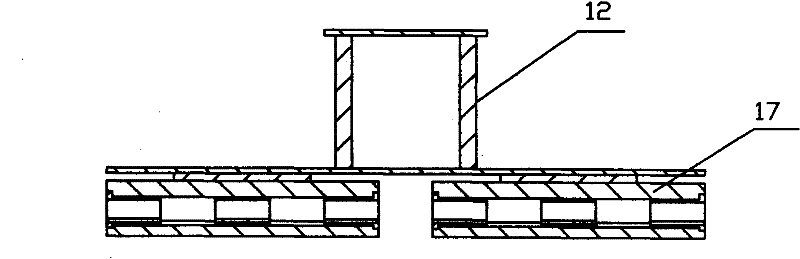

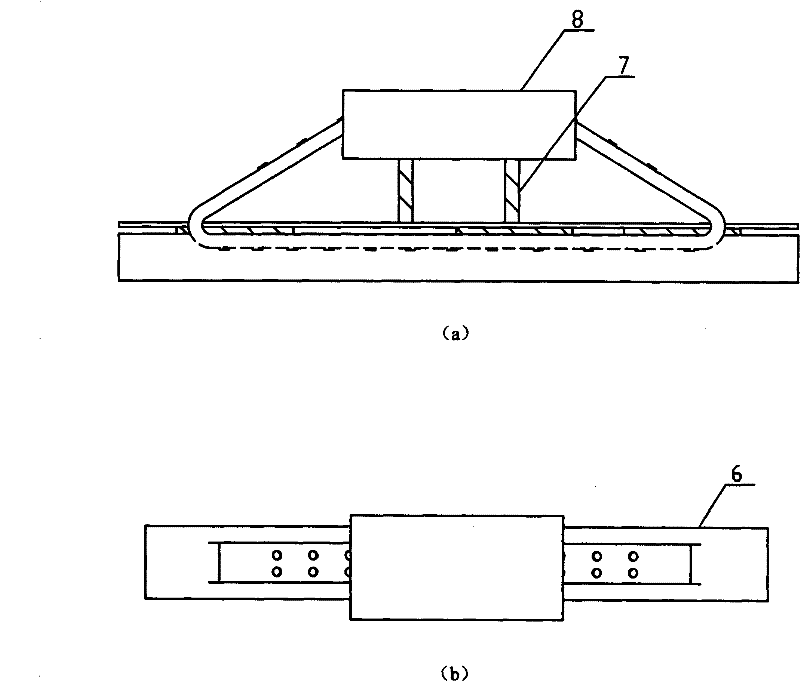

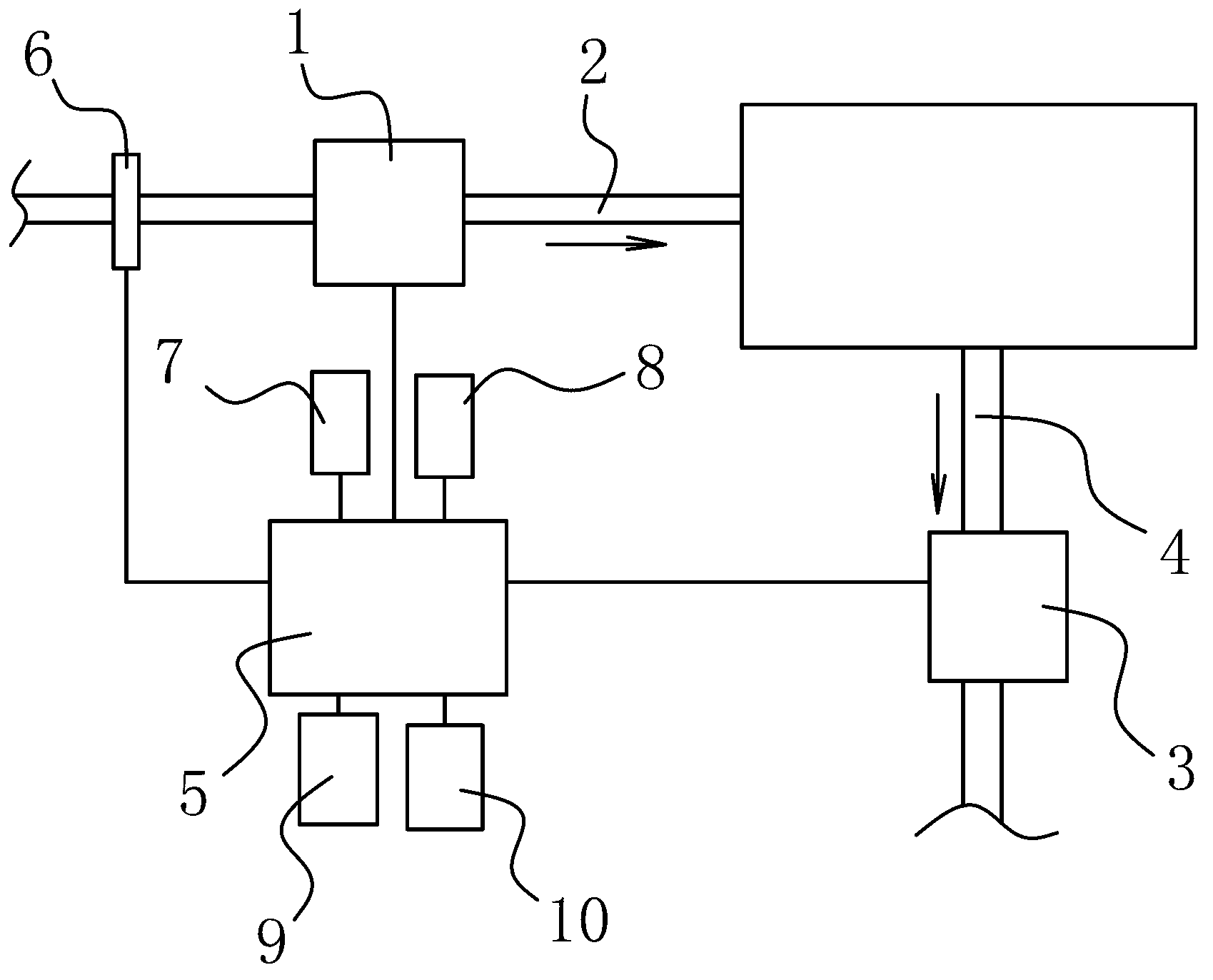

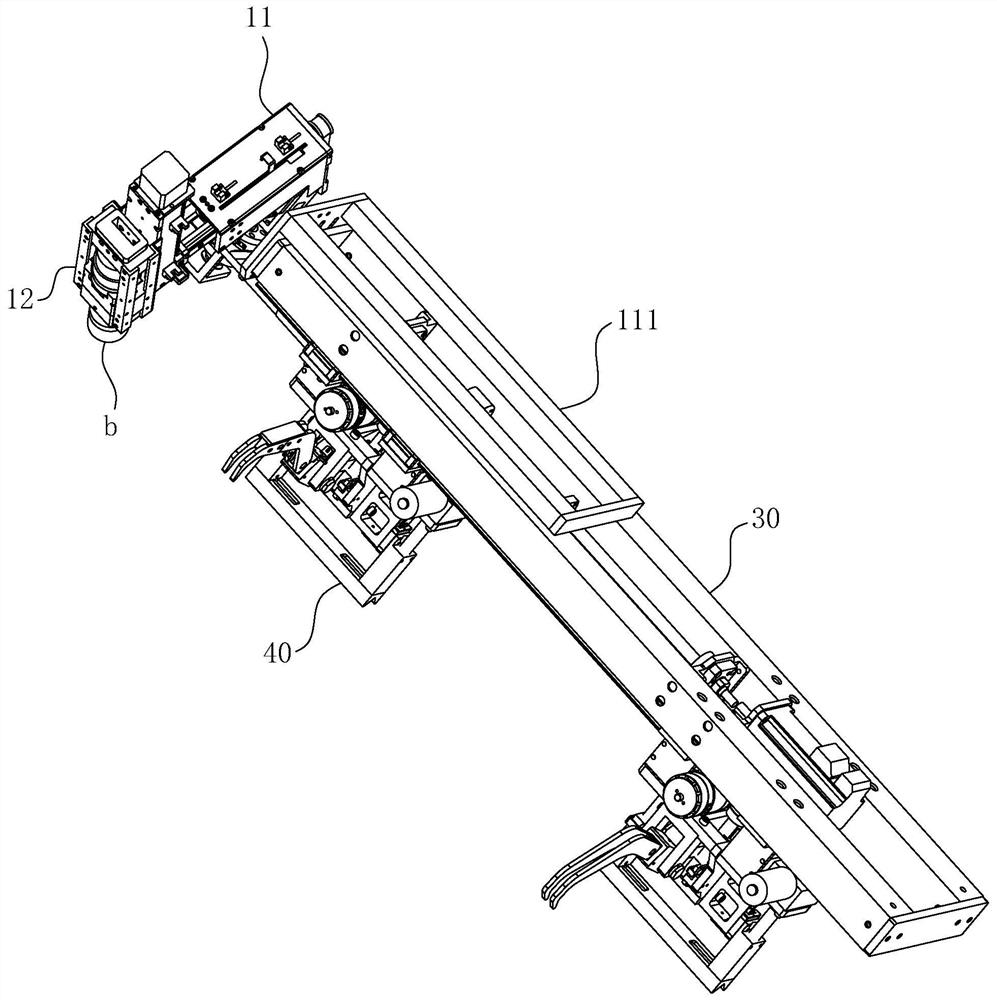

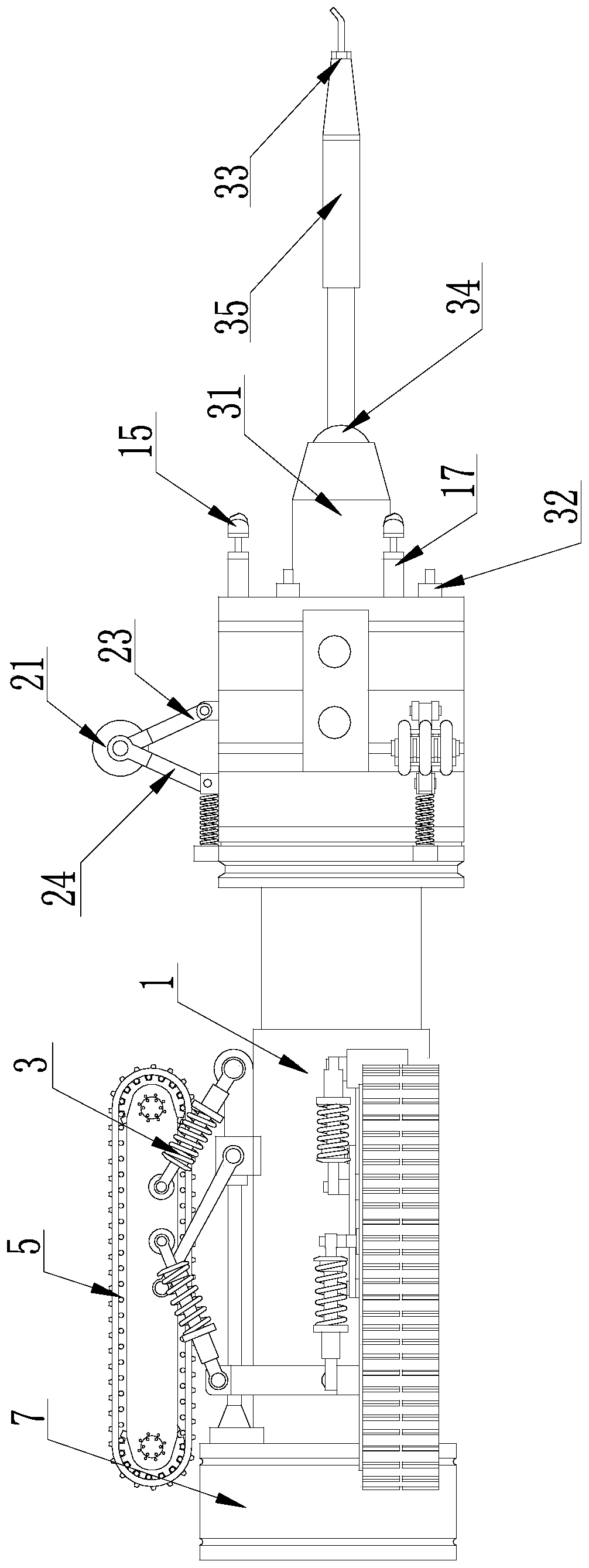

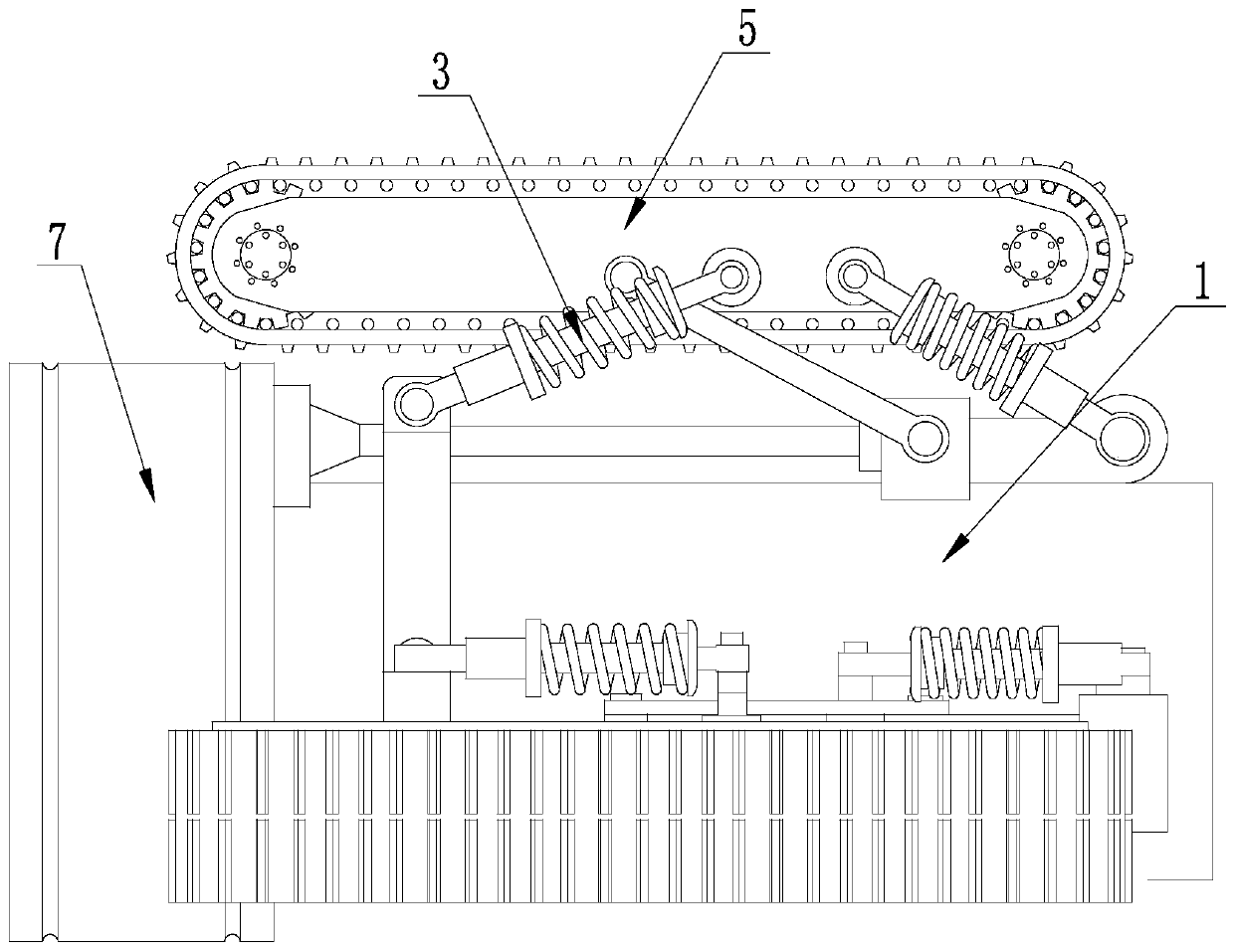

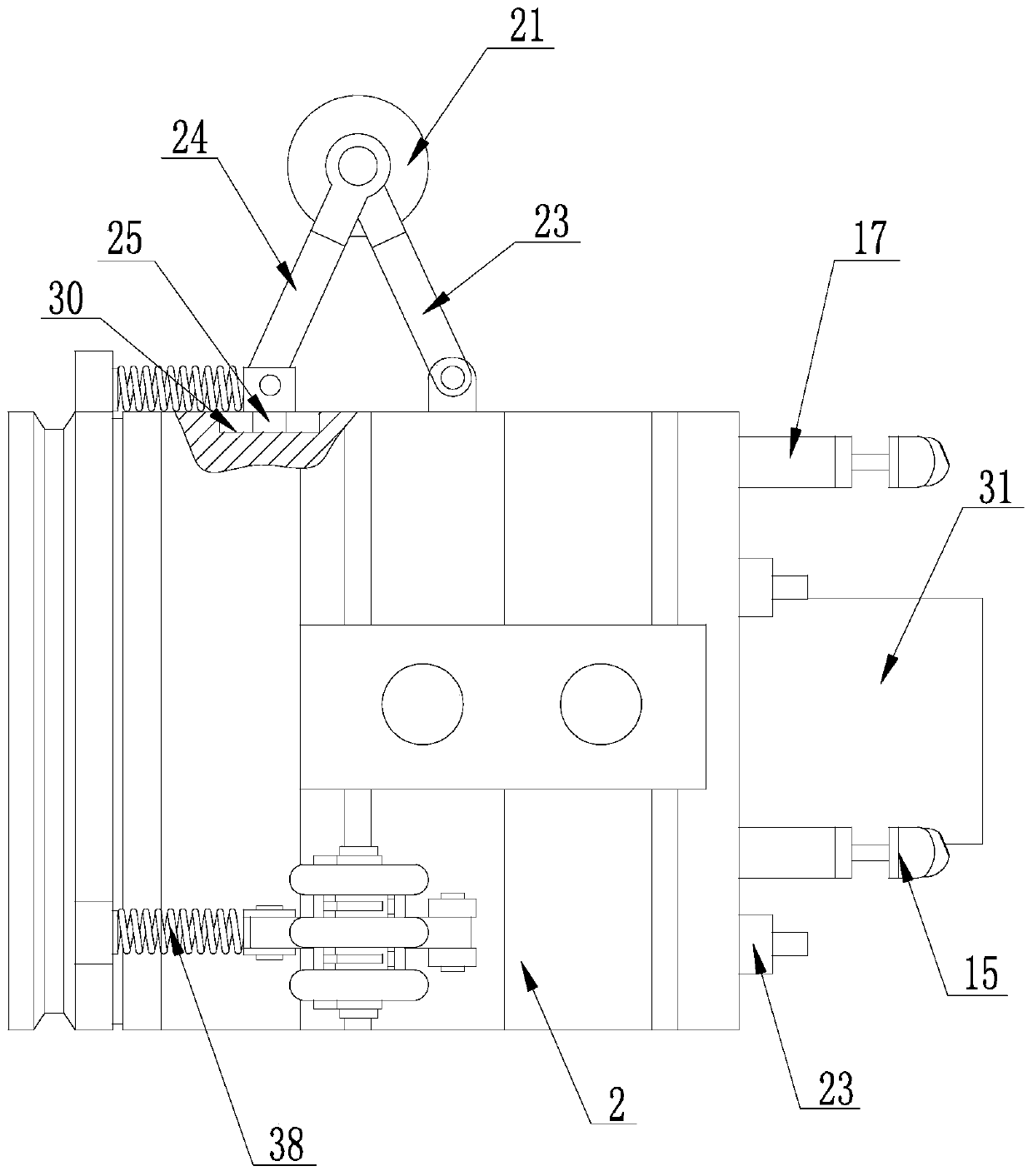

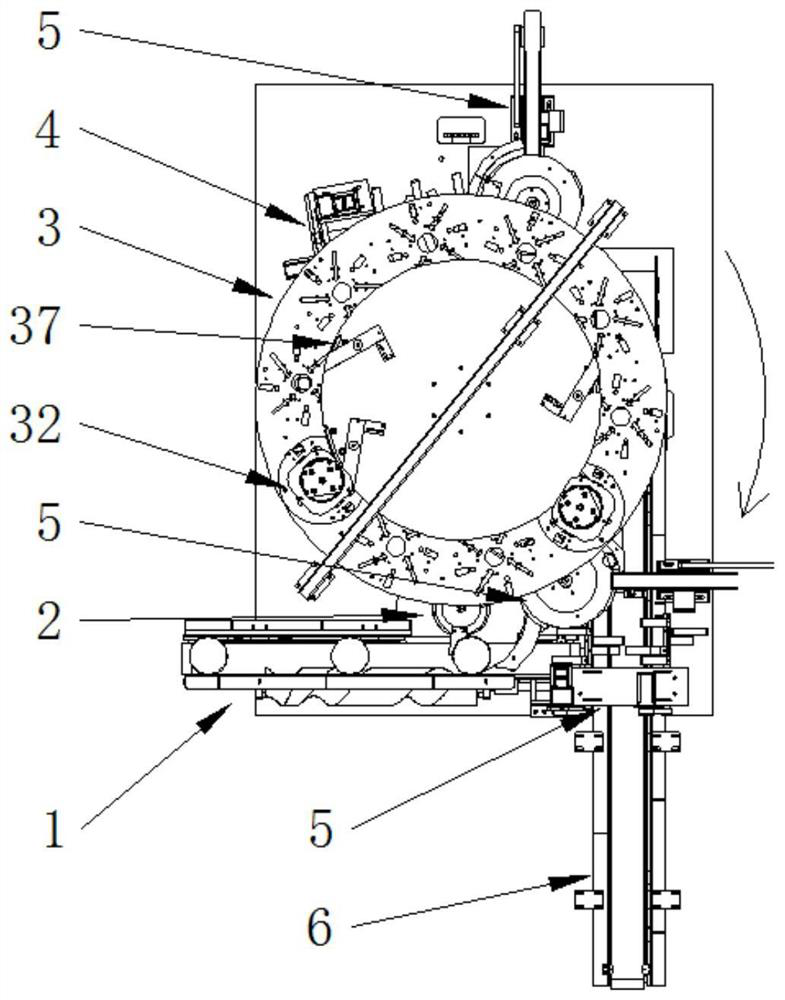

A cleaning maintenance vehicle using in a track

InactiveCN102162221AHigh degree of automationGuaranteed working accuracyRailway cleaningLight railSolvent

The invention discloses a cleaning maintenance vehicle using in a track, comprising a body device, a scraping mechanism, a scrubbing maintenance mechanism and a power energy mechanism. The cleaning maintenance vehicle using in the track is a track cleaning maintenance equipment of higher automation degree, and can realize a pre-treatment before the cleaning on the track working face, a thorough cleaning of the dirt on the track working face, a collecting and a cleaning of the cleaned down dirt, and an oiling maintenance of the cleaned track. The cleaning maintenance vehicle using in the tracktotally overcomes the problems in the prior art that the surface greasy filth and dry scab of the track can not be cleaned out automatically and effectively, the maintenance of the cleaned track is lacked, and the dirt and cleaning solvent can not be collected and cleaned in the process of cleaning. The cleaning maintenance vehicle using in the track of the invention realizes the automation of the cleaning and maintenance of the track, has the characteristics that the dirt is easy to recycle and clean, the cleanliness is high and the track working face is not easy to damage, etc. The cleaningmaintenance vehicle using in the track is not only suitable for cleaning dirt for the special track and similar track surfaces, but also suitable for maintenances of the city subway and city light rail.

Owner:海安磊洪新型建材有限公司 +1

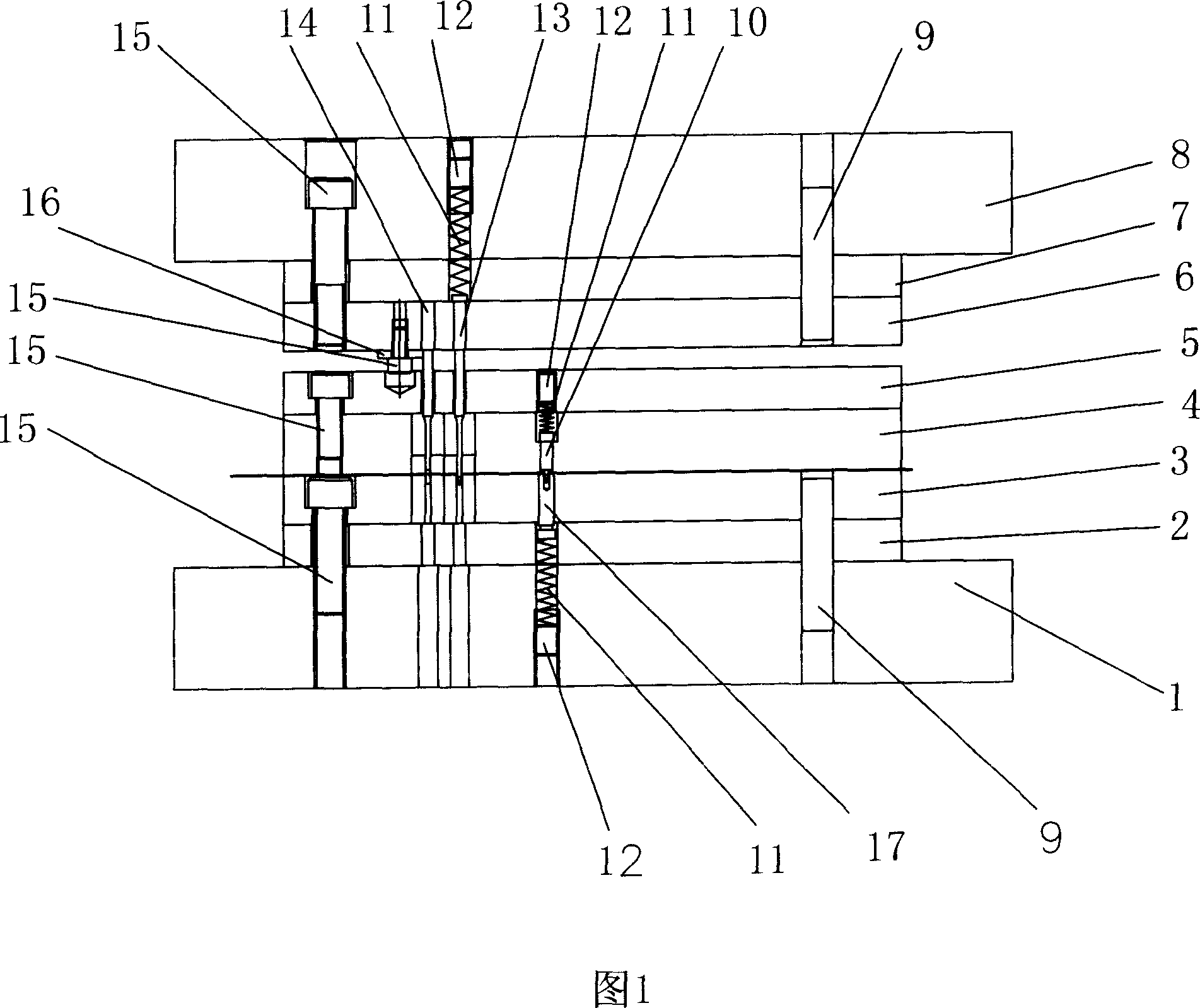

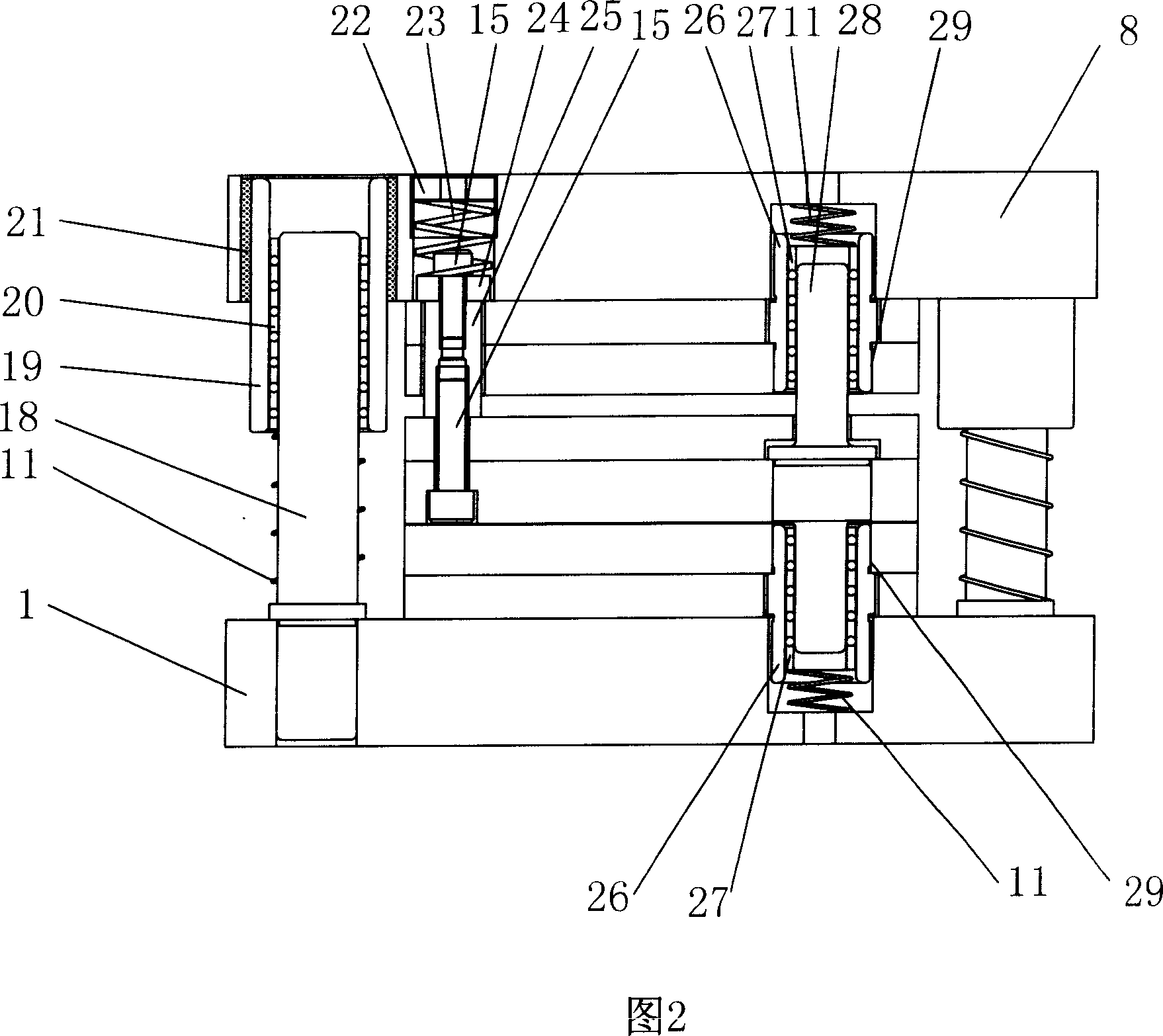

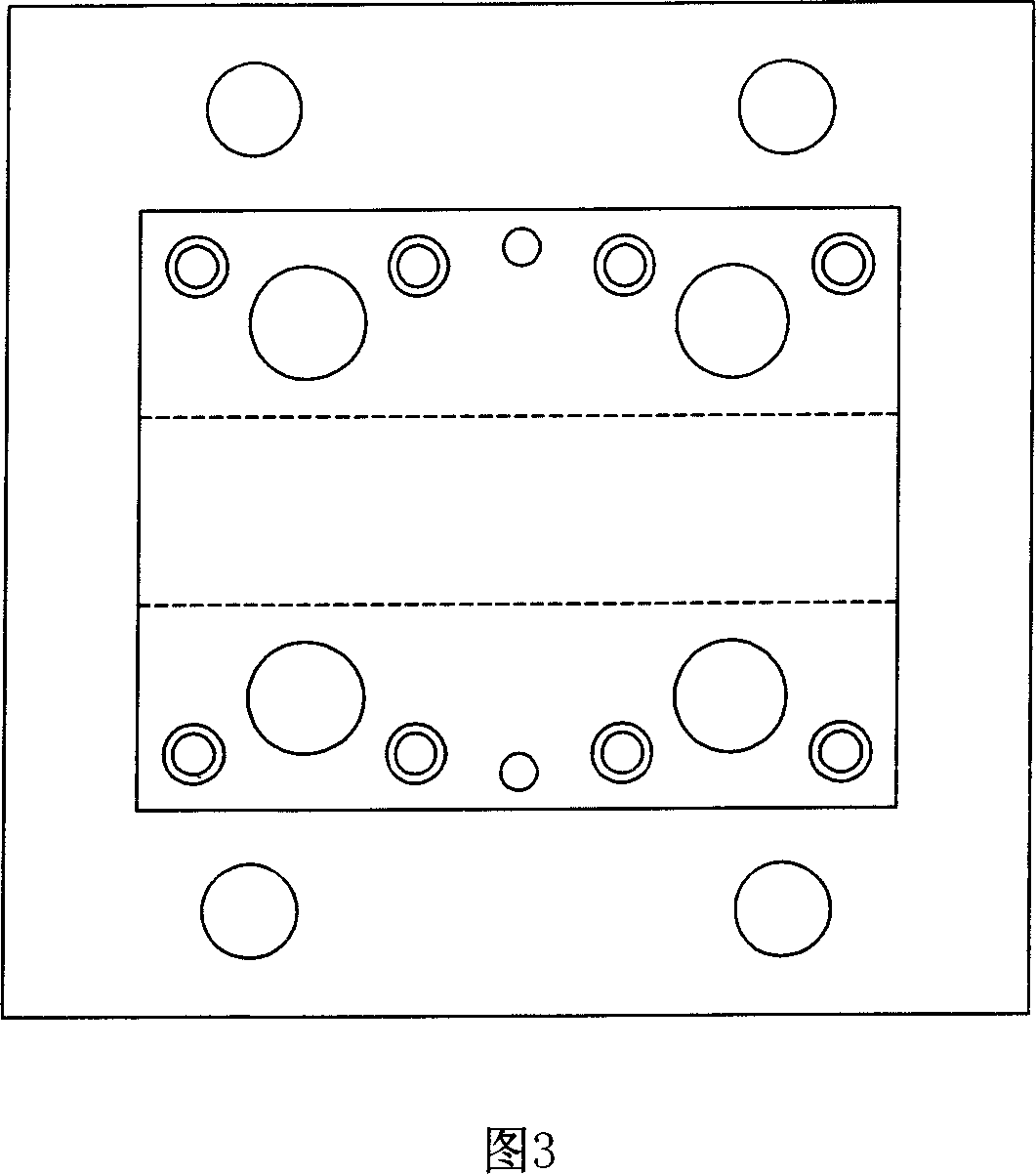

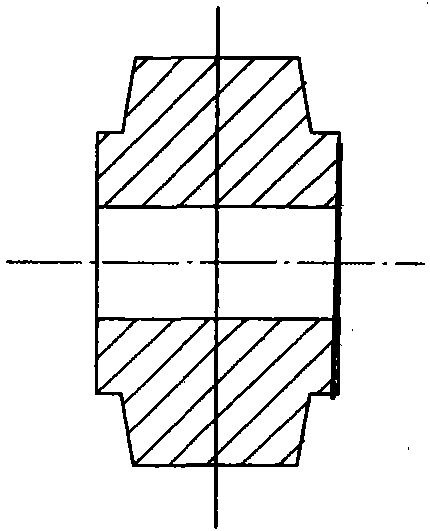

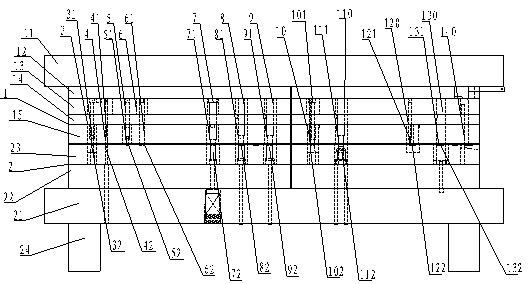

Precise multifunctional incremental pressing die and its making process

InactiveCN1931469AEasy maintenance, adjustment and replacementSimple structureShaping toolsDying backMechanical engineering

