Patents

Literature

60results about How to "With fine-tuning function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

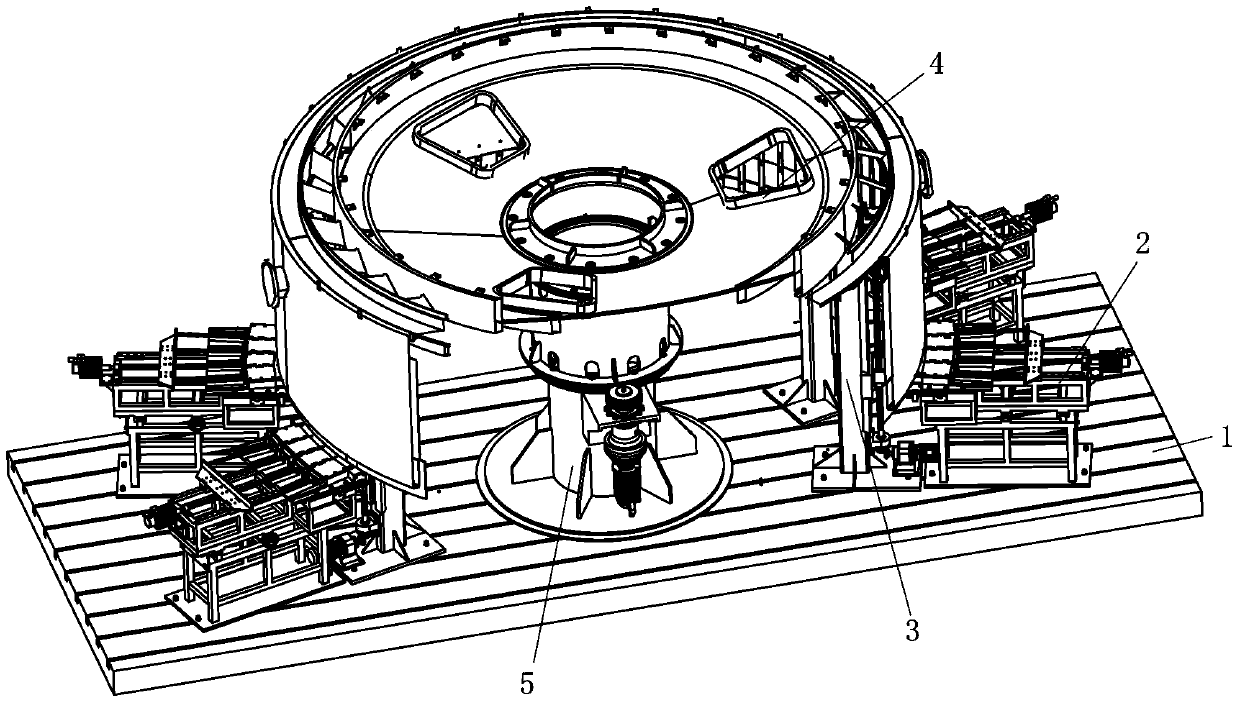

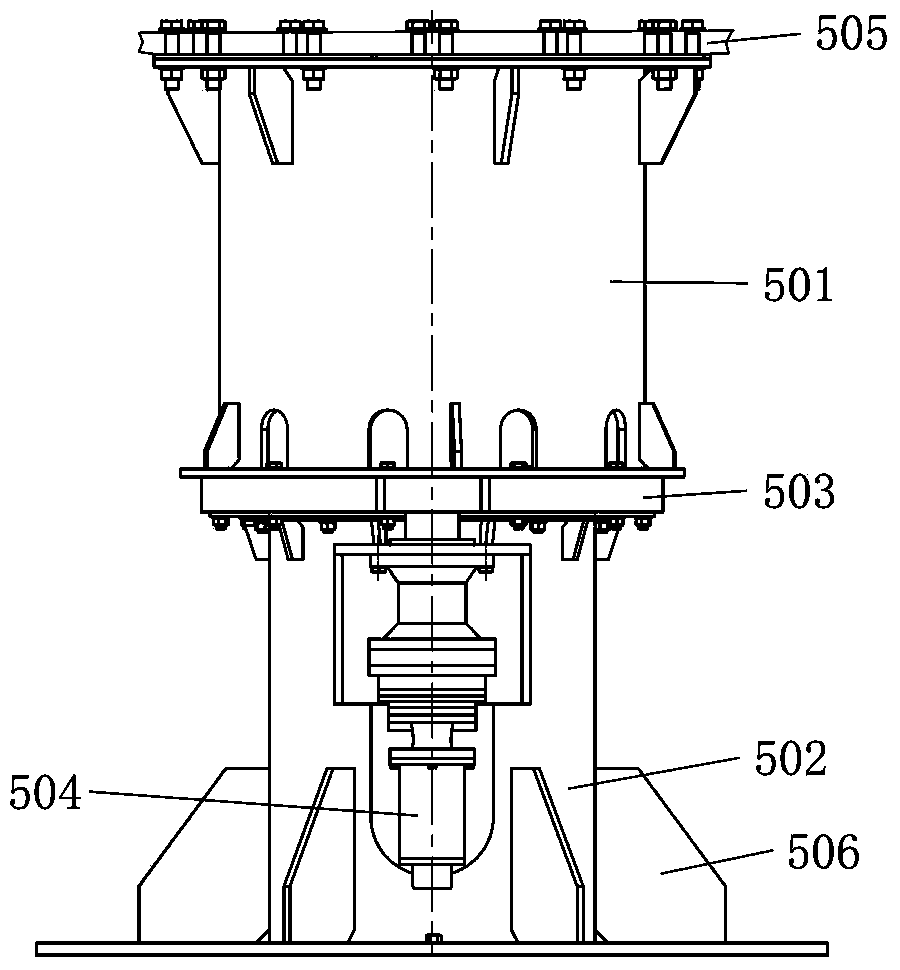

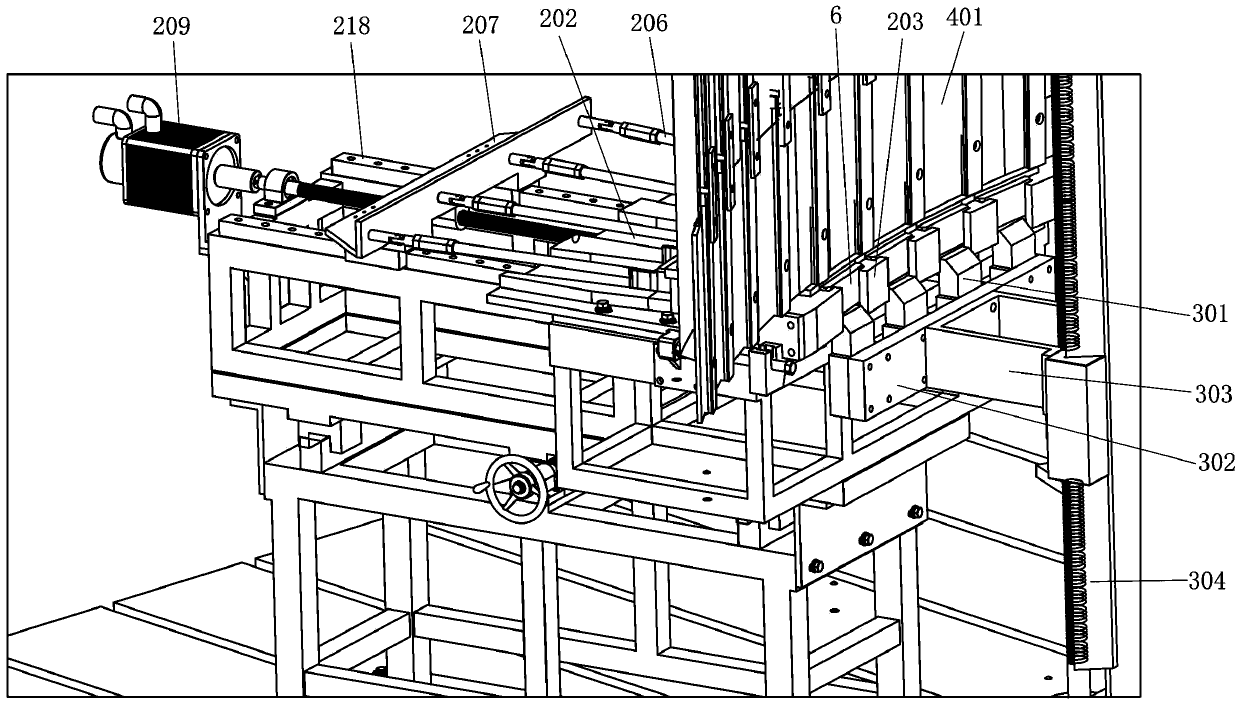

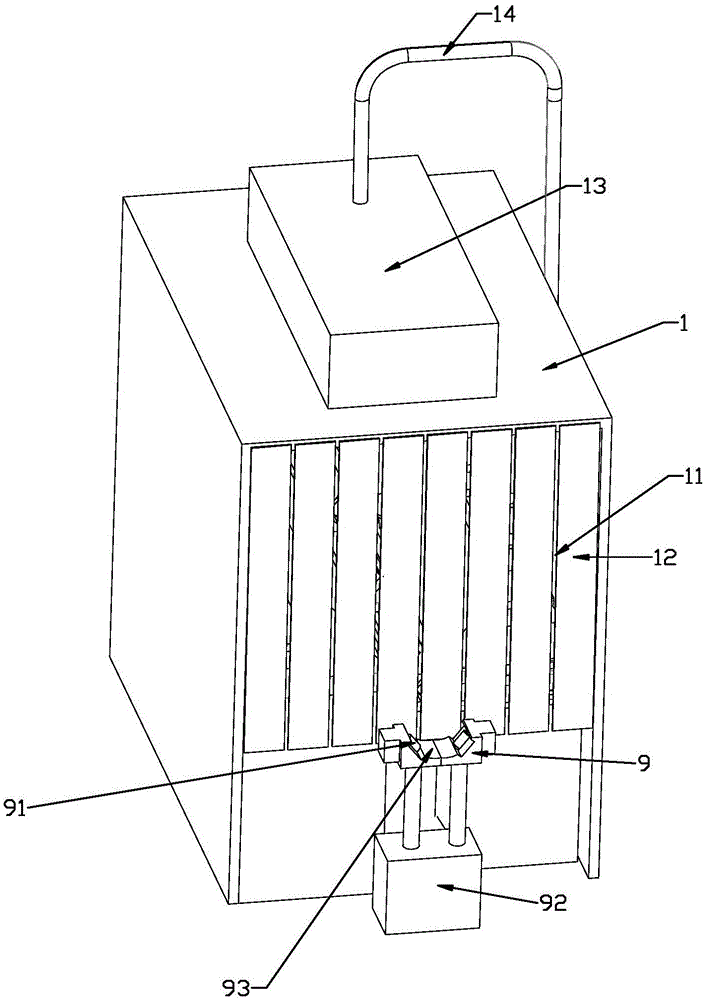

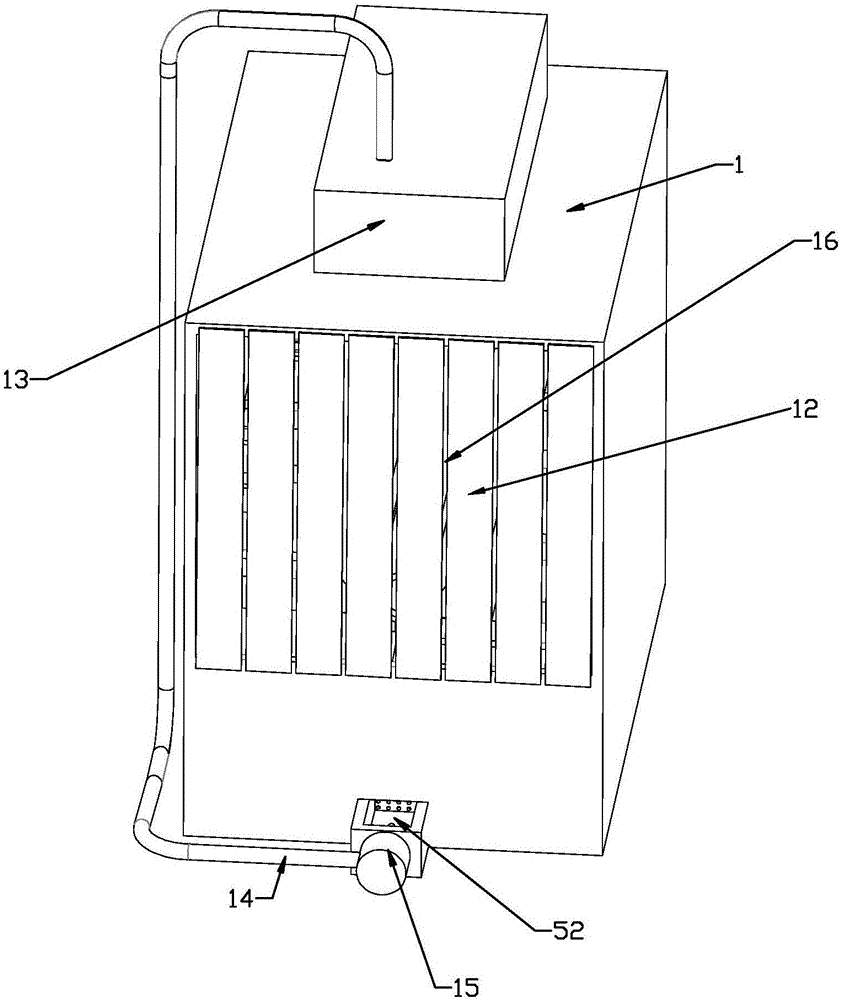

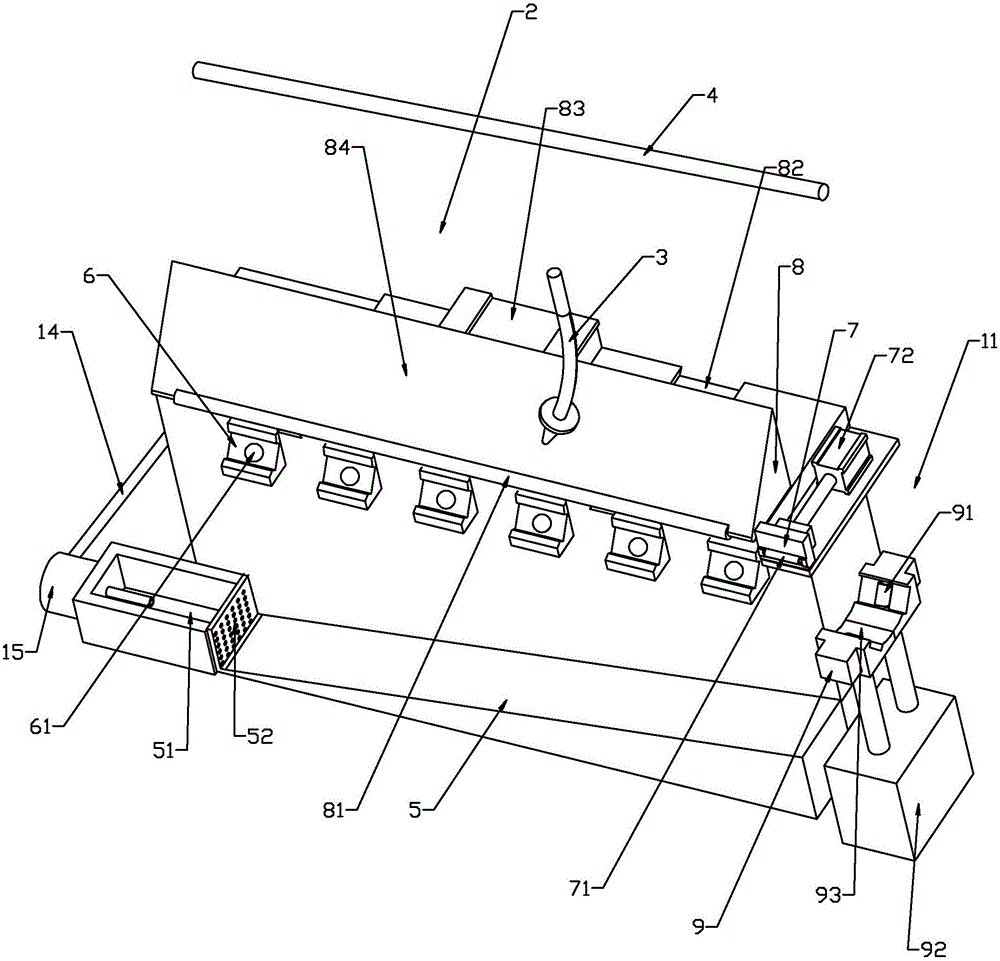

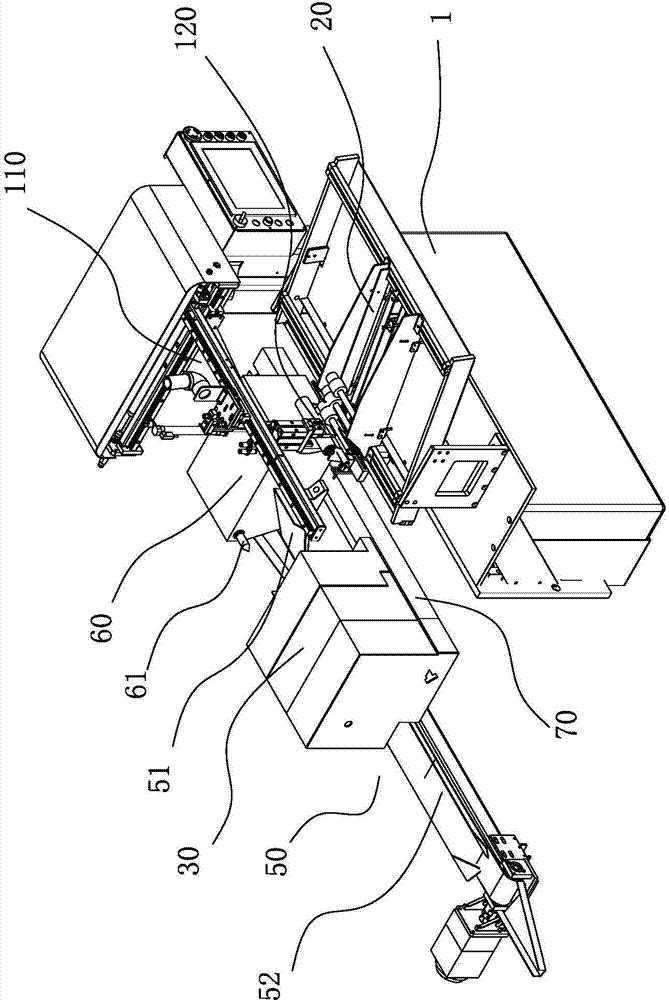

