Novel divider

A splitter, a new type of technology, applied in the field of machinery, can solve problems such as high cost, easy installation errors, and affecting processing effects, and achieve the effects of high applicability, low cost, and guaranteed work efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

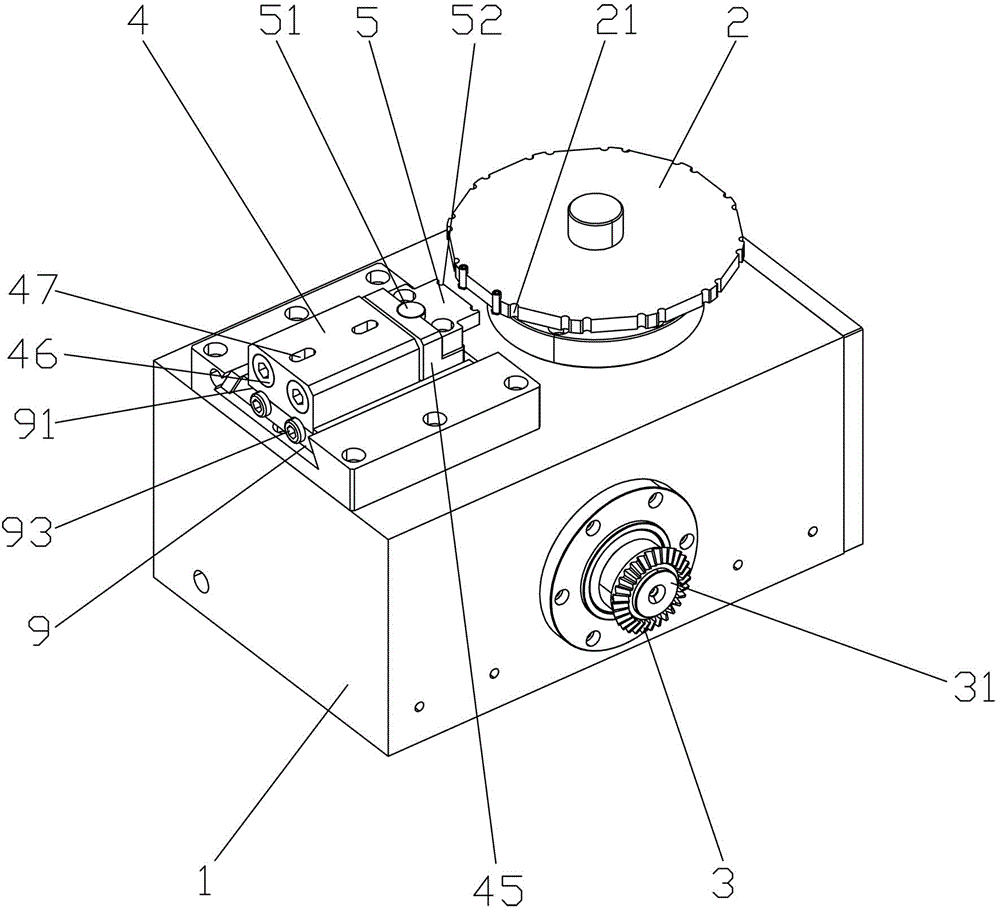

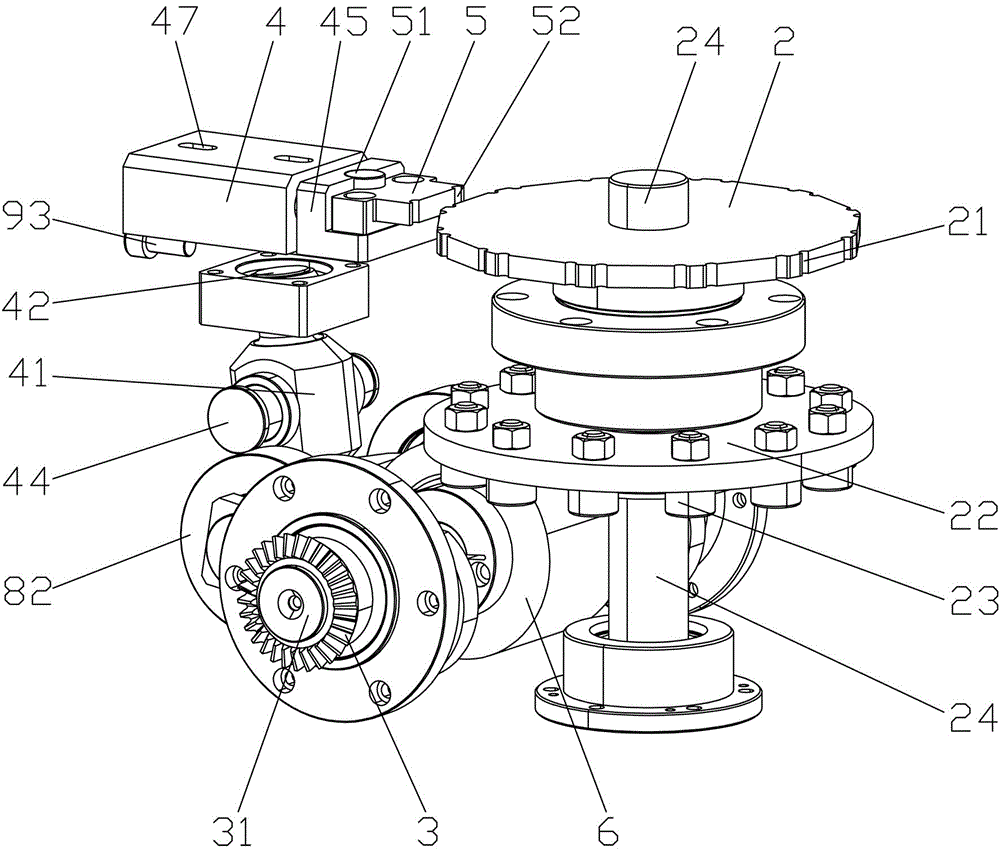

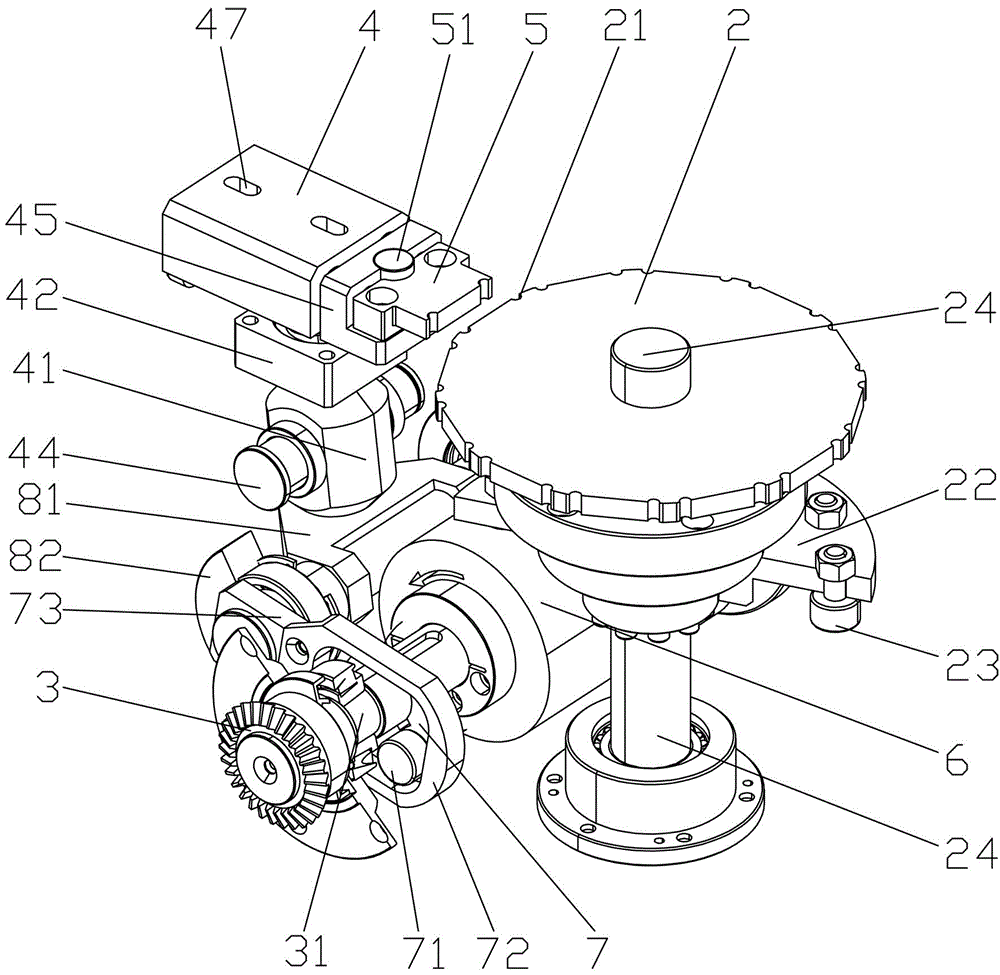

[0018] refer to figure 1 , figure 2 , image 3 , Figure 4 , a new type of divider, including a base 1, a turntable 2 on the base 1, and a power input end 3. Stations 21 are distributed on the outer edge of the turntable 2. Generally, a station 21 corresponds to a component to be processed. The rear of the turntable 2 is provided with a push block 4 that can be retracted forward and backward, and the end of the push block 4 facing the turntable 2 is provided with a clamp block 5, and the station 21 of the turntable 2 needs to cooperate with the clamp block 5 to clamp the parts to be processed . The base 1 is also provided with a drive main shaft 31 connected to the power input end 3. The power input end 3 is used as the power input source of the entire divider and is generally connected to a motor. The power input end 3 can be a gear or a Connecting rod structure or other elements that can realize transmission. In this application, only one power input end 3 is needed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com