The precise multifunctional incremental pressing die includes a lower die, an upper die, an internal guiding mechanism and an outer guiding mechanism. The upper die includes an upper die seat, a convex die back plate, an unloading back plate, and an unloading plate. The lower die includes a lower die seat, a concave back plate and a concave die plate. The outer guiding mechanism includes a large guide pin, a large ball sleeve, a large guide sleeve and a spring. The internal guiding mechanism includes a small guide pin, a small ball sleeve, a small guide sleeve and a spring. The making process features that the unloading plate and the concave die plate are fastened together.

Owner:GELIPU ELECTRONICS SHENZHEN CITY

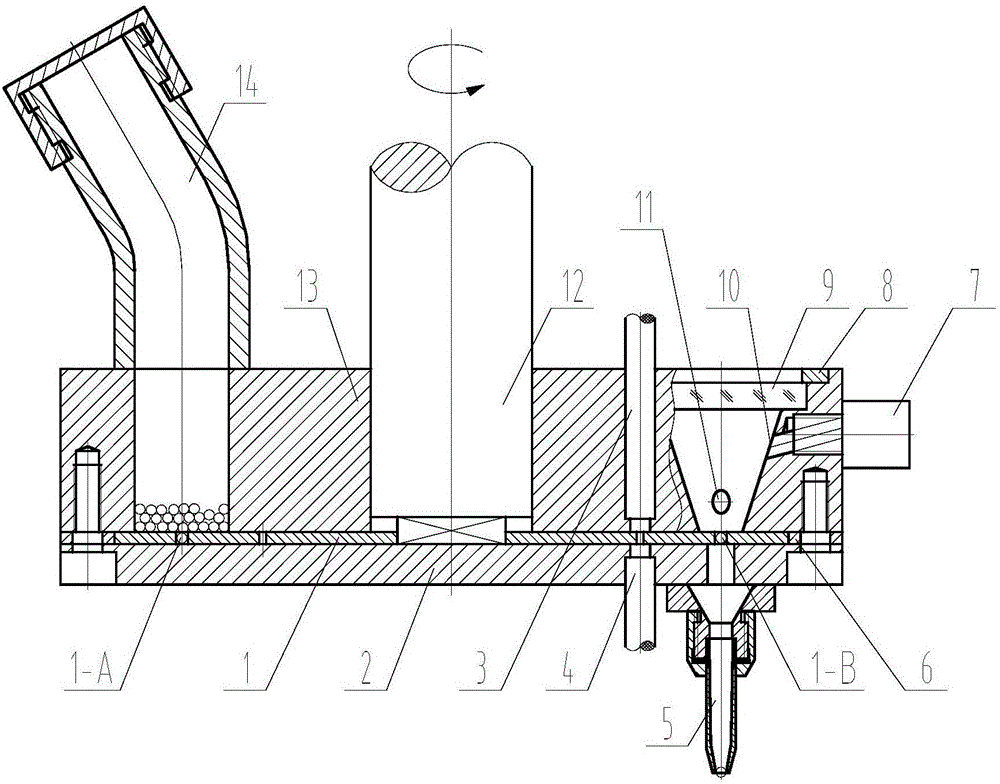

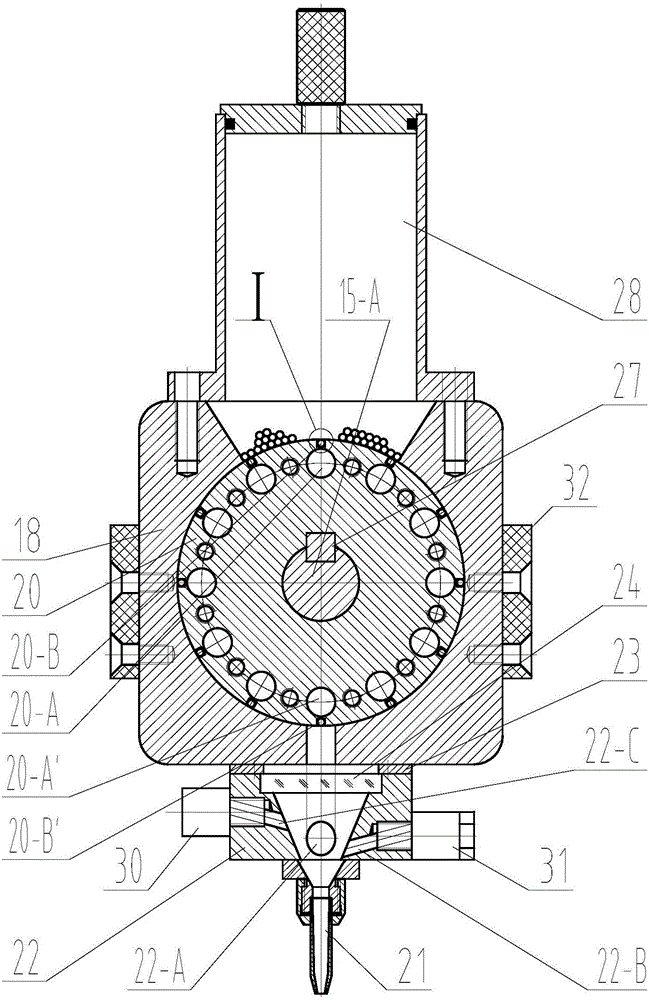

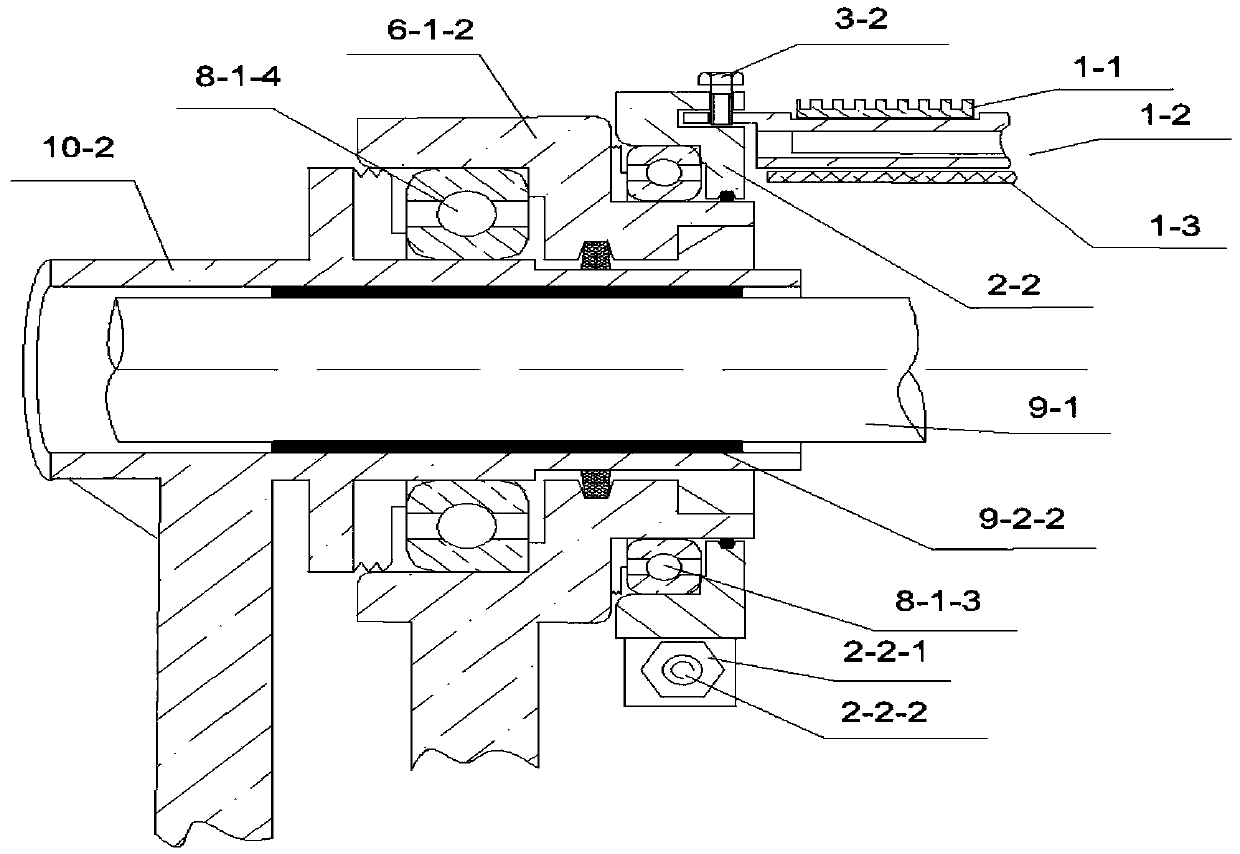

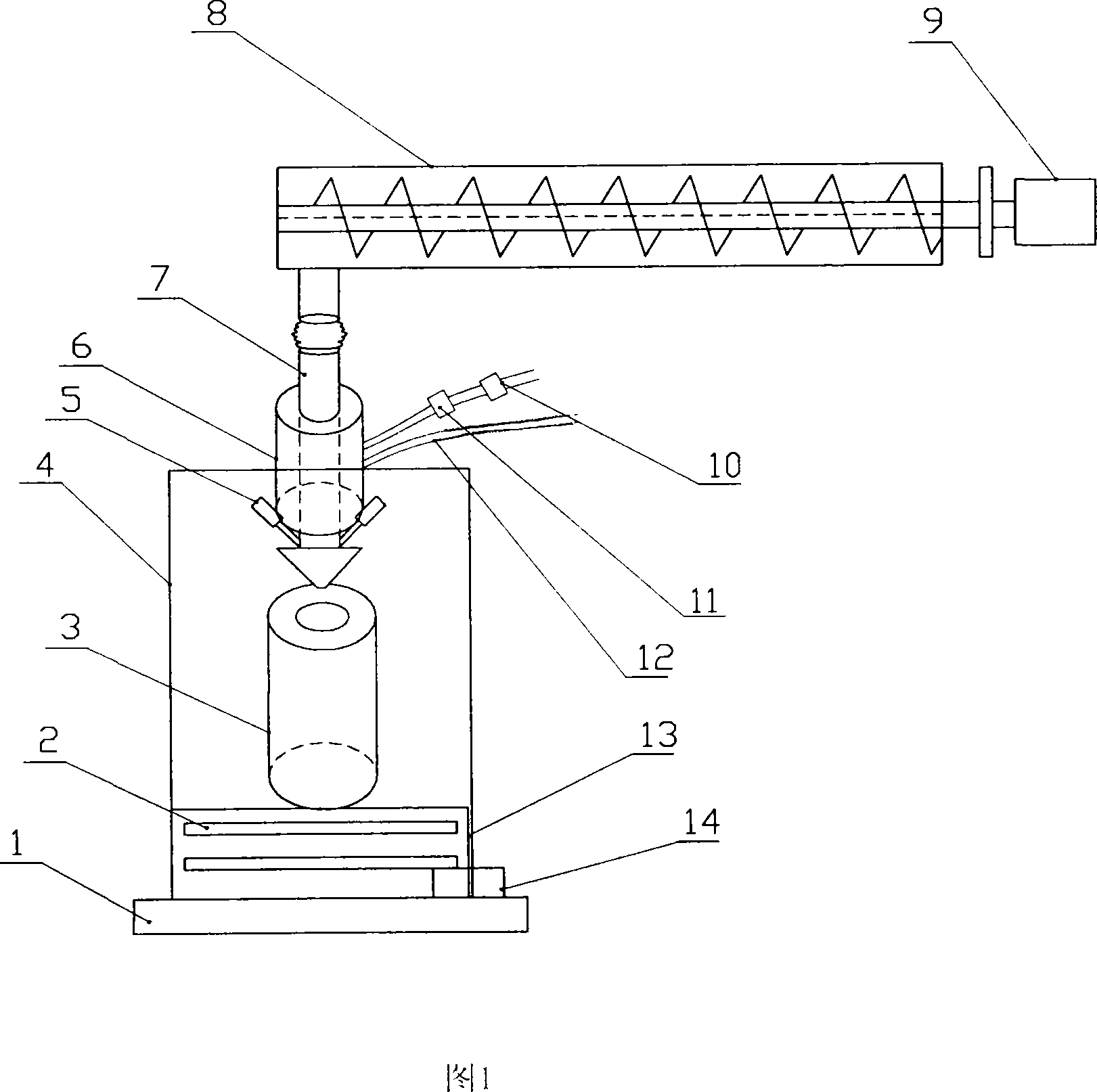

Solder ball pump head for laser soldering

ActiveCN105108264ALow manufacturing costGuarantee working accuracySolder feeding devicesLaser solderingSolder ball

The invention provides a solder ball pump head for laser soldering. The solder ball pump comprises an outer sleeve, a solder ball barrel installed on the outer sleeve, a rotor arranged in the outer sleeve and a motor driving the rotor to rotate. The outer wall of the cylindrical surface of the rotor is concaved inwards to form at least one ring of solder ball containing tank distributed circumferentially. The solder ball barrel is installed above the longitudinal plane where the solder ball containing tanks are located and communicated with the solder ball containing tanks. The lower portion of the outer sleeve is provided with ball falling channels communicated with a nozzle through a chute. When rotated to the lower portion, the solder ball containing tanks on the rotor are communicated with the ball falling channels; the solder ball containing tank at the upper end of the rotor is used for receiving a solder ball falling from the solder ball barrel, and the solder ball is closed in the solder ball containing tank when the rotor rotates, slides along the inner wall of the outer sleeve, and enters the corresponding ball falling channel of the outer sleeve till the solder ball containing tank moves to the lower portion of the rotor. According to the solder ball pump head, the manufacturing cost is low, machining precision can be easily guaranteed, and the fault that the ball gets stuck can be effectively reduced.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

