Wall surface putty treatment robot

A robot and putty technology, applied in construction, building construction, etc., can solve the problems of high operation cost, inability to guarantee the overall operation accuracy, inconvenient use, etc., and achieve the effect of ensuring operation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

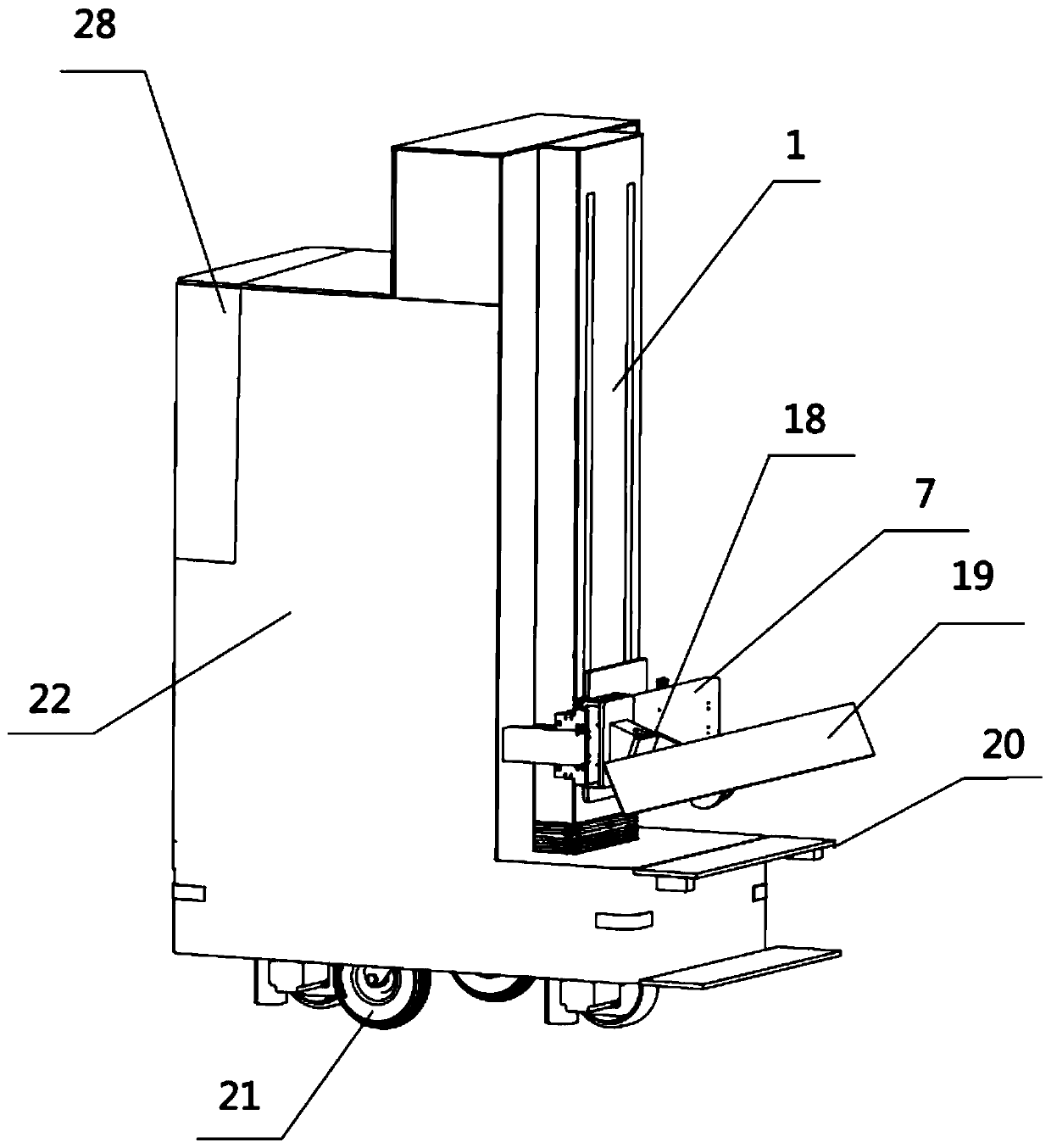

[0090] Such as figure 1 As shown, a large scraper 19 is installed on the clamp bar 10 to become a large putty scraper robot. The putty large scraper robot can complete the finishing work after putty coating, and complete the flatness scraping operation of the entire wall through the lifting mechanism 1 .

[0091] It works as follows:

[0092] (1) First, assemble the large scraper 19 to the clamp rod 10, and adjust the clamp rod 10 to a suitable position by twisting the assembly 9 to position it;

[0093] (2) Move to the wall to be operated by the steering wheel 21, and complete the operation accuracy calibration by the accuracy correction device 20;

[0094] (3) The large scraper 19 completes the leveling operation from the lower end to the upper end of the wall under the cooperation of the lifting mechanism 1;

[0095] (4) After the operation is completed, the connecting mechanism 18 is driven by the translation mechanism 7 to drive the large scraper 19 to move horizontall...