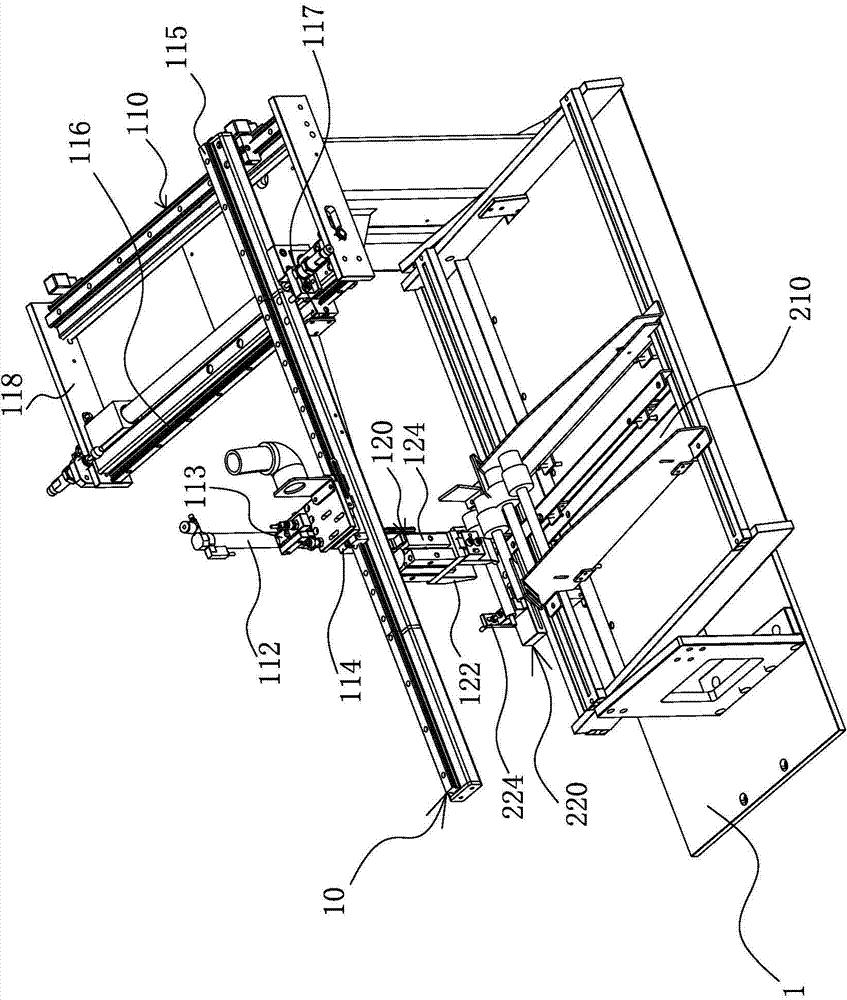

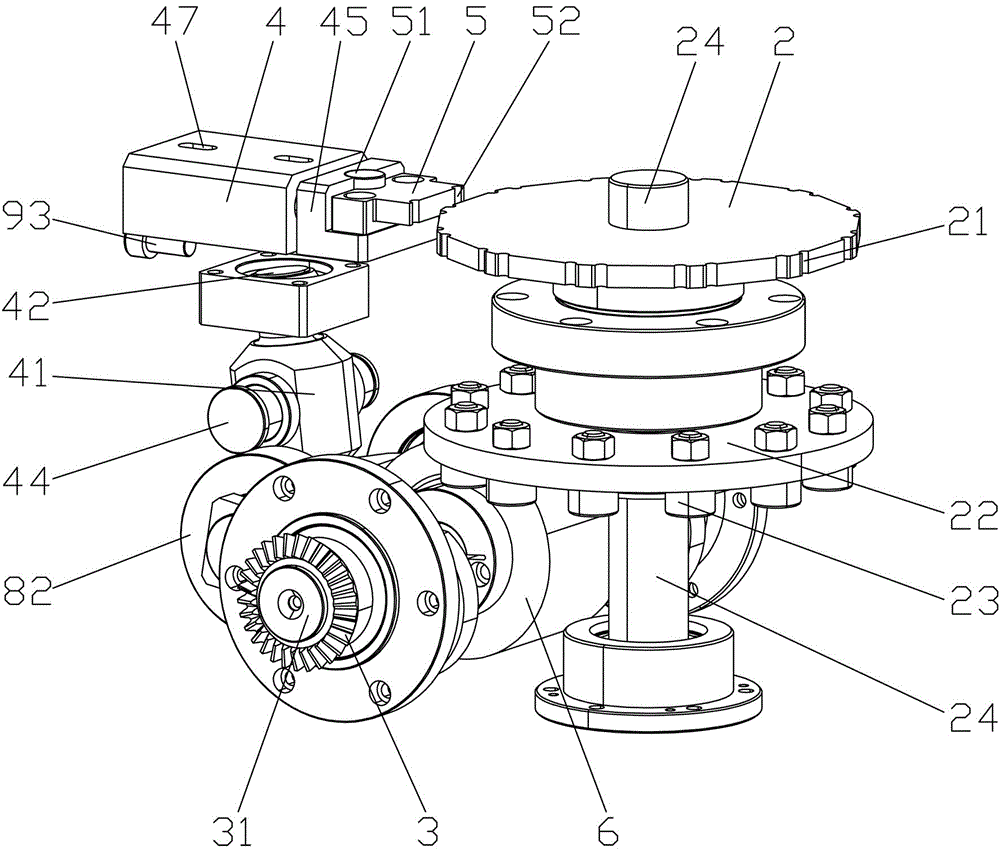

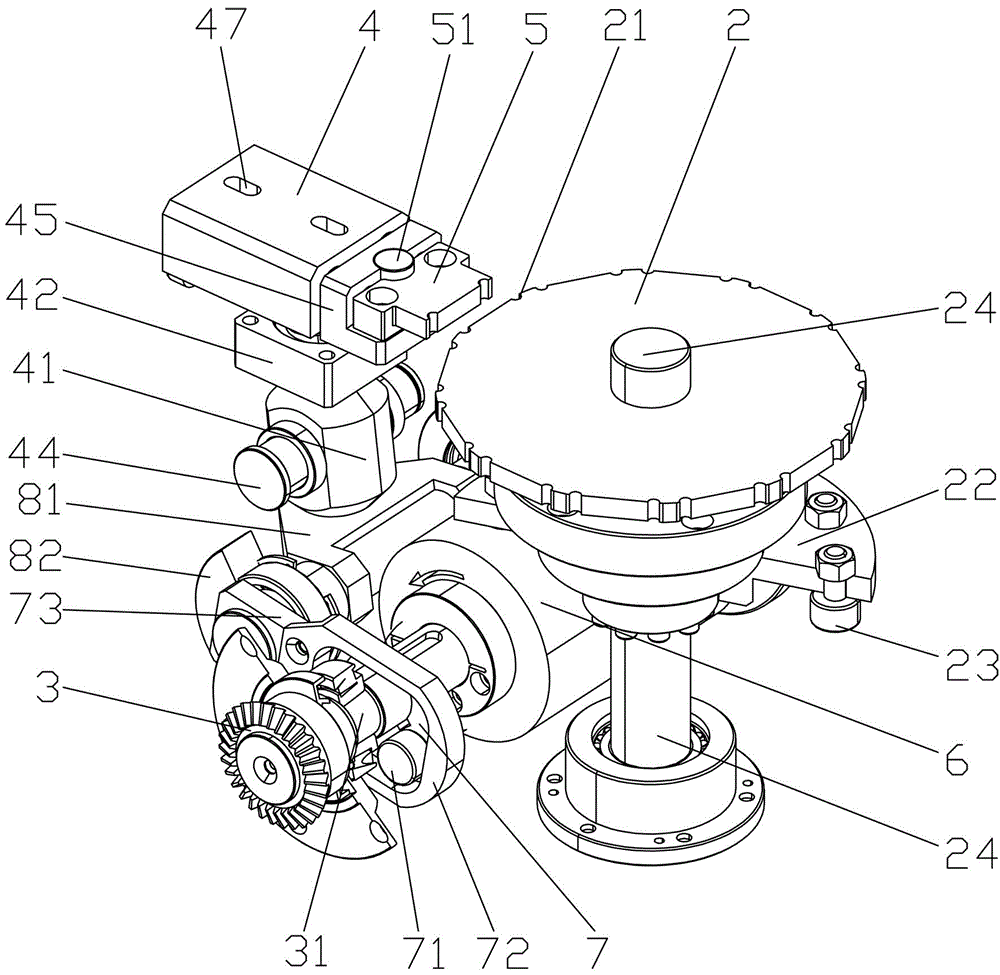

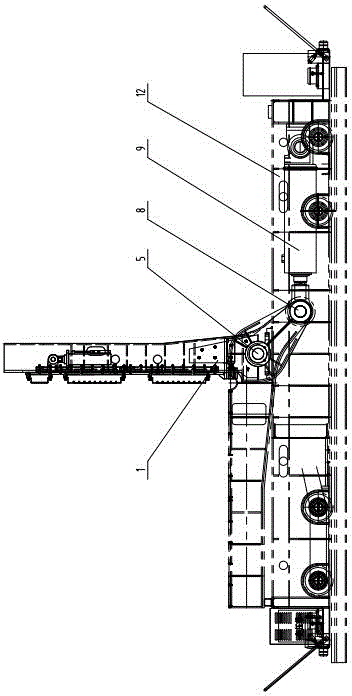

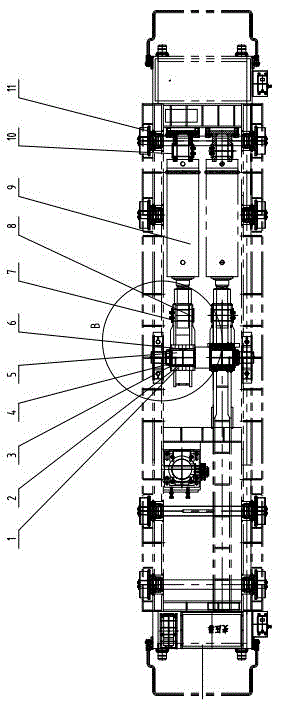

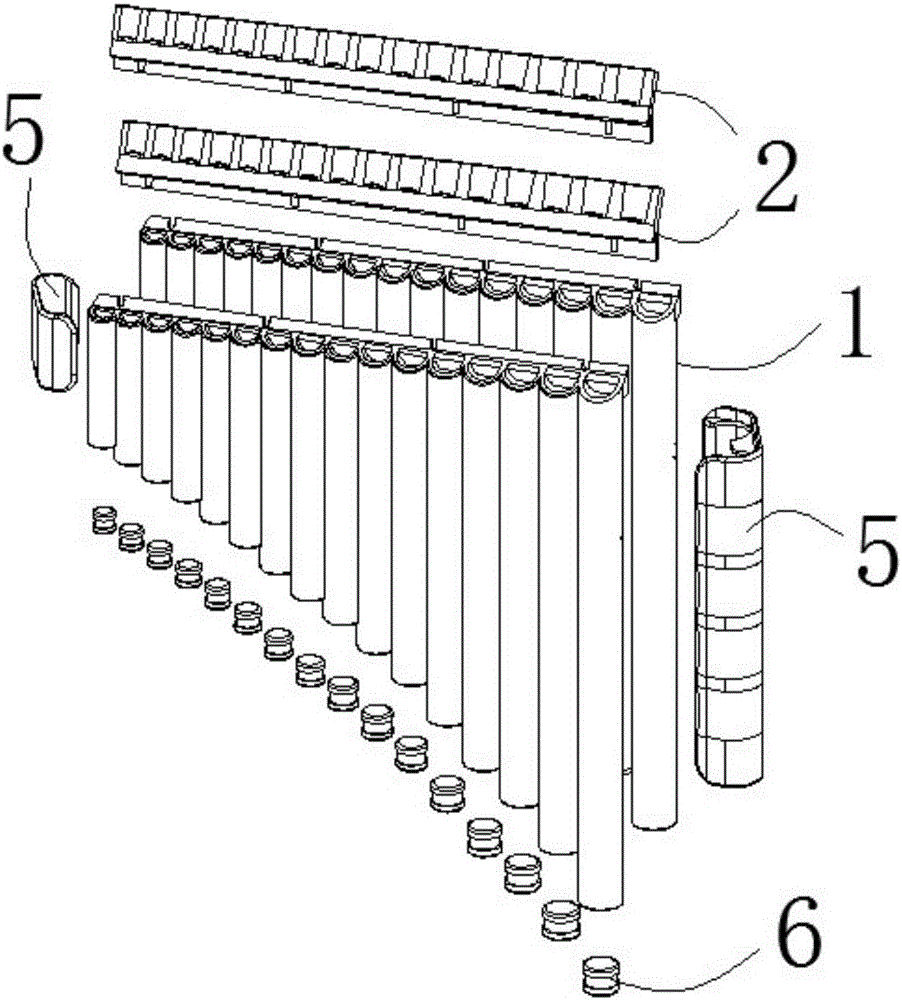

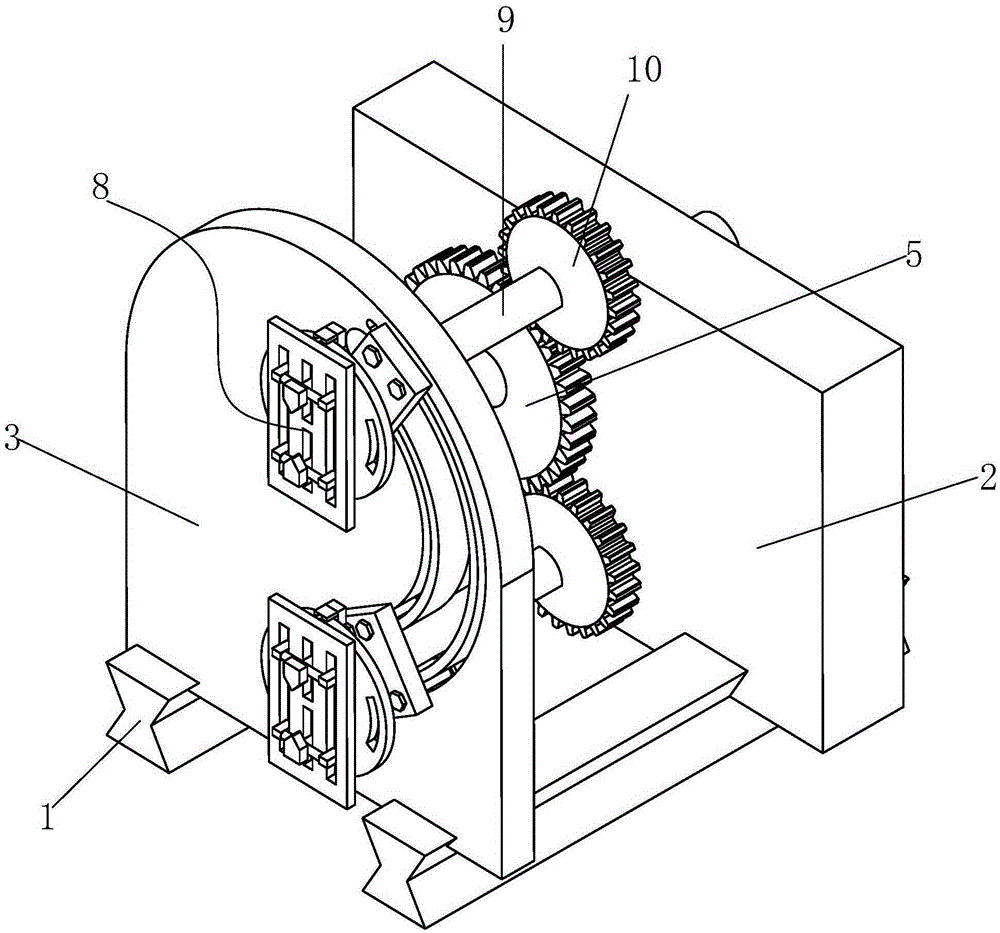

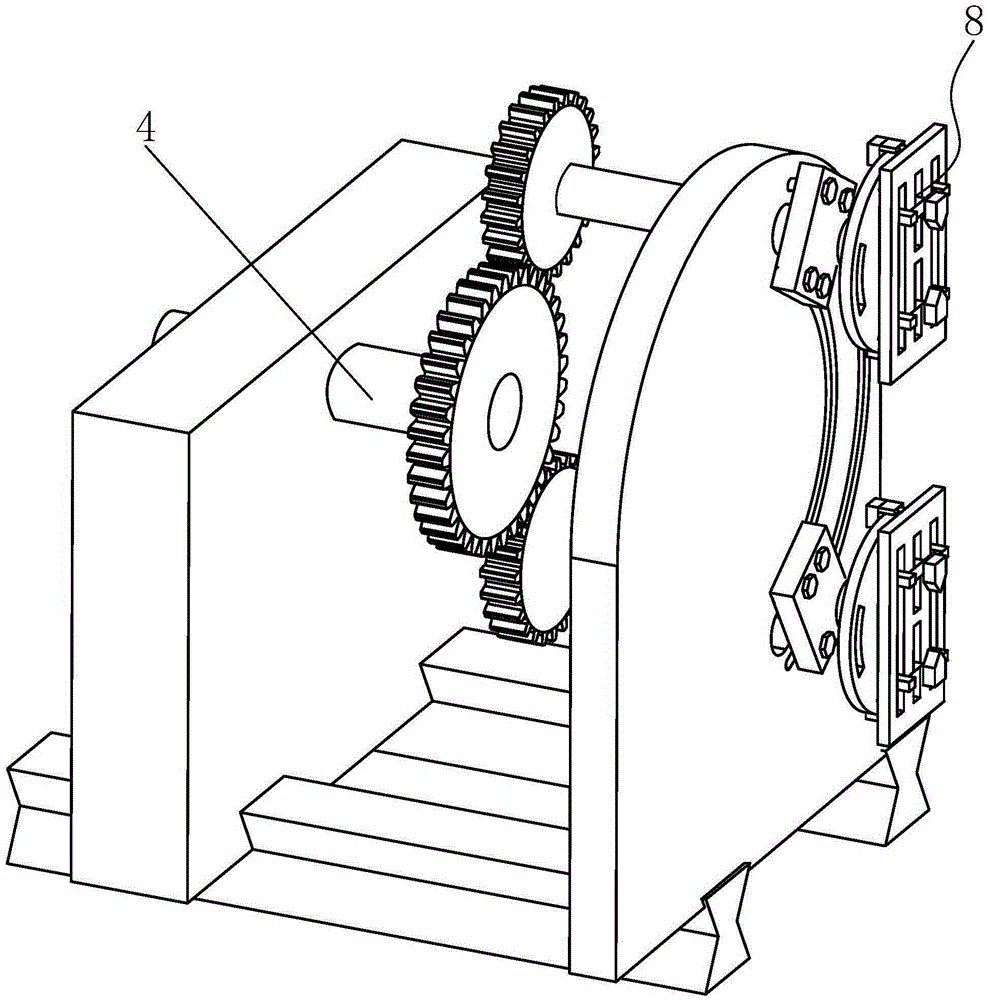

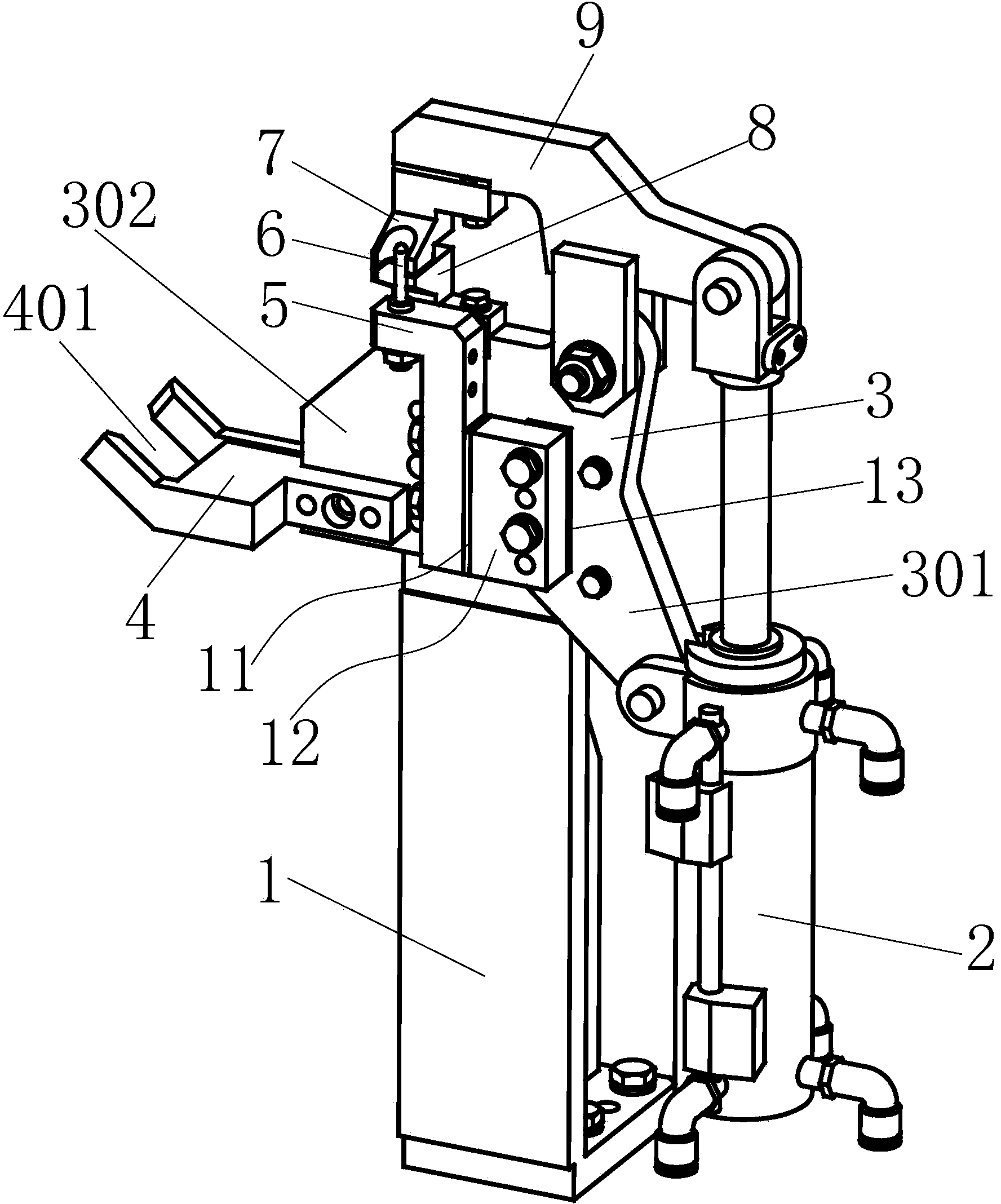

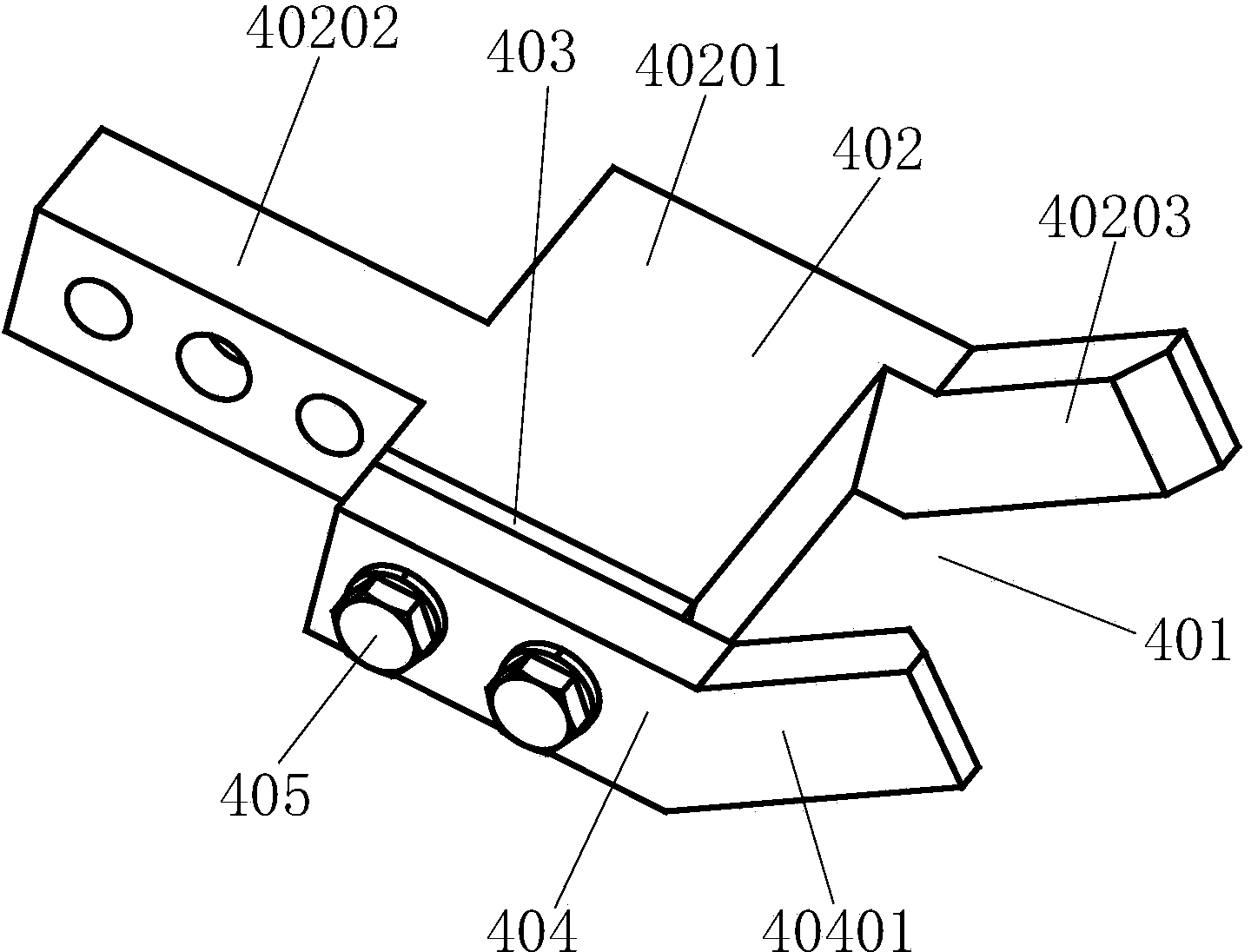