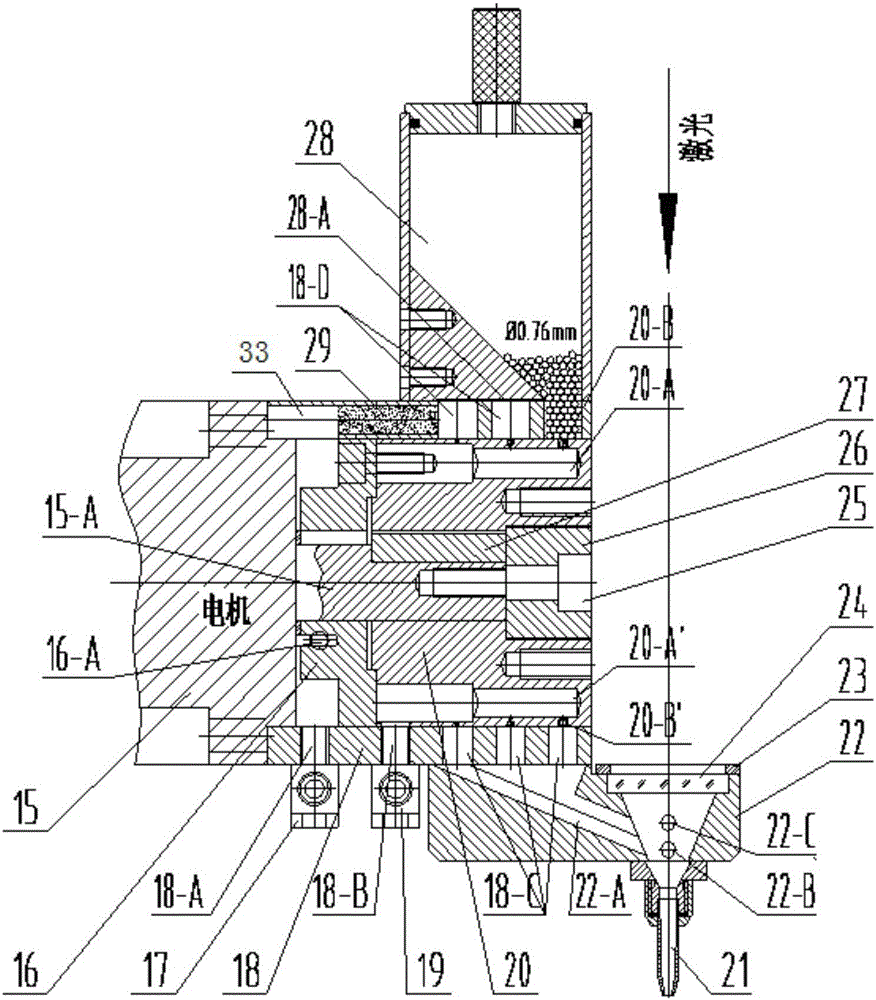

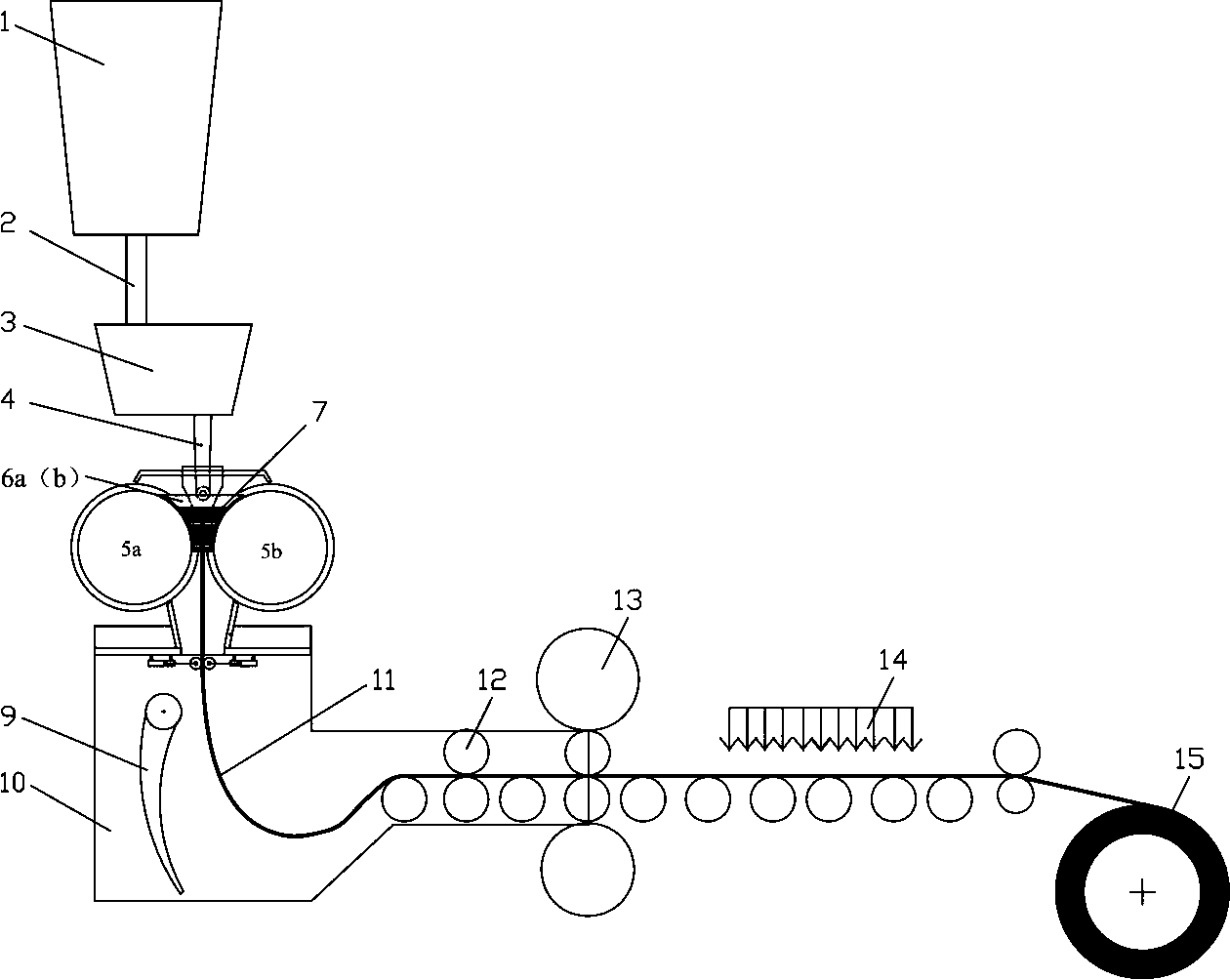

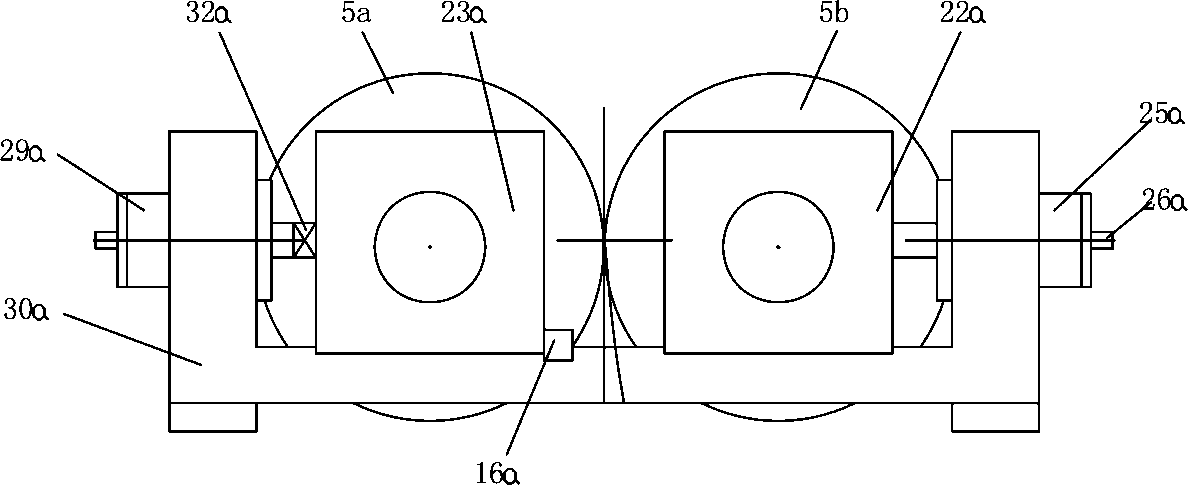

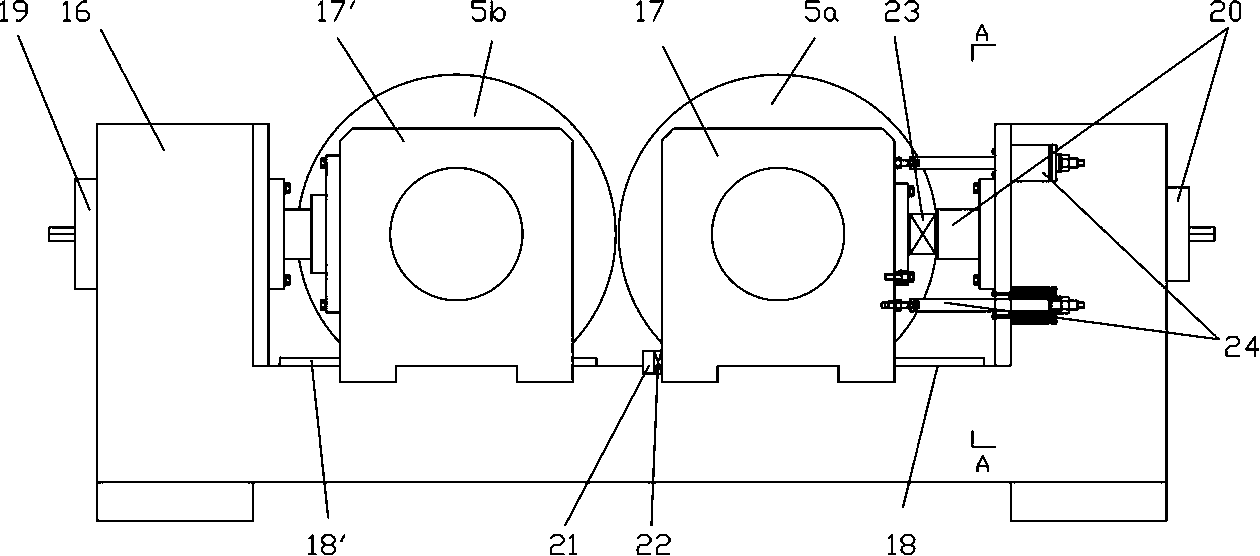

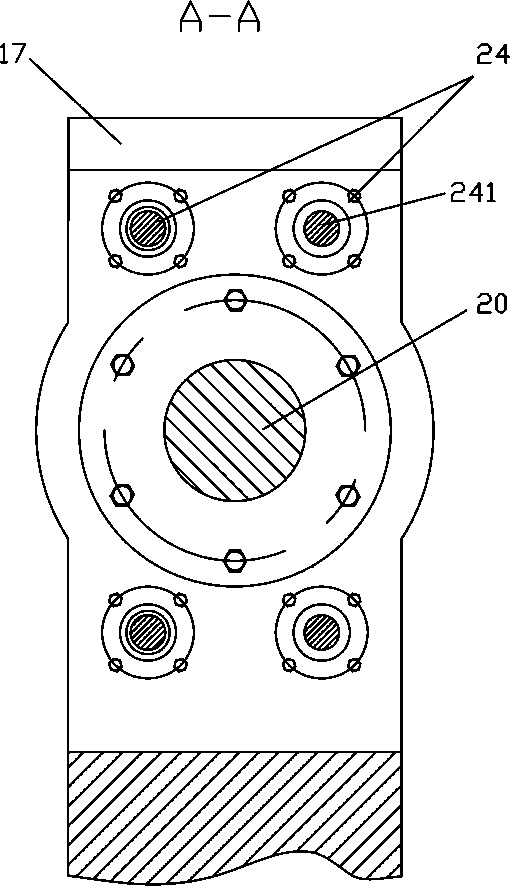

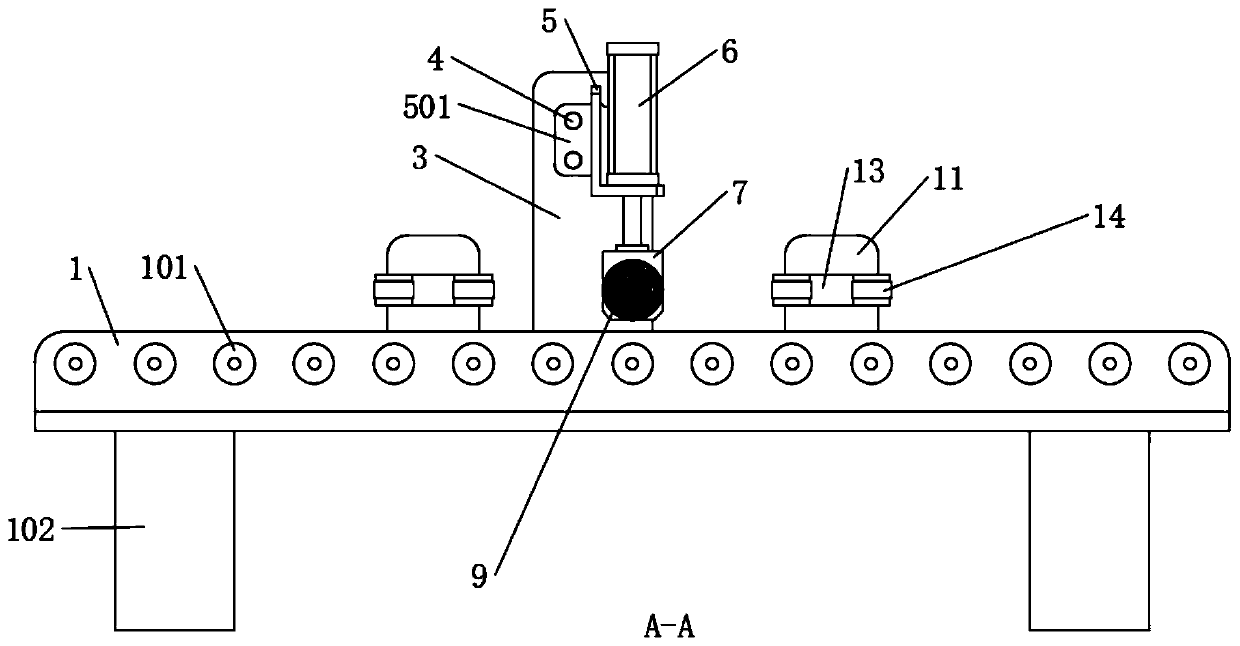

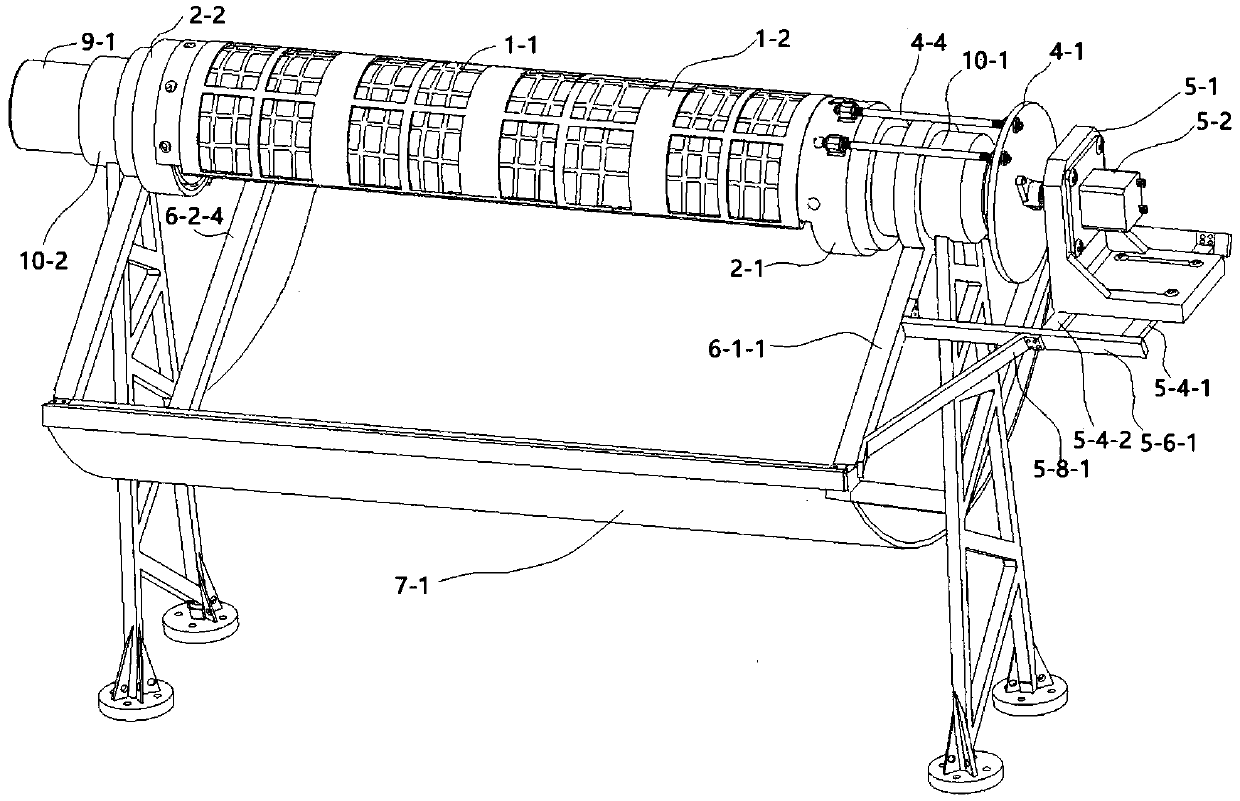

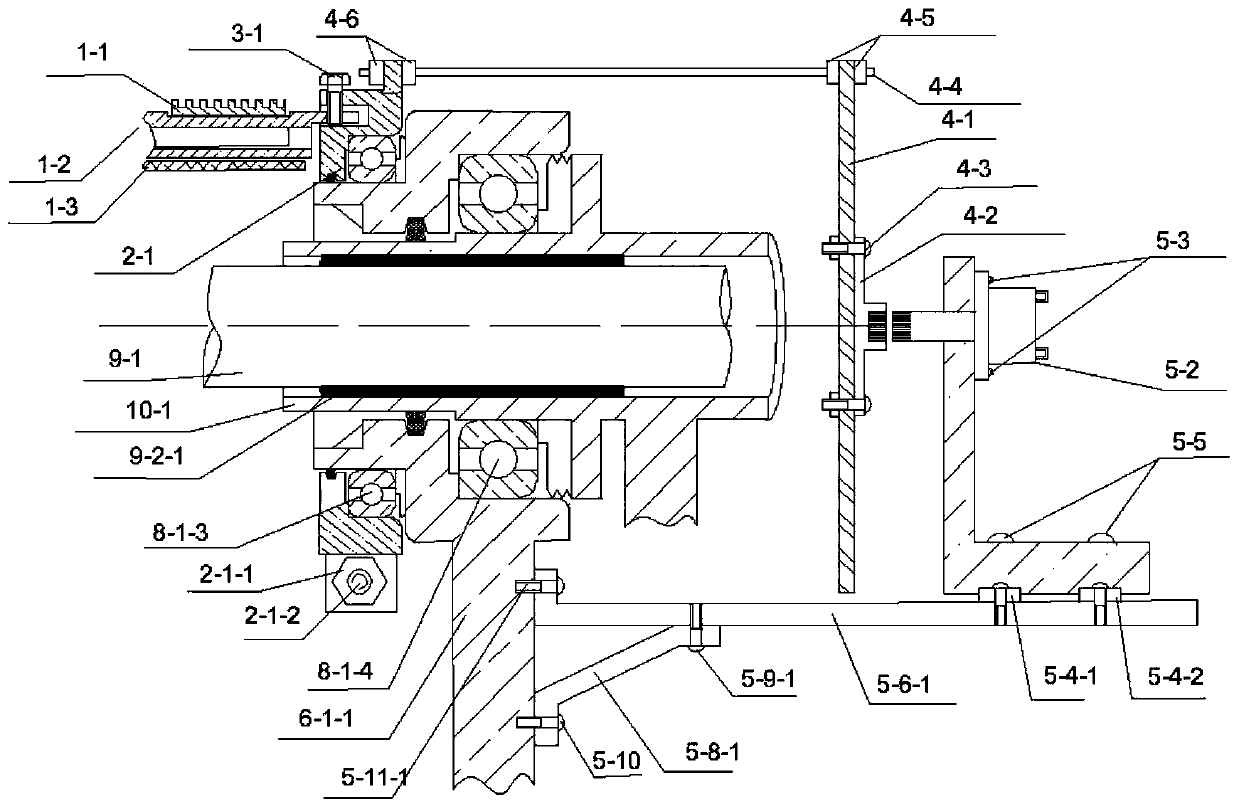

Method and device for positioning double-roller thin-strip continuous casting roller and adjusting roller gap

The invention discloses a method and a device for positioning a double-roller thin-strip continuous casting roller and adjusting a roller gap. A stand of a thin-strip continuous casting roller is a memorial arch with a U-shaped structure and is used for supporting bearing blocks on two sides of each casting roller; the bearing blocks can drive the casting roller to slide on a guide rail of the memorial arch; a hydraulic cylinder fixed on the U-shaped memorial arch of a casing machine can drive a movable roller to move relative to a fixed roller in a close or away manner; the size of a parallel gap, namely the size of the roller gap between the movable roller and the fixed roller is adjusted; a fixed stop block is arranged on one side, which corresponds to the bearing roller of the fixed roller and is close to a casting center line, on the stand; after the casting roller is replaced for each time, the casting center line of the casting machine is calibrated; the axis of the casting roller is adjusted to be parallel to the casting center line by adjusting the thickness of the fixed stop block on the stand; and meanwhile, the distance between two casting rollers is limited by the fixed stop block. According to the method and the device disclosed by the invention, the position of the fixed roller can be correspondingly adjusted along with the change of the diameter of the casting roller, so that the axis of the casting roller is parallel to the casting center line of the casting machine; and on the other hand, the detection precision of a casting and rolling force can be improved and the casting stability is improved.

Owner:BAOSHAN IRON & STEEL CO LTD +1

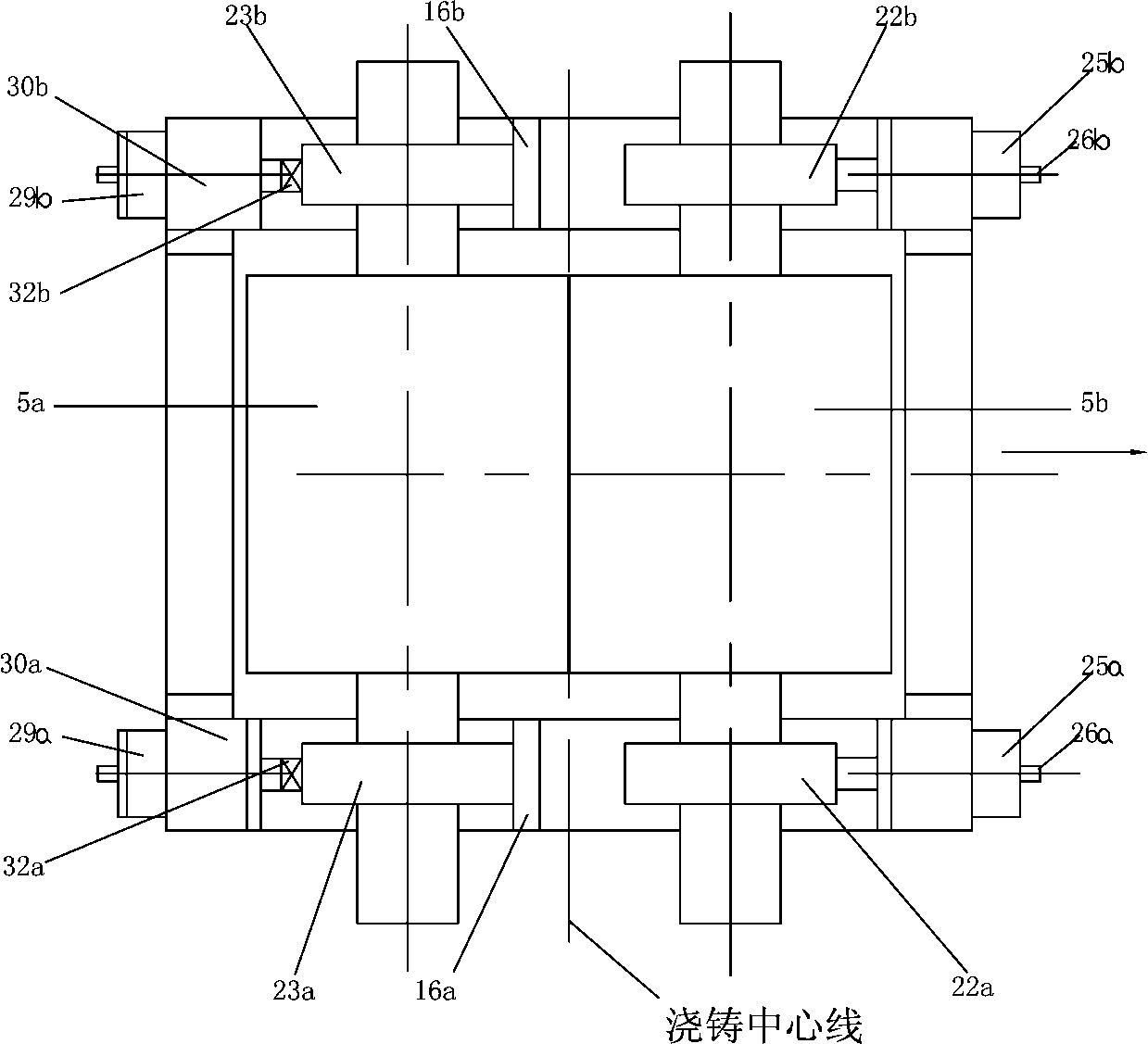

Regulation method and device for double-roll thin-strip continuous casting machine fixing roll

The invention discloses a regulation method and device for a double-roll thin-strip continuous casting machine fixing roll. The regulation method comprises the following steps of: a) a hydraulic cylinder is arranged corresponding to a casting roll continuous casting machine rack on a fixed side, the head part of the hydraulic cylinder is connected with a casting roll bearing pedestal, tensioning mechanisms are respectively arranged above and below the hydraulic cylinder, each tensioning mechanism comprises a draw bar, a spring, a gland and regulation nuts, a stop dog is arranged below the other side of the bearing pedestal, a pressure sensor is arranged between the stop dog and the bearing pedestal, and a cast rolling force sensor is arranged on the front end of the hydraulic cylinder; b) before the casting operation, the hydraulic cylinder on the fixed side pushes the casting roll bearing pedestal to press the stop dog; c) the pressure of the draw bars and the springs is regulated by the regulation nuts, the bearing pedestal, the cast rolling force sensor and the hydraulic cylinder are pressed together until the numerical value of the pressure sensor between the stop dog and the bearing pedestal is zero, and the pressure numerical value detected by the cast rolling force sensor is more than the sum of pressuring pressure FN and the maximum friction force f of the bearing pedestal on a guide rail; and after a casting center line is calibrated, the casting state is waited to start. According to the regulation method and device for the double-roll thin-strip continuous casting machine fixing roll, which are disclosed by the invention, the casting center line positioning precision is guaranteed, the cast rolling force detection degree is improved, and stable casting is realized.

Owner:BAOSHAN IRON & STEEL CO LTD

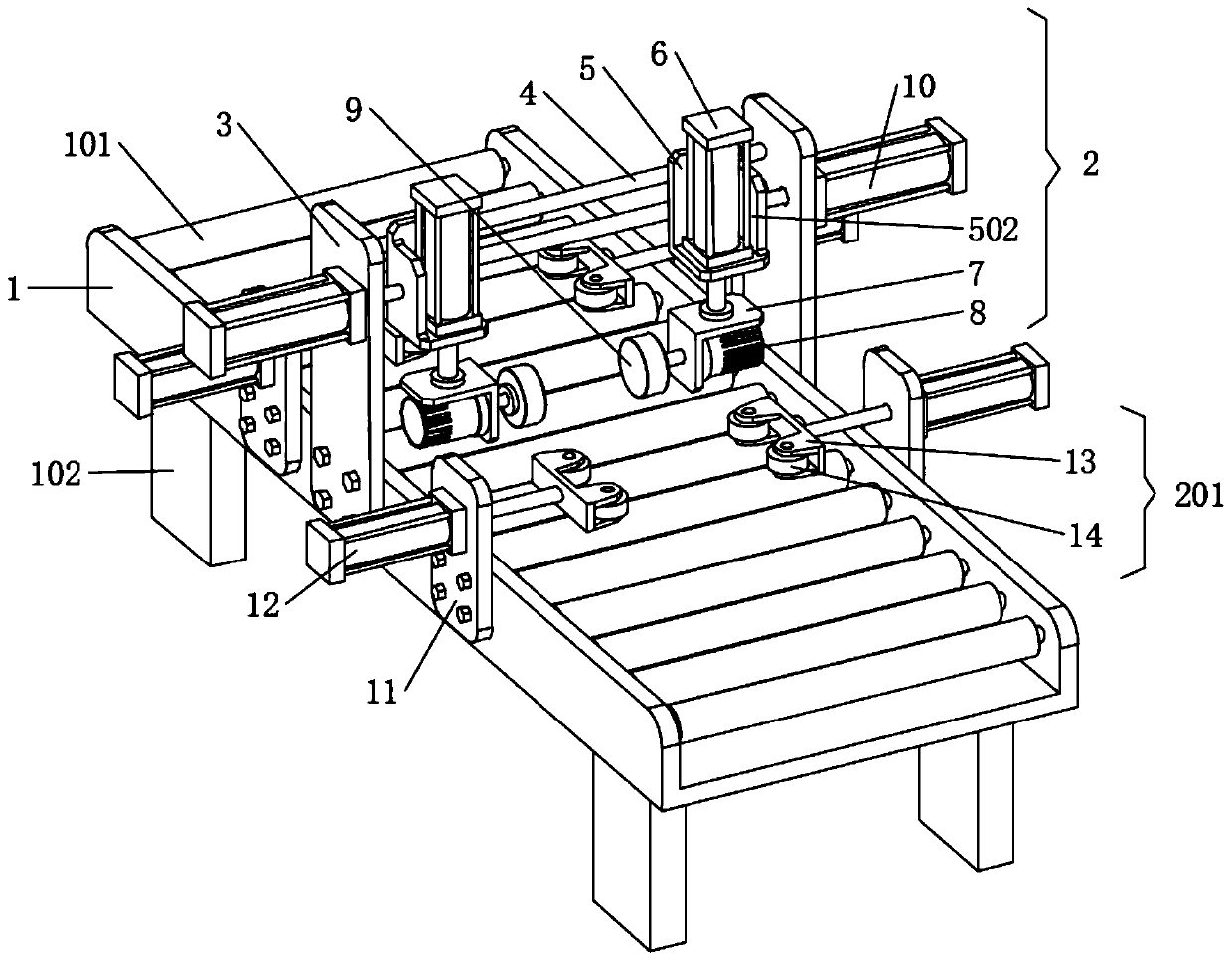

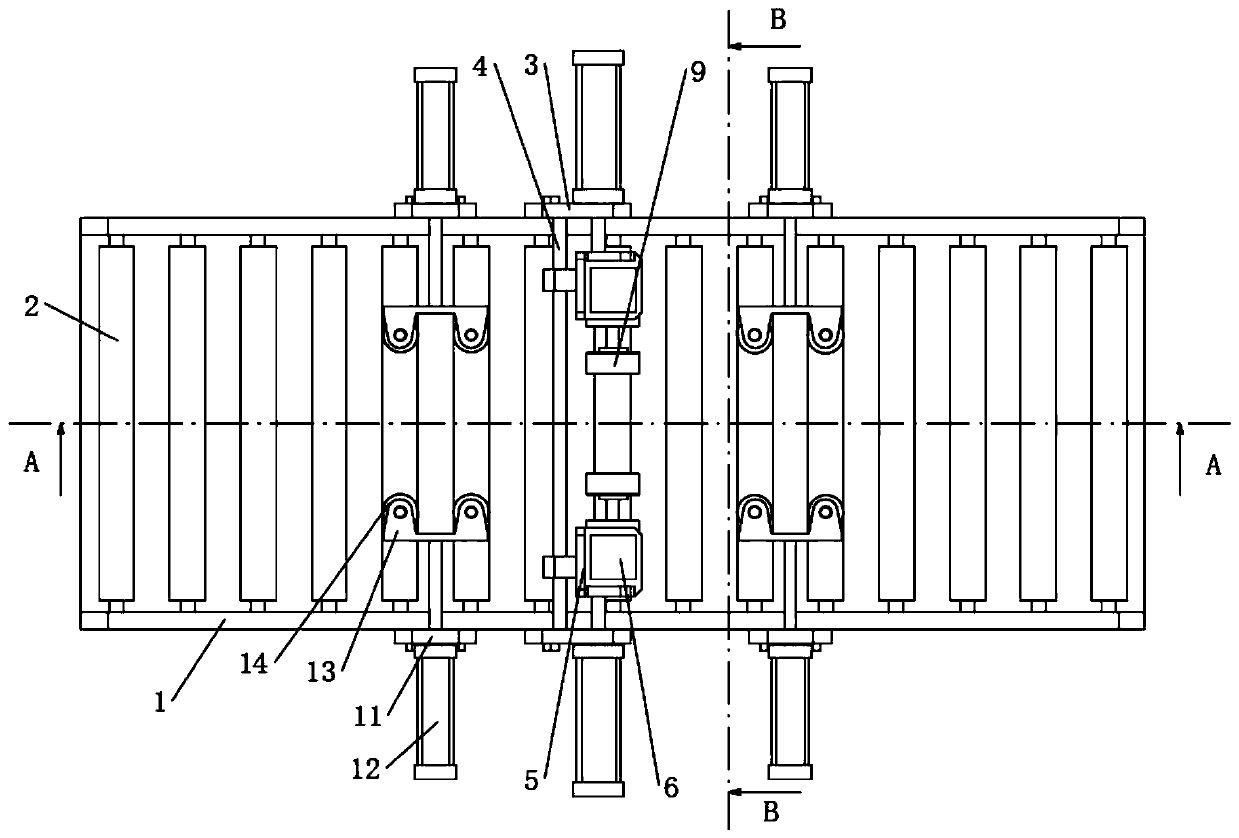

I beam burring device capable of being suitable for different specifications

InactiveCN111571356ARealize up and downSanding removal is comprehensive and effectiveEdge grinding machinesGrinding carriagesHydraulic cylinderPolishing

The invention discloses an I beam burring device capable of being suitable for different specifications and relates to the field of burring devices. The I beam burring device capable of being suitablefor different specifications comprises a machine table, a polishing device and guiding devices. A roller bed is arranged in the machine table, the polishing device is arranged on the machine table, and the guiding devices are arranged on two sides of the polishing device. By controlling a telescopic rod of a transverse shifting driven hydraulic cylinder to stretch, two lifting hydraulic cylinderblocks are adjusted to move in an axial direction of a sliding shaft till two millstones are in contact with the side wall of an I beam. By driving the millstones by a polishing motor, the side wall of the I beam is polished to burr. Meanwhile, by controlling the telescopic rod of a lifting hydraulic cylinder to stretch, the millstones lift up and down, so that it is convenient to polish and burrthe side wall of the I beam comprehensively and effectively.

Owner:陈烁

Detection device and detection method for liquid leakage of ground heating pipeline

ActiveCN103225745AEliminate distractionsReduce distractionsLighting and heating apparatusPipeline systemsEngineeringInlet flow

The invention belongs to the technical field of ground heating, relates to a detection device and a detection method for liquid leakage of a ground heating pipeline, and solves the technical problems that the prior art is unreasonable in design and the like. The device comprises a liquid inlet flow detection device, a liquid outlet flow detection device, a liquid inlet and outlet flow comparer and a flow cut-off valve, wherein the liquid inlet flow detection device, the liquid outlet flow detection device and the flow cut-off valve are connected with the liquid inlet and outlet flow comparer. The detection device and the detection method for the liquid leakage of the ground heating pipeline have the advantages that the design is reasonable, the structure is simple, the working accuracy is high, the sensitivity is good, the operation and the use are easy, and the starting preliminary interference of a ground heating system is eliminated effectively. Besides, due to the fact that an electromagnetic flow-meter is arranged, even during long-term use, the sensitivity reduction of the electromagnetic flow-meter caused by impurity accumulation is prevented, and the working accuracy is guaranteed sufficiently; and a warning device is arranged, so that a warning signal can be sent timely to remind a user or a maintenance worker.