Embodiment 2

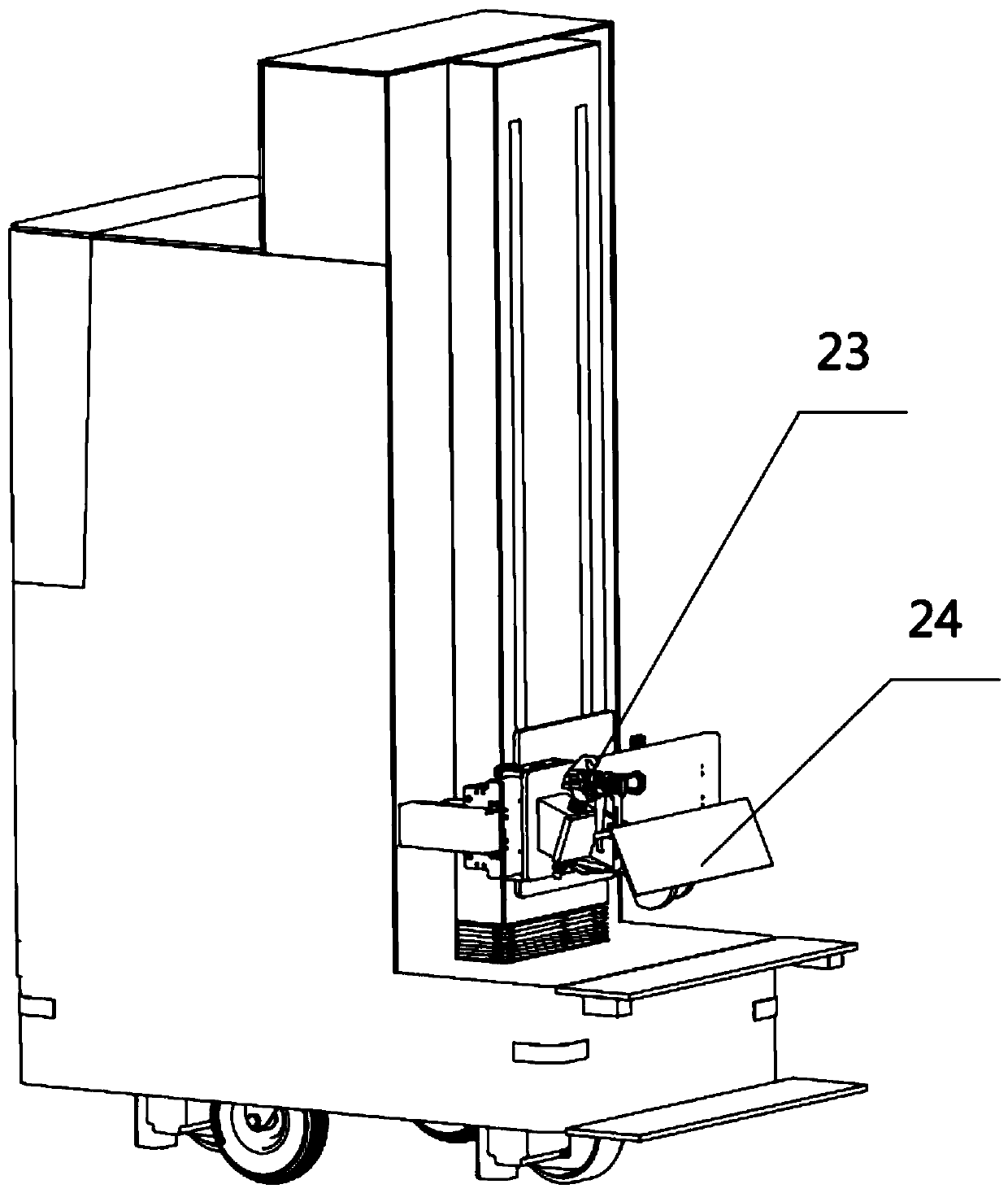

[0098] Such as figure 2 As shown, the putty spraying equipment 23 is equipped at the installation interface 8, and a small scraper 24 is installed on the clamp bar 10 to become a putty spraying robot. The putty spraying and scraping robot is mainly used on the initial concrete wall surface. The fine putty can complete the viscous pavement of the wall surface, and the small scraper 24 can complete the hole filling operation along with the scraping.

[0099] It works as follows:

[0100] (1) First install the putty spraying equipment 23 on the installation interface 8, assemble the small scraper 24 on the clamp rod 10, adjust the clamp rod 10 to a suitable position by twisting the assembly 9 and then position it;

[0101] (2) Move to the working wall surface through the steering wheel 21, and complete the working precision calibration through the precision correction device 20;

[0102] (3) The putty spraying equipment 23 carries out the putty spraying operation from low to h...