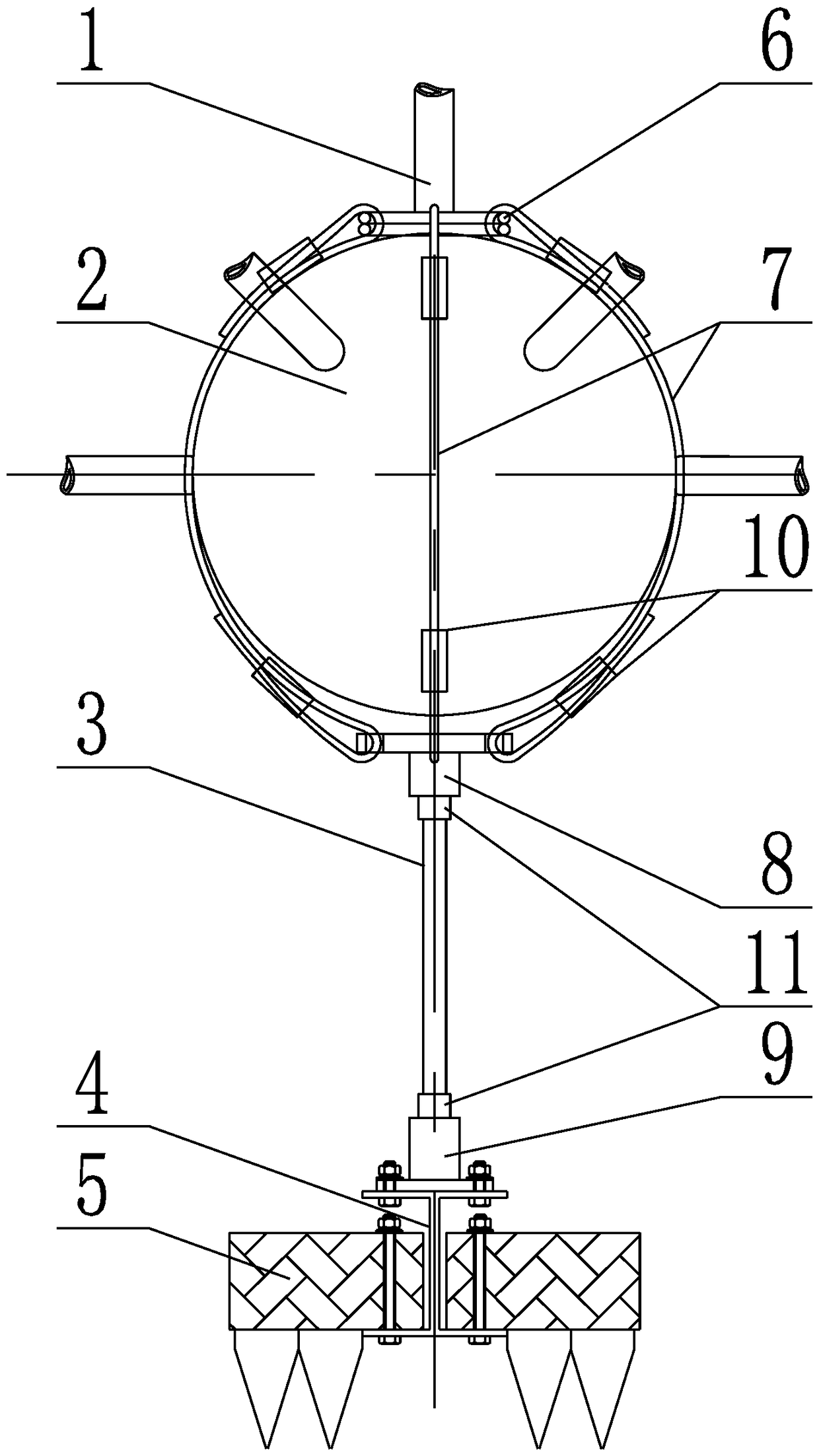

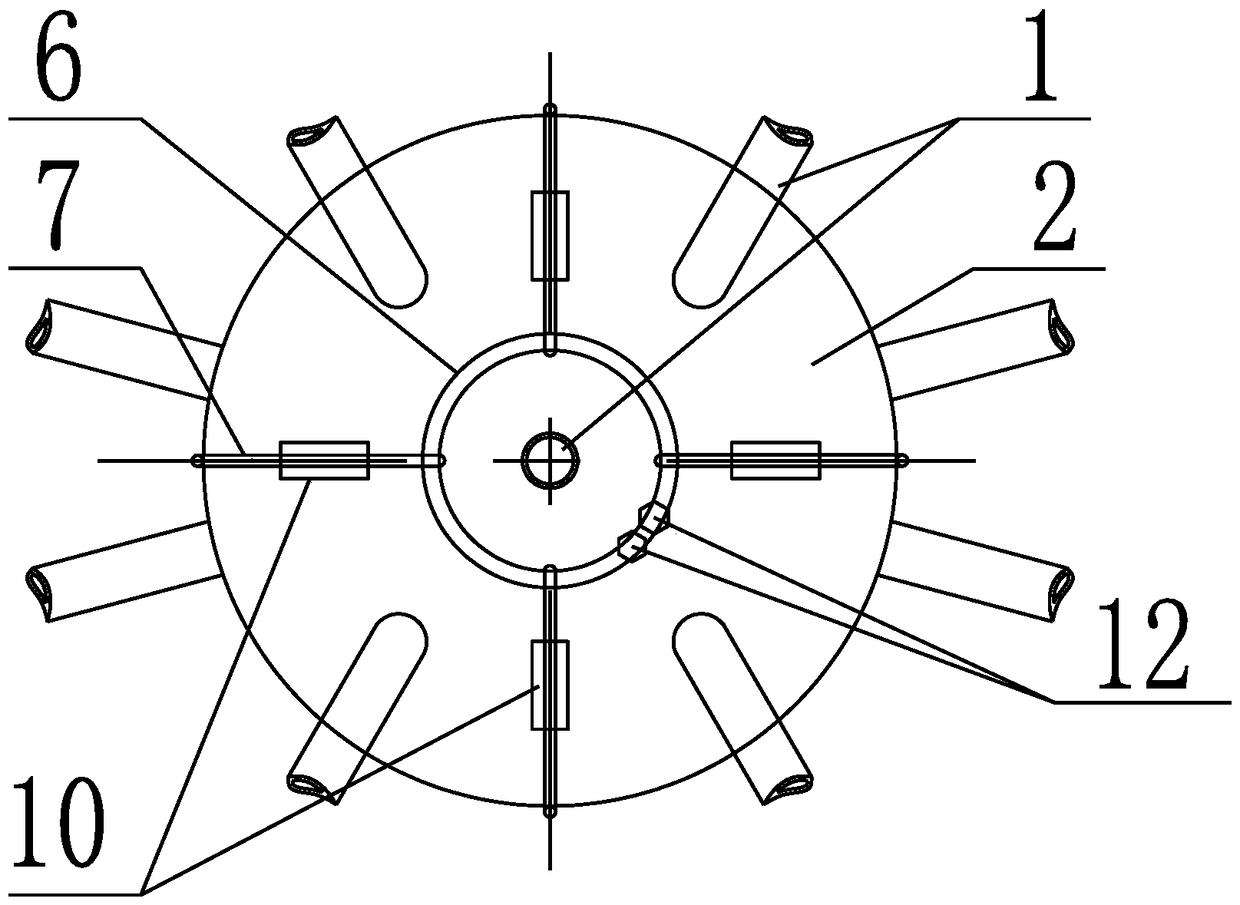

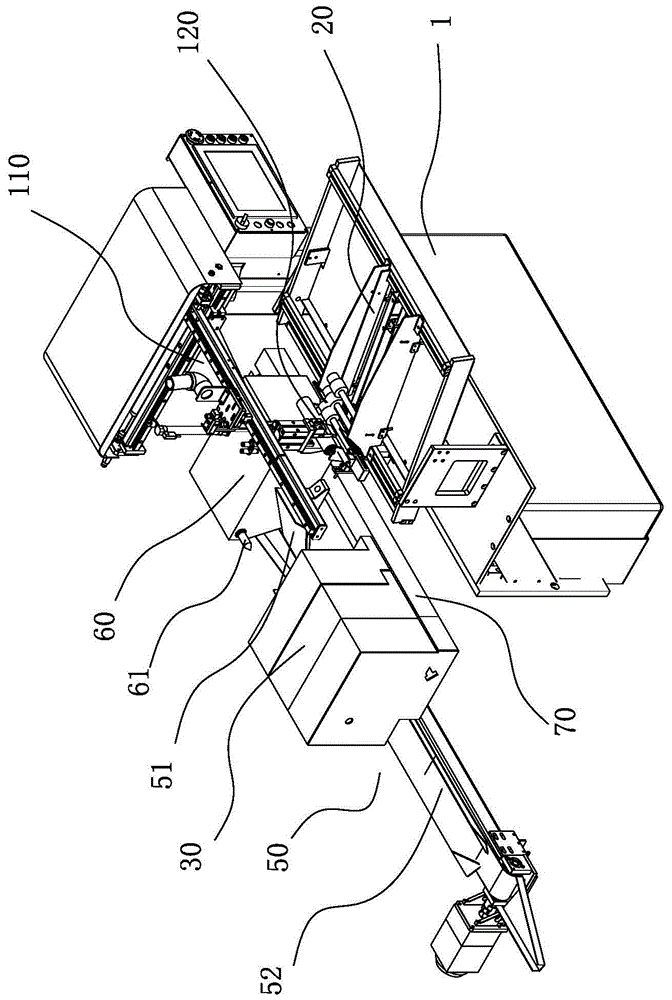

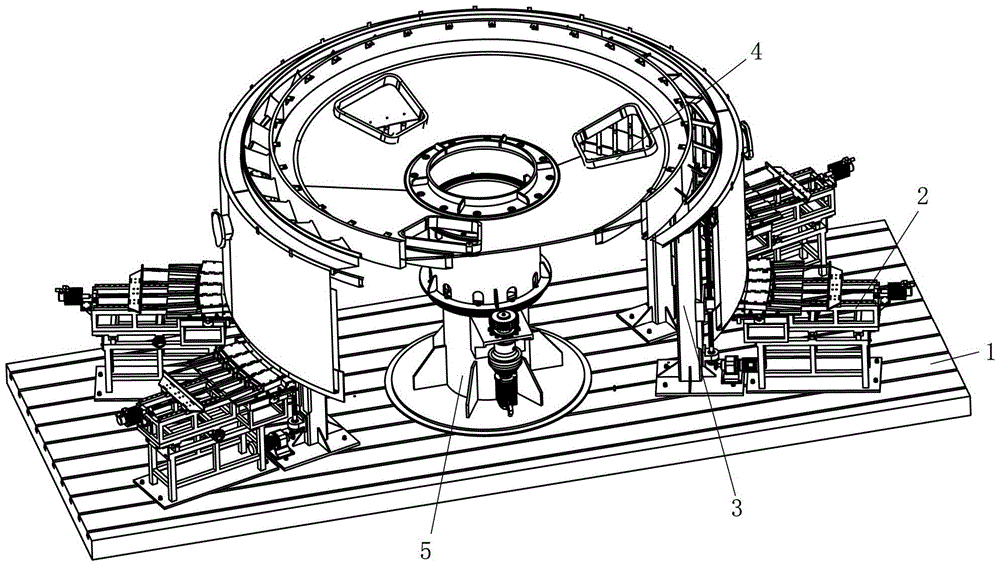

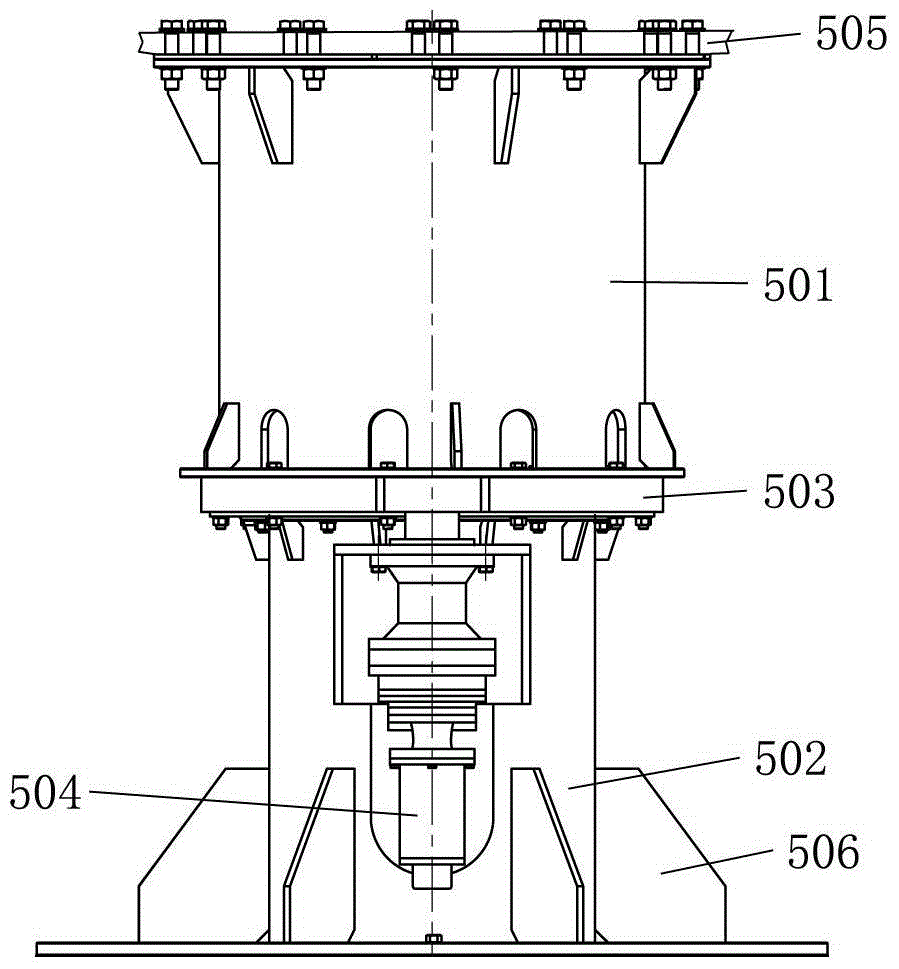

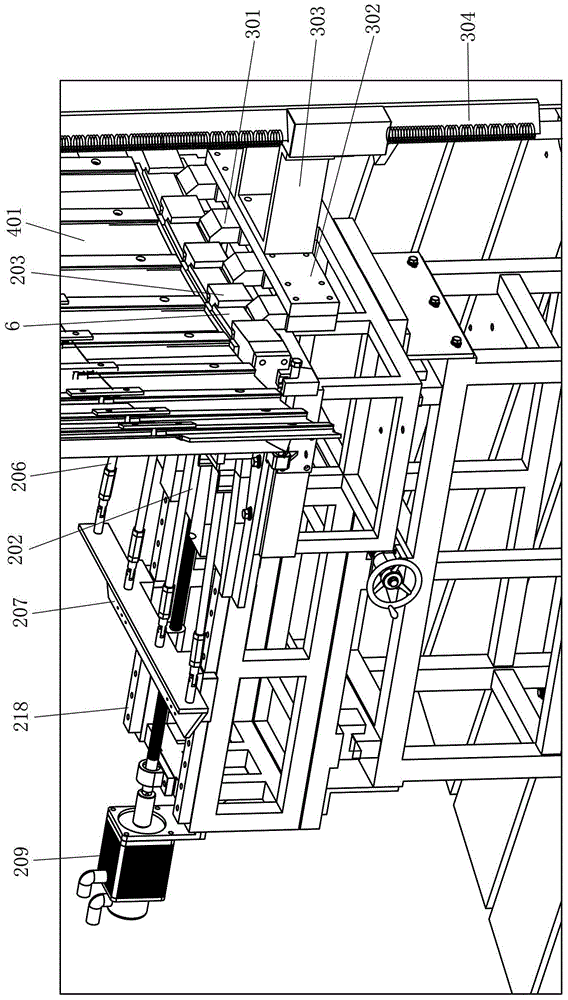

Automated magnet assembling device for wind power generator set

ActiveCN103633792AAutomateImprove assembly efficiencyManufacturing stator/rotor bodiesMagnetEngineering