Owner:HUAXING AOYA HLDG

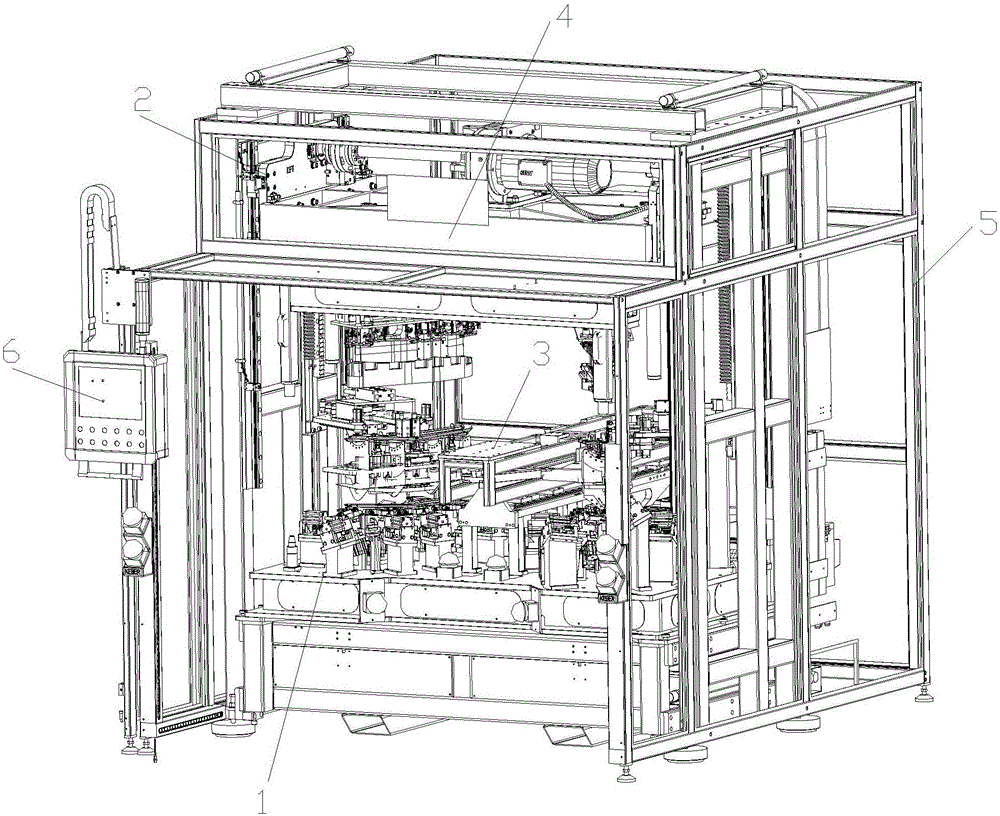

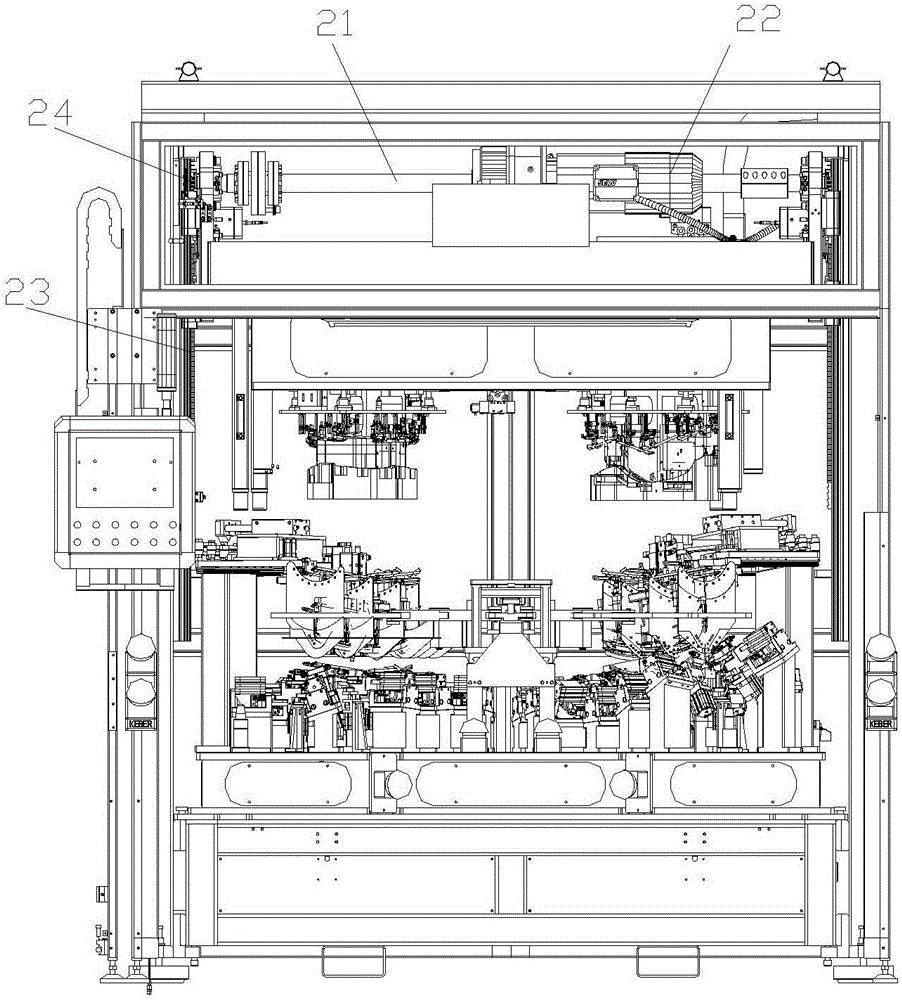

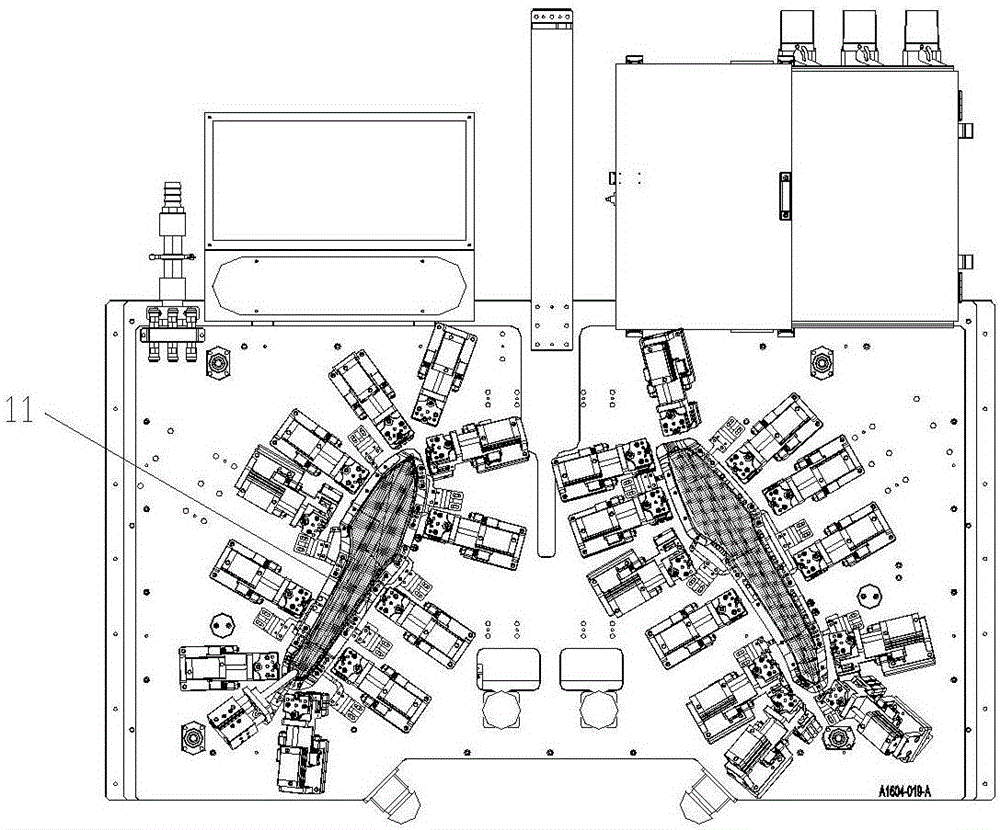

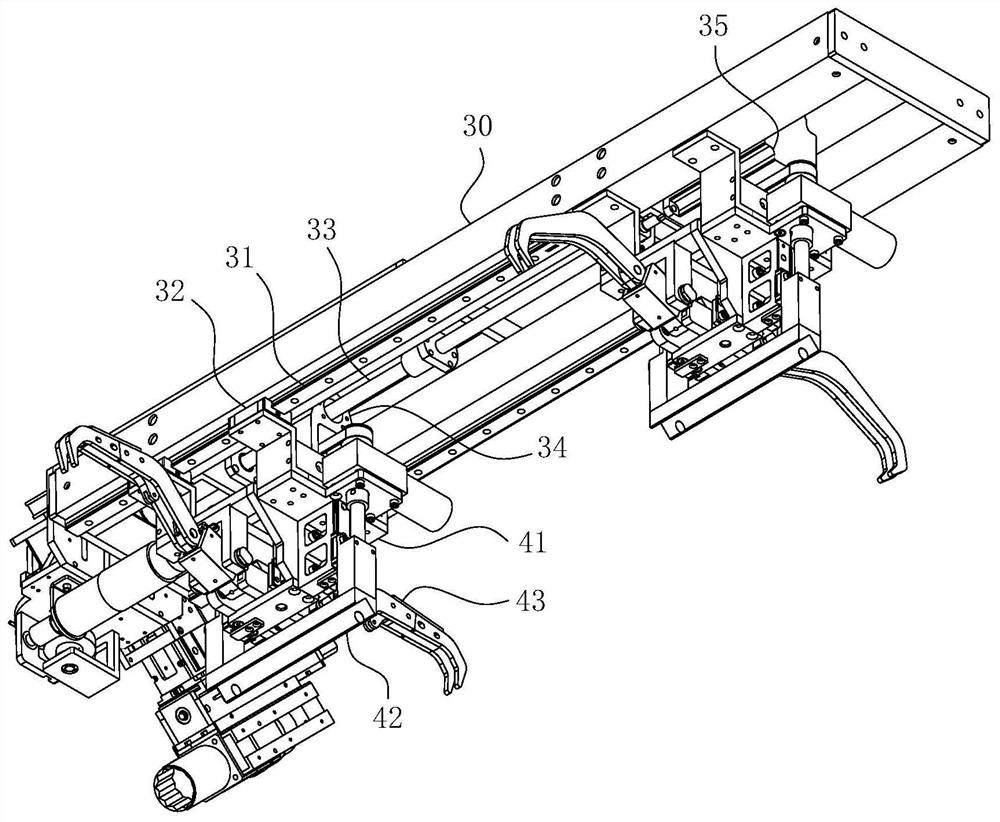

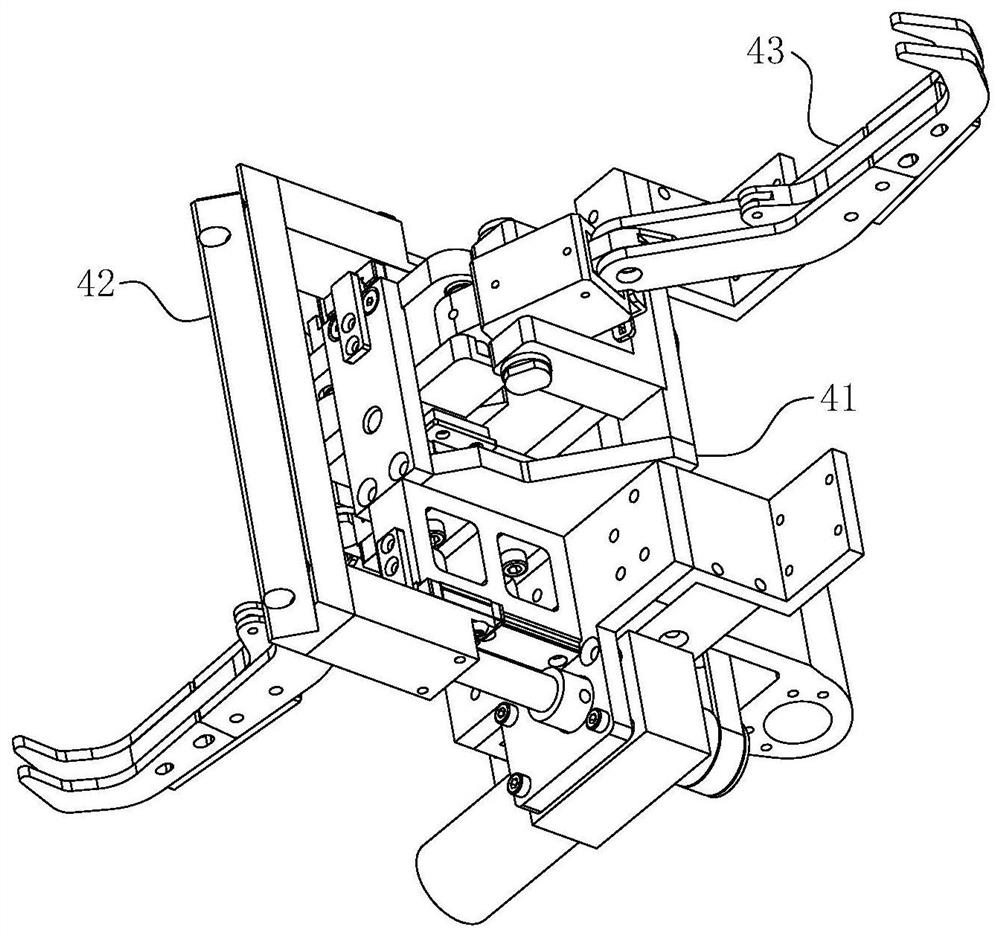

Automatic hot-pressing overlock machine

The invention discloses an automatic hot-pressing overlock machine and relates to the field of precision mechanical equipment. The automatic hot-pressing overlock machine comprises an upper mold device, a transmission device, a lower mold device and a baking device. The upper mold device is provided with a clamping mechanism for clamping an automobile armrest base plate. The lower mold device is provided with positioning needles for positioning and tightening a surface sheet. The baking device stretches to the part between the lower mold device and the upper mold device and meanwhile bakes and fuses solid glue on the surface sheet and solid glue on automobile armrest base plate. The transmission device drives the upper mold device to descend and to be pressed to the lower mold device so that the automobile armrest base plate can be attached to the surface sheet. The lower mold device is further provided with an overlock mechanism used for wrapping the surface sheet onto the overlock mechanism on the automobile armrest base plate. The automatic hot-pressing overlock machine can be adjusted according to different process parameters, and the problem of product hot-pressing overlaying with different configuration requirements is solved. Moreover, by means of double faces of baking and heating, the hot-pressing effect is better; and meanwhile, a positioning structure and an aligning structure on a bottom mold can accurately position a workpiece, and the working precision is guaranteed.

Owner:SUZHOU KEBER PRECISION MACHINERY

Slot type solar combined heat and power generation device

ActiveCN109612124AFlexible switchingFlexible regulation of heat and electricity ratioPhotovoltaic supportsSolar heating energyComputer moduleEngineering

The invention discloses a slot type solar combined heat and power generation device. The slot type solar combined heat and power generation device comprises a condensation heat collection module, a condensation photovoltaic power generation module and a function switching mechanism. The solar heat collection technology and the condensation photovoltaic power generation technology are combined well, and high-quality electric energy and heat energy can be produced; and meanwhile, the problem about the energy distribution ratio of solar energy of a certain area between condensation heat collection and condensation power generation and the problem about heat radiation of circuit boards of high condensation multiples are solved, and the utilization efficiency of solar energy of unit area can beimproved. According to the slot type solar combined heat and power generation device, operation of singly utilizing solar energy for power generation or heating is avoided, condensation heat collection and condensation power generation are integrated, and the device can flexibly adjust and control the thermoelectric ratio so as to meet the requirements of different application occasions for different ratios of heat energy and electric energy.

Owner:JIANGSU UNIV OF SCI & TECH

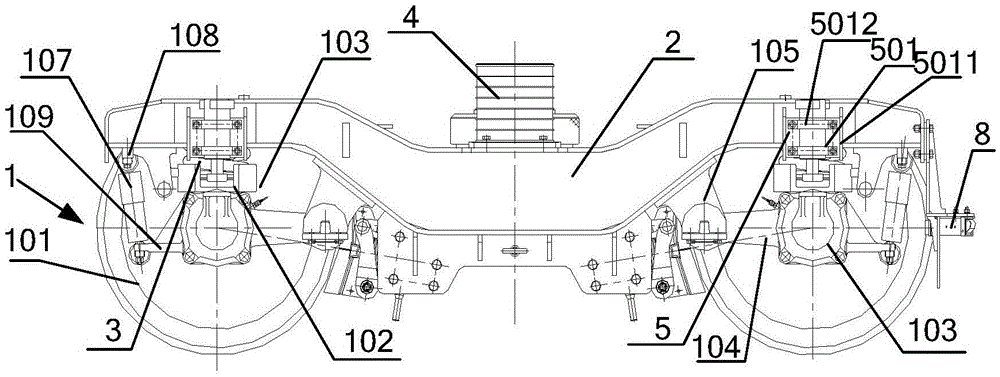

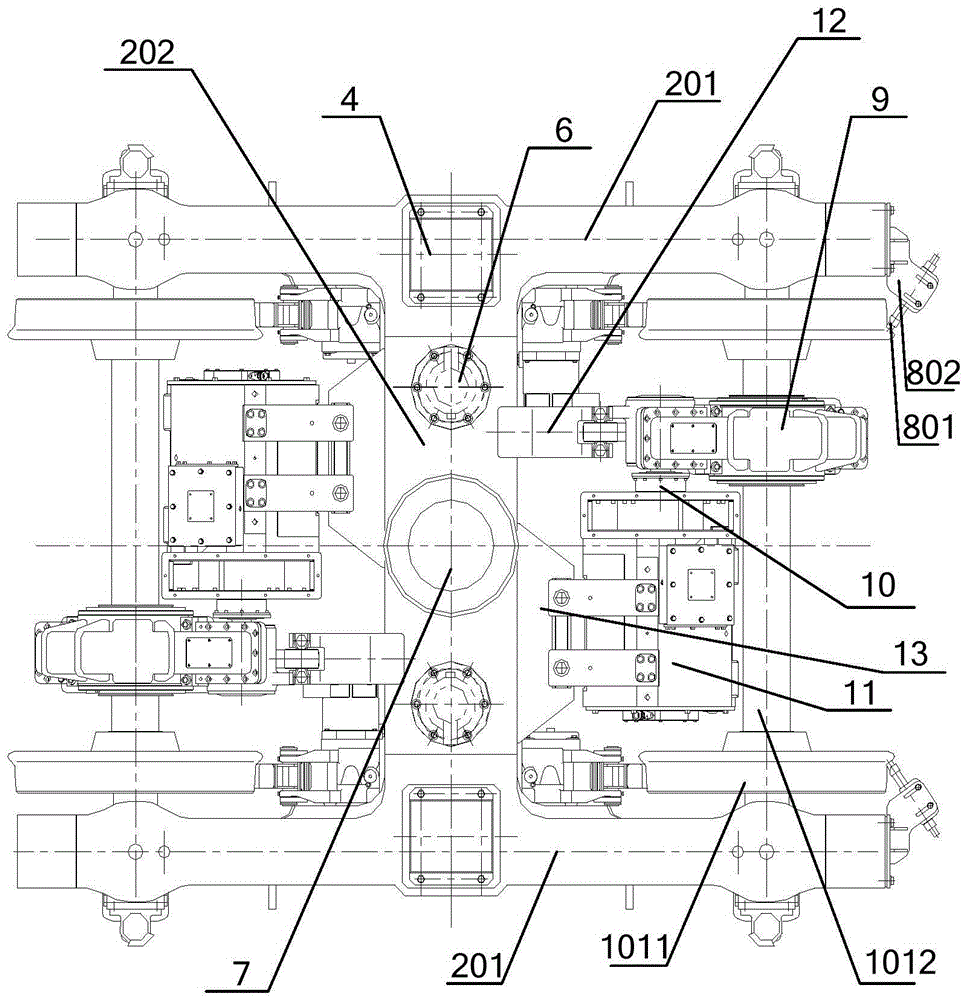

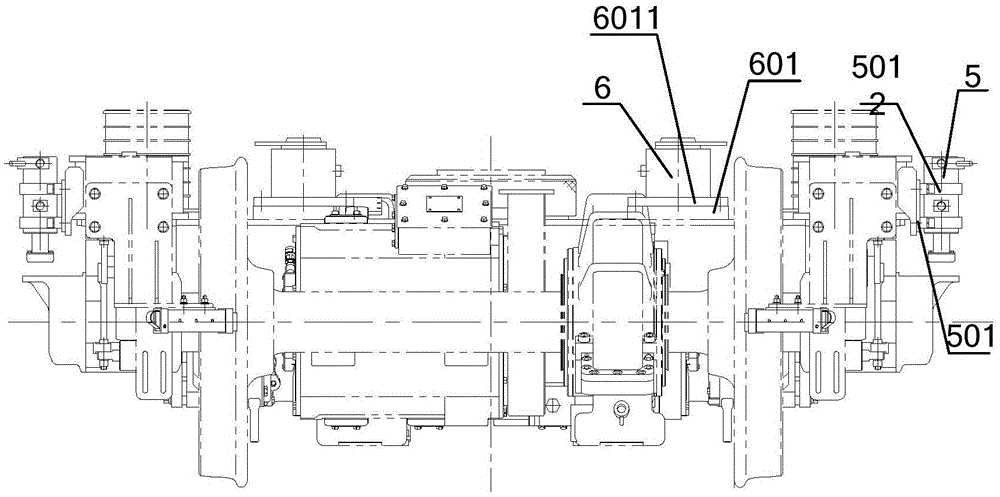

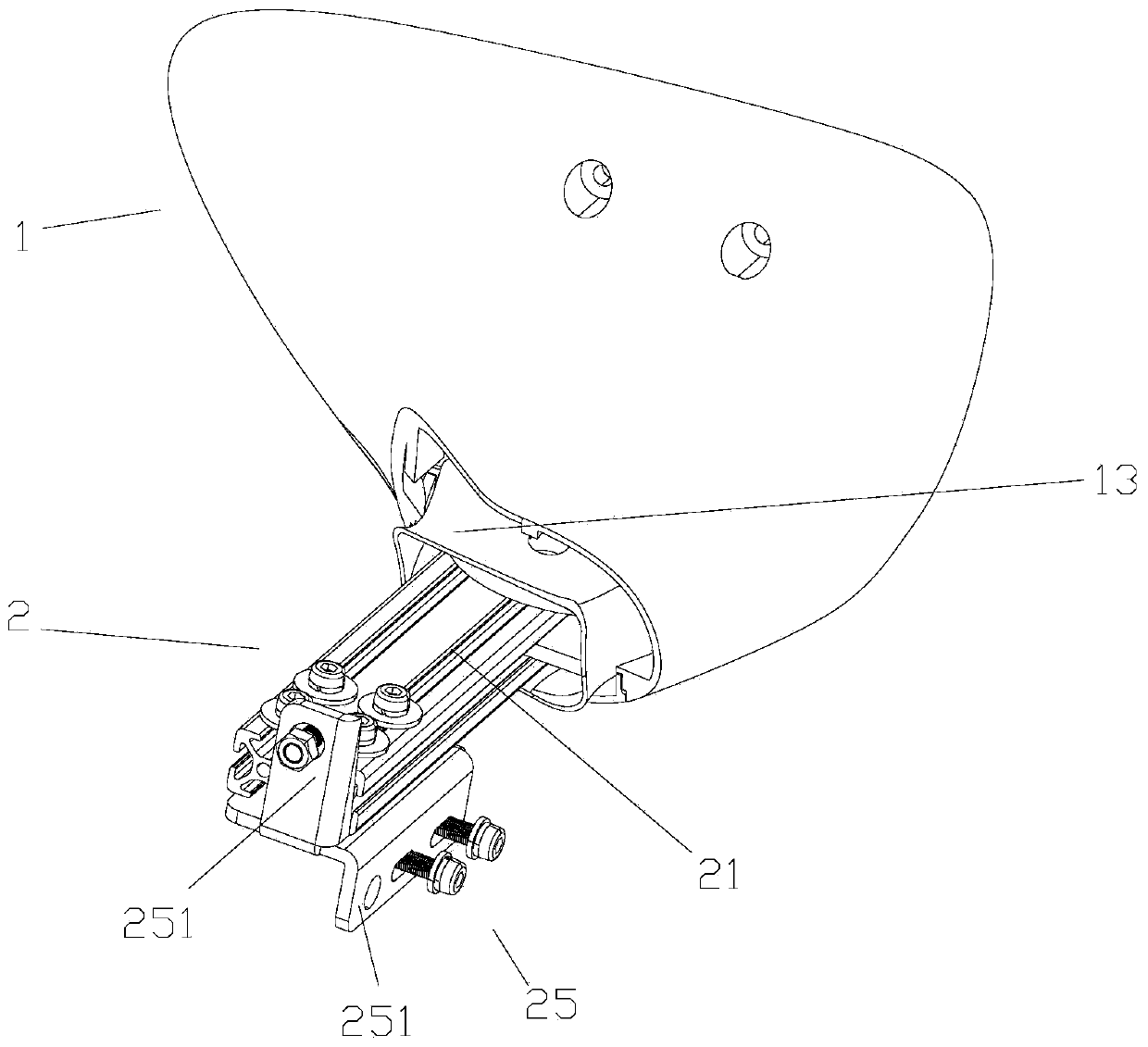

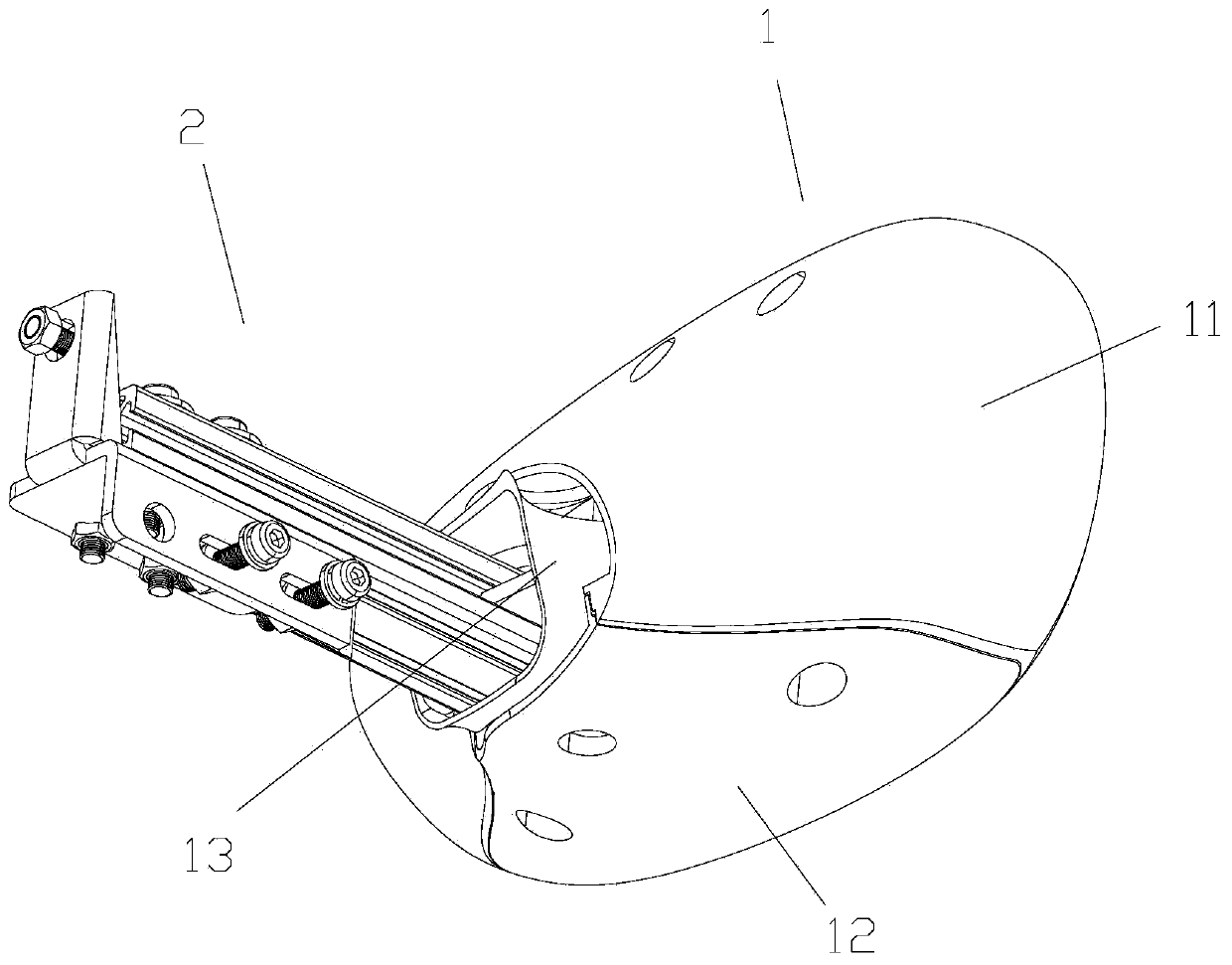

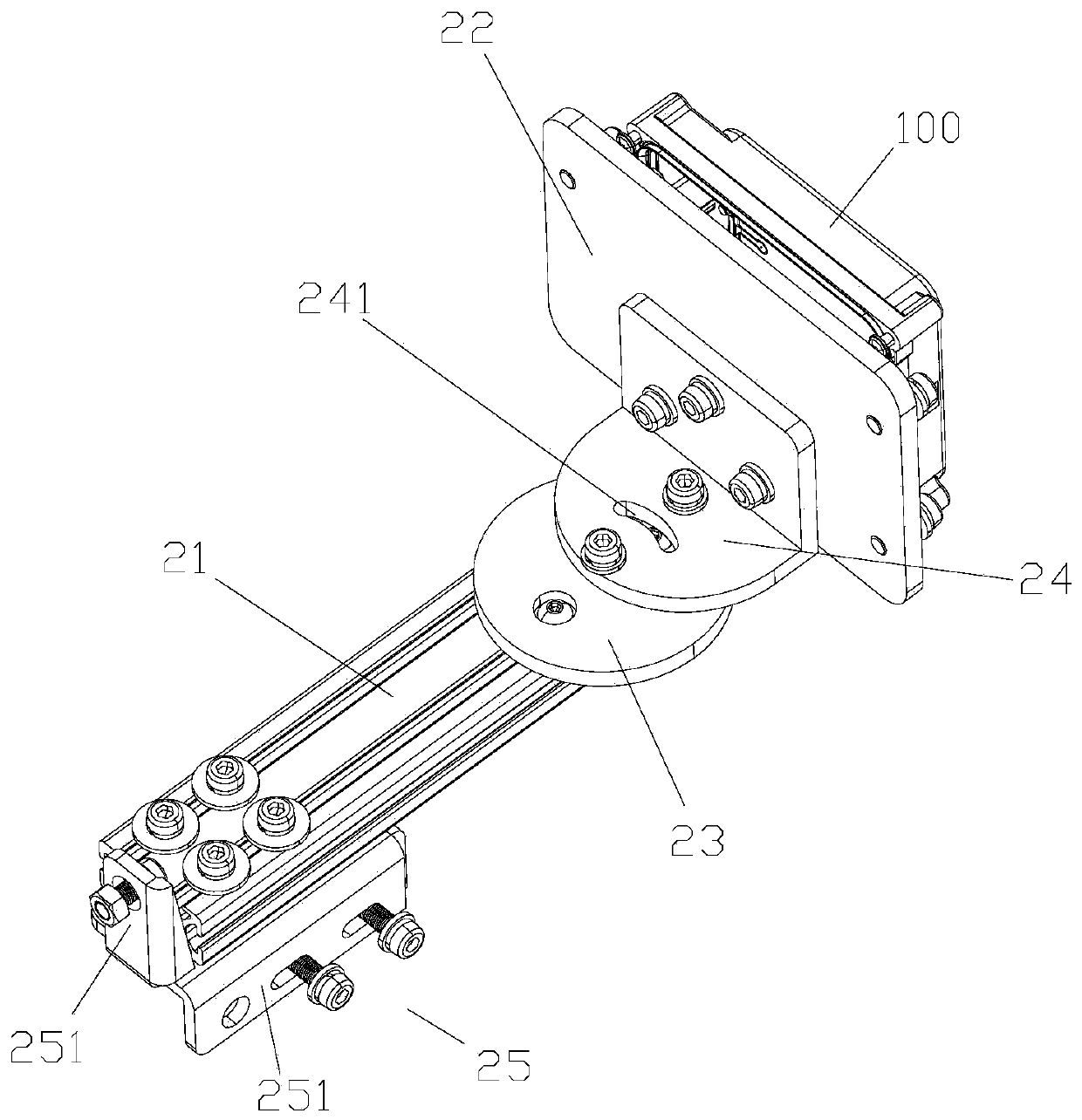

Rail engineering vehicle bogie and rail engineering vehicle

InactiveCN105460039AReliable rigid supportGuaranteed working accuracyBogie-underframe connectionsAxle-boxes mountingBogieCylinder block

The invention discloses a rail engineering vehicle bogie and a rail engineering vehicle. The rail engineering vehicle bogie comprises wheel set axle box devices and a framework arranged on the wheel set axle box devices and used for supporting a vehicle body. The framework is elastically connected with the wheel set axle box devices through first elastic parts, and the framework is provided with second elastic parts used for elastically supporting the vehicle body. The framework is further provided with first supporting oil cylinders and second supporting oil cylinders, a cylinder body of each first supporting oil cylinder is fixedly connected with the framework, and a piston rod of each first supporting oil cylinder is used for abutting against the corresponding wheel set axle box device; a cylinder body of each second supporting oil cylinder is fixedly connected with the framework, and a piston rod of each second supporting oil cylinder is used for abutting against the bottom of the vehicle body. According to the rail engineering vehicle bogie and the rail engineering vehicle, operation precision and operation safety of the rail engineering vehicle can be guaranteed.

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

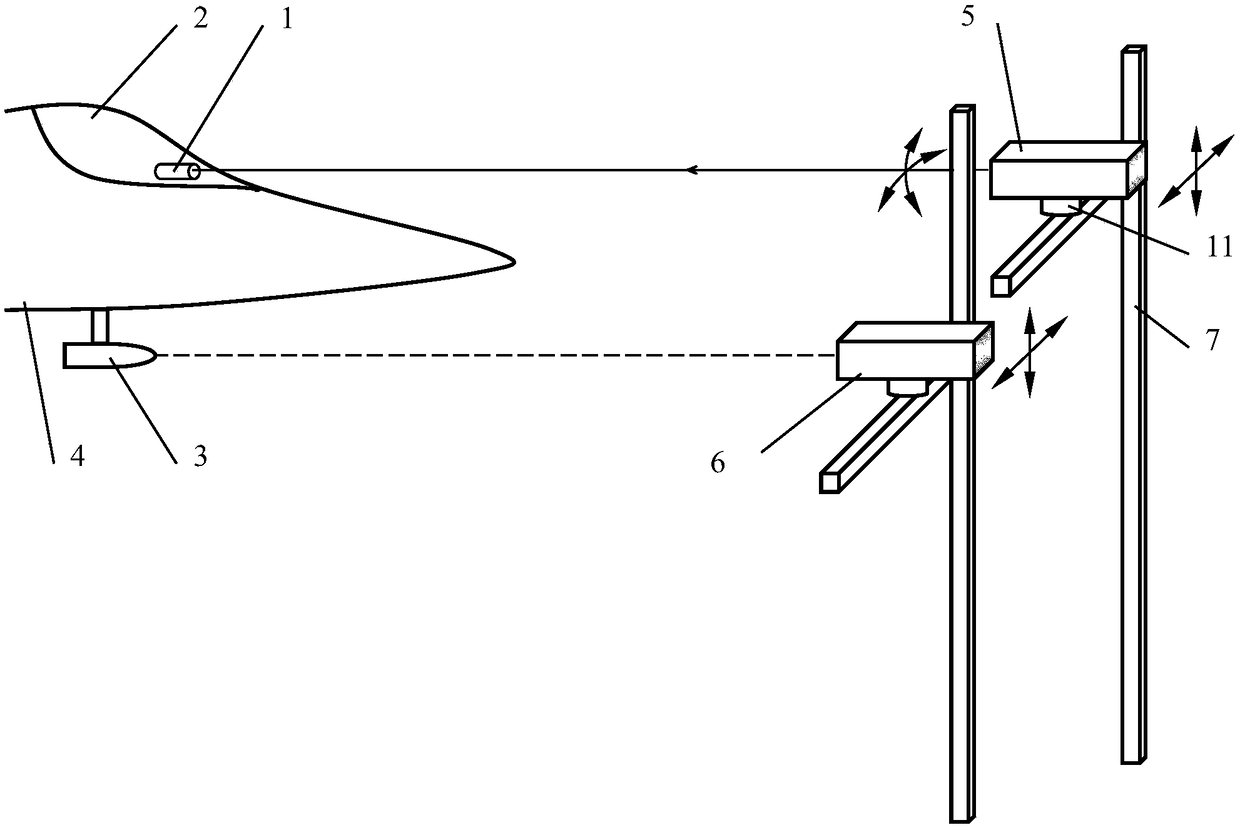

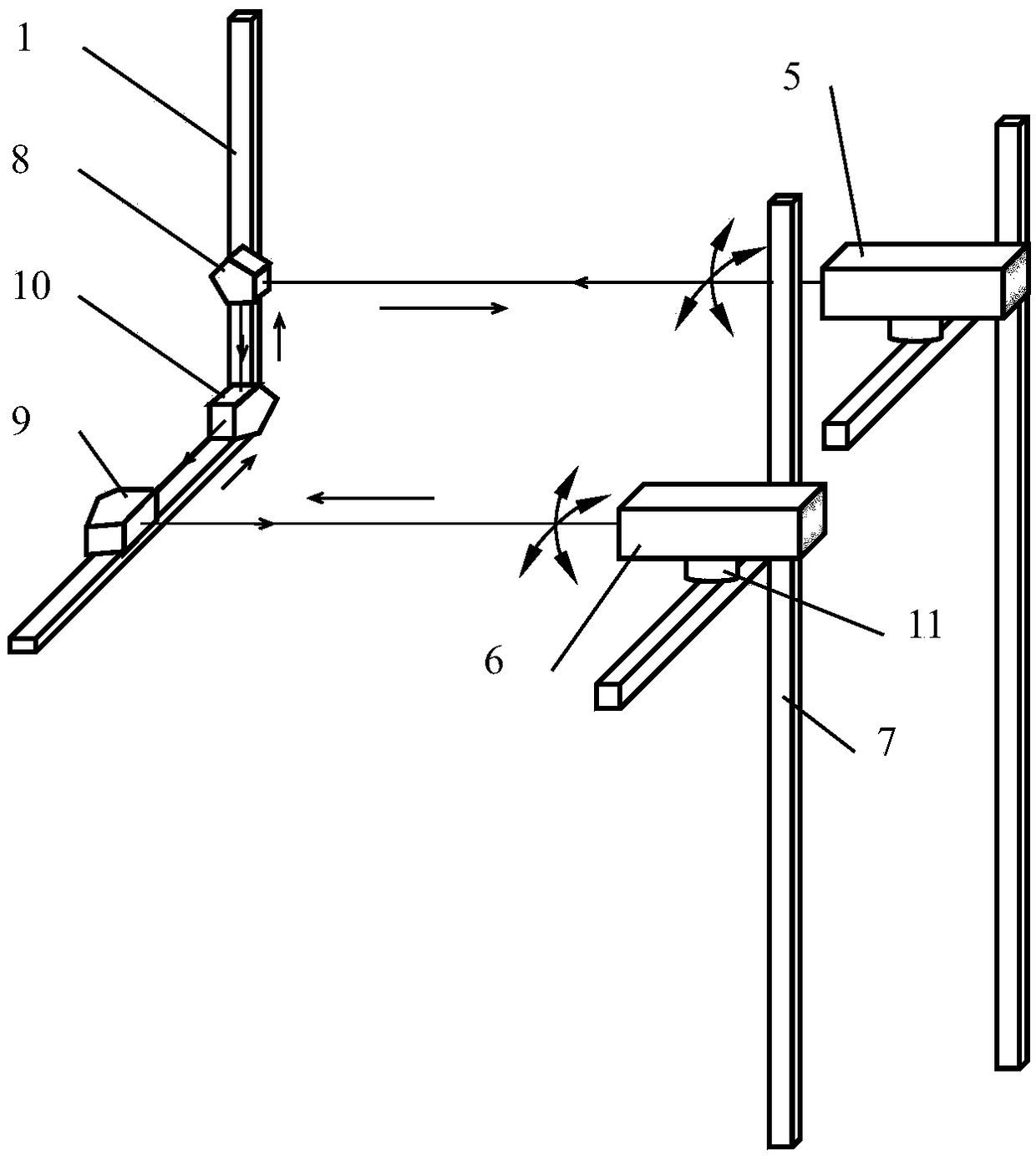

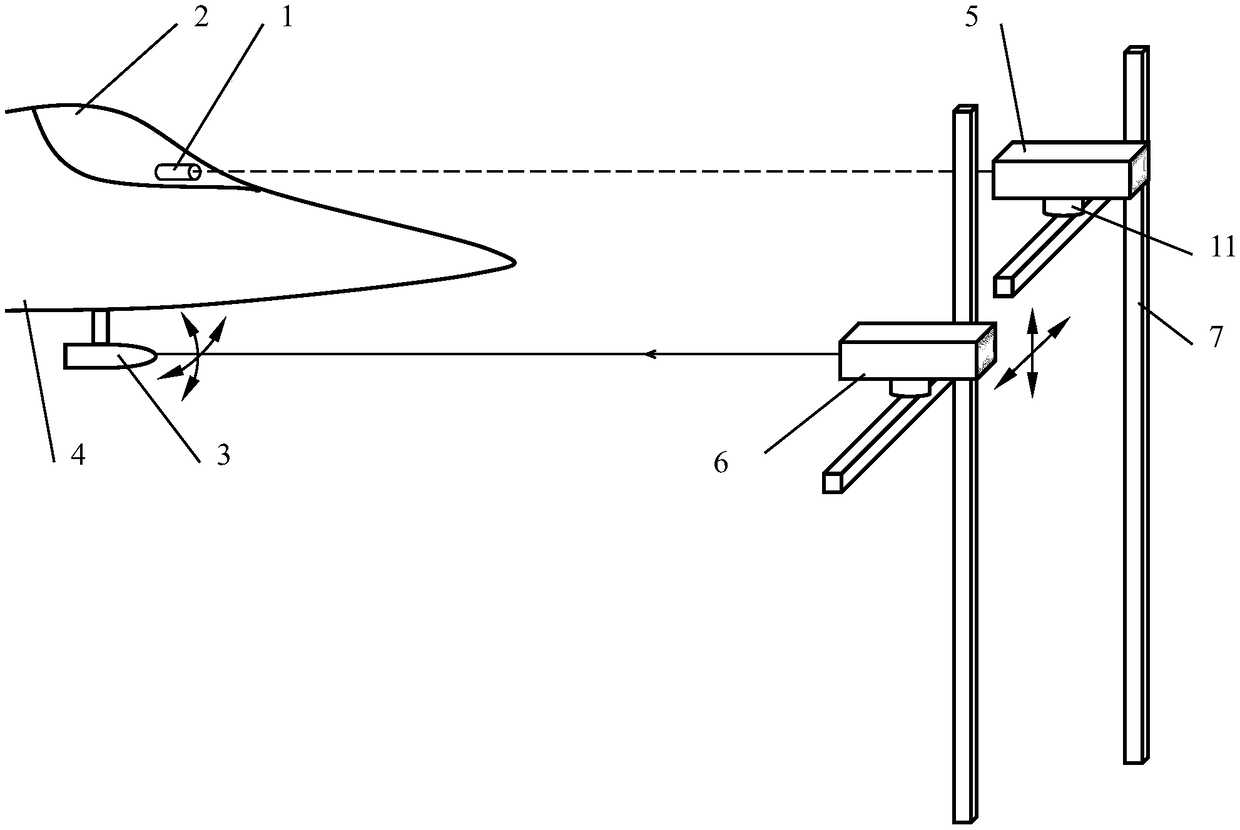

Optical axis consistency calibration method of airborne multi-optical axis optical load