Embodiment 3

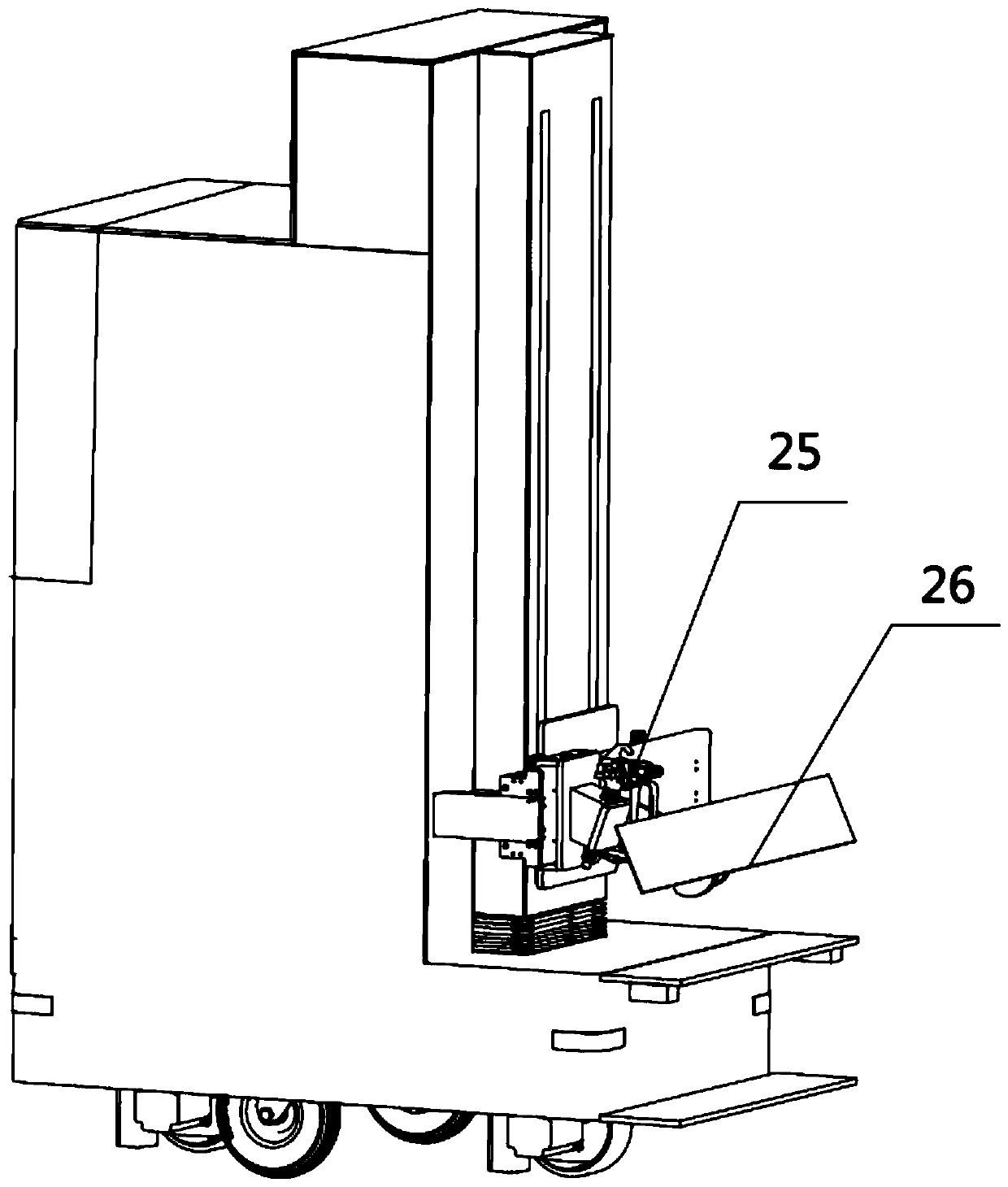

[0106] Since there will be a small amount of pits that cannot be processed after the robot sprays the putty operation, and subsequent hole filling operations are required for partial repair, the installation interface 8 can be equipped with a putty block coating device 25, and a small scraper 26 can be installed on the clamp rod 10 to become Putty spraying robot (such as image 3 shown). The putty block coating device 25 can use a mechanical device capable of spraying the putty in a block form, preferably a putty spraying device with a diffuser disassembled.

[0107] It works as follows:

[0108] (1) First install the putty block coating equipment 25 on the installation interface 8, assemble the small scraper 26 to the clamp rod 10, adjust the clamp rod 10 to a suitable position by twisting the assembly 9 and then position it;

[0109] (2) Move to the working wall surface through the steering wheel 21, and complete the working precision calibration through the precision corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com