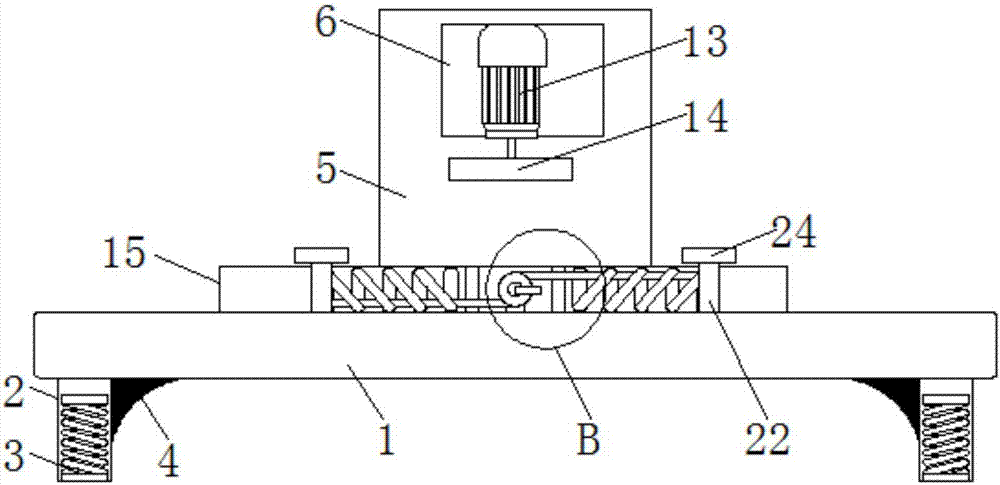

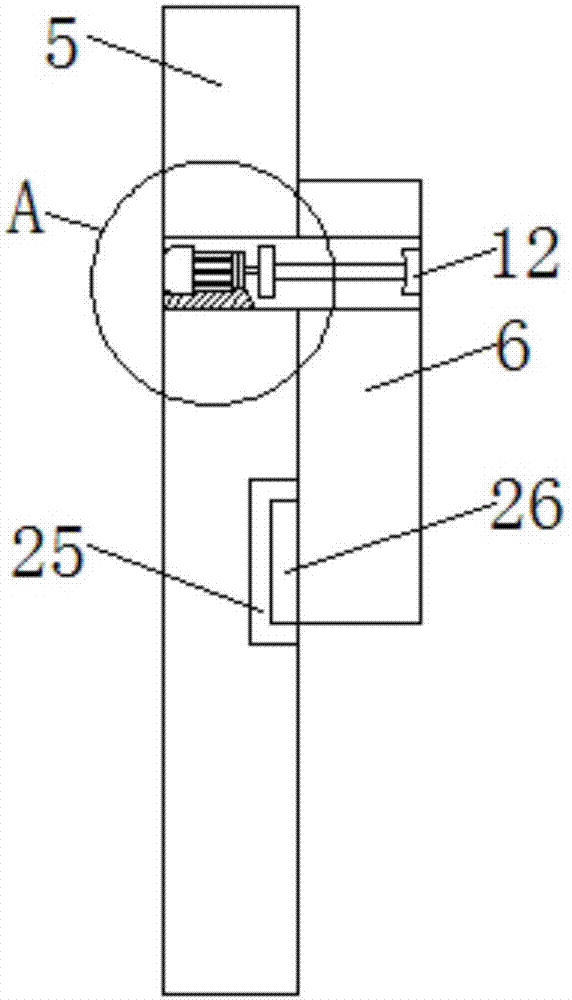

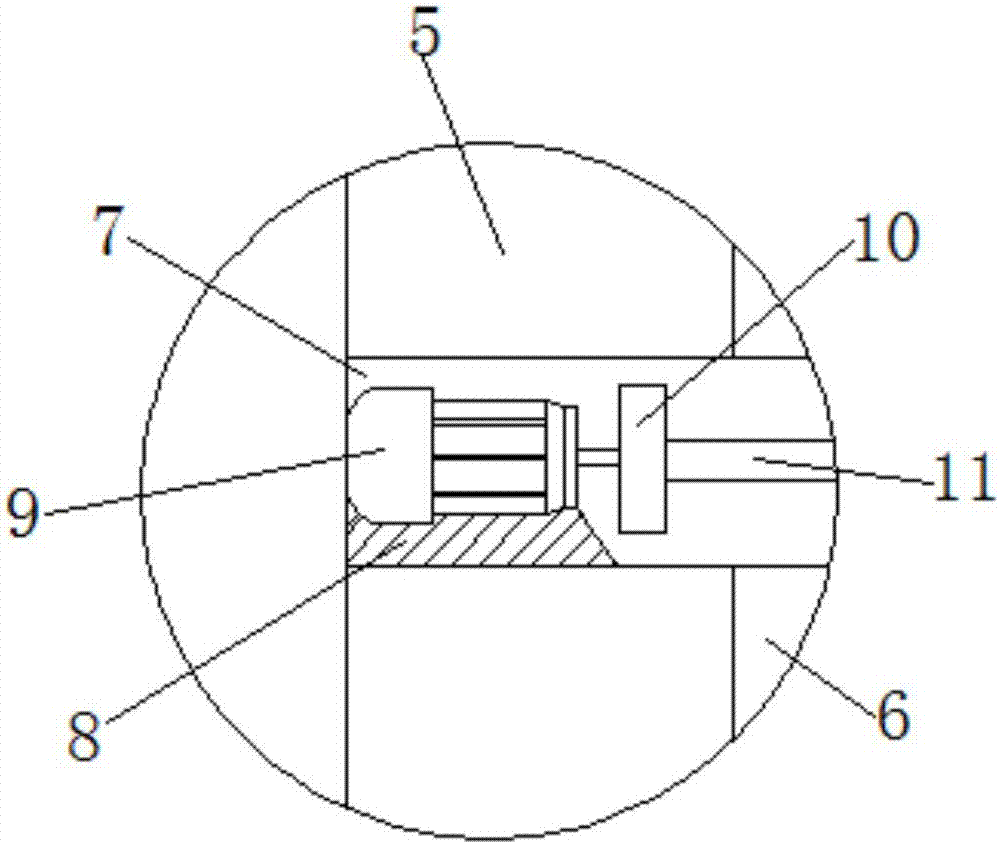

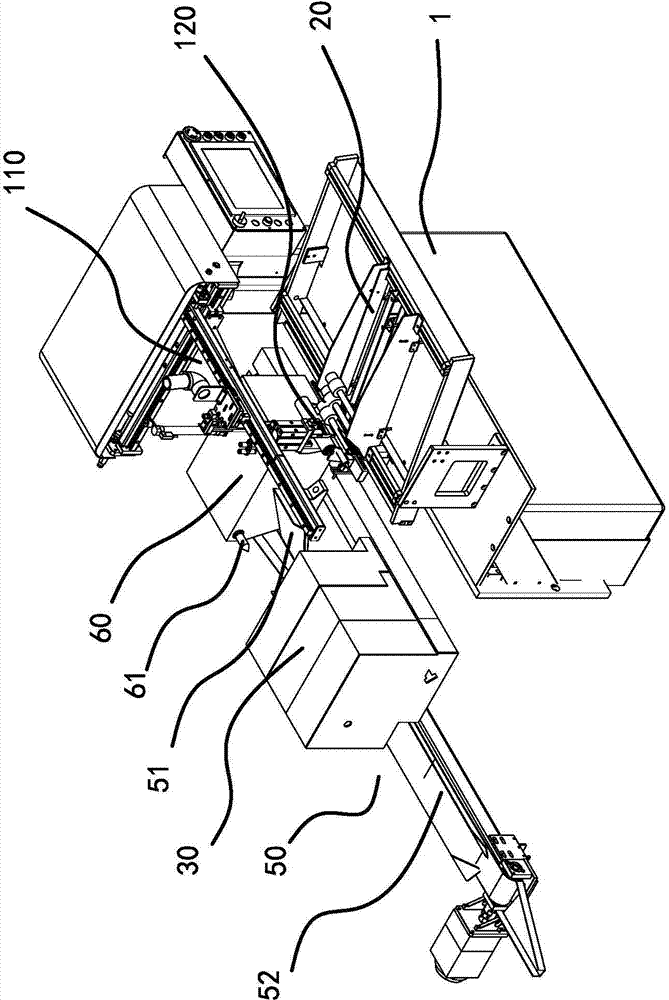

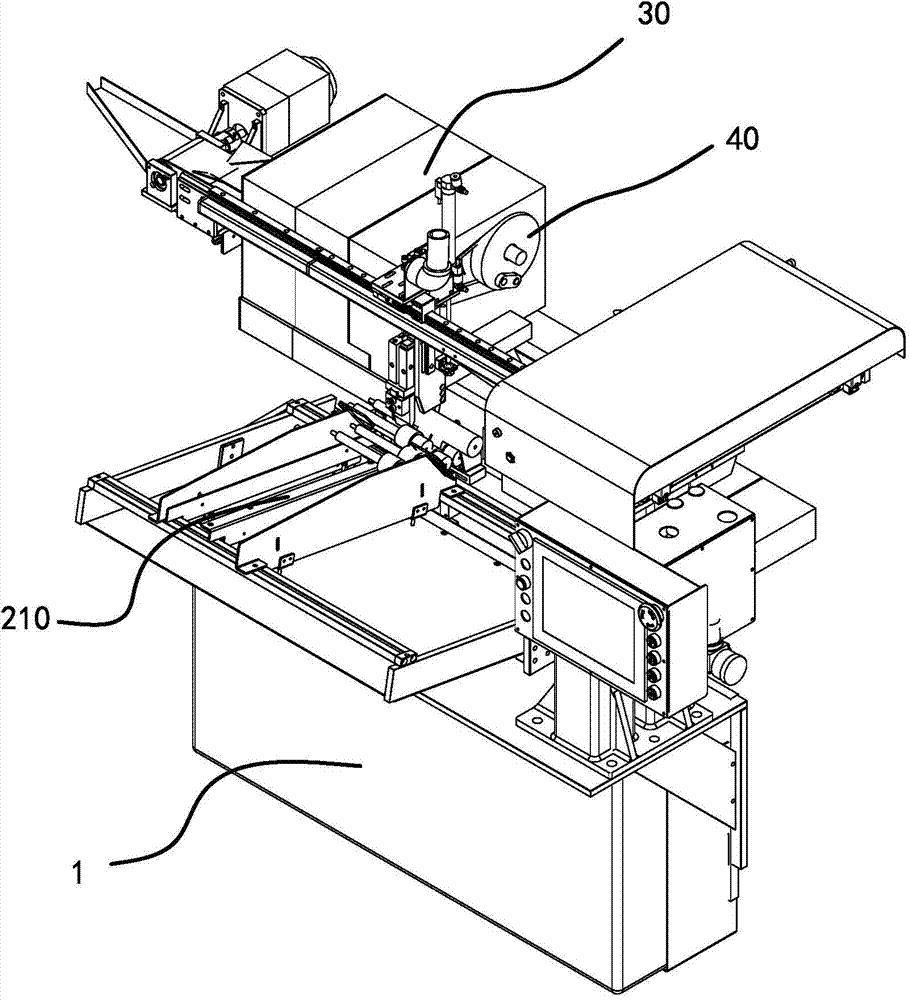

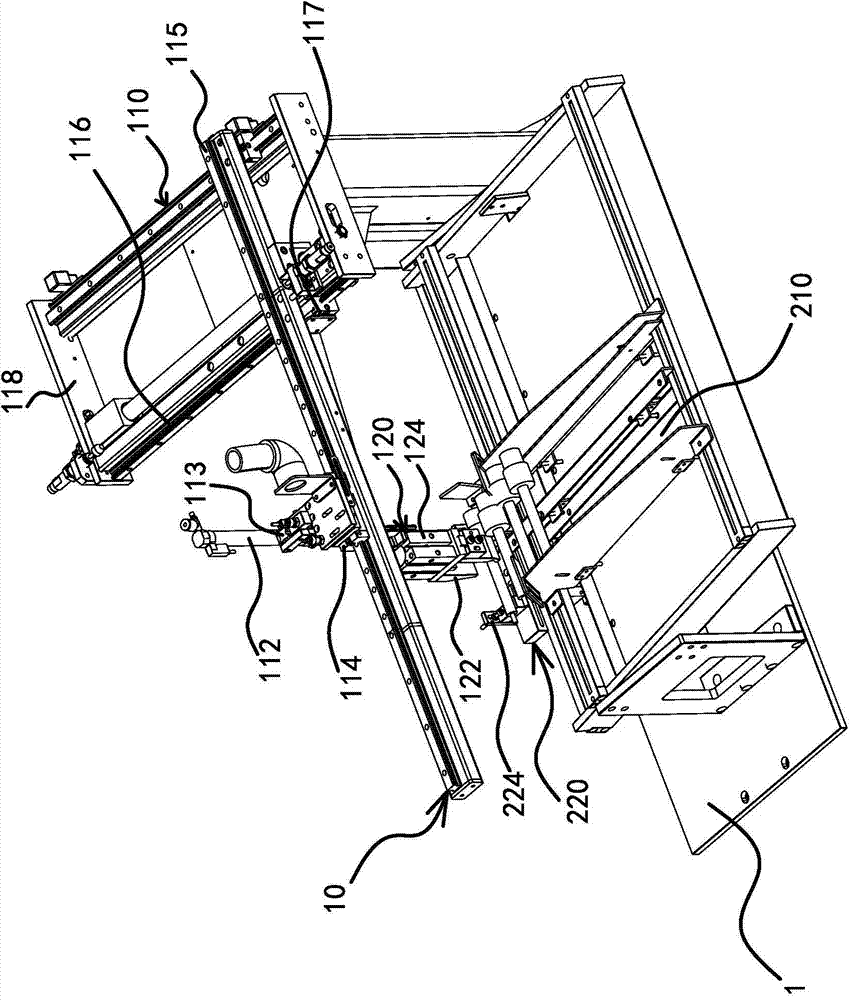

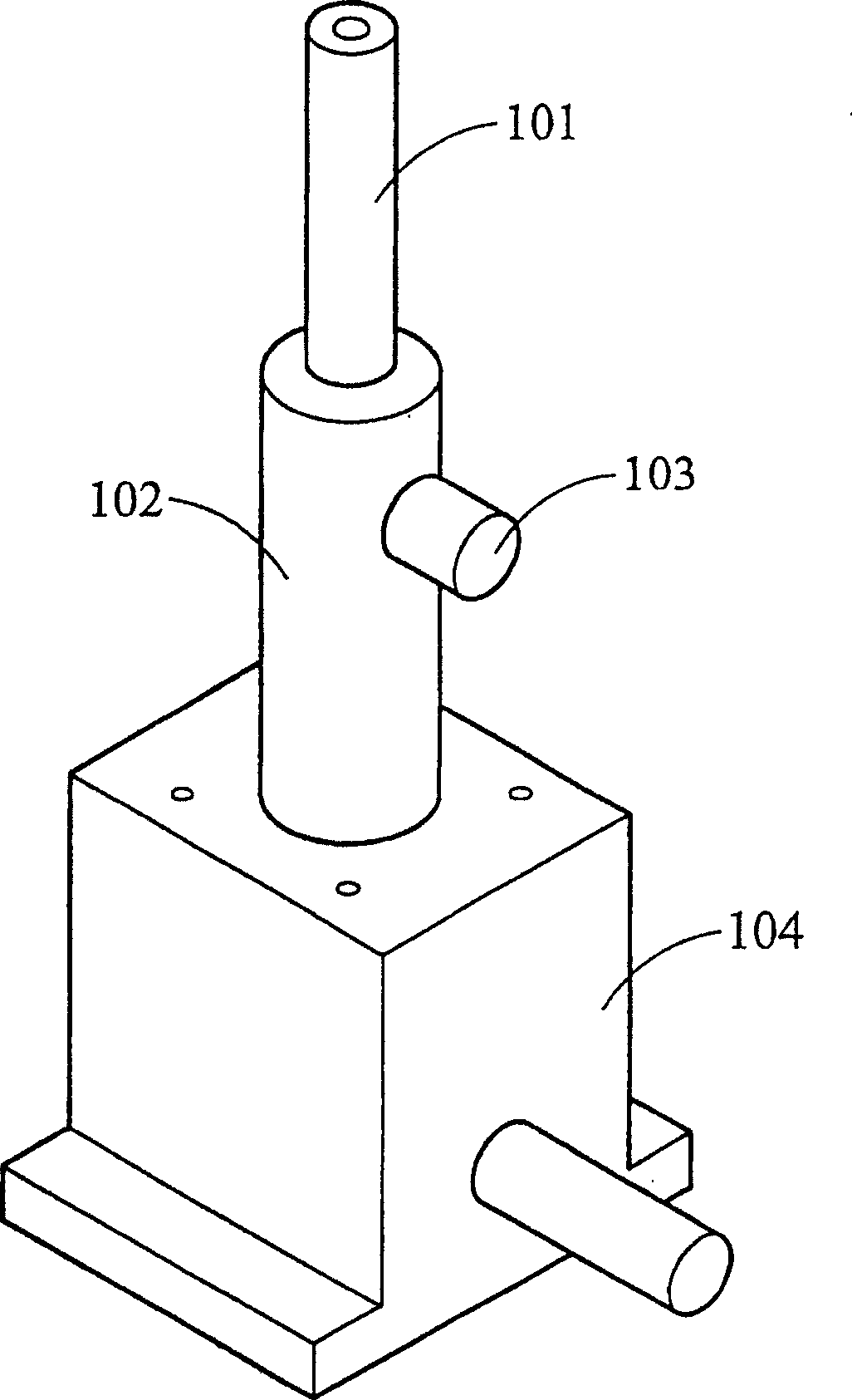

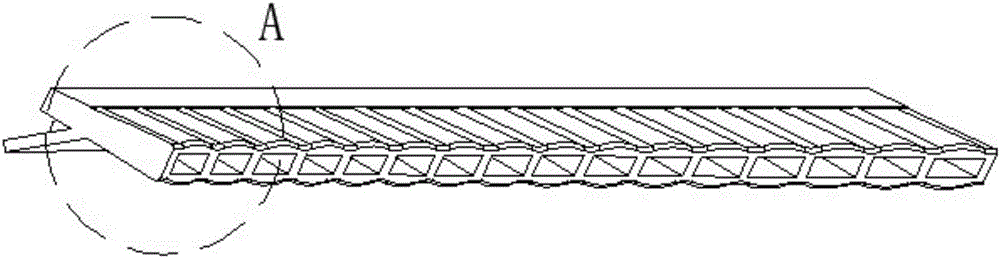

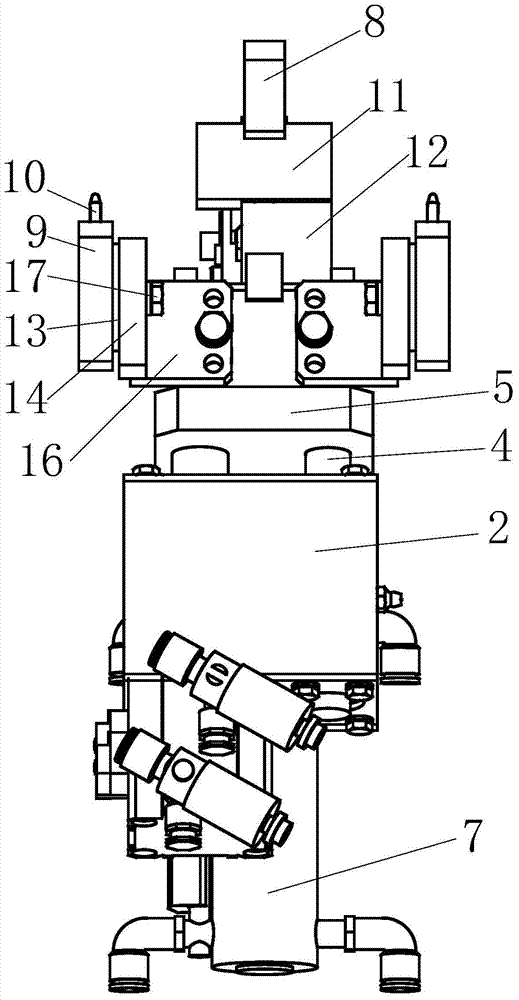

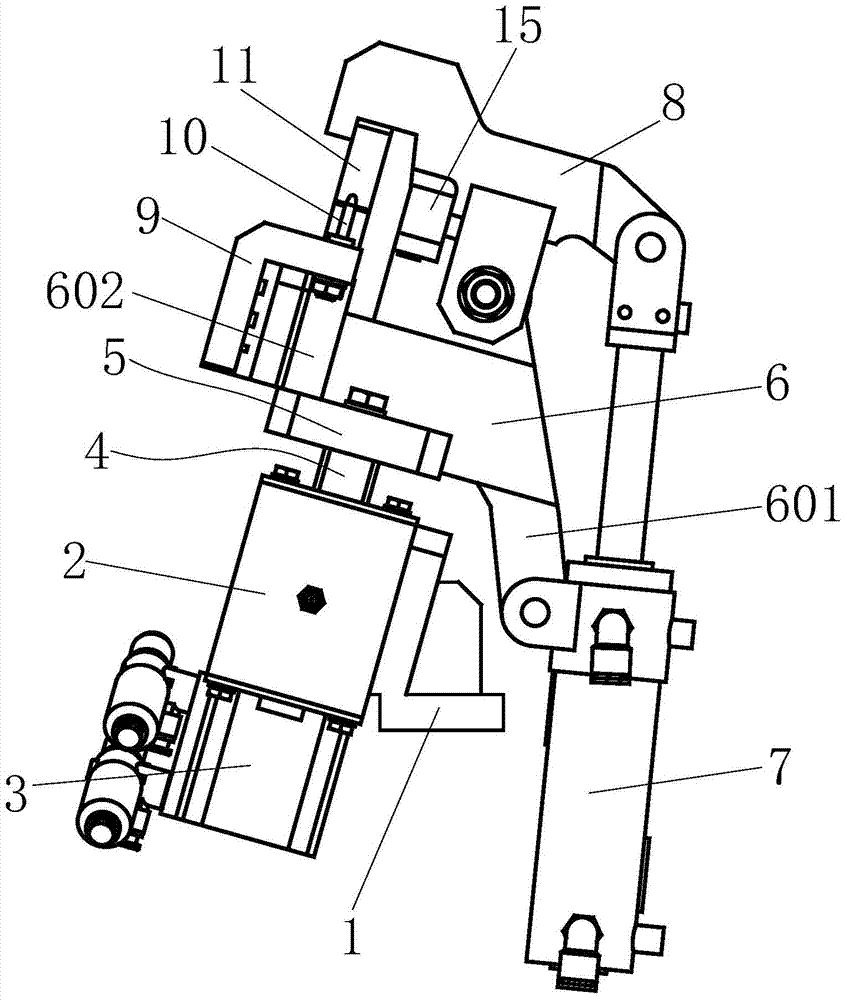

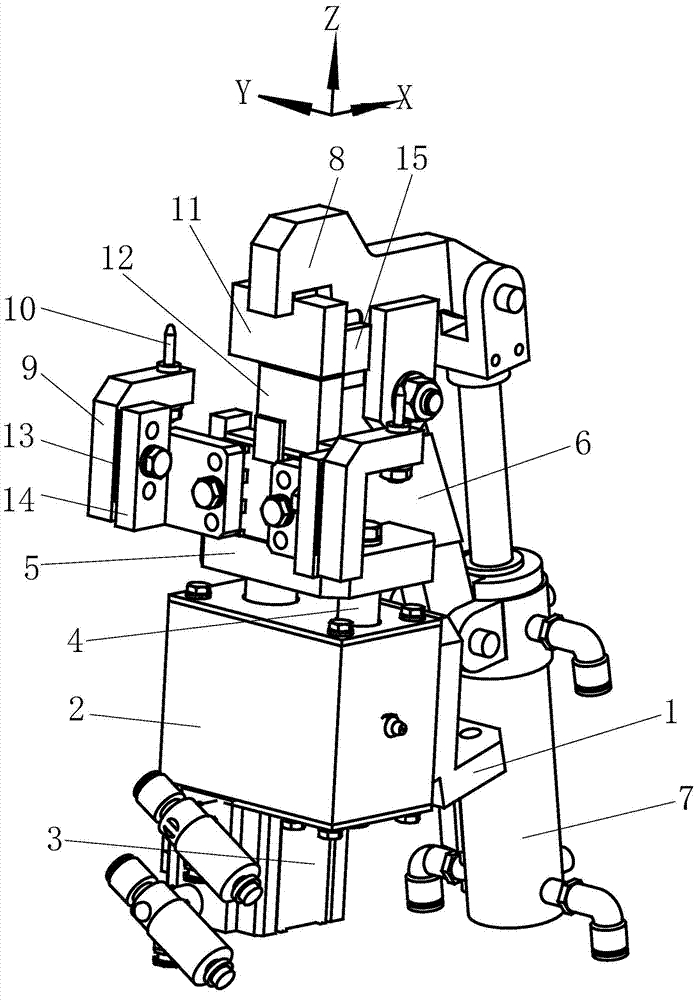

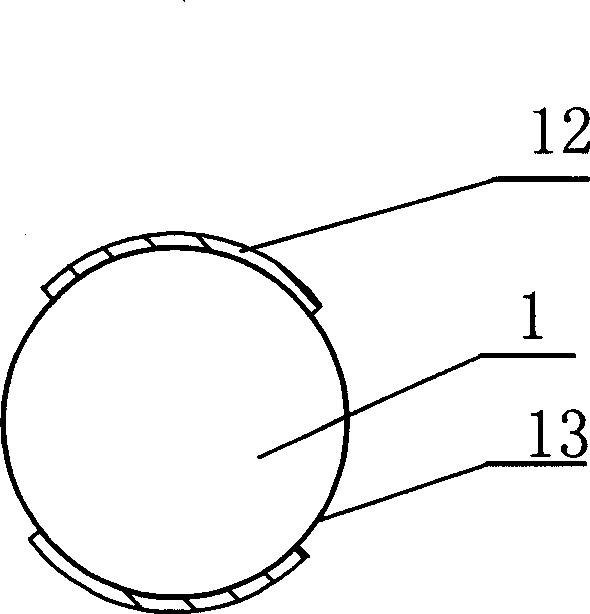

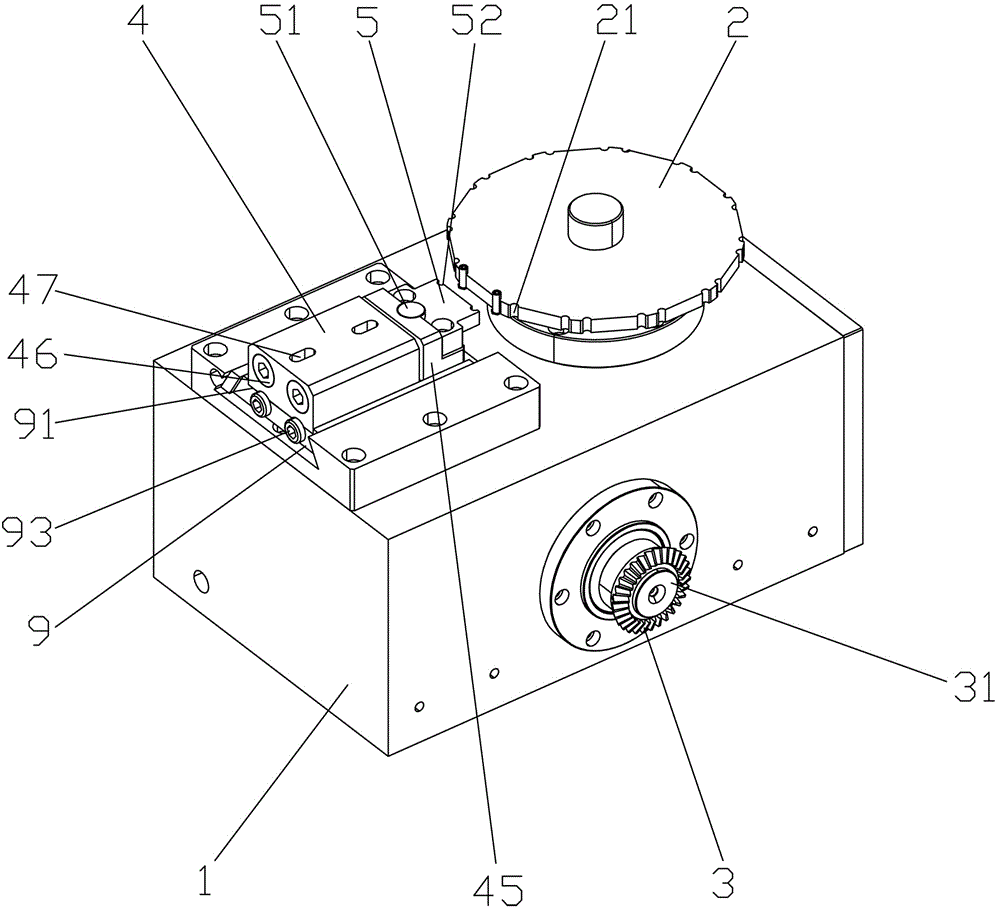

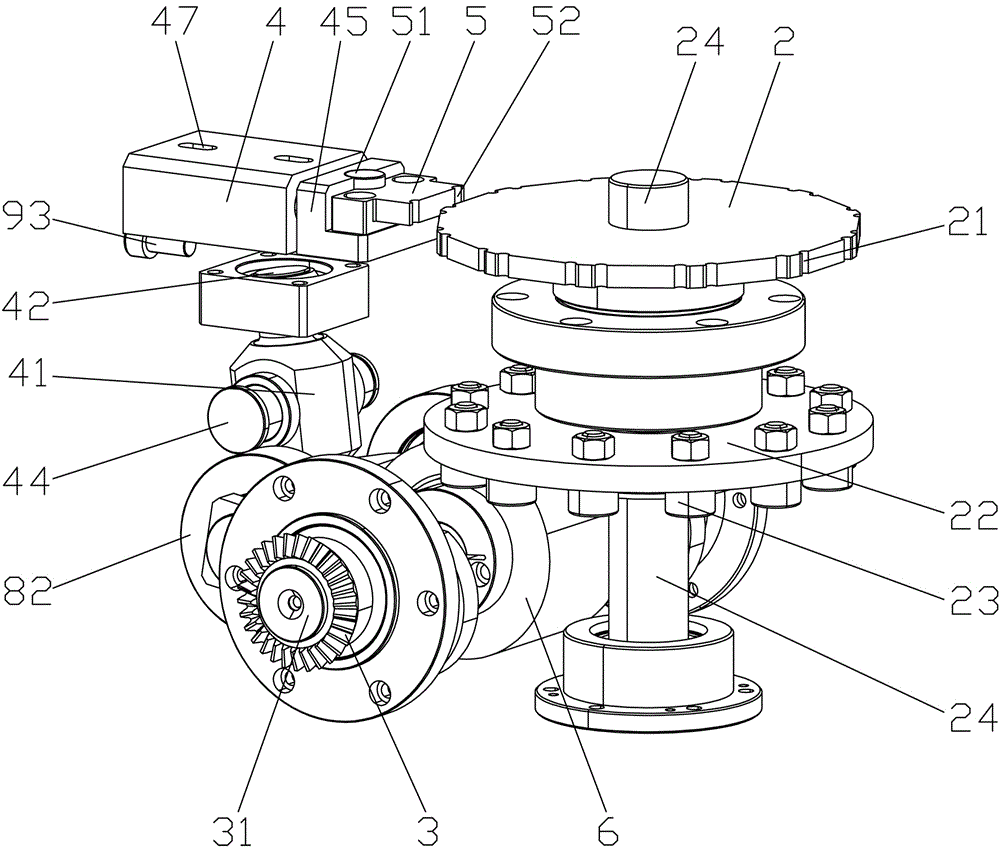

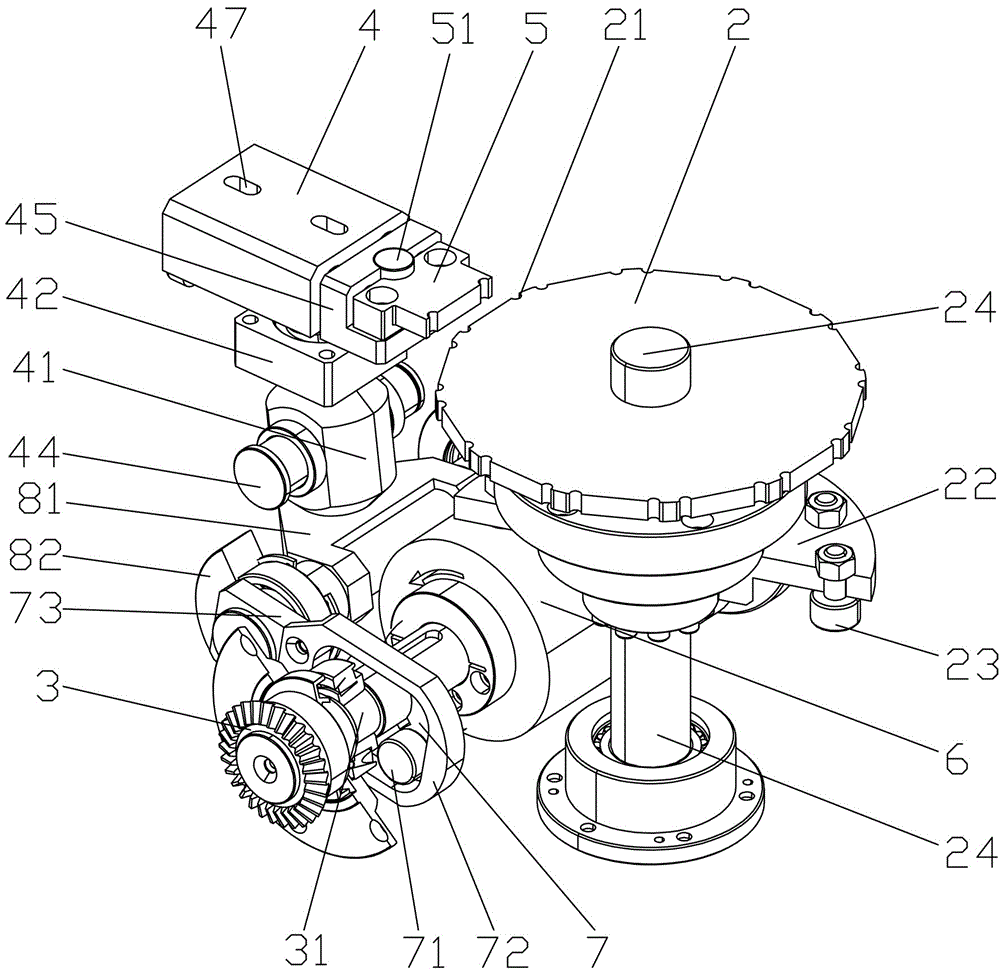

The invention discloses an automated magnet assembling device for a wind power generator set. The automated magnet assembling device comprises a support device for being fixed with a rotor of the wind power generator set and driving the rotor to rotate, feeders arranged outside the rotor, pushing-in devices arranged inside the rotor, and a control system for controlling the rotation of the rotor, the operation of the feeders and the operation of the pushing-in devices, wherein the feeders comprise supports, feeding slots arranged on the supports and pushing assemblies for pushing magnets to be assembled along the feeding slots; one end of each feeding slot is positioned below a magnetic yoke of the rotor; the feeding slots correspond to magnet assembling slots on the magnetic yoke to push the magnets to be below the magnet assembling slots; the pushing-in devices can push the magnets to preset positions in the magnet assembling slots. The automation of the magnet assembling process is realized by the automated magnet assembling device, the investment of manpower in the assembling process is reduced, and the assembling efficiency and precision are improved.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