ActiveCN109186944AGuaranteed working accuracyGuaranteed accuracyOptical apparatus testingControl systemOptical axis

The invention discloses an optical axis consistency calibration method of an airborne multi-optical axis optical load, and belongs to the technical field of optical calibration. The calibration operation of the prior art is complicated, the difficulty is large, and the labor intensity is high. The optical axis consistency calibration method comprises the steps of: arranging a main laser auto-collimator and an auxiliary laser auto-collimator in front of a machine body; making the optical window of an aiming device of an airborne fire force control system opposite to the optical window of the main laser auto-collimator, and making the optical window of the photoelectric pod opposite to the optical window of the auxiliary laser auto-collimator; completing the coaxial calibration of the aimingaxis of the airborne fire force control system and the optical axis of the main laser auto-collimator; completing the coaxial calibration of the optical axis of the auxiliary laser auto-collimator and the optical axis of the main laser auto-collimator; completing the coaxial calibration of the optical axis of a central photoelectric sensor and the optical axis of the auxiliary laser auto-collimator; and finally, completing the coaxial calibration of the optical axis of each photoelectric sensor and the optical axis of the auxiliary auto-collimator one by one. According to optical axis consistency calibration method, the optical axis consistency calibration can be realized by only adjusting the calibration device and the to-be-calibrated optical load.

Owner:CHANGCHUN UNIV OF SCI & TECH

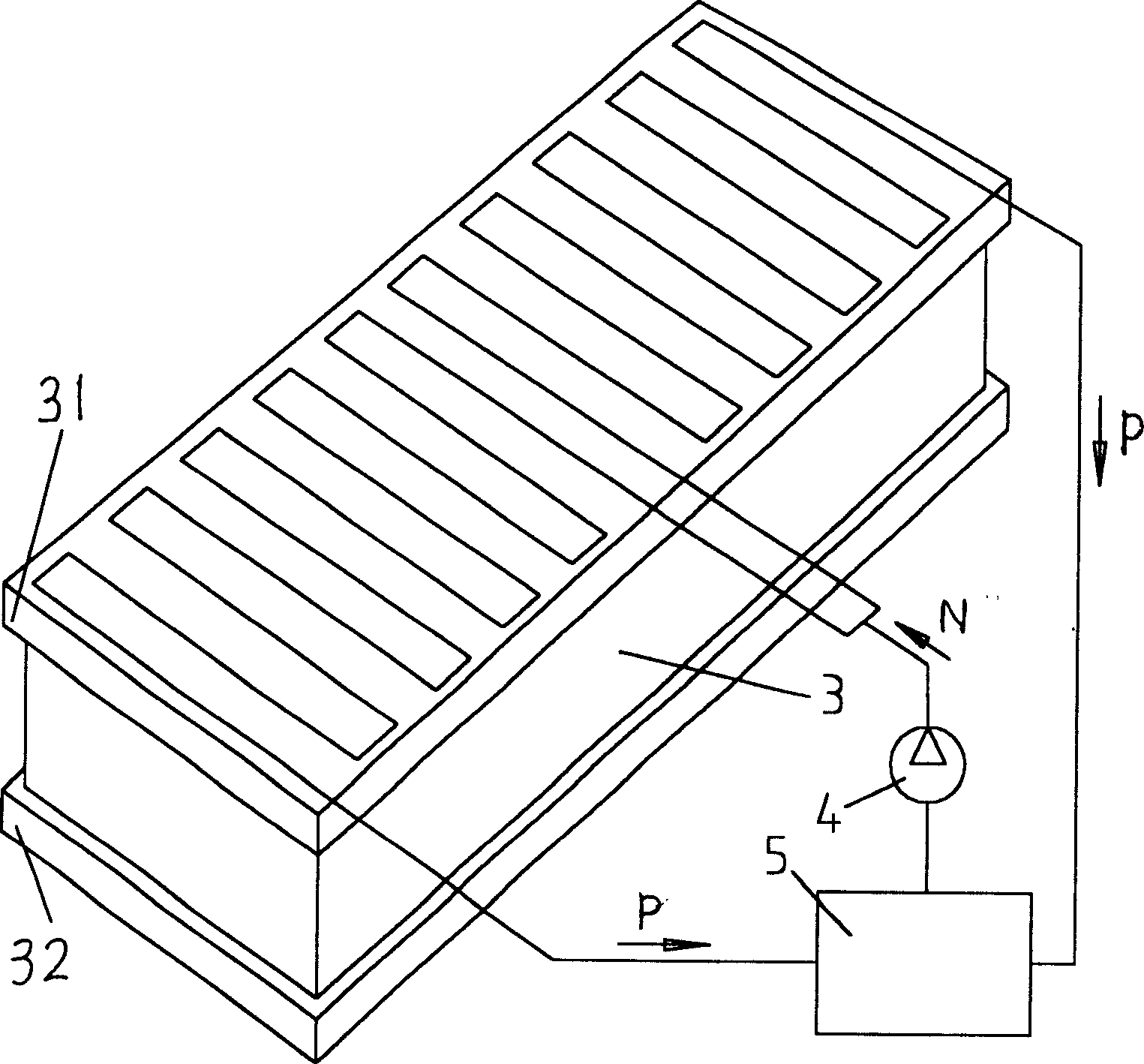

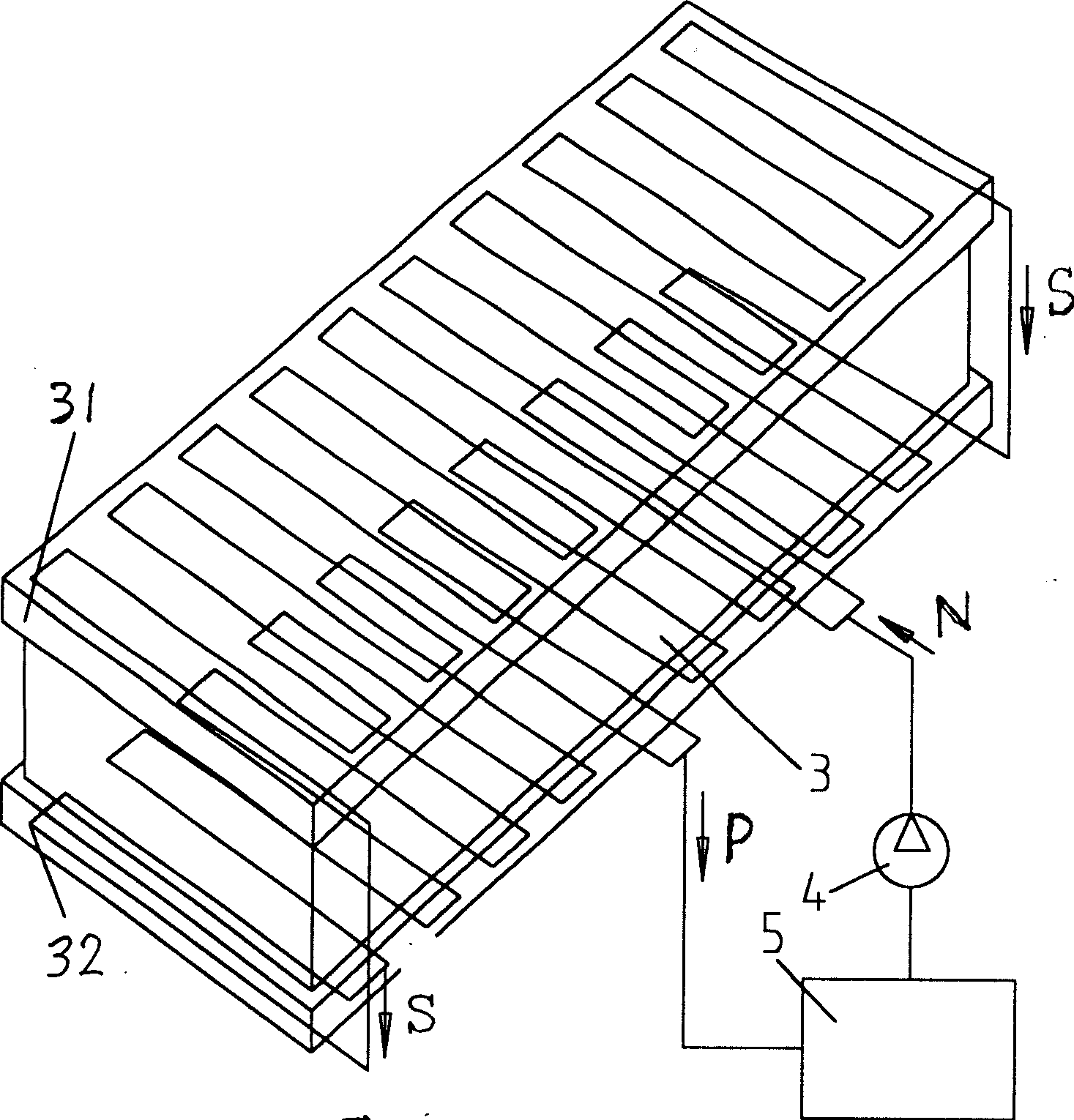

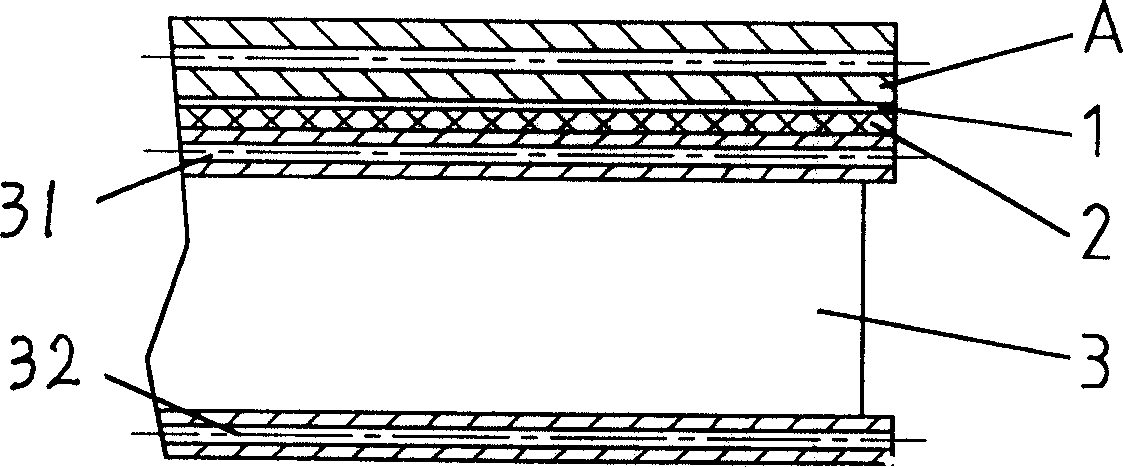

Cold balance and structure of hot pressing plate and working crossbeam of large-format hot press

The invention relates to the technique and the structure ensuring the large-area hot press working precision. The structure comprises the hot press board, the hot reflecting materials, the heat insulation materials, the working bunton, the cycling pump and the cooling equipment. The technique are the hot reflection, the heat isolation and the cooling water cycle to realize that the cooling balancing technology replaces the hot balancing technology so as to save the heat energy and ensure the balance of the upper and the lower face boards of the working bunton, and also ensure the working precision of the hot press. And the plane degree of the pressed products is controlled in the range of 0.25mm.

Owner:上海恒纽科技发展有限公司

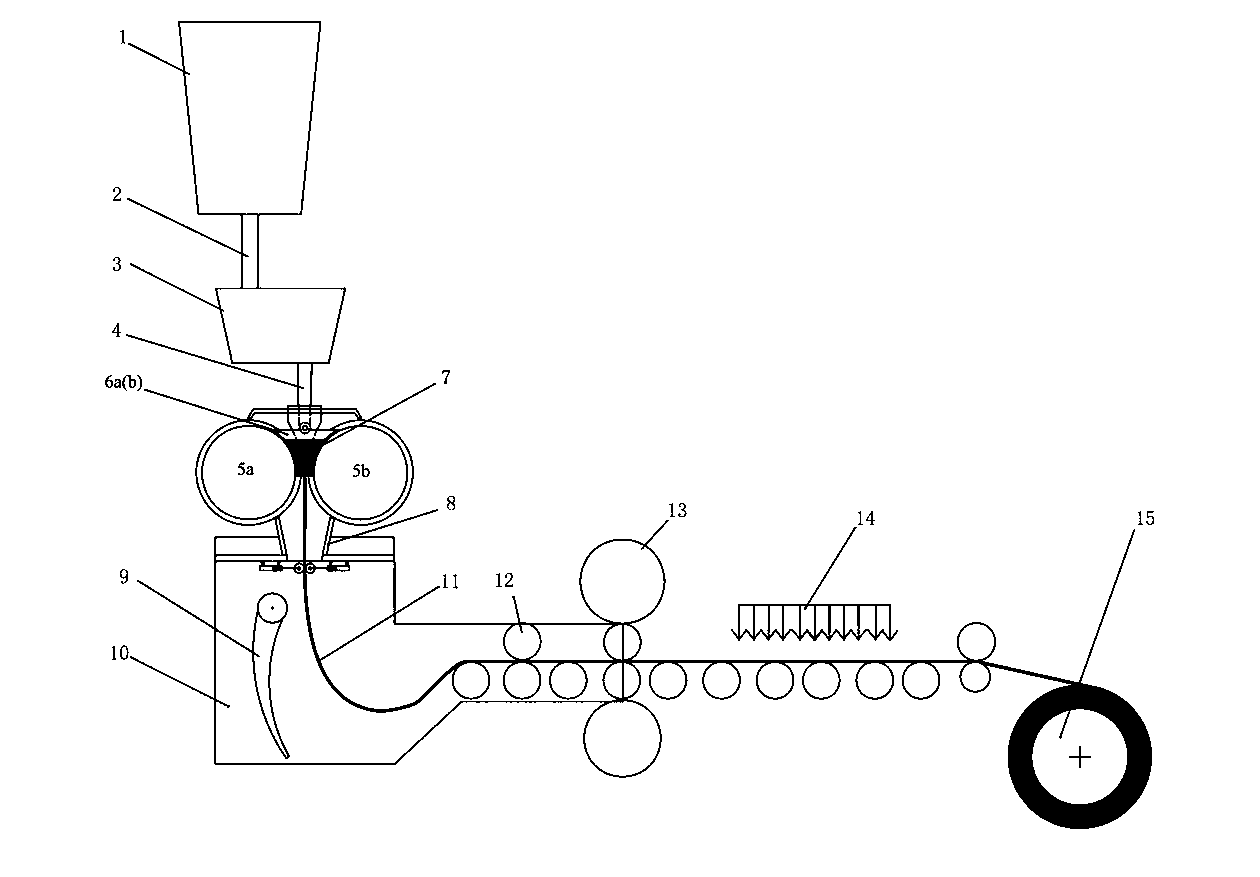

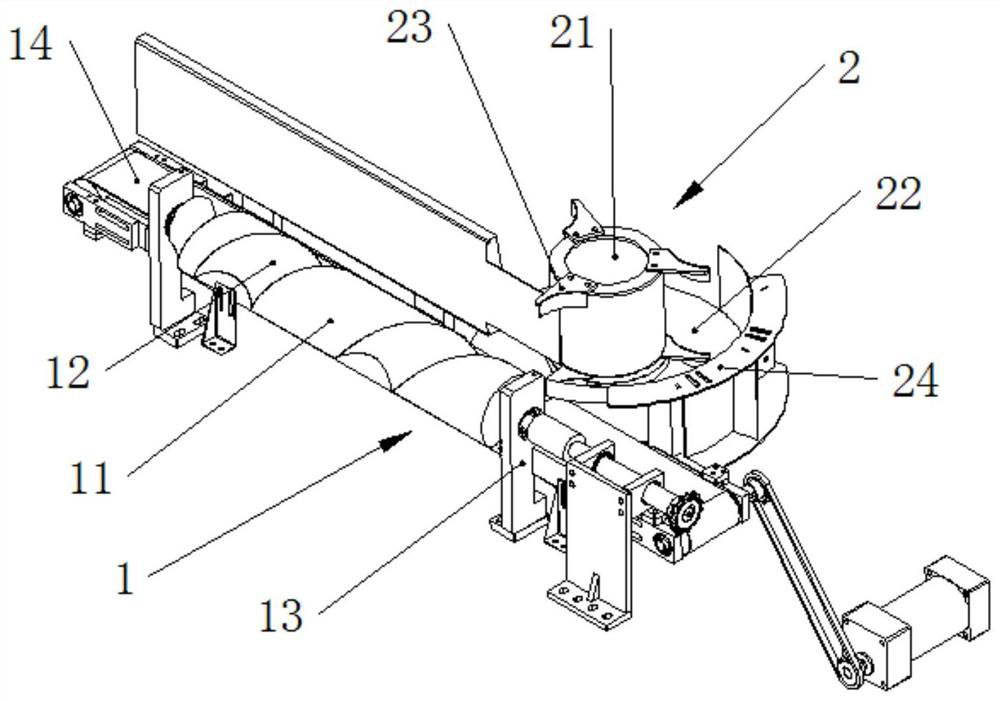

Quantitative packing machine

The invention relates to a sealing and dedusting precise fixed quantity packing machine, which includes a feed system and a weighing system, wherein, the feed system includes a packing auger, an electric motor for the packing auger, a feed pipe, and a sleeve for the feed pipe; the weighing system includes a sensor, a pedestal and a roller frame; the sensor is arranged on the pedestal, the roller frame on the sensor is connected with the sensor, a roller is arranged in the roller frame and the roller frame is arranged on the pedestal; the weighing system additionally includes a feed pipe bracket which is respectively connected with the feed pipe and the roller frame, the feed pipe is connected with a junction box and the sensor is connected with a control instrument. The beneficial effect of the invention is that: a pneumatic gate valve and the packing auger are adopted to control the feeding simultaneously, thus guaranteeing the working precision, preventing the packing auger from falling material so as to cause dust pollution; a dust collection device adopted can effectively reduce the dust; the feed pipe can move up and down and is provided with a sealing gasket, thus effectively preventing the dust from escaping.

Owner:王春阳

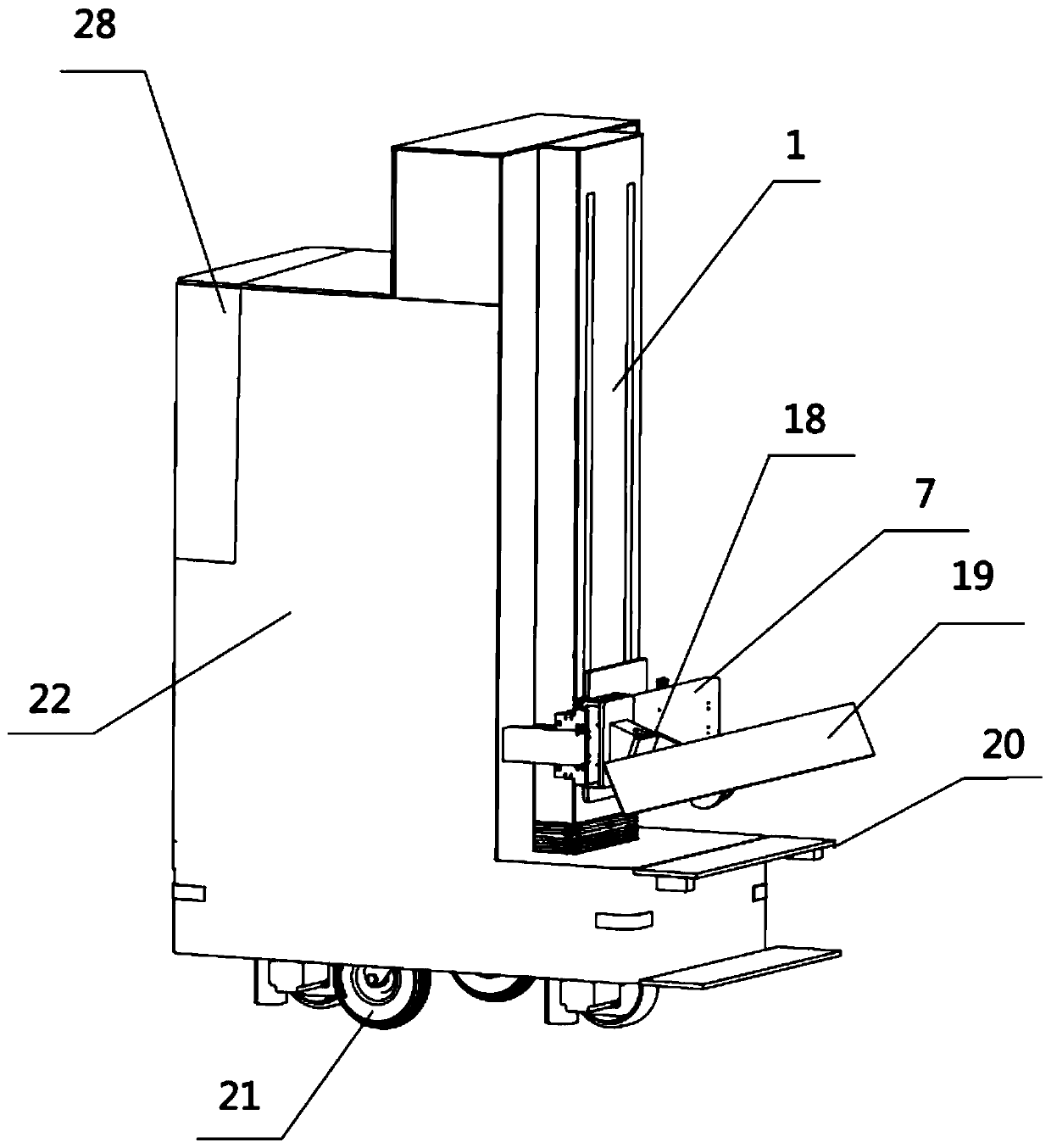

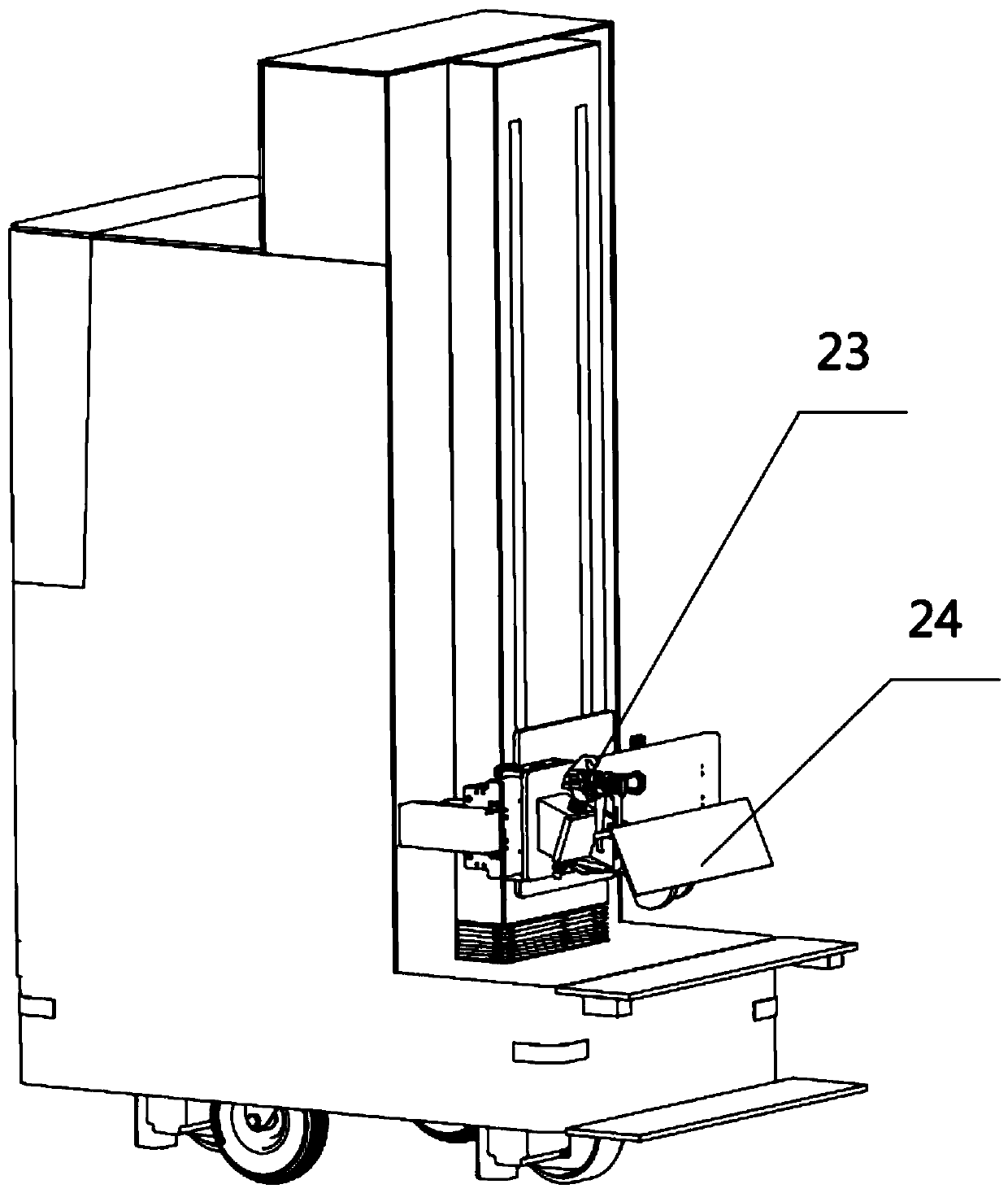

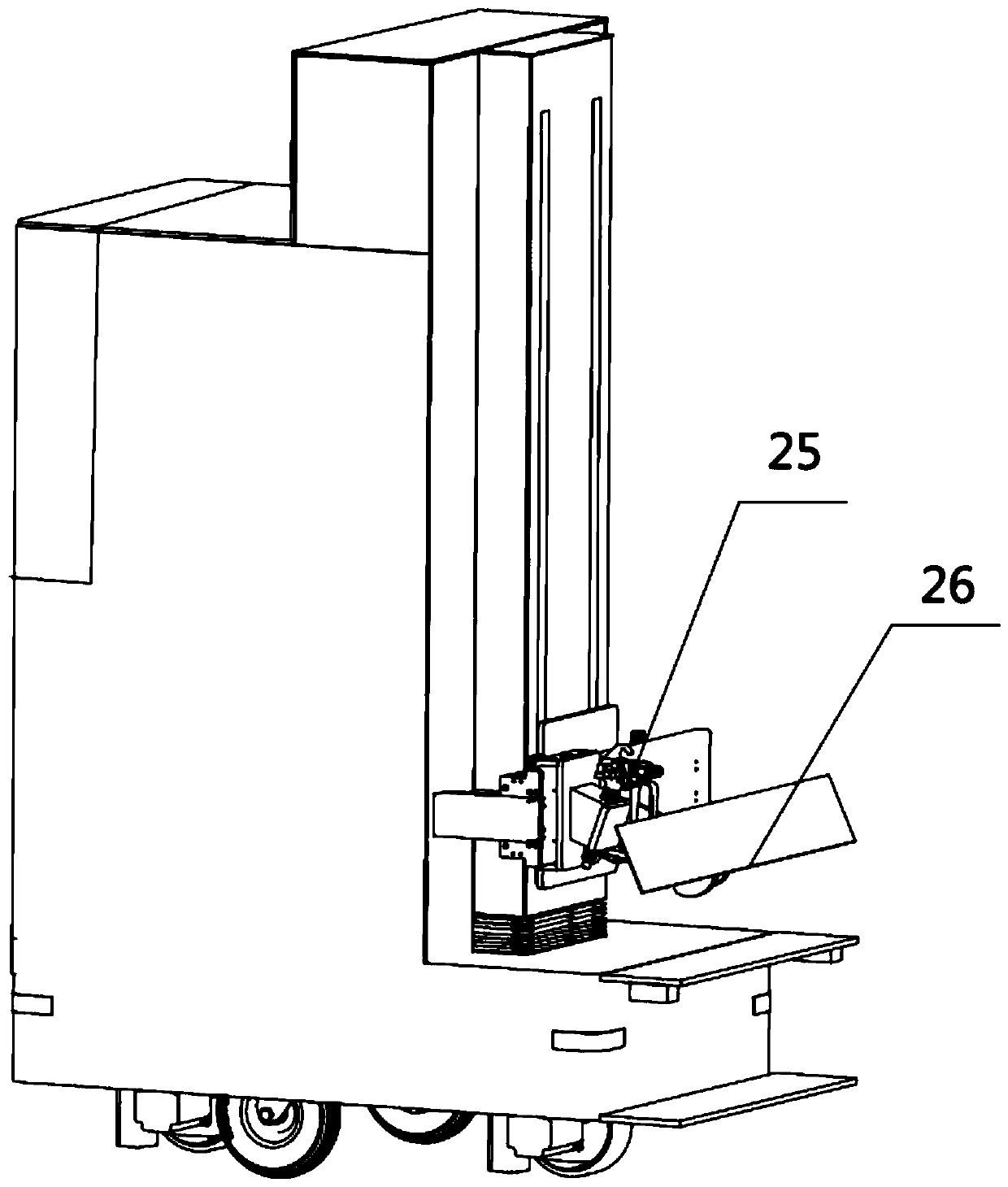

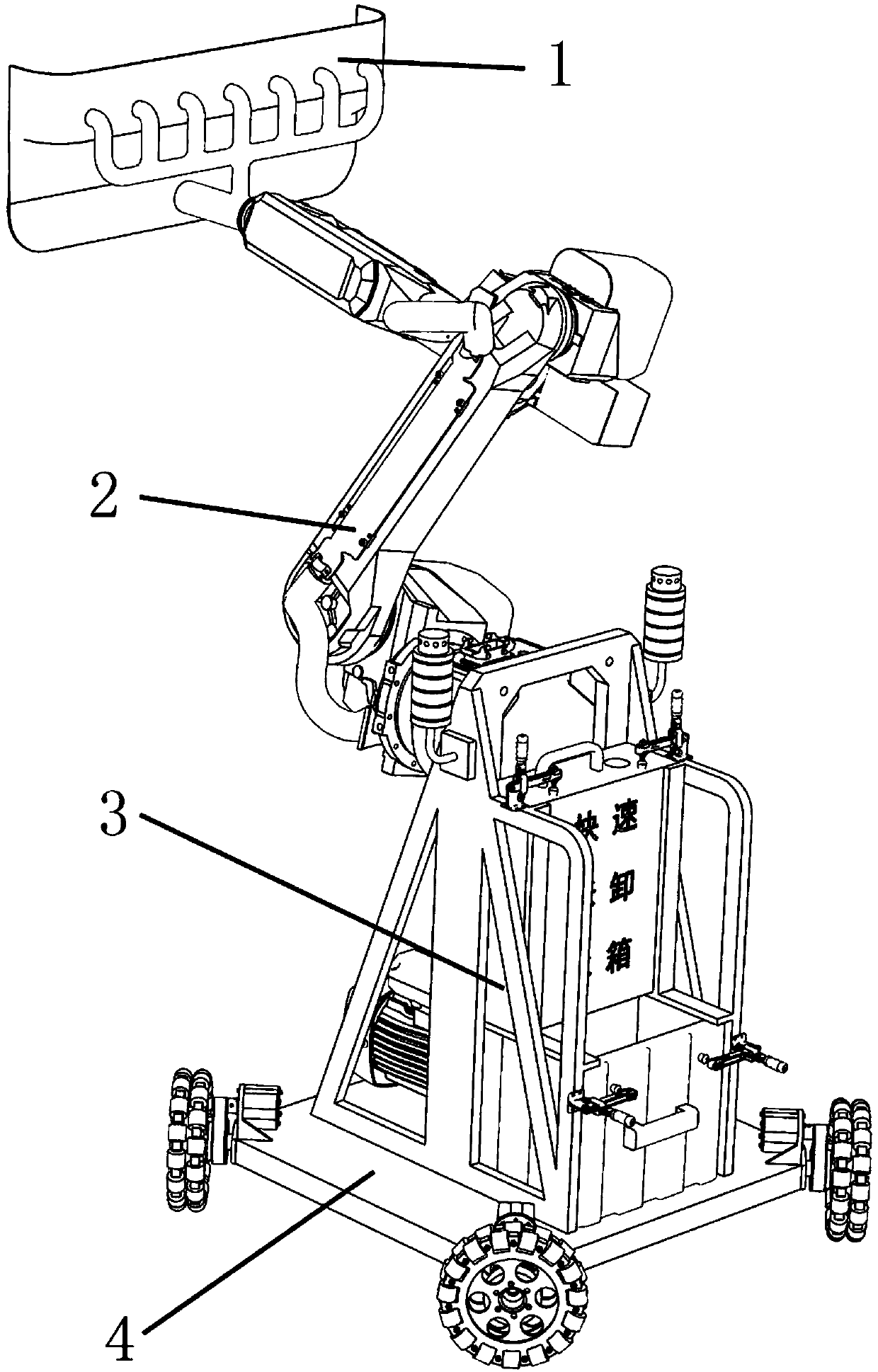

Wall surface putty treatment robot

ActiveCN110512841AImplement the translation functionGuaranteed working accuracyBuilding constructionsEmbedded systemRobot

The invention discloses a wall surface putty treatment robot. The wall surface putty treatment robot comprises various execution mechanisms, a connecting mechanism, a horizontal-moving mechanism, a lifting mechanism and a precision calibration device, wherein the connecting mechanism is selectively and detachably connected with the one or more execution mechanisms; the horizontal-moving mechanismis connected with the connecting mechanism and configured to be capable of driving the connecting mechanism to move in the horizontal direction; the lifting mechanism is connected with the horizontal-moving mechanism and configured to be capable of driving the connecting mechanism to ascend and descend; and the precision correction device is configured to be capable of calibrating the precision ofthe execution mechanisms. According to the wall surface putty treatment robot, the connecting mechanism is driven by the horizontal-moving mechanism to move in the horizontal direction so as to realize the horizontal-moving function of the execution mechanisms; the lifting mechanism can drive the connecting mechanism to ascend and descend so as to realize the lifting function of the execution mechanisms; and the precision calibration device can calibrate the precision of the execution mechanisms, the connecting mechanism is selectively and detachably connected with the one or more execution mechanisms, thus the various execution mechanisms can be assembled, and overall operation of putty coating inside a building is completed independently while the operation precision is ensured.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

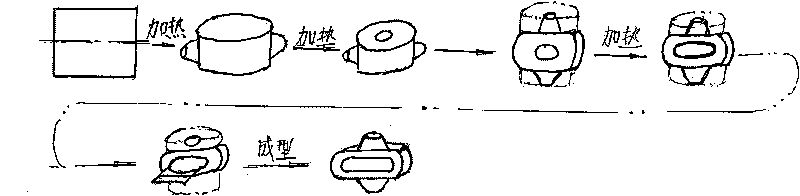

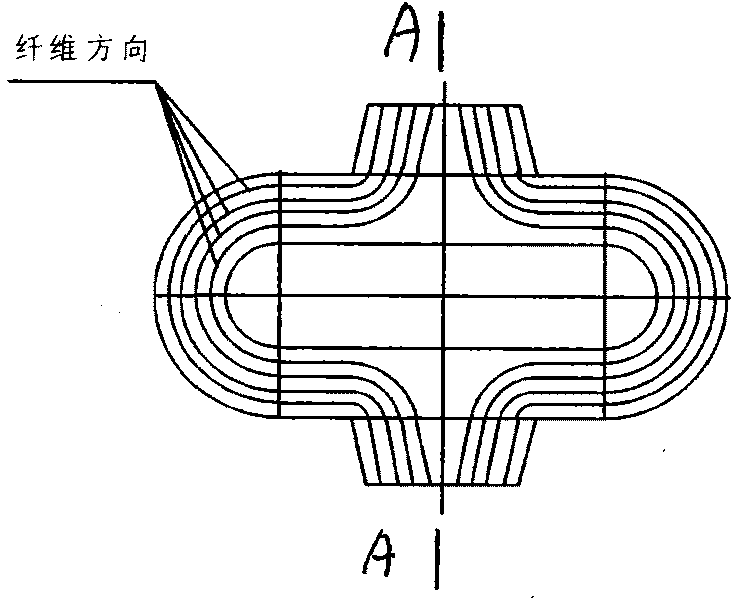

Forging process and tool of dynamometer annulus

InactiveCN101745593AGuaranteed working accuracyGuaranteed long-term stabilityForging/hammering/pressing machinesDynamometerFiber orientation

The invention discloses forging process and tool of a dynamometer annulus and relates to a free forging process, aiming at ensuring that the fiber direction of the internal organization of the dynamometer annulus is consistent with the forced direction of the annulus during working and fiber flows are not cut off so as to improve the force property of the annulus and guarantee the working precision and the long-term stability of the dynamometer. The forging process flow comprises the following steps of: blanking; heating; forging into a flat square shape and pulling out the tail part; heating for a second time; chamfering and punching into an annular body; upsetting; heating for a third time; chambering and pressing into a long round shape; necking and trimming the punched hole to form a required appearance and size; and cooling and annealing. The tool comprises a round drain cap, a flat drain cap and a flat punch. The invention is used for forging and processing the dynamometer annulus.

Owner:TIANSHUI HONGSHAN TESTING MACHINE

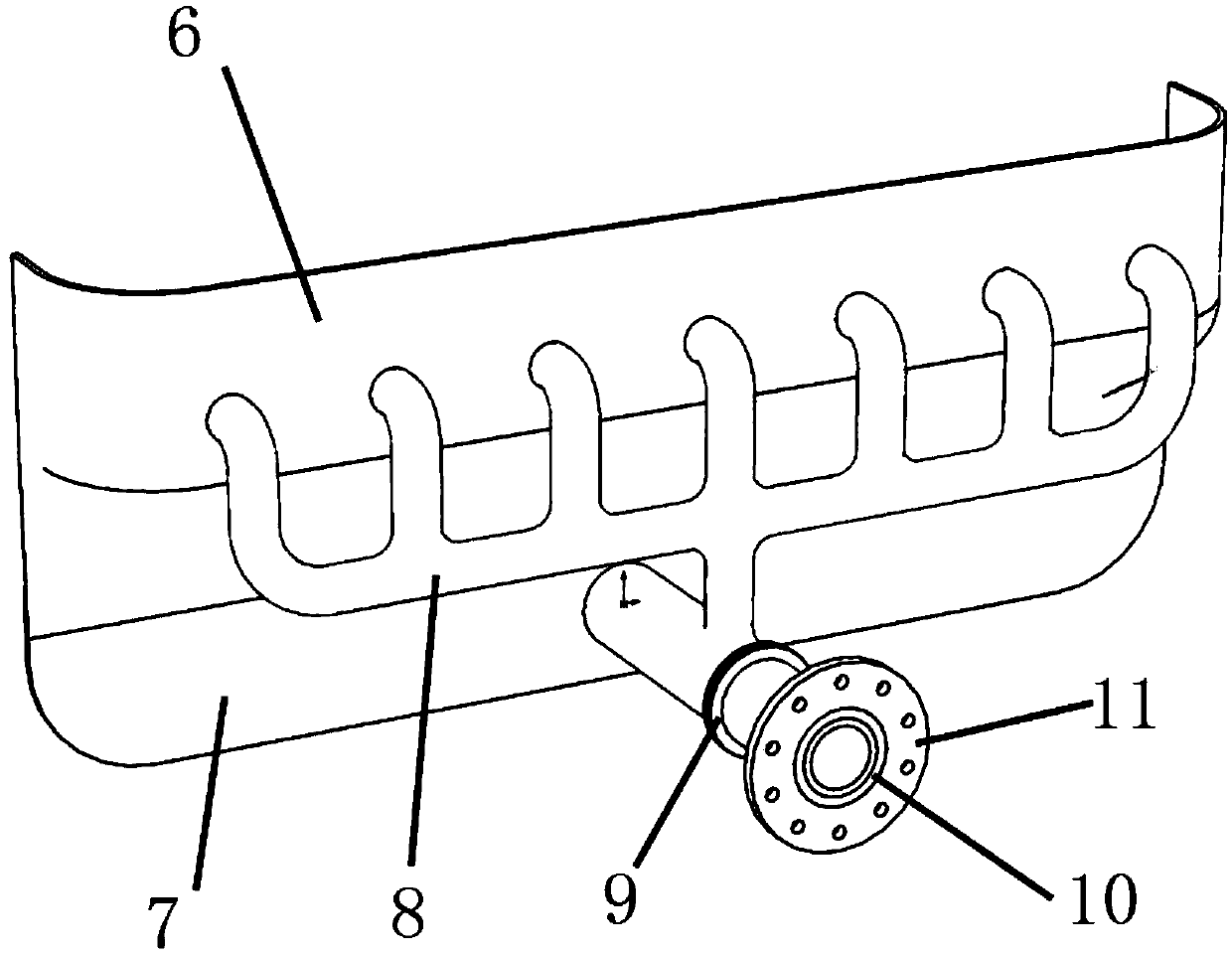

Maintenance robot with online bolt retightening function

InactiveCN113649796ARealize the demand of retightening operationAchieving force closure effectWind energy generationMetal working apparatusRotation - actionControl engineering

The invention belongs to the technical field of electric power operation climbing robots, and particularly relates to a maintenance robot with an online bolt retightening function. The maintenance robot comprises a main machine and an angle steel clamping assembly arranged on the main machine, wherein a bolt retightening device used for retightening a bolt is arranged at the head end of the main machine, and comprises an extension arm and a working head fixed to the extension arm; the extension arm comprises a bottom frame fixed to the main machine; a rotating assembly used for driving the working head to rotate and a plane displacement assembly used for driving the working head to operate at a fixed point are mounted on the bottom frame; a sleeve auxiliary replacement box facilitating high-altitude sleeve replacement operation with the working head is further fixed to the main machine; and the sleeve auxiliary replacement box and the bolt retightening device are both fixed to the head end of the main machine. On the premise that safe construction is ensured, the sleeve online replacement function under full high-altitude operation can be achieved, the manual inspection cost is greatly saved finally, the maintenance efficiency is improved, and safe and reliable operation of a power transmission system is ensured.

Owner:STATE GRID ANHUI ELECTRIC POWER +1

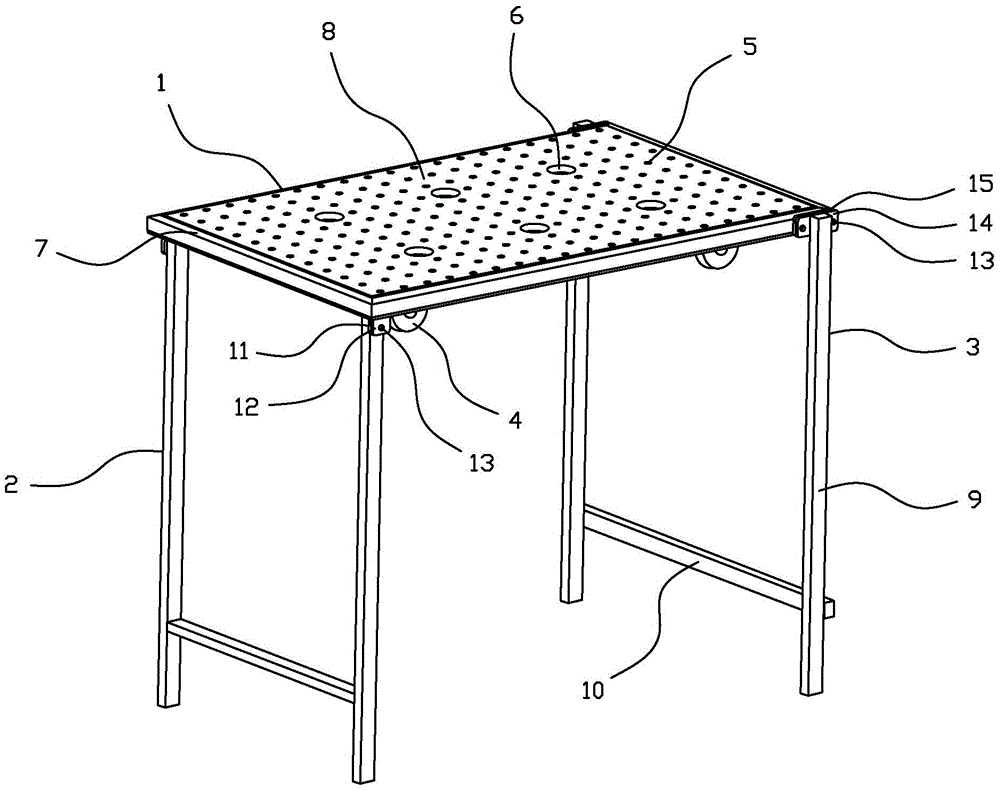

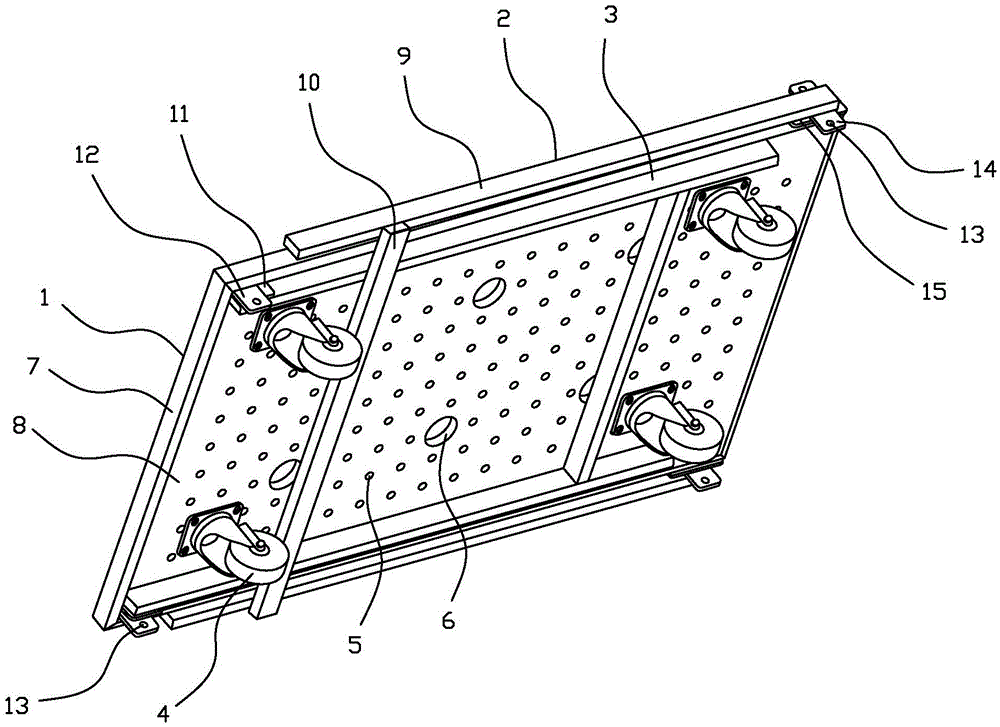

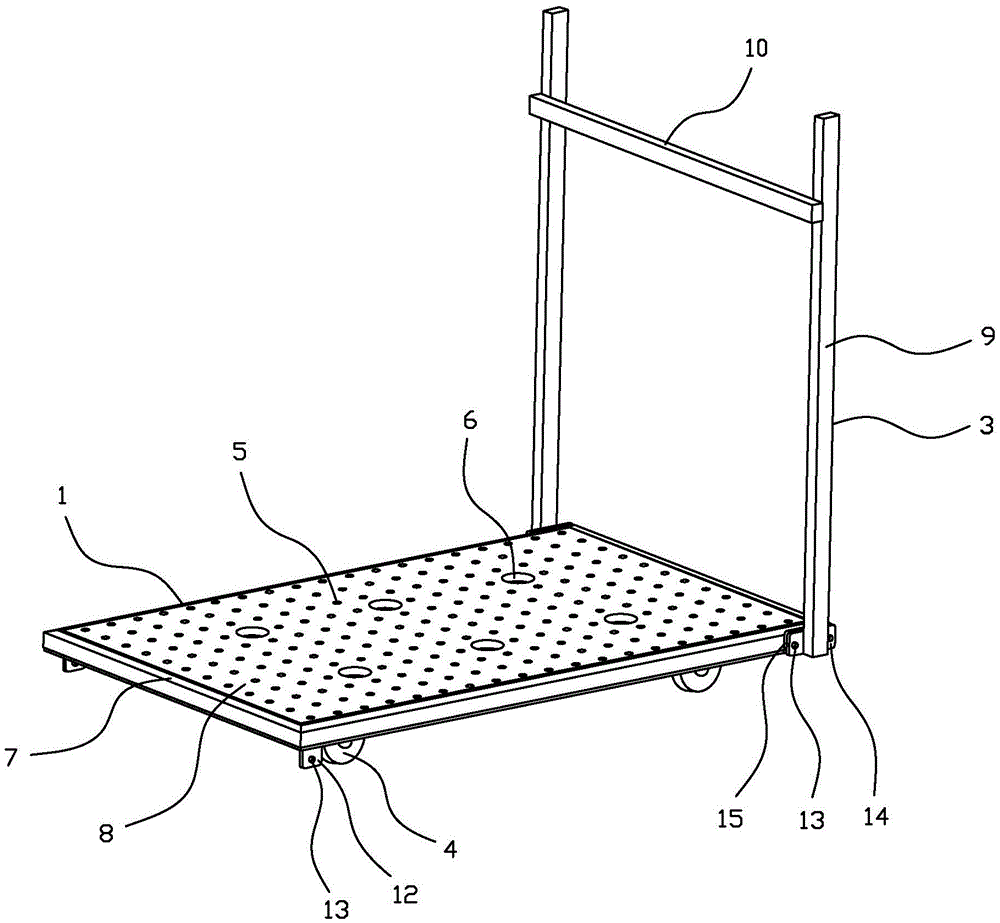

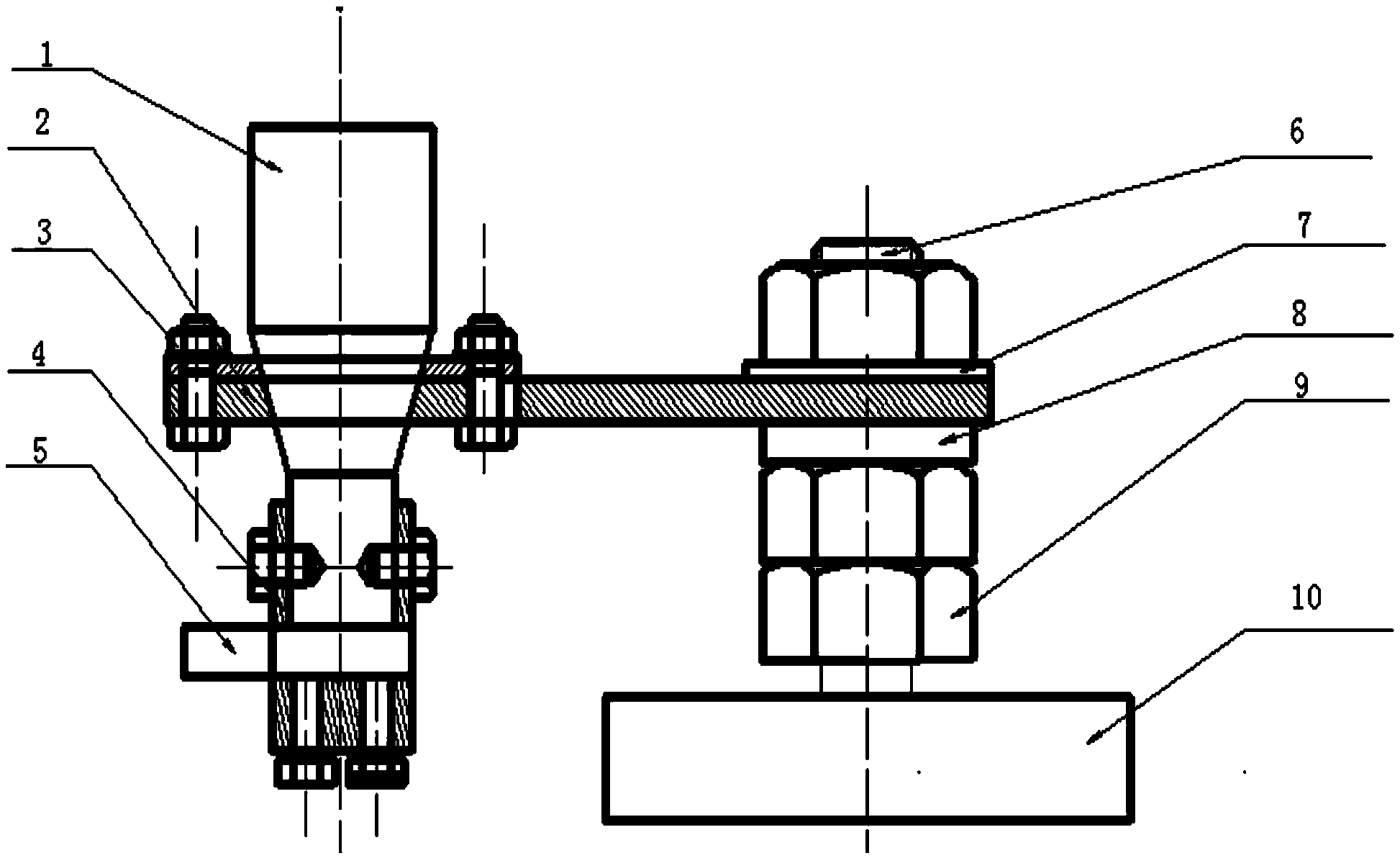

Multipurpose portable high-voltage isolating switch overhaul worktable and using method thereof

ActiveCN105552761AReduce space consumptionEasy to carryWork benchesSwitchgearModular fixtureProcess quality

The invention discloses a multipurpose portable high-voltage isolating switch overhaul worktable. The multipurpose portable high-voltage isolating switch overhaul worktable comprises a worktable board and multiple foldable support legs which are hinged to the worktable board and are used for supporting the worktable board; rolling wheels are arranged at the bottom of the worktable board; and at least one foldable support leg can be turned to the upside of the worktable board. The overhaul worktable can be folded, so that relatively small space is occupied; a platform plate which is made from a polyformaldehyde resin material is light in weight and convenient to carry; the rolling wheels are arranged at the bottom of the worktable board, and the multipurpose portable high-voltage isolating switch overhaul worktable can be used as a trailer by folding one foldable support leg at the bottom of the worktable board and turning another foldable support leg to the upside of the worktable board, so that the high-voltage isolating switch overhaul worktable can be used for multiple purposes, is convenient to carry tools and various modular fixtures and is convenient to use, the work efficiency can be improved greatly, and the labor intensity can be reduced; meanwhile, a series-hole modular fixture structure is formed on the worktable board and via holes are formed in the worktable board, so that more convenience is brought to assembly and disassembly of the isolating switch overhaul fixtures, the work precision can be ensured, and the work efficiency as well as the process quality can be improved.

Owner:QUANZHOU POWER SUPPLY COMPANY OF STATE GRID FUJIAN ELECTRIC POWER +1

Height-adjustable ultrasonic turning tool clamping device

InactiveCN103480871AGuaranteed working accuracyEasy loading and unloadingTurning toolsTool holdersTransducerMechanical engineering

Disclosed is a height-adjustable ultrasonic turning tool clamping device comprising a turning tool and an amplitude-change pole which are connected through a sleeving ring. The turning tool is mounted on the sleeving ring through a hole formed on the side wall fo the sleeve ring. The lower end of the amplitude-change pole is sleeved in the sleeving ring, the lower end face of the amplitude-change pole contacts with the upper surface of the turning tool tightly, and the lower surface of the turning tool is pressed through screws. According to the height-adjustable ultrasonic turning tool clamping device, the turning tool and the amplitude-change pole are connected, the upper surface of the turning tool contacts with the lower end of the amplitude-change pole tightly, and the lower surface of the turning tool is pressed through the screws, so that the tool tip can be perpendicular to the processing surface constantly, operating accuracy can be guaranteed, disassembling is easy, and the tool can be changed conveniently. The ultrasonic turning tool and the amplitude-change pole can resonate with vibration frequency of a transducer after being connected, structure is simple, operation is facilitated, generality is high, sound energy loss is small, and the height-adjustable ultrasonic turning tool clamping device is prevented from heating during long-time operation.