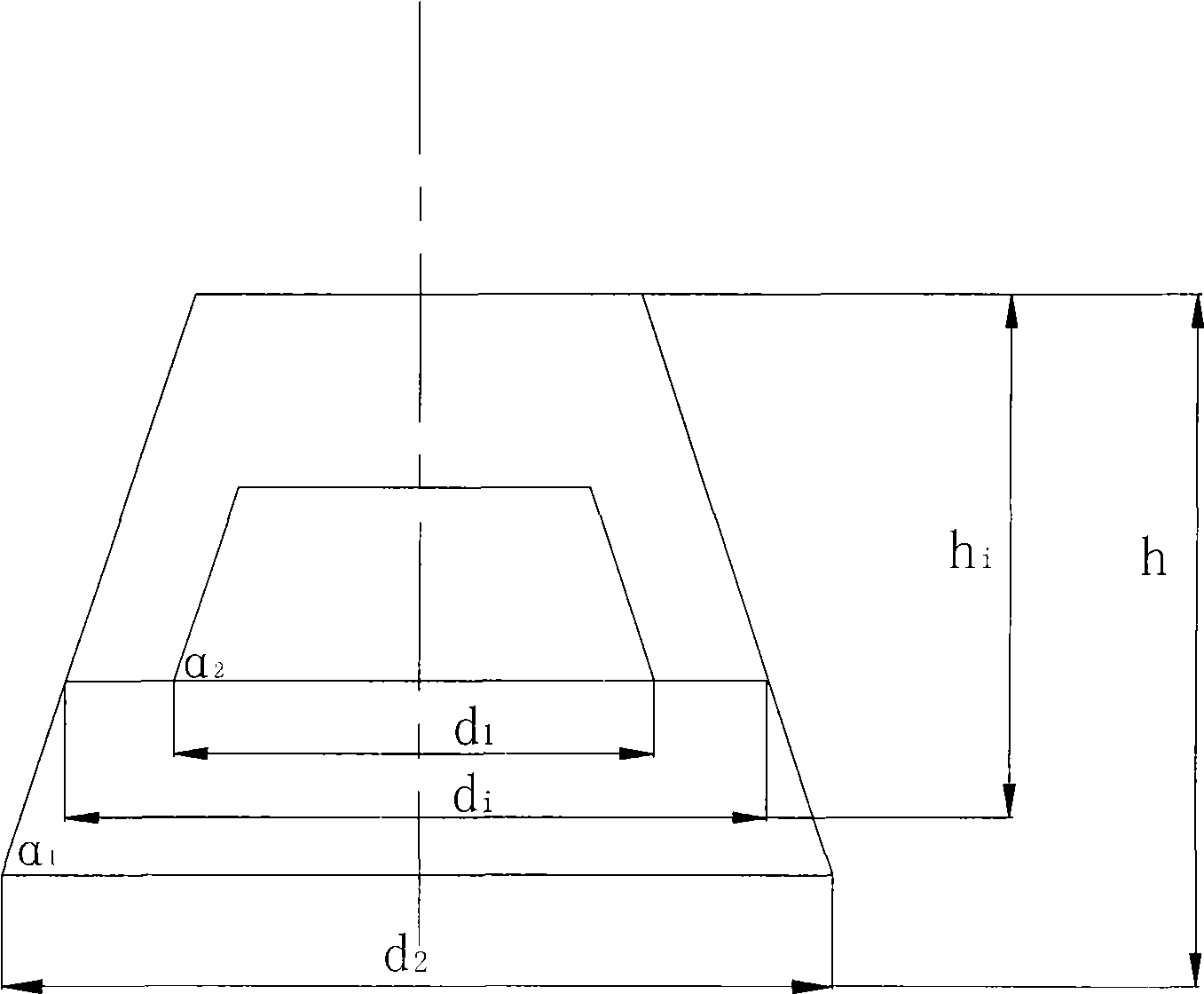

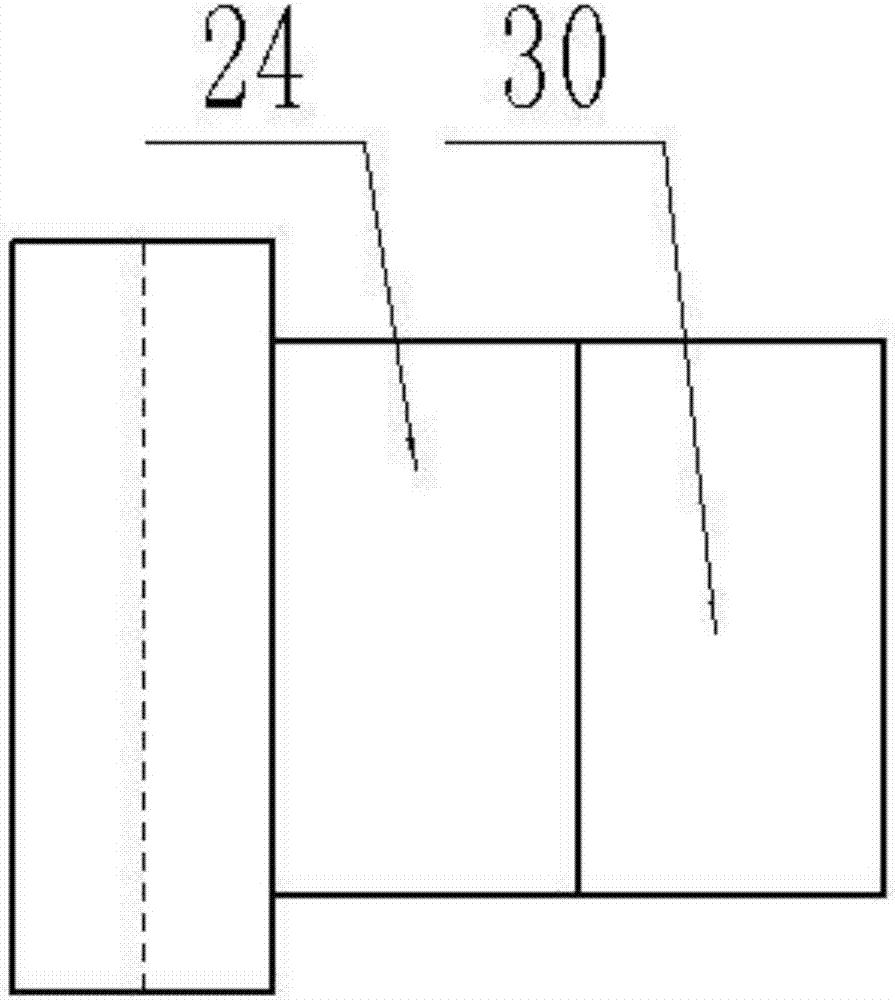

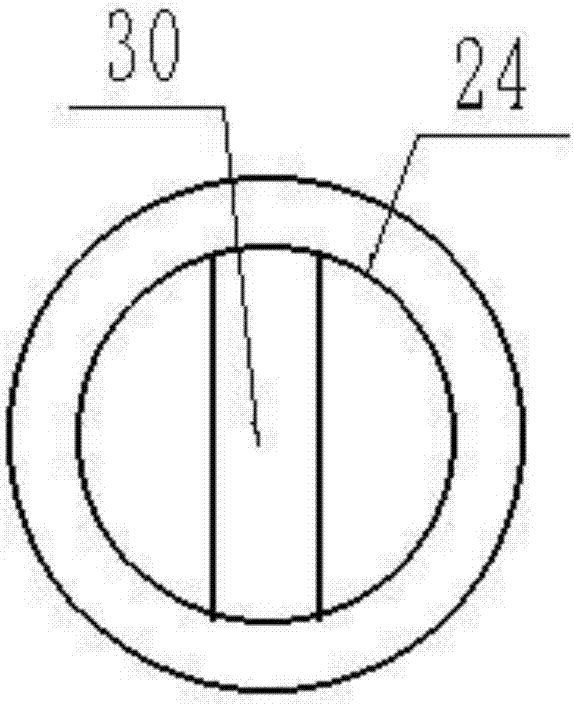

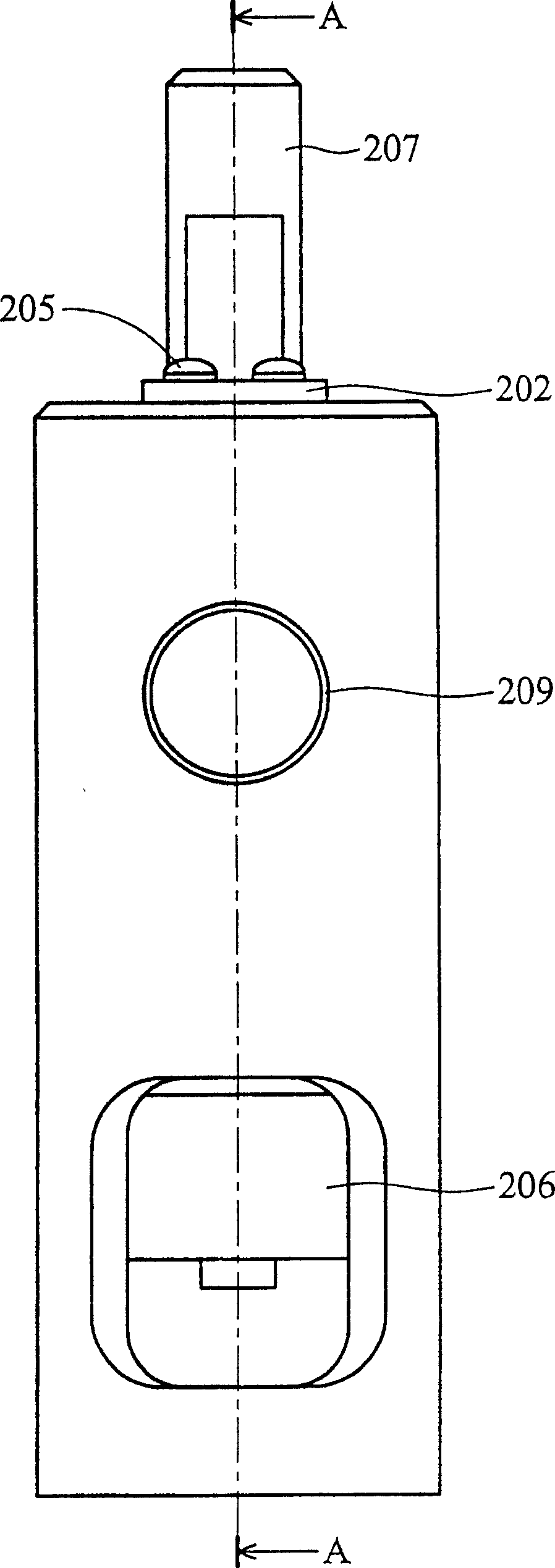

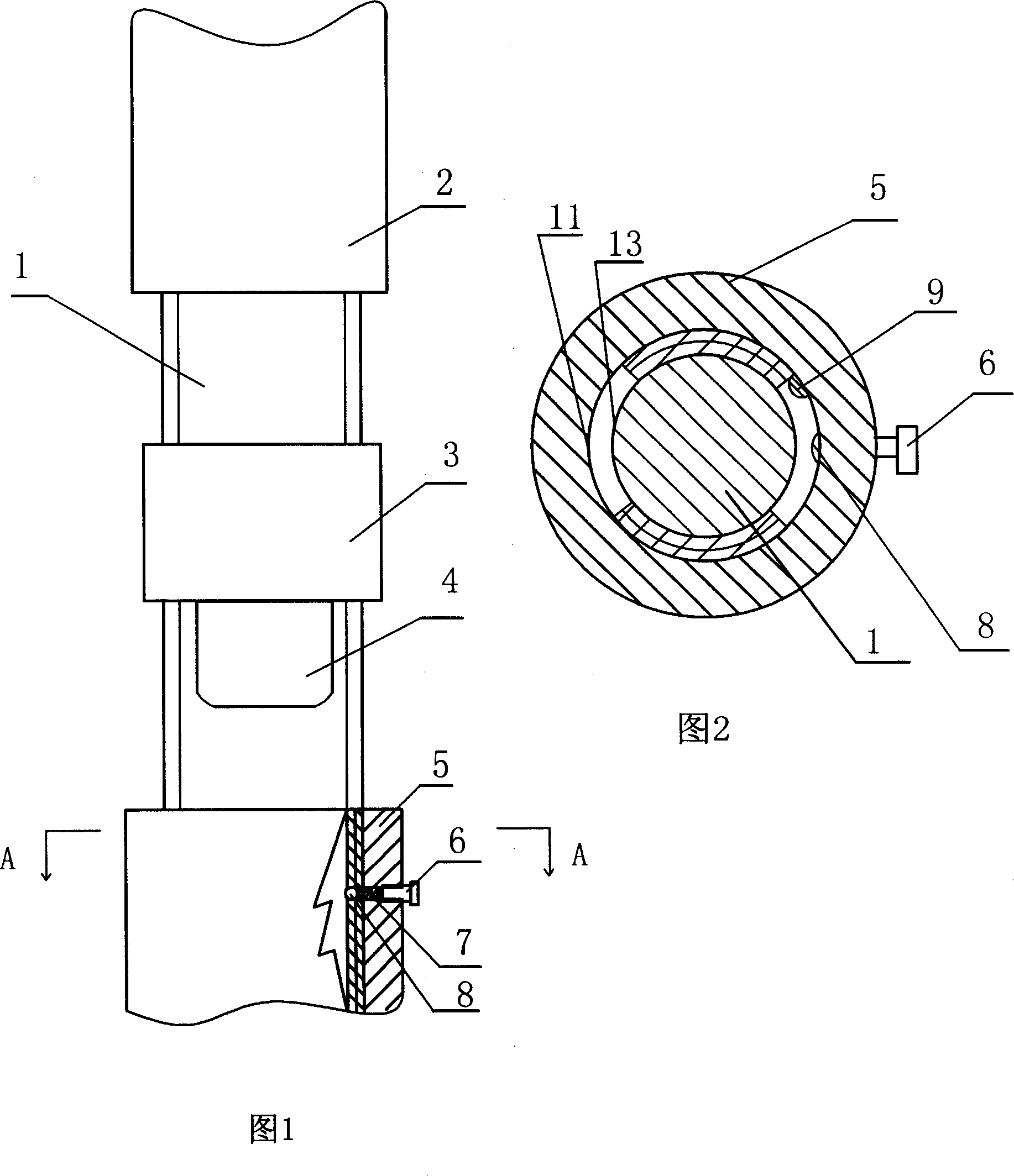

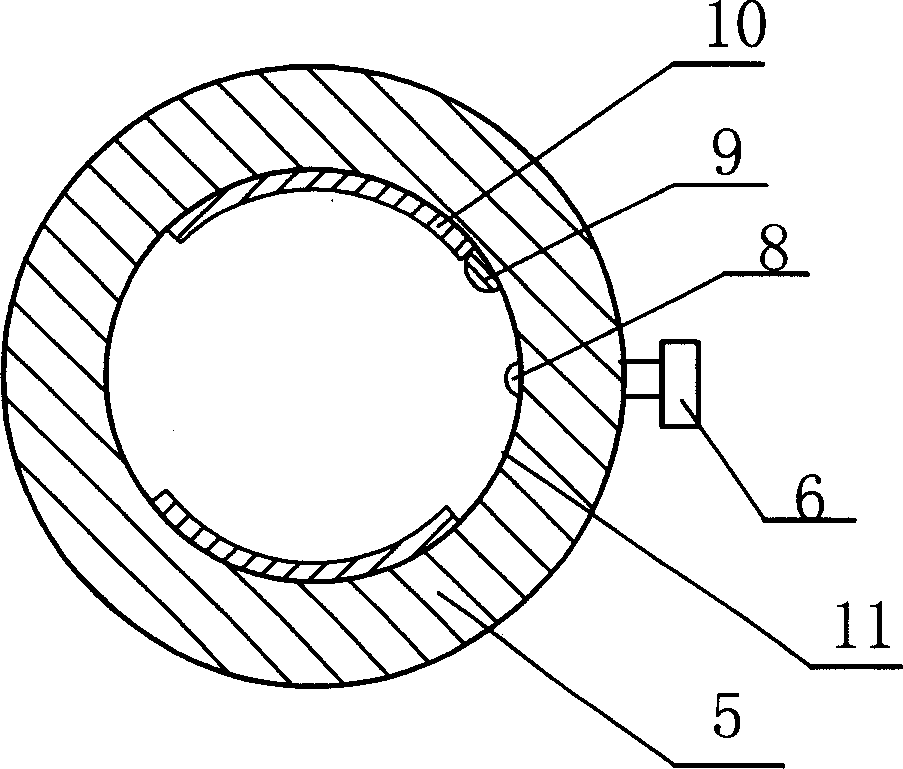

Method and device for controlling flow

InactiveCN101532570AHigh temperature resistantWear-resistantLift valveValve housingsTraffic capacityMathematical model

The invention relates to a method and a device for controlling flow. The method takes preset flow rate as a constant state, and realizes the adjustment of the flow of a fluid by adjusting the sectional area of a gas channel, and the flow adjustment is in a linear state. A method for adjusting the area of the gas channel is realized by making a conical ring valve core move up and down in a flow guiding cylinder through a controller according to a specified mathematical model and adjusting the change of channel area between the conical ring valve core and the flow guiding cylinder; and the output flow of the fluid is controlled in a real-time mode according to the requirement of process parameters of downstream equipment. The method has accurate metering, fine adjustment function, and no noise. The control device has the advantages of good sealing performance, simple and convenient structure, small occupied space, easy maintenance, high temperature resistance, wear resistance and the like.