Owner:XIAN UNIV OF TECH

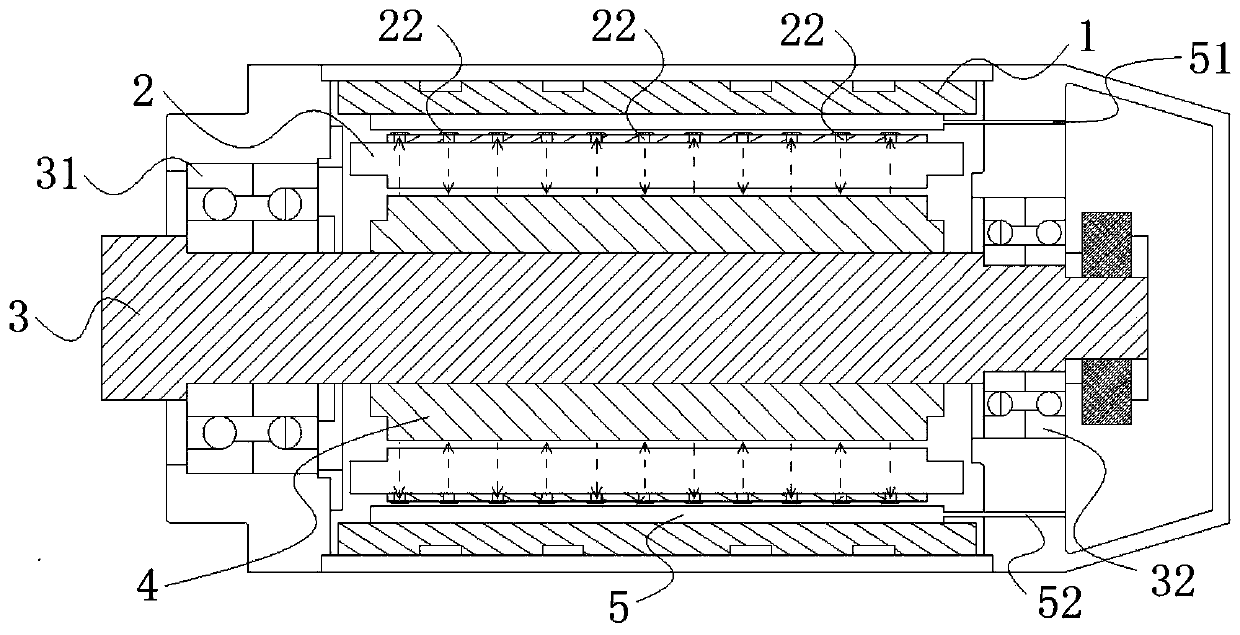

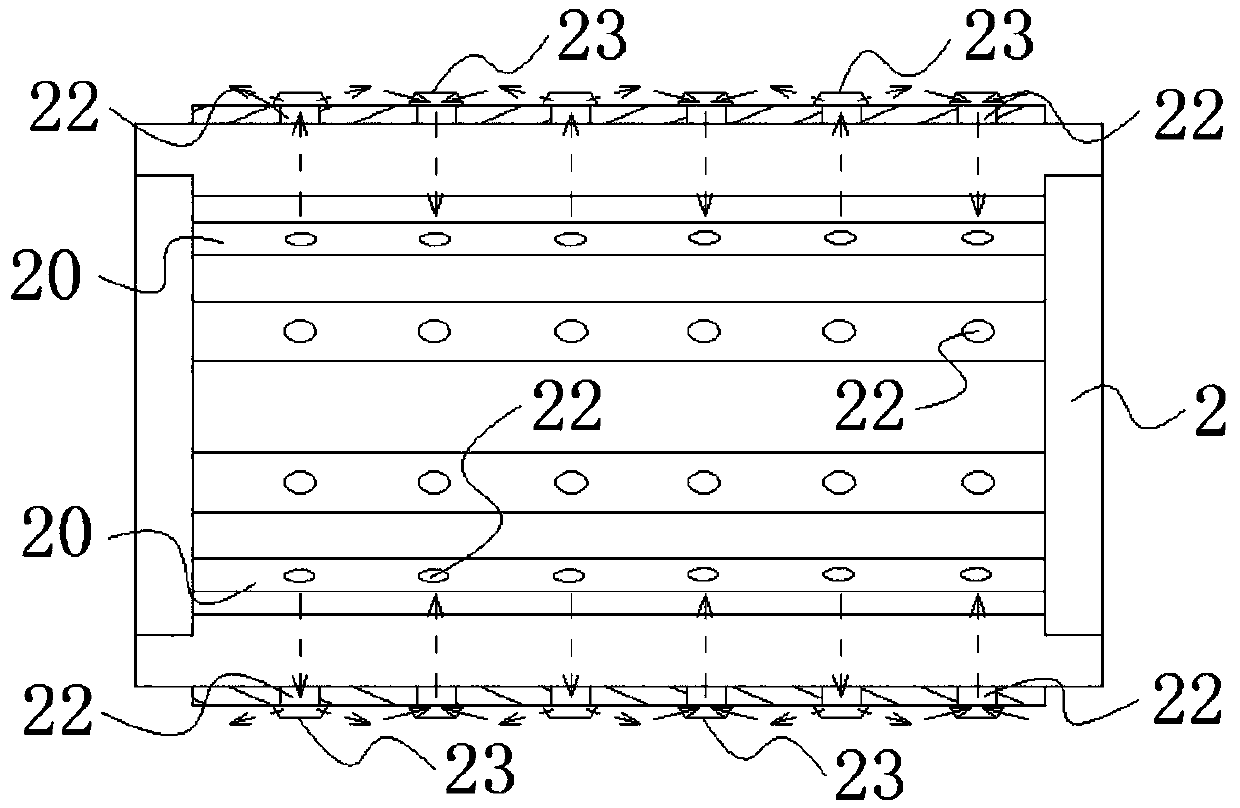

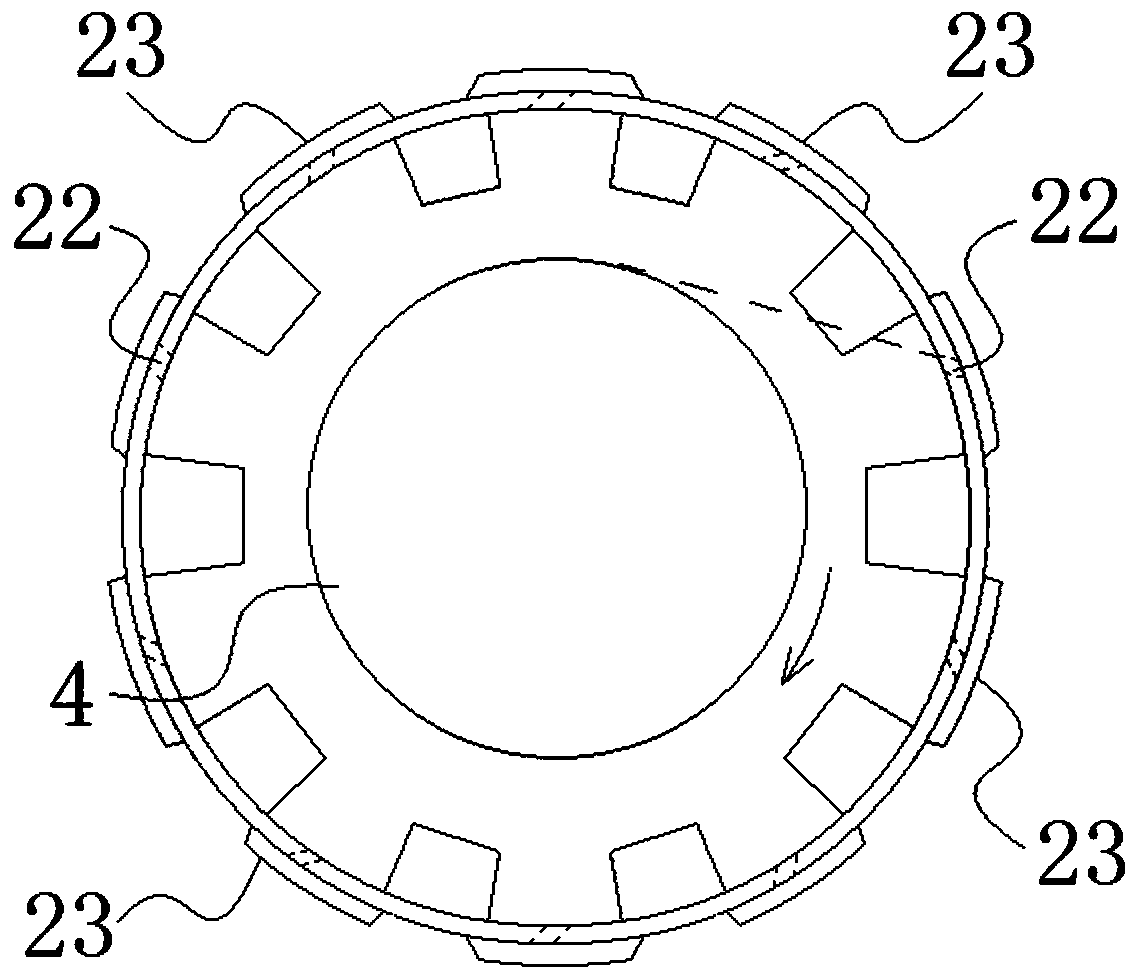

High-speed motor with spindle heat dissipation structure

PendingCN110417170AAvoid accumulationAvoid high temperatureMagnetic circuit stationary partsSupports/enclosures/casingsInterior spaceEngineering

The invention provides a high-speed motor with a spindle heat dissipation structure, which relates to the field of motor cooling. The high-speed motor with a spindle heat dissipation structure includes a motor shell, a stator core, and a spindle and a rotor rotationally installed inside the stator core. A cooling sleeve is arranged between the motor shell and the stator core. A heat exchange channel for gas circulation is reserved between the stator core and the cooling sleeve. Air holes are arranged in the outer circumferential wall of the stator core. The air holes communicate the heat exchange channel with the internal space of the stator core. The air holes communicate the inner and outer spaces of the stator core, so that the heat emitted by the spindle and the rotor can be transferred to the outside of the stator core through the air holes, and heat accumulation inside the stator core is avoided. The heat is driven by gas flow to diffuse outward and fully contacts the inner wallof the cooling sleeve for heat exchange, so that the spindle and the rotor are cooled, high temperature caused by the piling up of heat on the spindle is prevented, and the working accuracy and service life of the high-speed motor are ensured.

Owner:GUANGDONG HI 1 NEW MATERIALS TECH RES INST CO LTD

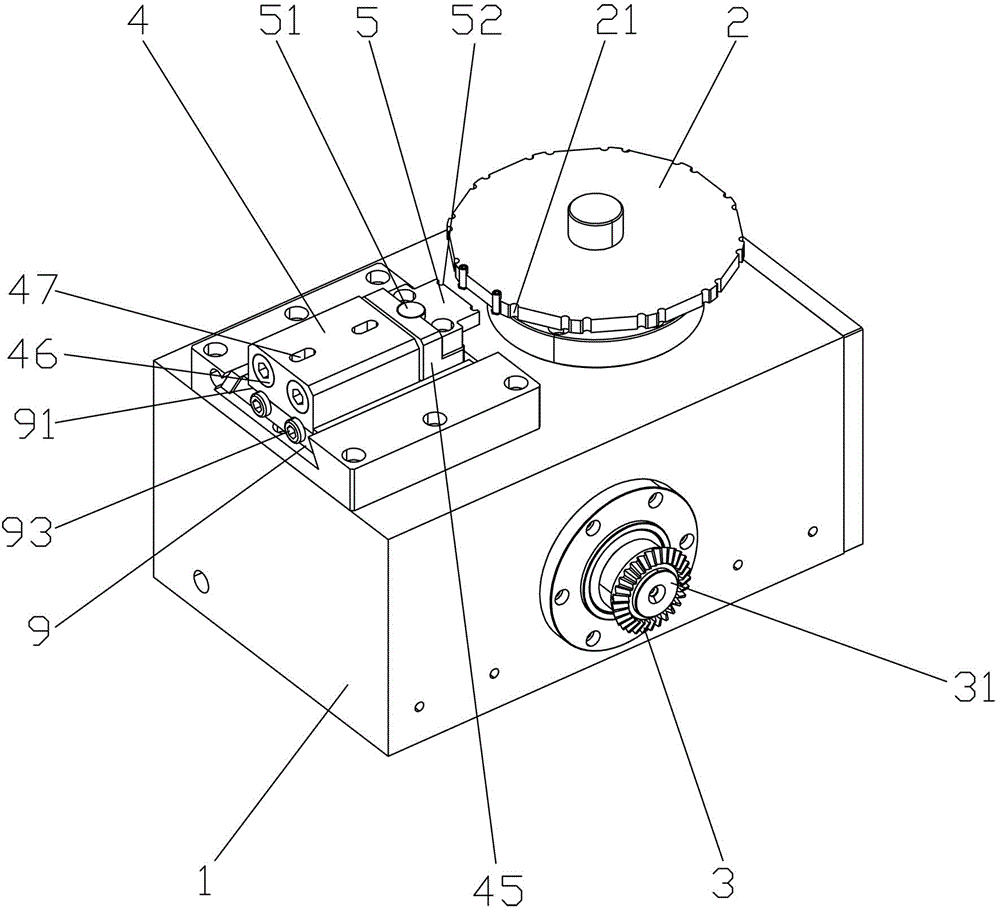

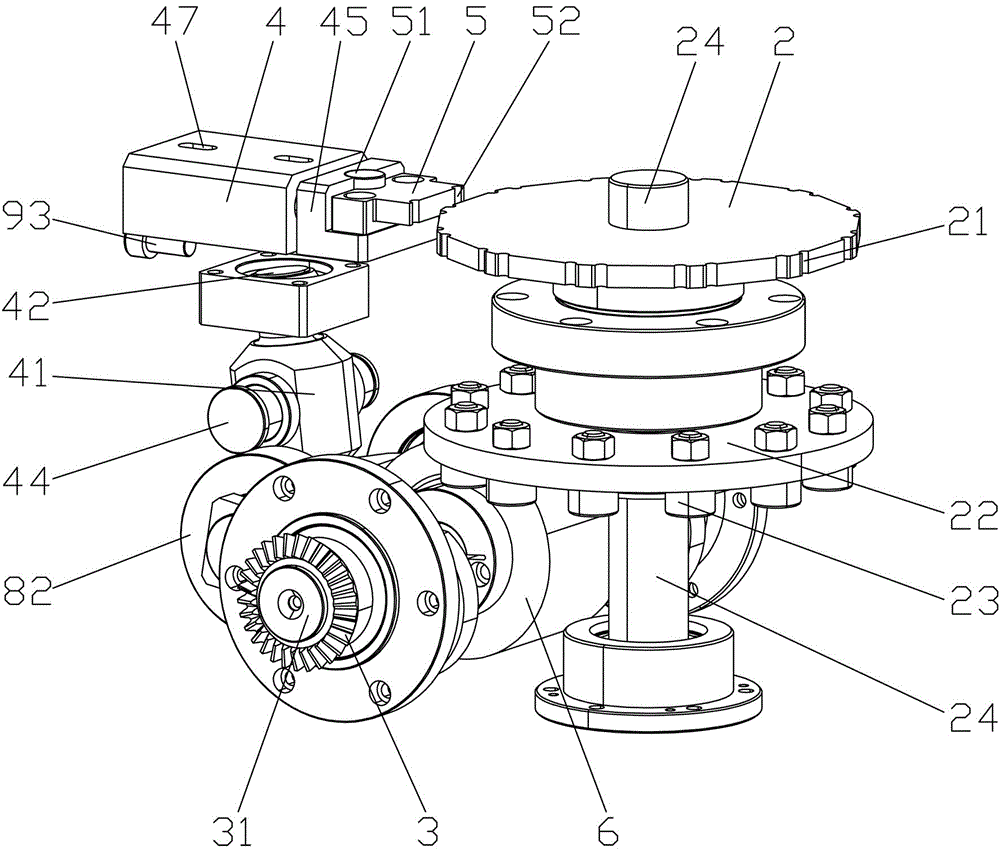

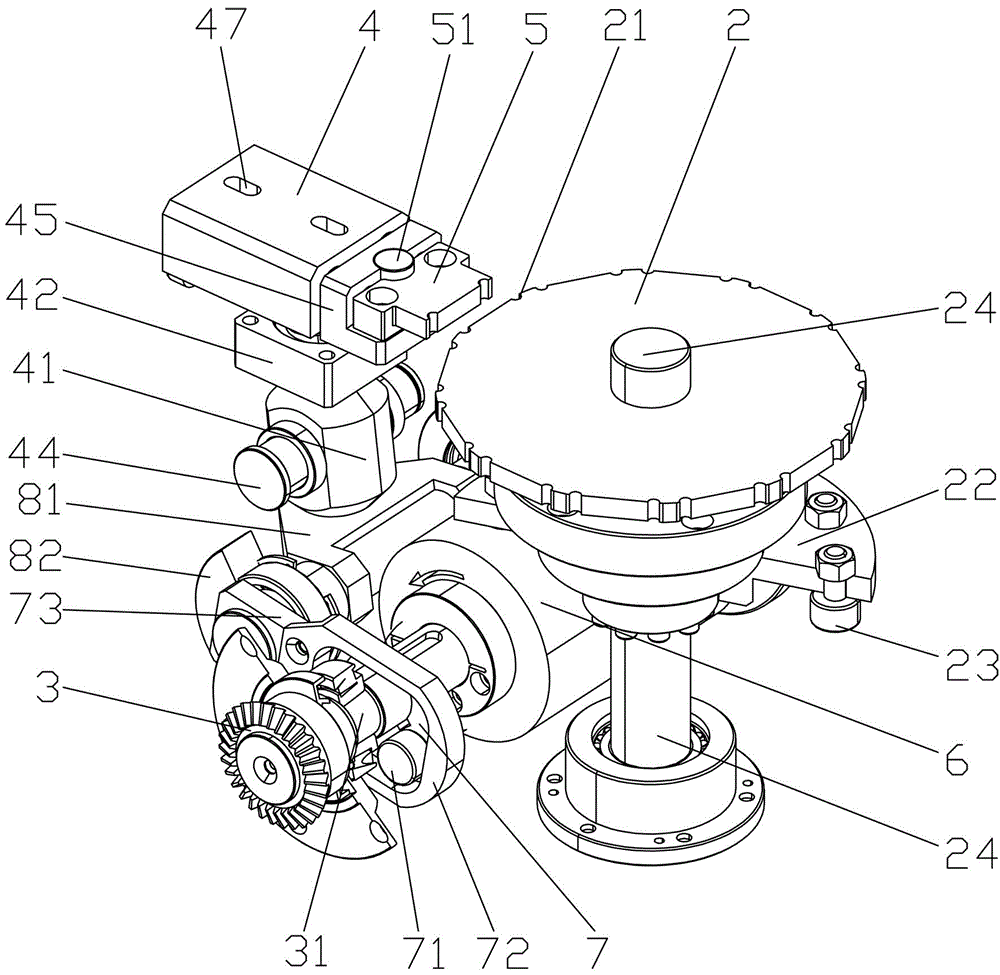

Novel divider

ActiveCN104440018ASimple structureGuaranteed work efficiencyWork holdersMetal working apparatusEngineeringCam

The invention discloses a novel divider which comprises a machine base, a rotary disk arranged on the machine base and a power input end. Positions are distributed on the outer edge of the rotary disk. A push block capable of stretching and retracting forwards and backwards is arranged behind the rotary disk. The end, facing the rotary disk, of the push block is provided with a clamping block. The machine base is also provided with a driving spindle connected with the power input end. A cam is mounted in the middle of the driving spindle in a sleeving mode. An index plate is arranged beside the cam. Indexing rollers capable of clamping a straight flange and an oblique flange are distributed along the circumference of the index plate. The index plate is connected with the rotary disk through an indexing shaft. A movable lever shaft is arranged behind the driving spindle. A lever block facing the rear side of the movable lever shaft is arranged in the middle of the movable lever shaft. The lever block is connected with a push block lever shaft in a rotatable mode. According to the divider, through a reasonable structural improvement and especially through the design of simultaneous linkage of the index plate and the push block, the effect that stepping indexing and stretch and retraction of the push block are controlled simultaneously through one divider is achieved.

Owner:FOSHAN HUIJIE AUTOMATED MACHINERY

Continuous punching die for mobile phone lens

InactiveCN102989878AGuaranteed working accuracyImprove work efficiencyShaping toolsProduction linePunching

The invention discloses a continuous punching die for a mobile phone lens. The continuous punching die comprises an upper die and a lower die which are occluded with each other in a positioned manner; and a side hole coarse punching die, an intermediate hole coarse punching die, a longitudinal outline punching die, a longitudinal outline punching die, a first forming punching die, a second forming punching die, a third forming punching die, an intermediate hole fine punching die, a fine forming punching die, a small hole fine punching die, a semi-shearing punching die and a blanking punching die are sequentially arranged between the upper die and the lower die from left to right. Through the mode, the continuous punching die carries out forming processing and hole position processing on the mobile phone lens during one process, is convenient and quick, can accurately ensure the working precision and is suitable for the production operation of a product production line, and the working efficiency can be greatly increased.

Owner:SUZHOU WUZHONG ECONOMIC DEV ZONE BOYU MOLD PROCESSING FACTORY

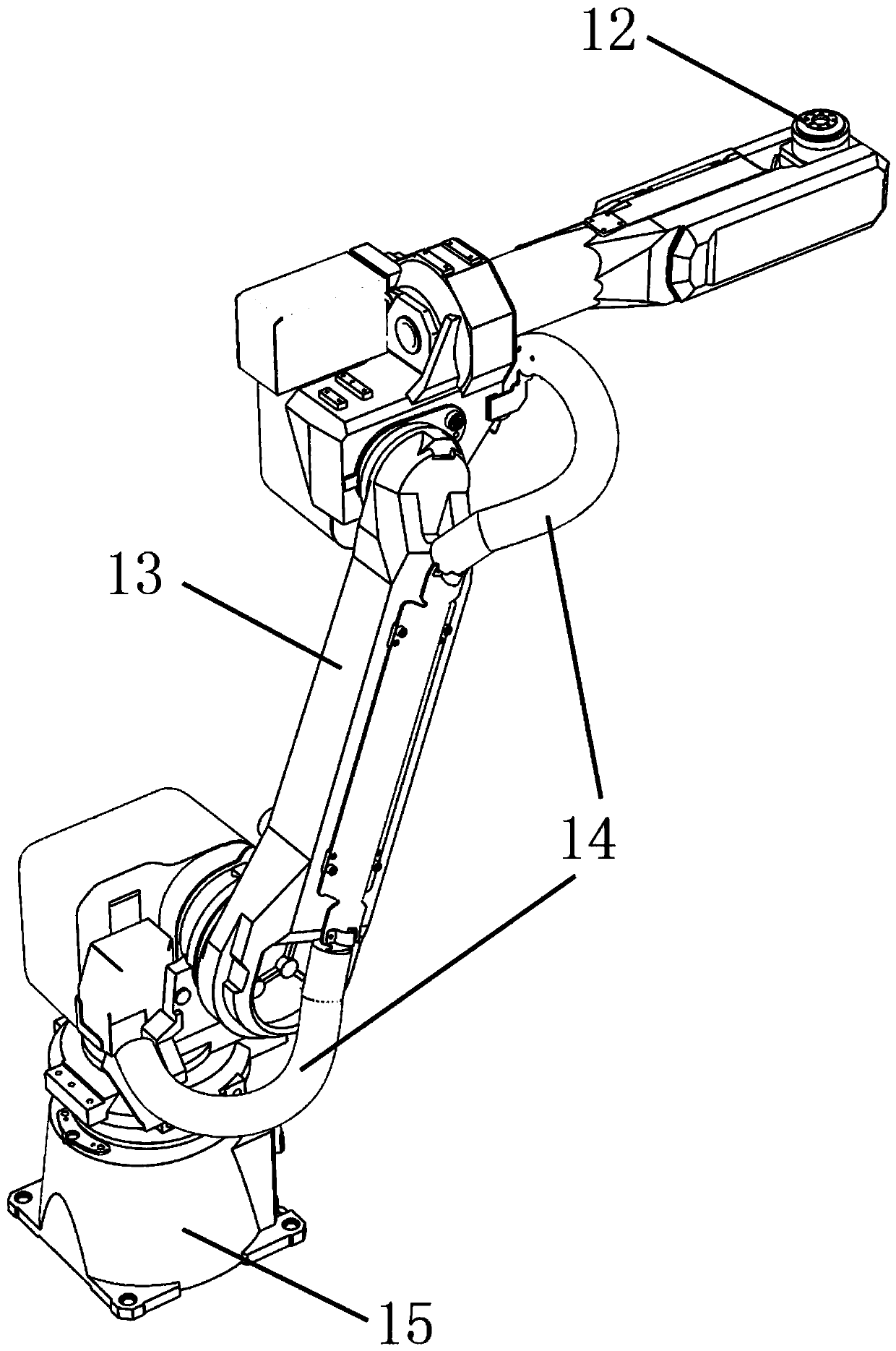

Full-automatic intelligent plastering robot

InactiveCN109098408ARoom dimensions are accurateGuaranteed working accuracyBuilding constructionsEngineeringRadar

The invention discloses a full-automatic intelligent plastering robot which comprises a uniform smearing device, a multiaxis mechanical arm, a stirring and pumping system, an all-around chassis movingsystem and a laser assistant positioning standard system. The uniform smearing device, the multiaxis mechanical arm, the stirring and pumping system and the all-around chassis moving system are sequentially connected from top to bottom. The full-automatic intelligent plastering robot has the advantages that laser radar is utilized to scan a whole room, so that size of the room is more accurate, and a robot plastering working face is determined to ensure working accuracy; in the process of plastering, pumping amount of the pumping system can be adjusted in real time by taking material amount in the uniform smearing device as a reference.

Owner:北京乂斯科技有限公司

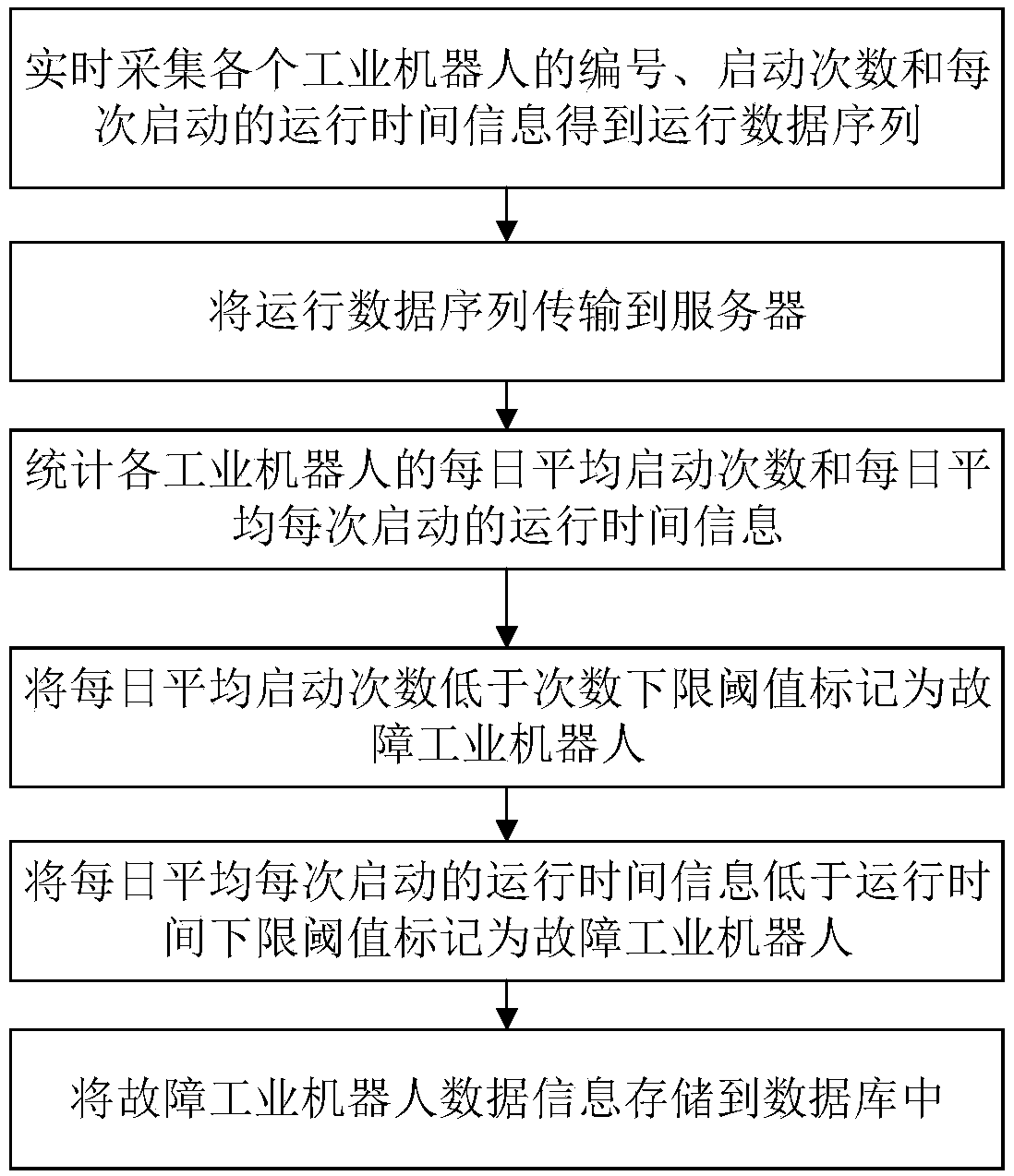

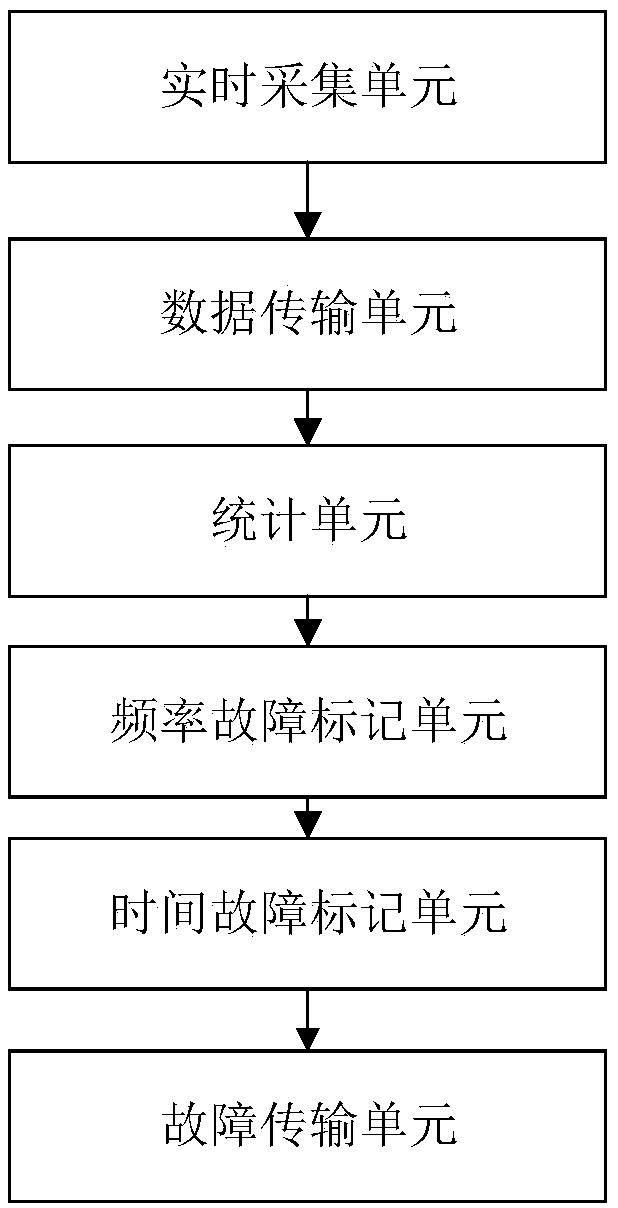

Real-time industry robot fault detection method and device

ActiveCN108673503AEasy to locate and maintainSimple Fault Diagnosis MethodProgramme-controlled manipulatorDiagnosis methodsRunning time

The invention discloses a real-time industry robot fault detection method and device. Industrial robots suspected to get faults are judged through real-time monitoring and statistics of the information of the average number of daily average starting times and the daily average every-time starting running time of the industrial robots and are submitted to a database, and maintaining personnel can conveniently conduct positioning and maintaining. The simple, visual and practical fault diagnosis method easy to achieve is provided, the industrial robots suspected to get faults are judged through real-time monitoring and statistics of the information of the average number of daily average starting times and the daily average every-time starting running time of the industrial robots and are submitted to the database, the maintaining personnel can conveniently conduct positioning and maintaining, accordingly, running safety is guaranteed, the work precision is guaranteed, the maintaining efficiency is improved, and the maintaining expense is saved.