Owner:辽宁华运控制设备制造有限公司

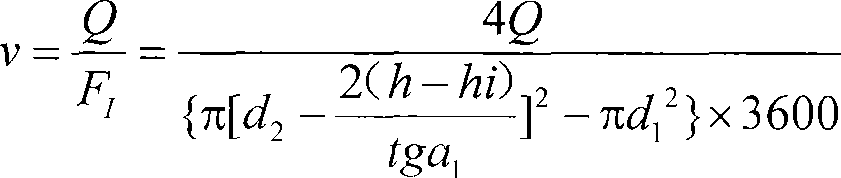

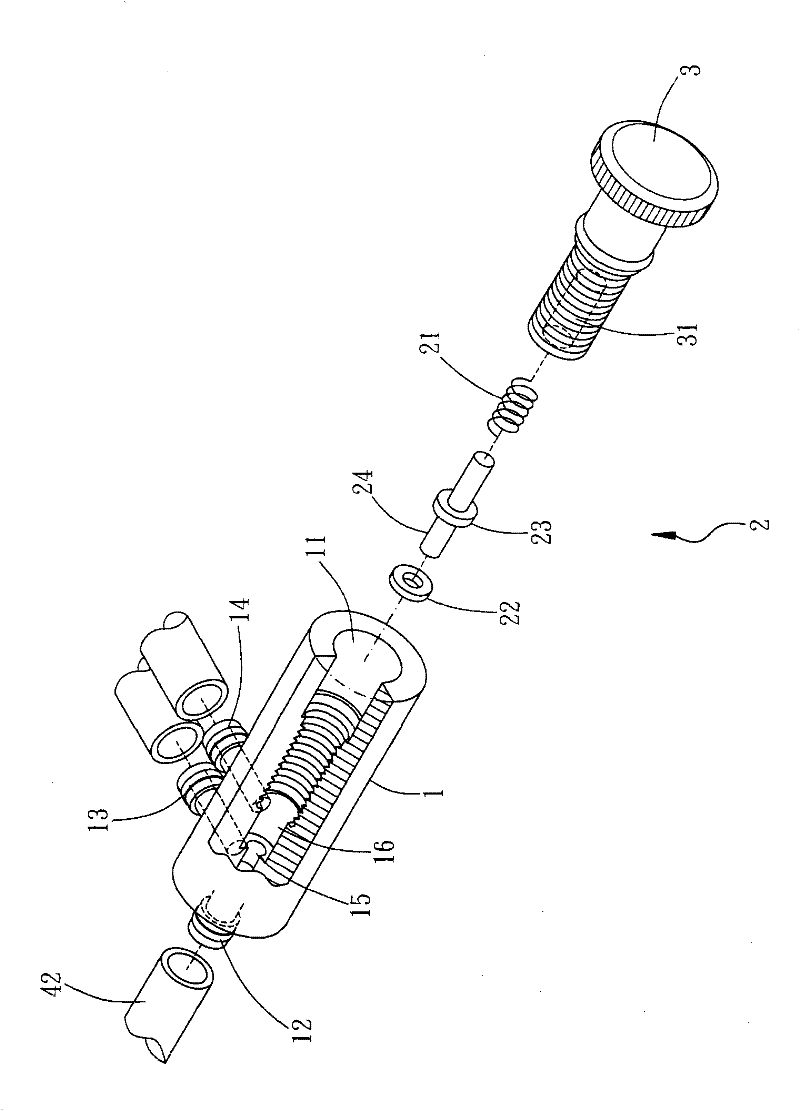

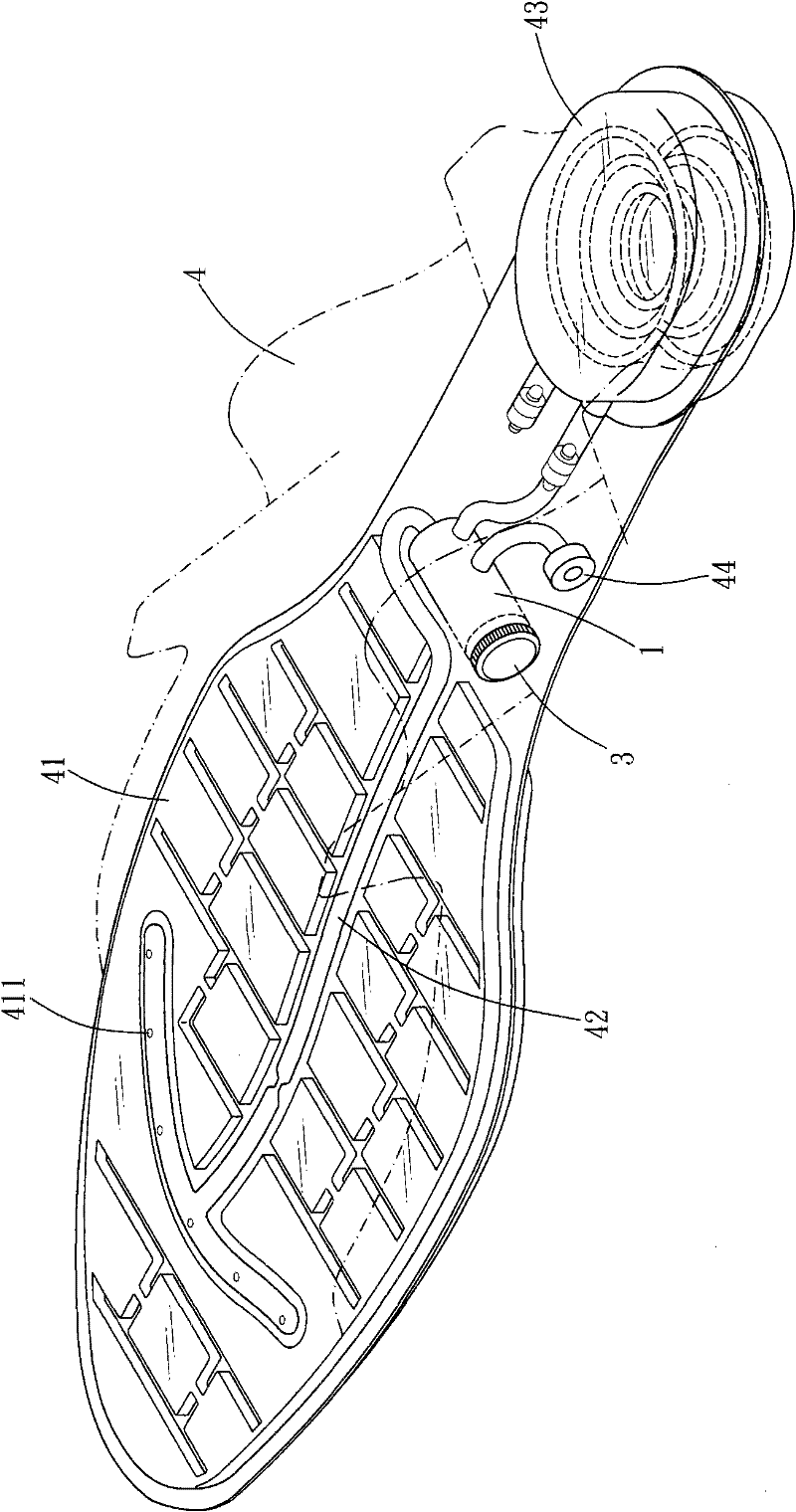

Air cushion adjusting device

An air cushion adjusting device comprises a valve body which can be mounted at a sole, a pushing member and an adjusting member, wherein one end of the valve body is provided with an air delivery part; one side of the valve body is provided with an air input part and an air output part; the air input part is connected with an air inflation device, and the air output part is connected with a one-way valve communicated with the external; the pushing member is mounted in the valve body, and two ends of an elastic member are elastically butted with the pushing member and the adjusting member respectively; when the air pressure in an air cushion is higher, the air pressure pushes against the pushing member to resist the elastic member to make the air current flow out from the air output part to the external; when the air pressure of the air cushion is normal, the elastic member pushes the pushing member to isolate the air delivery part relative to the air output part to make the air input part only deliver the air to the air cushion from the air delivery part.

Owner:欣合信股ふん

Convenient floating clamp

InactiveCN104476338AGood clamping effectEven distribution of clamping forceRevolution surface grinding machinesGrinding work supportsEngineering

The invention provides a convenient floating clamp, belonging to the technical field of machinery. The convenient floating clamp comprises a fixed turnplate with a hollow structure, a movable turnplate movably arranged behind the fixed turnplate and a top tip coaxial with the fixed turnplate; three involute clamping jaws around the axial line of the fixed turnplate are arranged in front of the fixed turnplate and respectively connected with the movable turnplate; the movable turnplate is capable of driving the three clamping jaws to swing, so that the three clamping jaws are gathered inward or expanded outward; a fisheye bearing is installed at the middle part of the fixed turnplate; the top tip is penetrated in the movable turnplate and the fisheye bearing in sequence and partially stretches out of the fixed turnplate. The convenient floating clamp has good clamping effect and a fine-tuning function.

Owner:NINGBO MEIDE ROBOT

Automatic bothway sand-blasting machine

ActiveCN106695473APrevent leakagePrevent splashRevolution surface grinding machinesAbrasive machine appurtenancesSand blastingWorking environment

The invention relates to an automatic bothway sand-blasting machine. The automatic bothway sand-blasting machine comprises a shell internally provided with a sand-blasting chamber. Sand-blasting heads are arranged in the sand-blasting chamber. The shell is provided with a push inlet through which a pipe is pushed into the sand-blasting chamber, and a conveying outlet through which the pipe is conveyed out of the sand-blasting chamber. Dustproof parts covering the push inlet are arranged on the parts, located at the push inlet and the conveying outlet, of the shell correspondingly. A water curtain circulating device is arranged in the shell and comprises a water spraying pipeline and a circulating water tank. The sand-blasting chamber is provided with a secondary grinding device for grinding through secondary use of blasting sand. The shell is provided with an adjusting mechanism used for adjusting the orientation of the sand-blasting heads. Through the scheme, the automatic bothway sand-blasting machine provided by the invention is high in quartz sand processing efficiency and capable of preventing flying dust from polluting the working environment.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

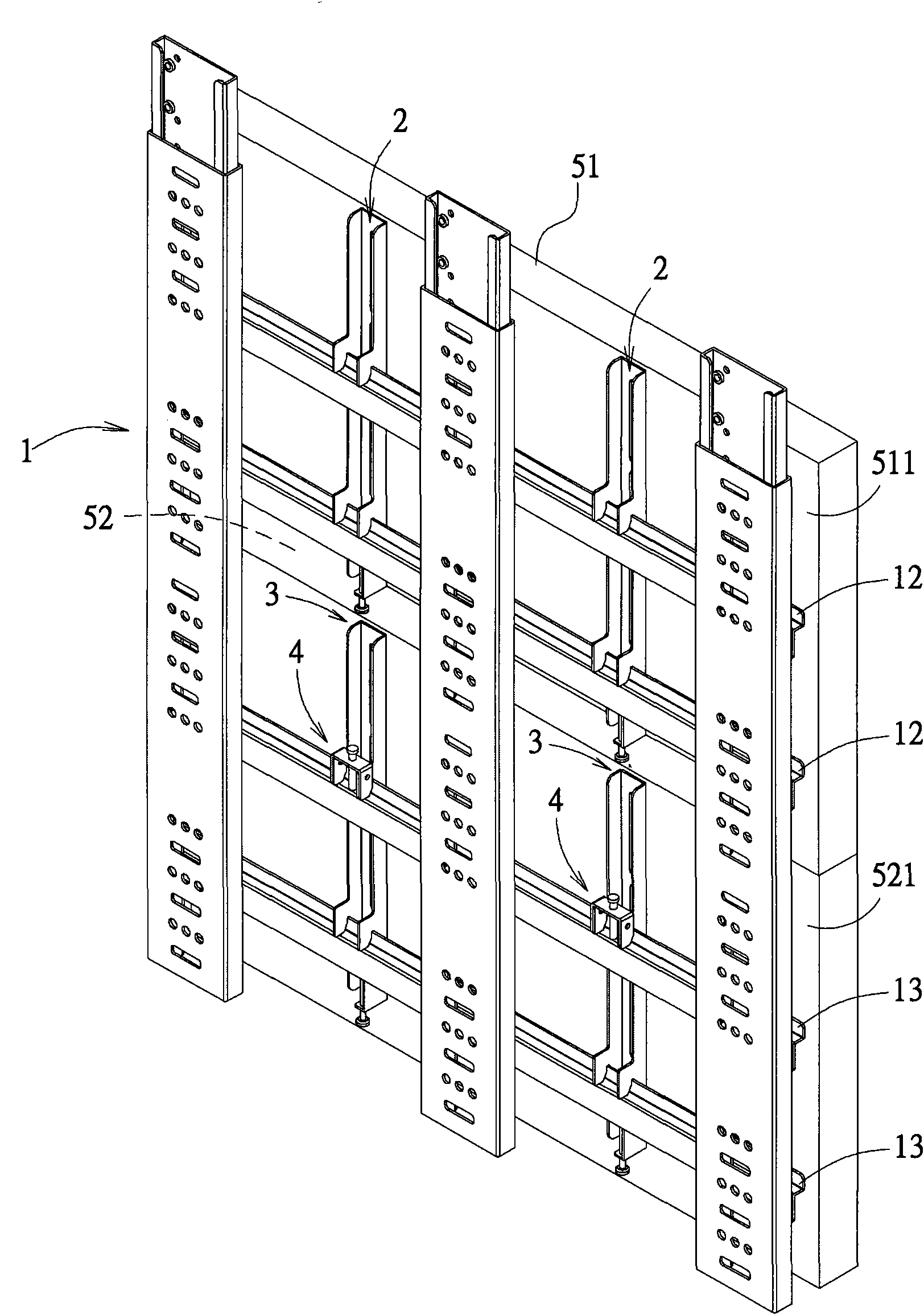

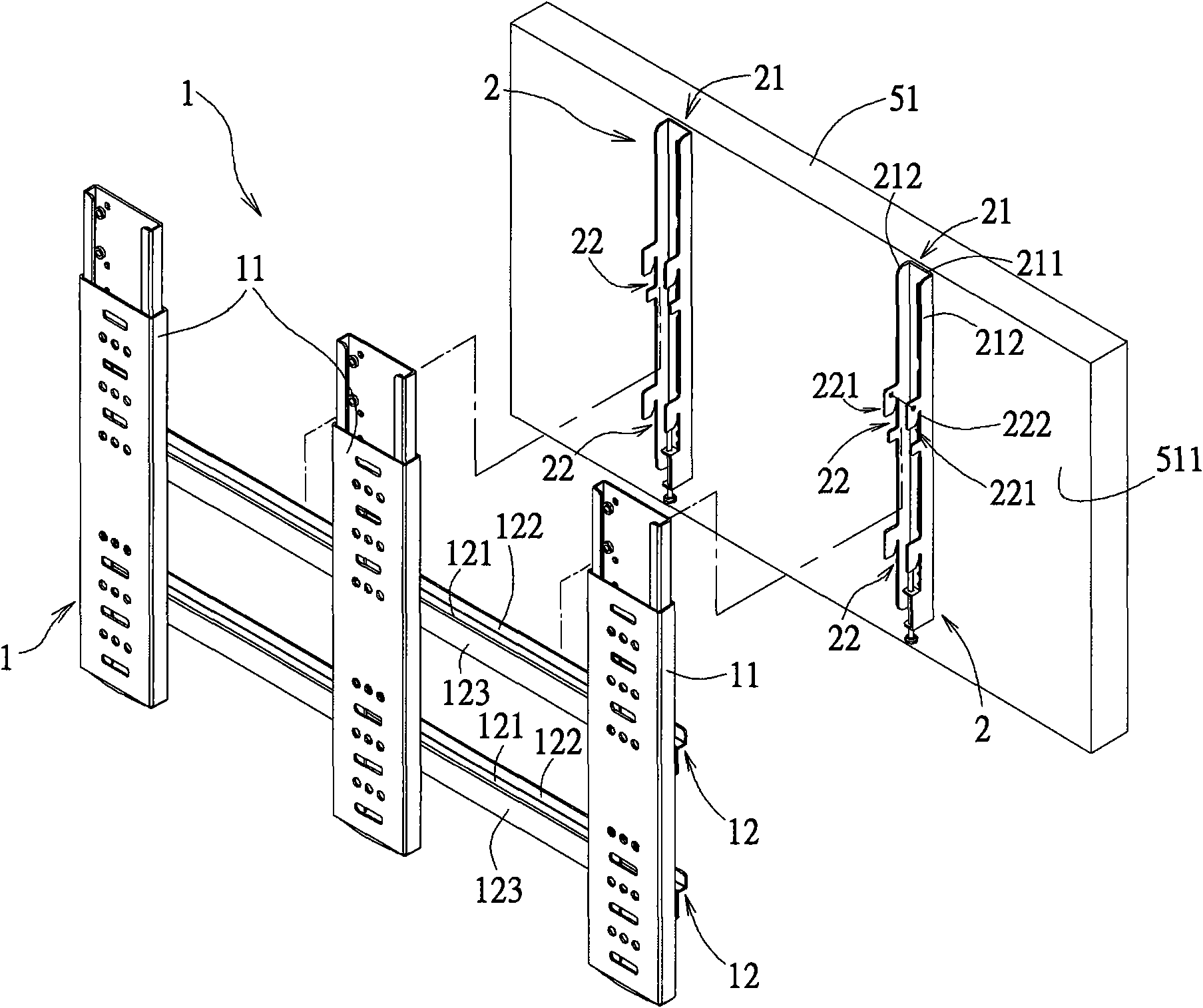

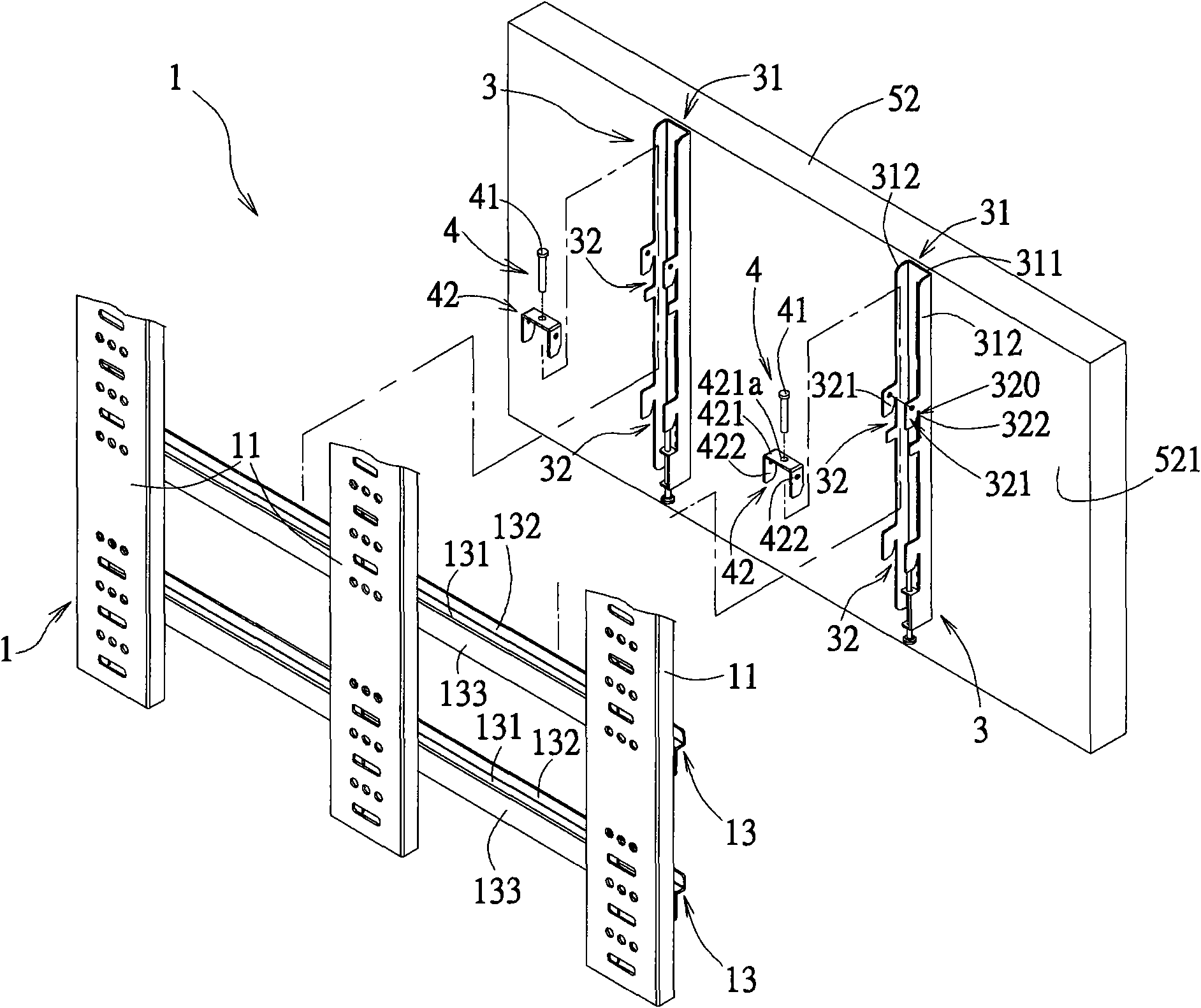

Display rack device

InactiveCN101871551AWith fine-tuning functionEliminate voidsMachine supportsIdentification meansFixed frameDisplay device

The invention relates to a display rack device, which is used for hanging a first display and a second display from top to bottom and comprises a fixed frame, a first rack, a second rack and a fine tuning unit, wherein the fixed frame consists of a first supporting part and a second supporting part; the first rack is arranged on the back surface of the first display to enable the first display to be hung on the first supporting part; the second rack consists of a second rack body and a second hanging part, the second rack body is arranged on the back surface of the second display, the second hanging part is invert L-shaped, a hanging groove with a downward opening is defined between the second hanging part and the second rack body, and when the second display is hung at the second supporting part and is arranged below the first display, the second supporting part partially stretches into the hanging groove; and the fine tuning unit is used for adjusting the position of the second hanging part relative to the second supporting part and is arranged between the second hanging part and the second supporting part, and when the fine turning unit is adjusted to enable the second hanging part to move upward relative to the second supporting part, the fine tuning unit is propped against the second supporting part. The invention has the advantage that the height of the display on the fixed frame can be adjusted.