Owner:FOSHAN UNIVERSITY

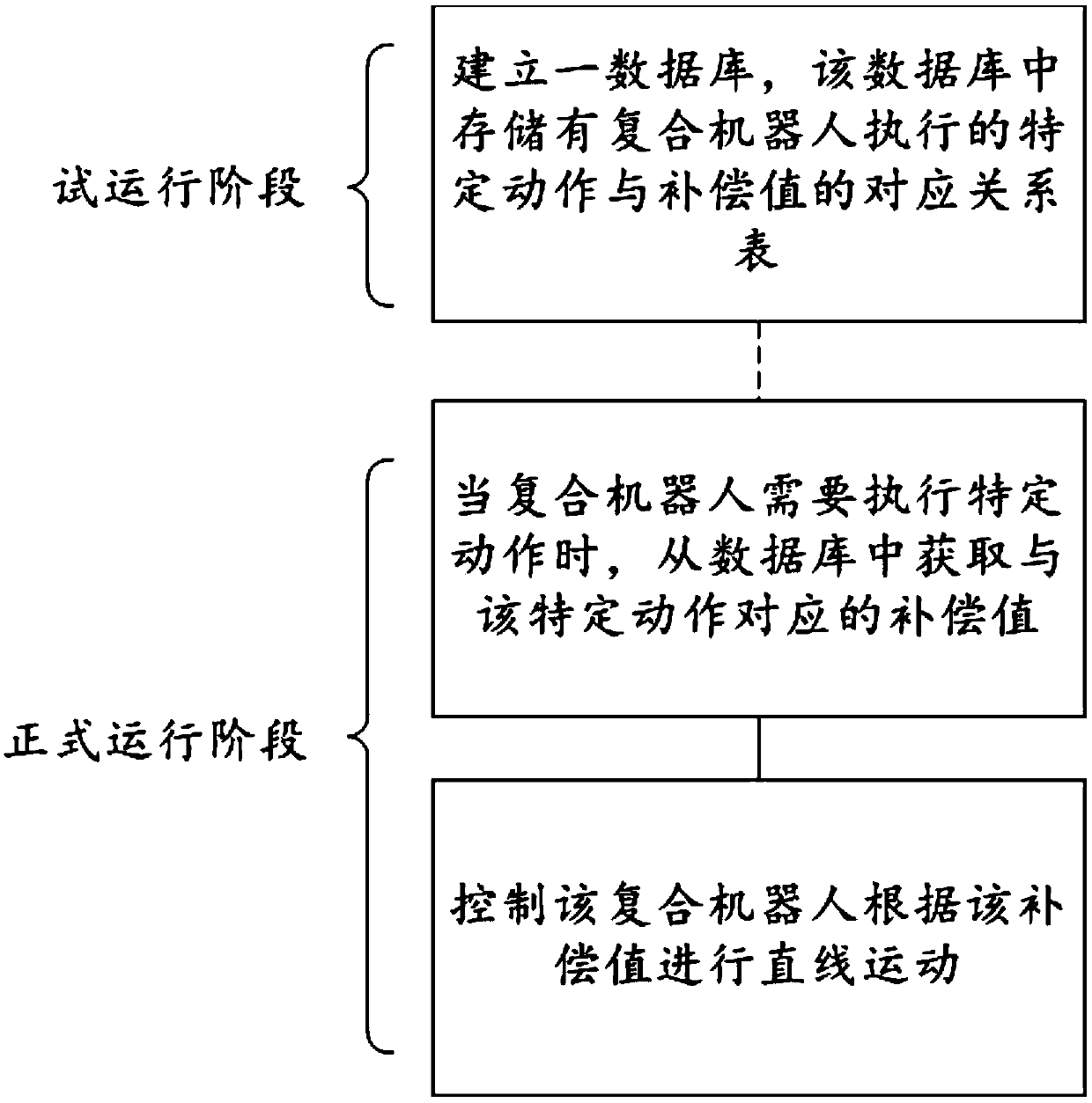

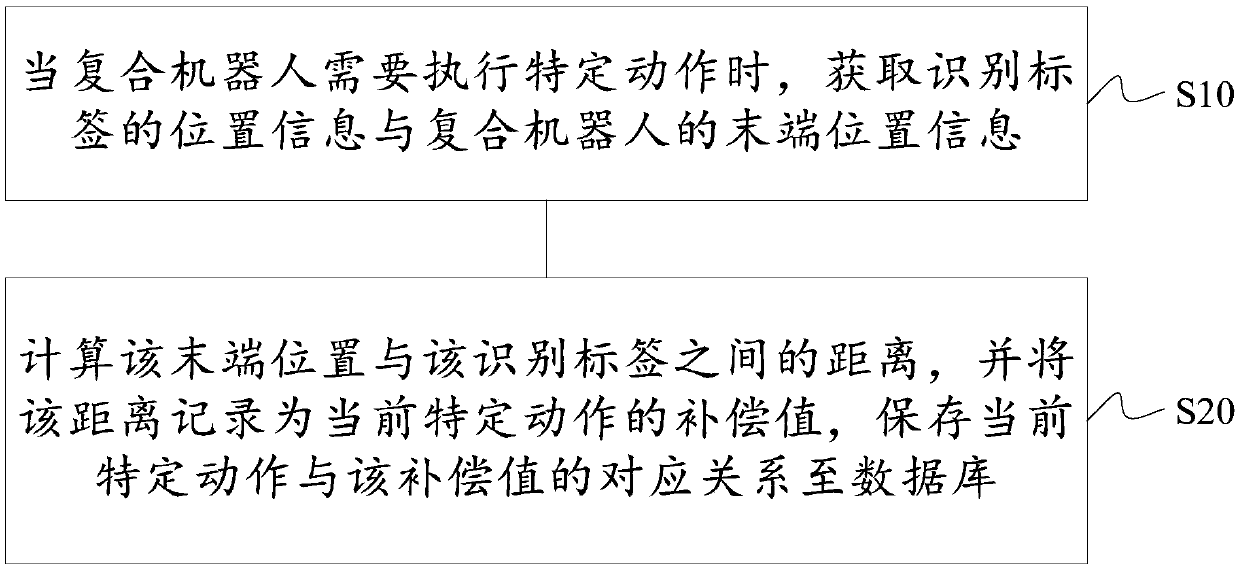

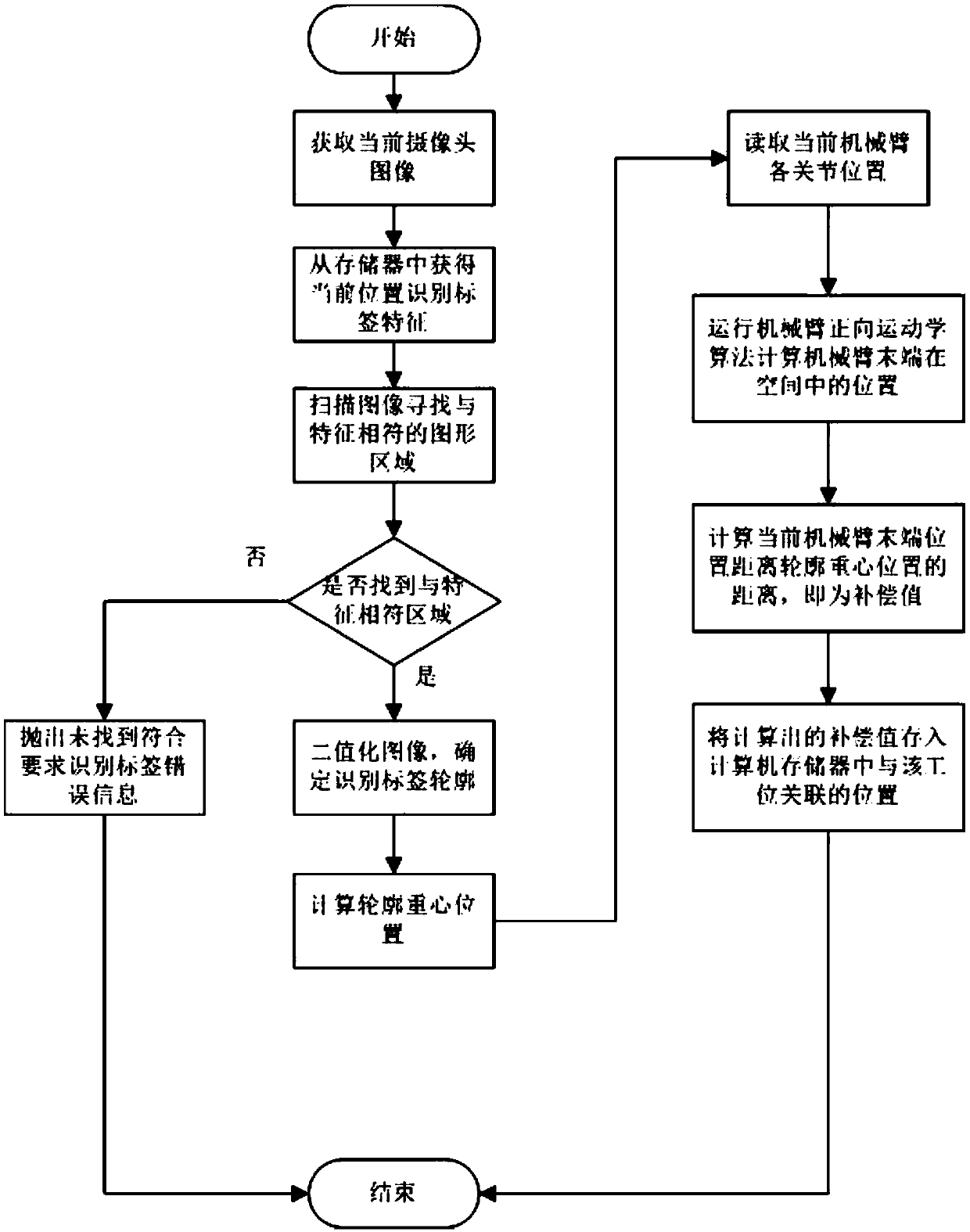

Hybrid robot working accuracy compensation method and system, and storage medium

ActiveCN109591051AEliminate error accumulationGuarantee working accuracyProgramme-controlled manipulatorEngineeringFormal verification

The invention discloses a hybrid robot working accuracy compensation method and system, and a storage medium. The method comprises two stages of trial operation and formal operation: in the trial operation stage, the method comprises the step of establishing a database, wherein a corresponding relation table between the specific actions executed by the hybrid robot and the compensation value is stored in the database; and in the formal operation stage, the method comprises the steps of acquiring a compensation value corresponding to the specific action from the database when the hybrid robot needs to perform the specific action, and controlling the hybrid robot to move linearly according to the compensation value. The accumulate error of mechanical arms caused by the sliding of an AGV baseof the hybrid robot can be overcome, and the working accuracy of the hybrid robot can be guaranteed.

Owner:上海英医达医疗器械用品有限公司

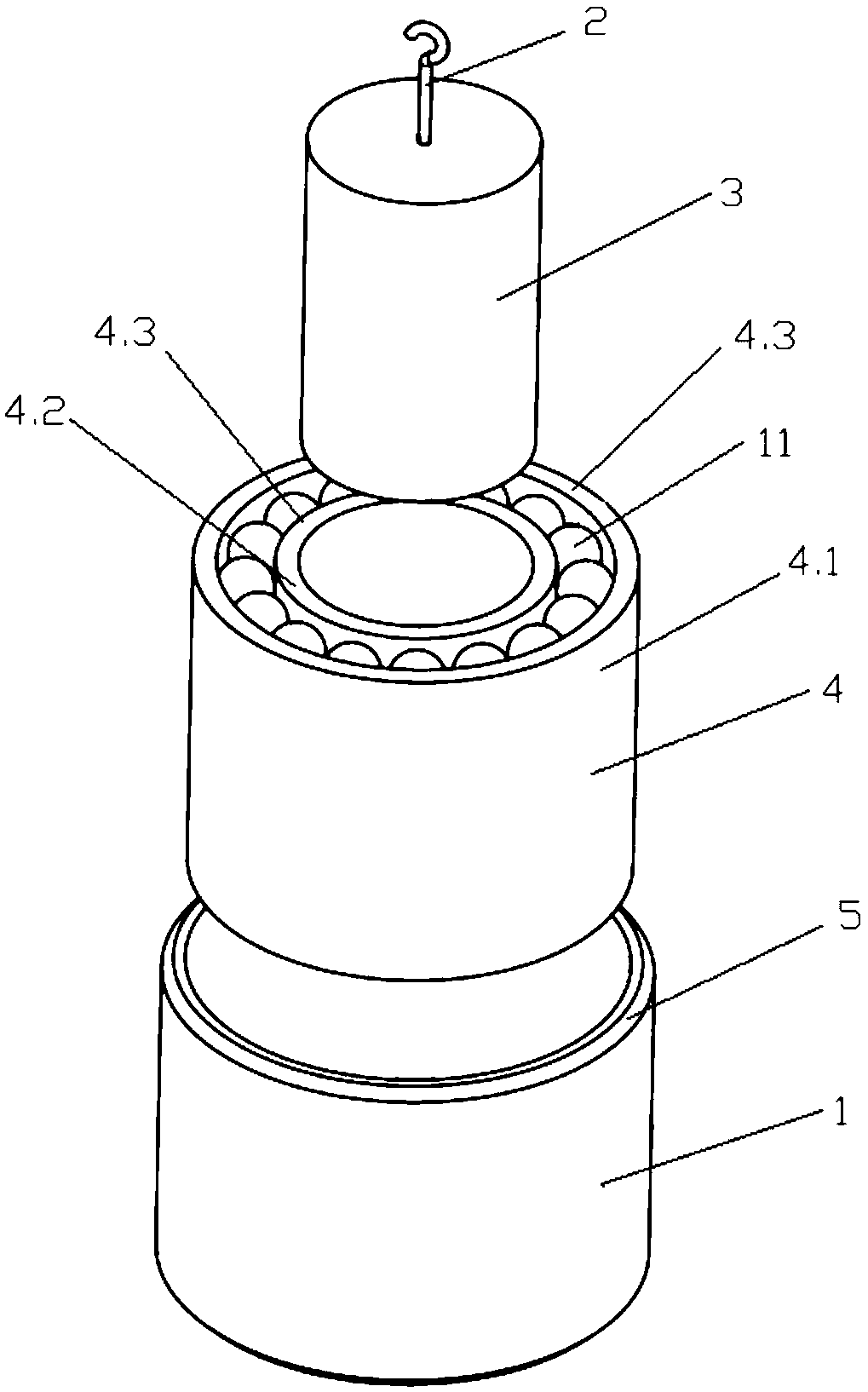

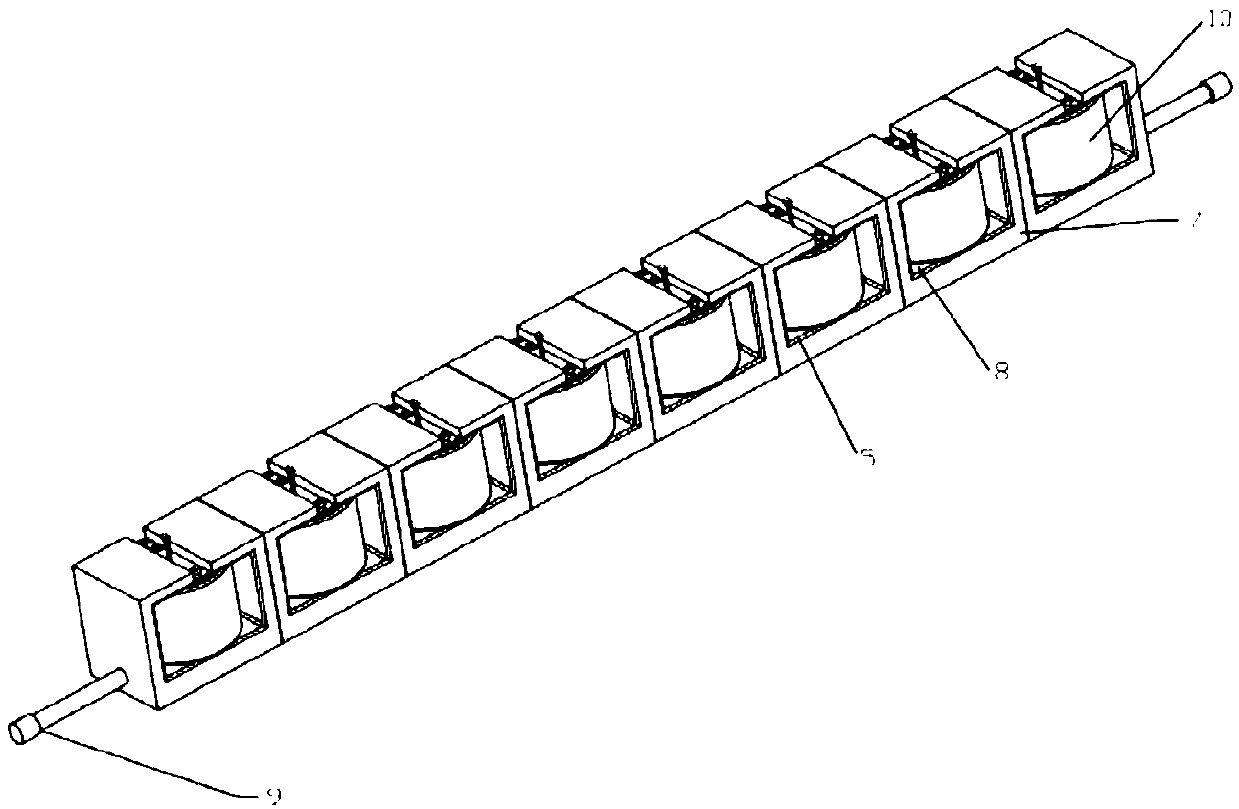

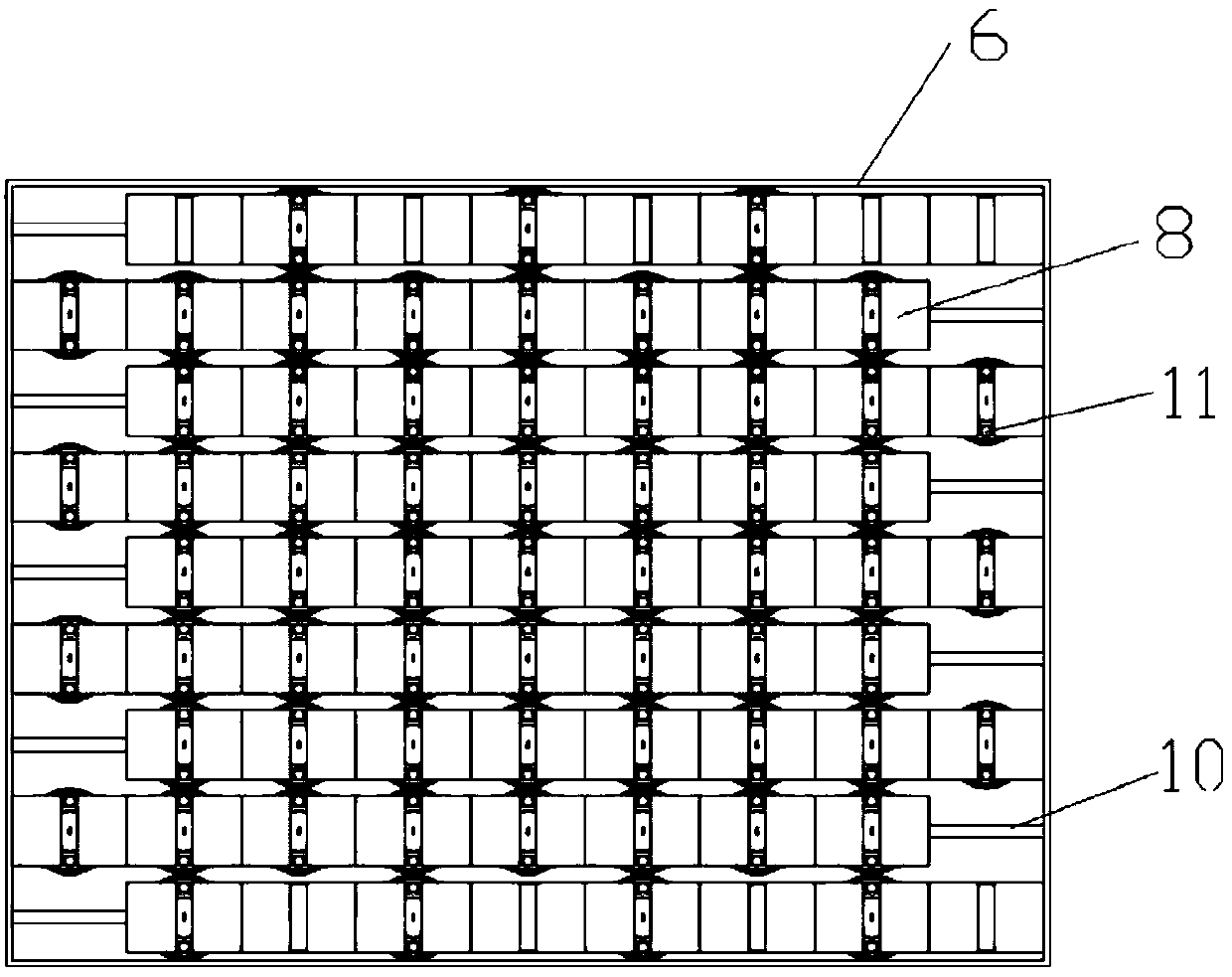

Cylindrical bearing yarn carrier and three-dimensional knitting machine adopting same

The invention relates to the technical field of three-dimensional knitting, and discloses a cylindrical bearing yarn carrier and a three-dimensional knitting machine adopting the same. The yarn carrier comprises a shaft sleeve and a motion assembly arranged inside the shaft sleeve in rotating fit with the shaft sleeve, and a hook for being connected with yarn is installed on the motion assembly. By improving the structure of the yarn carrier, the yarn carrier is not likely to be abraded, effective working of the three-dimensional knitting machine is ensured, and the yarn carrier is reasonablein structural design and high in working stability.

Owner:成都成维精密机械制造有限公司

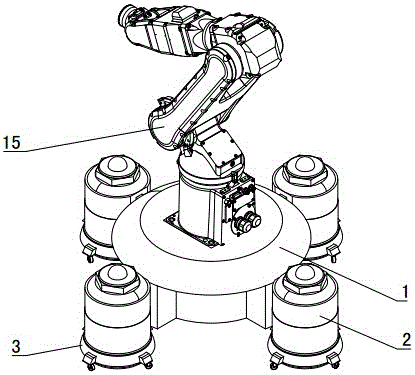

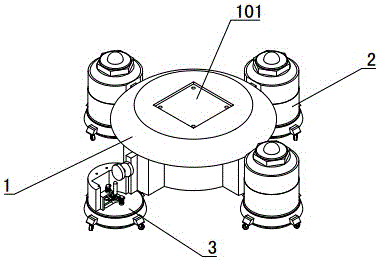

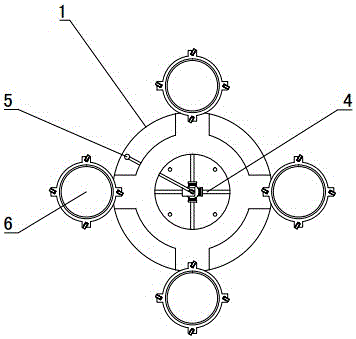

Movable Industrial Robot Fixtures

InactiveCN104908062BMove quicklyGuaranteed working accuracyManipulatorRobot handBiochemical engineering

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

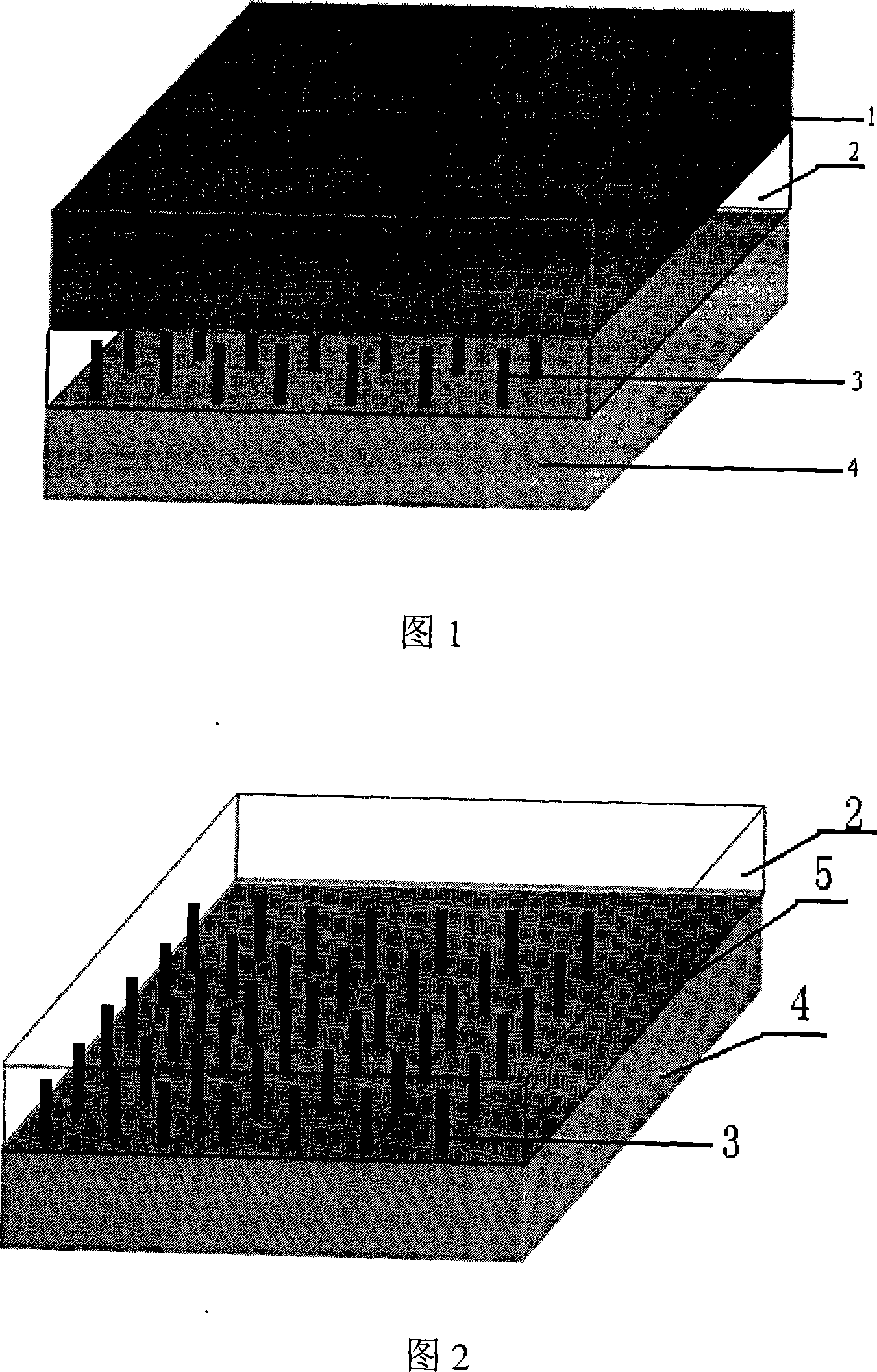

Thermal-barrier coating and method for making same

InactiveCN101200126AImprove shear resistanceEven by forceMetal layered productsYttria-stabilized zirconiaNanometre

A thermal barrier coating and the preparation method of the thermal barrier coating relate to a coating and the preparation of the coating, in which the issues that the relative sliding and falling of the material interface parallel to the direction of the high temperature nickel-based alloy and the vertical cracking of the thermal barrier coating perpendicular to the direction of high temperature nickel-based alloy in high temperature and in the prior art are resolved. The thermal barrier coating is composed of an external ceramic layer (1) and an internal combined layer (5), wherein the internal combined layer (5) is composed of a high temperature nickel-based alloy layer (4) and a bonding layer (2) linked with the external surface of the high temperature nickel-based alloy layer (4). The bonding layer (2) is composed of a nickel nano-wire (3) and yttria stabilized zirconia. According to the preparation, the nickel nano-wire connected to the high temperature nickel-based alloy layer is obtained through the electro-deposition on the outer surface of the high temperature nickel-based alloy layer. And then the sol of yttria stabilized zirconia is sprayed, and the bonding layer (2) is obtained after the calcinations. Afterwards the ceramic layer (1) is prepared on the bonding layer (2), so that the thermal barrier coating is obtained. In the invention, the horizontal and vertical directions of the thermal barrier coating are closely integrated.

Owner:严格集团股份有限公司

Radar mounting structure and vehicle with same

The invention provides a radar mounting structure and a vehicle with the same, the radar mounting structure comprises a protective shell, the protective shell is used for shielding at least part of aradar, the radar is provided with a transmitting surface for transmitting radar waves, the wavelength of the radar waves transmitted by the radar is a, and the protective shell is provided with a transmission part for radar waves generated by the radar to pass through; wherein the thickness of the transmission part is larger than na-0.2 mm and smaller than na + 0.2 mm, and n is a positive integer;the value range of the distance from the transmitting surface to the transmitting part is 10-20 mm; the transmission part comprises a flat plate structure, and the value range of the included angle between the surface, close to the radar, of the flat plate structure and the transmitting surface is 0-30 degrees; or the transmission part comprises an arc-shaped plate structure, and the value rangeof the included angle between the tangent plane at any position of the surface, close to the radar, of the arc-shaped plate structure and the transmitting surface is 0-30 degrees. According to the radar mounting structure, the problem that in the prior art, a radar mounting structure with a protective shell has a large shielding effect on radar waves is solved.

Owner:BEIJING XIAOMA HUIXING TECH CO LTD

Tunnel drainage system dredging equipment and using method thereof

The invention relates to tunnel drainage system dredging equipment, in particular to the tunnel drainage system dredging equipment and a using method thereof. The tunnel drainage system dredging equipment comprises a working end and a control end, wherein exploration, crushing and eliminating are carried out on a crystal bulkhead of a tunnel drainage system; and the control end provides power forthe working end to complete action, sends a motion command to the working end, and monitors the working state of the working end. Compared with the prior art, the tunnel drainage system dredging equipment has the beneficial effects that in the process of e tunnel drainage system dredging, exploration can be carried out on the crystal bulkhead, the dredging effect is monitored, the working precision is ensured, the working efficiency is improved, and the working effect is improved; and the working end of the dredging equipment can walk along the wall of the tunnel drainage system, the adaptability of a complex structural mode of the tunnel drainage system is higher, and the requirement of greater dredging depth of the tunnel drainage system can be met.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

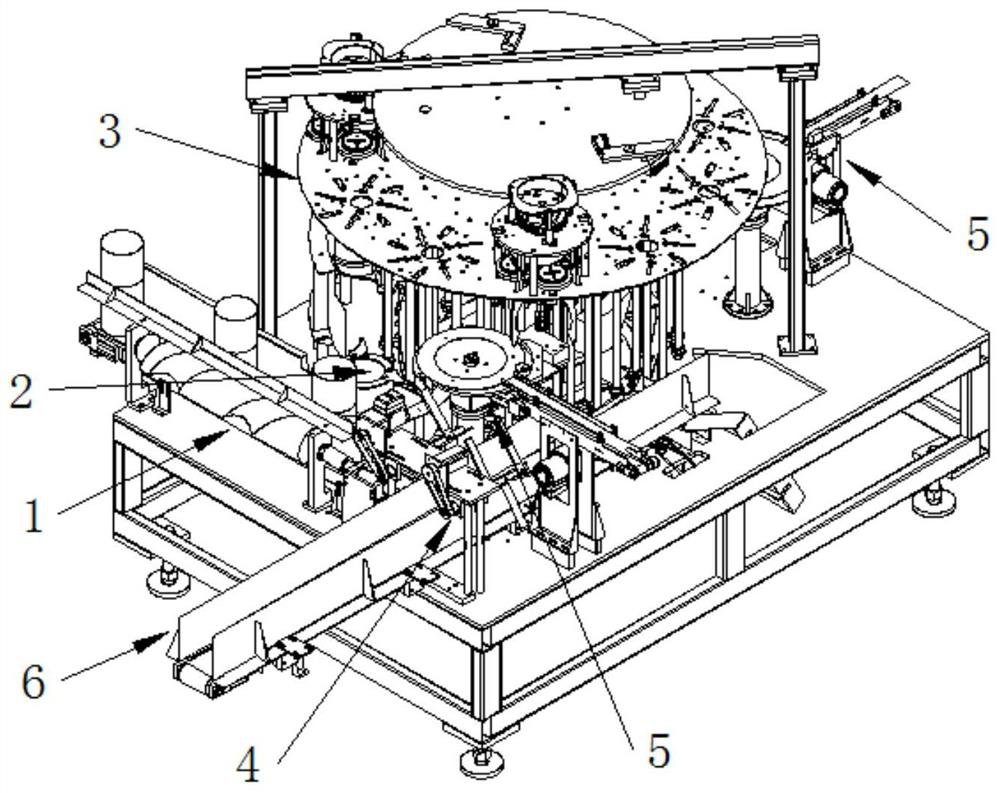

Fungus bag lantern ring capping machine

PendingCN112537475ARealize fully automatic ring cappingImprove stabilityPackagingCultivating equipmentsEngineeringLantern

The invention relates to a fungus bag lantern ring capping machine. The fungus bag lantern ring capping machine comprises a feeding device, a fungus bag sealing disc, a bag opening arranging device, supplying devices and a discharging device which are arranged on a workbench; one supplying device, the feeding device, the bag opening arranging device, the other supplying device and the dischargingdevice are sequentially fixed to the workbench in the rotating direction of the fungus bag sealing disc; a power shaft device is arranged on the workbench; the power shaft device is in transmission connection with the fungus bag sealing disc and drives the fungus bag sealing disc to rotate around the rotation center of the fungus bag sealing disc; the fungus bag sealing disc comprises a rack and aplurality of lantern ring capping assemblies; and each lantern ring capping assembly sequentially comprises a bag opening tightening claw, a capping claw, a lantern ring claw and a bag holding claw from top to bottom, wherein the bag opening tightening claw, the capping claw, the lantern ring claw and the bag holding claw are arranged on the rack. The fungus bag lantern ring capping machine can adapt to the production frequency of high-speed operation, can carry out full-automatic ring sleeving, cap covering and necking, and can achieve the purpose of full-automatic cap covering.

Owner:FUJIAN HAIYUAN THREE DIMENSIONAL PRINTING HIGH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com