Owner:AOPEN

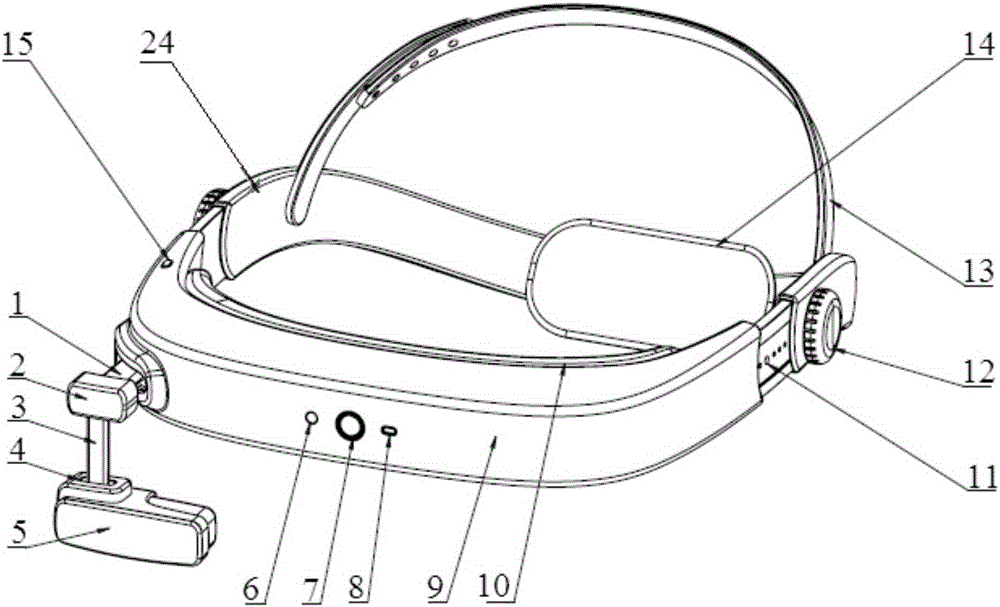

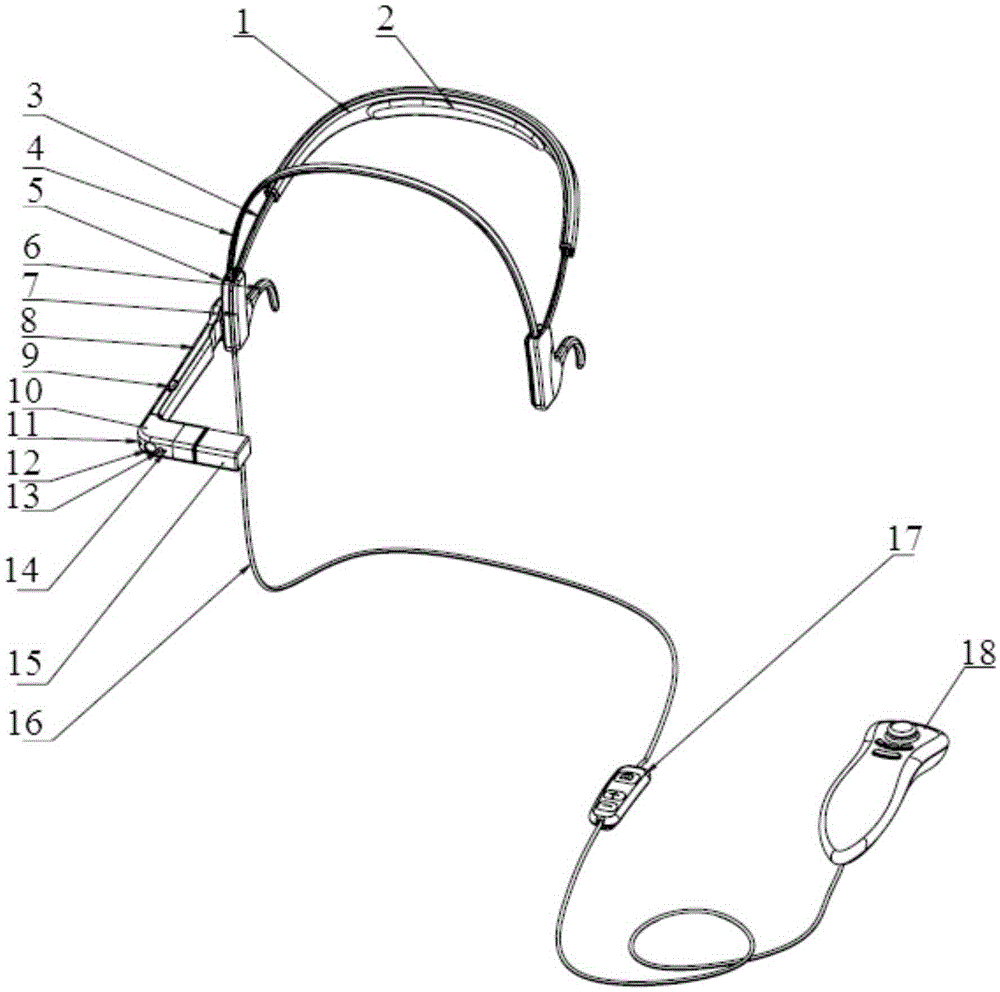

Wearable intelligent visual sense strengthening equipment

InactiveCN106842566ARealize human-computer interactive experienceEnhance virtual-real interactionInput/output for user-computer interactionCharacter and pattern recognitionVisual perceptionEmbedded system

The invention relates to wearable intelligent visual sense strengthening equipment, comprising a head adornment fixing device, a processor and a myopic display system. The head adornment fixing device comprises an arc-shaped main engine cabin and an arc-shaped rear baffle, and the main engine cabin and the rear baffle are assembled into a circular fixing device capable of being sleeved on the head; the processor is arranged in the main engine cabin and connected with the myopic display system, and the front end of the main engine cabin is provided with a camera connected with the processor; the myopic display system stretches out of one end of the front side of the main engine cabin through a stretchable revolving device, and the position and angle of the myopic display system are adjusted by the stretchable revolving device. Compared with the prior art, the intelligent visual sense strengthening equipment disclosed by the invention is simple in setup, the processor is integrated in the head adornment fixing device, and the device is adjustable in size and comfortable to wear, thereby improving the experience sense of a user. Meanwhile, the intelligent visual sense strengthening equipment disclosed by the invention has strong functions, can realize multiple functions, selectively adopts a fingerprint verification or iris verification manner, and improves safety.

Owner:上海翊视皓瞳信息科技有限公司

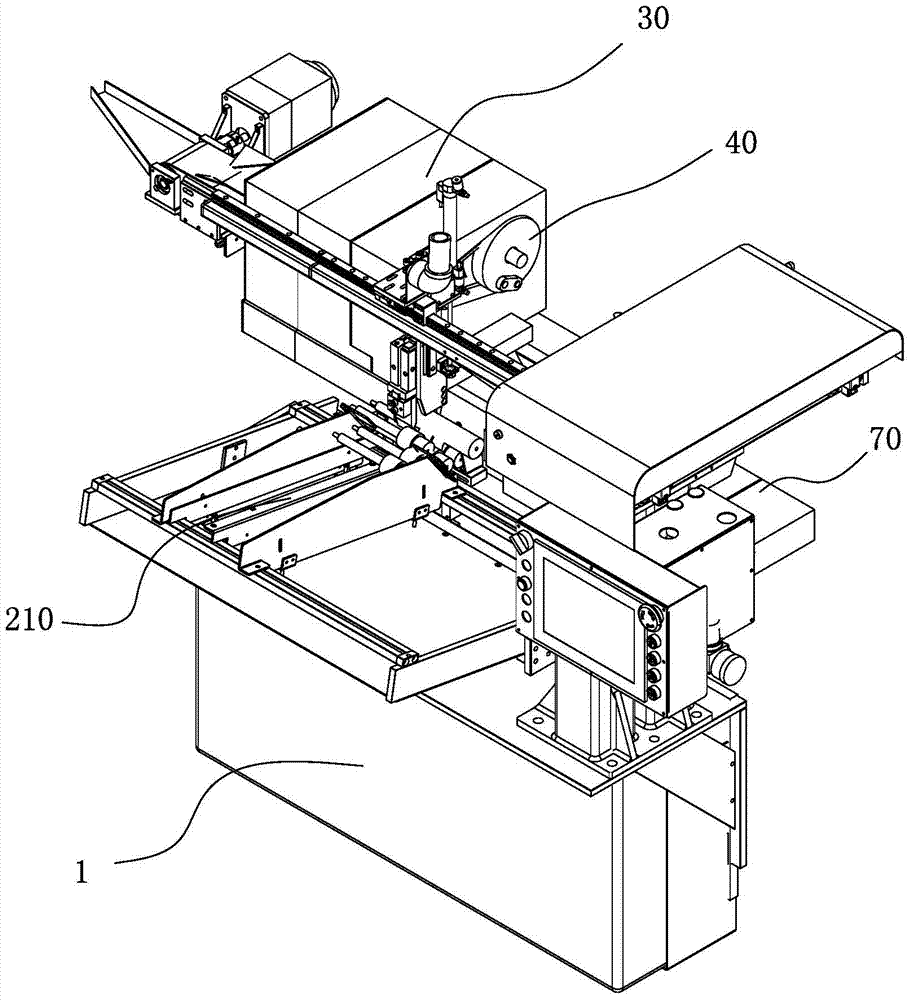

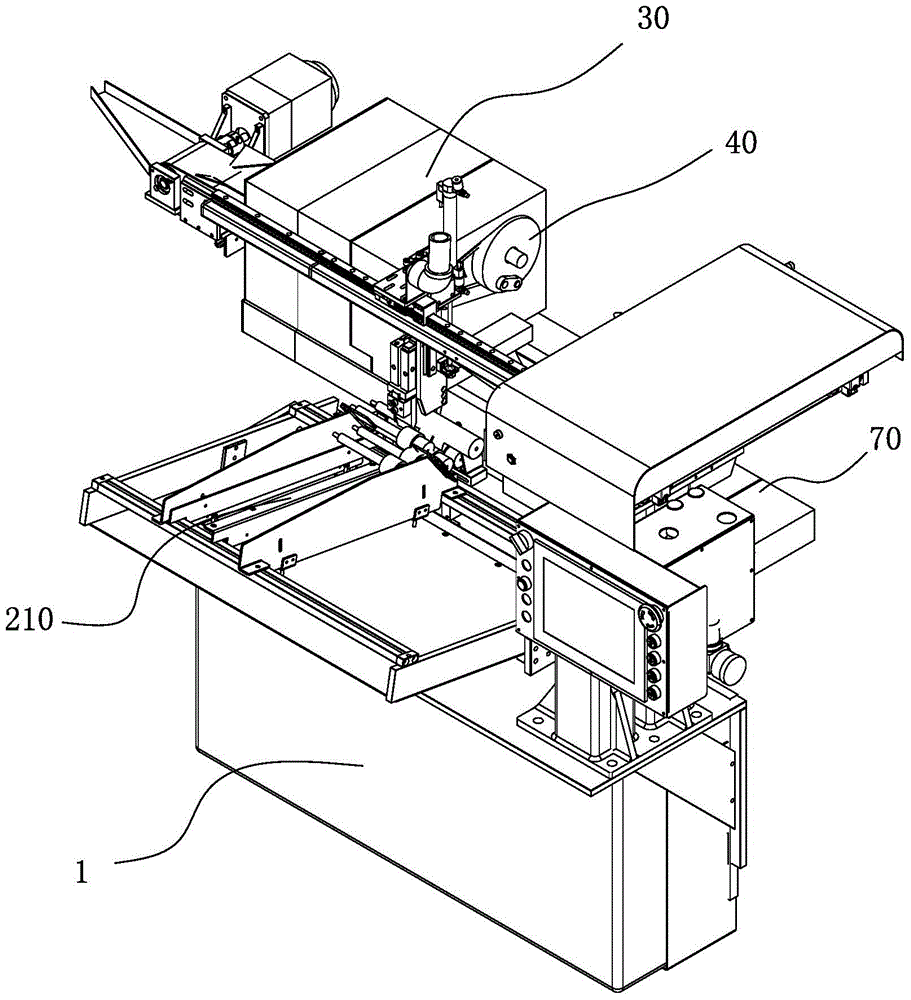

CNC (computer numerical control) grinding machine

InactiveCN104493677ADoes not affect workHigh degree of automationGrinding machinesGrinding feedersReciprocating motionCnc grinding

The invention provides a CNC (computer numerical control) grinding machine and belongs to the technical field of machinery. The CNC grinding machine comprises a frame, a grinding tool and a bench movably mounted on the frame. The frame includes a conveying area and a processing area sequentially from front to rear. An incoming mechanism and a conveying mechanism are disposed in the conveying area. A spindle box and a discharging mechanism are disposed in the processing area. The discharging mechanism and the incoming mechanism are disposed on two sides of the spindle box. The conveying mechanism is disposed over the incoming mechanism and can linearly reciprocate between the incoming mechanism and the spindle box. A floating chuck is mounted on the spindle box. The frame is provided with an ejector base arranged right in front of the spindle box. The grinding tool is movably mounted right in rear of the spindle box. The spindle box is fixedly connected with the bench. The ejector base is disposed over the bench. The frame is further provided with a first drive motor and a second drive motor; the first drive motor can control the grinding tool to linearly move in the horizontal direction; the second drive motor can control the bench to linearly slide. The CNC grinding machine has the advantages of high automation level and operational convenience.

Owner:NINGBO MEIDE ROBOT

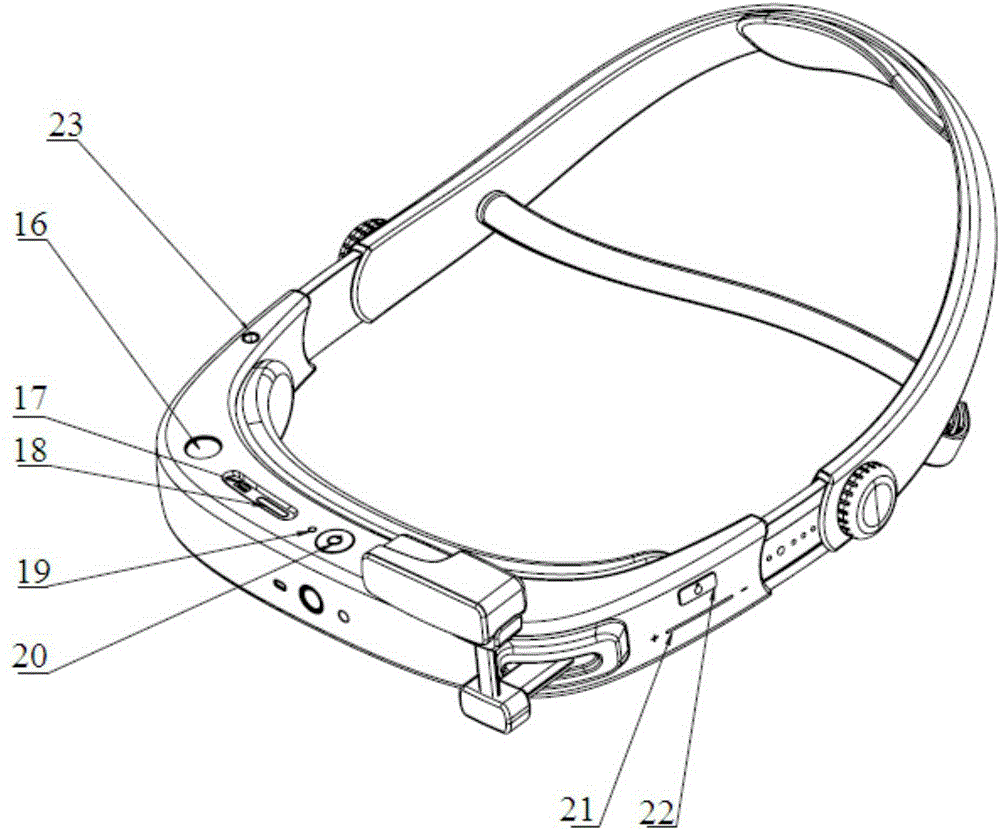

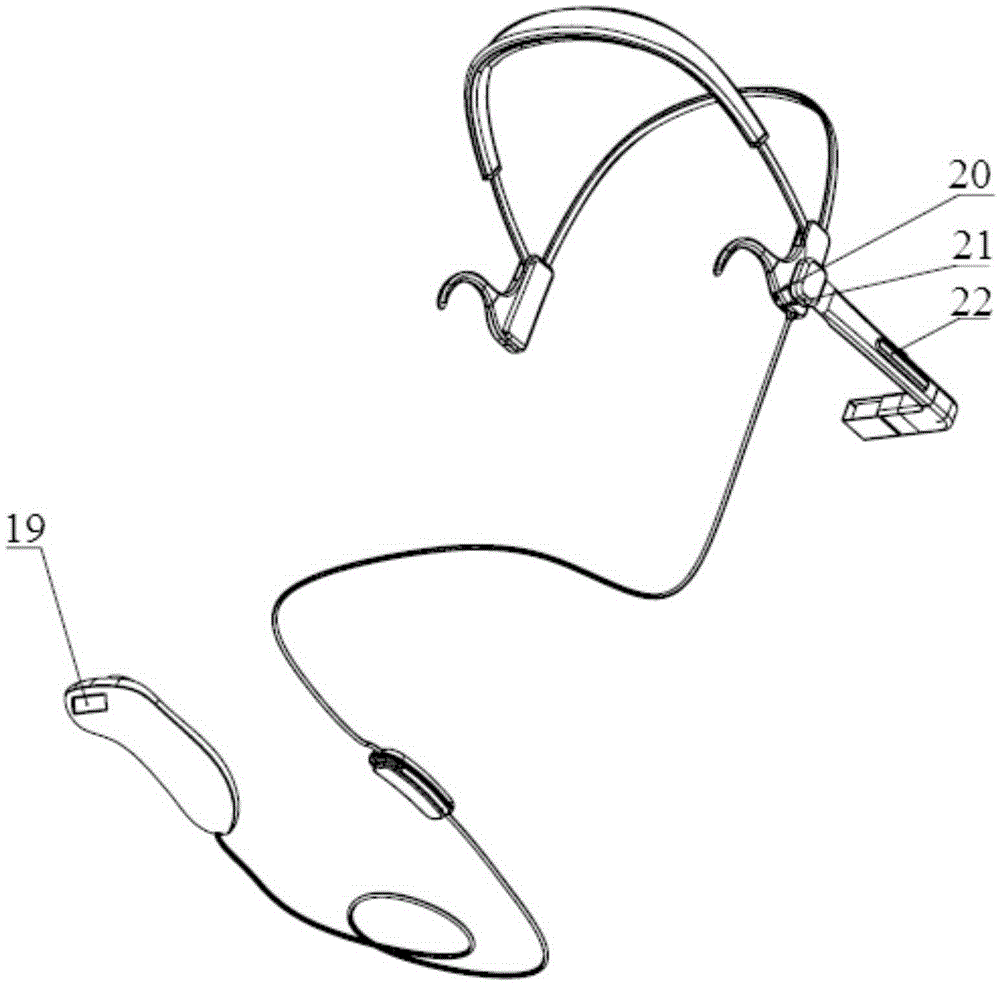

Separated type wearable intelligent visual enhancement device

InactiveCN106842565ARealize human-computer interactive experienceEnhanced industrial operation guidanceOptical elementsVisual perceptionEmbedded system

The invention relates to a separated type wearable intelligent visual enhancement device. The separated type wearable intelligent visual enhancement device comprises a head wearing fixing device, an L-shaped connecting pipe, cables, a near-to-eye display system and a processor, wherein the head wearing fixing device is composed of an arc-shaped rear connecting rod and connectors connected with both ends of the rear connecting rod, and the connectors are provided with ear hooks; the L-shaped connecting pipe is composed of a long pipe and a short pipe which are perpendicular to each other, the long pipe is rotatably connected to one of the connectors; due to the fact that the L-shaped connecting pipe is rotatably connected with one of the connectors, when not needing to watch the near-to-eye display system, a user can rotate the entire L-shaped connecting pipe; the near-to-eye display system is arranged on the inner side of the short pipe and connected with the processor through the cables, and the front side of the short pipe is provided with a camera which is connected with the processor through the cables. Compared with the prior art, the separated type wearable intelligent visual enhancement device is simple in structure; the processor and the head wearing fixing device are separated, and meanwhile, the separated type wearable intelligent visual enhancement device is adjustable in size and comfortable to wear, so that the separated type wearable intelligent visual enhancement device can achieve various functions.

Owner:重庆翊视皓瞳信息科技有限公司

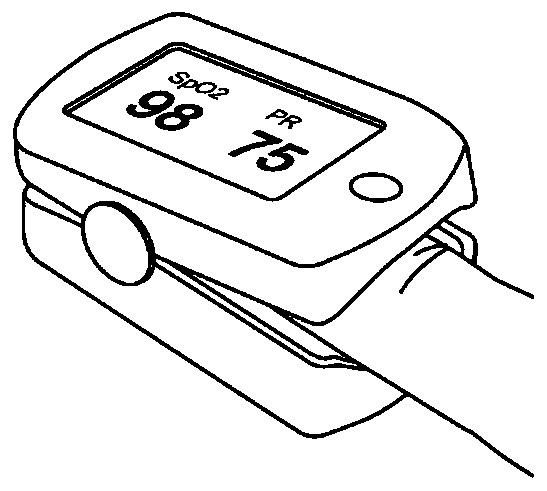

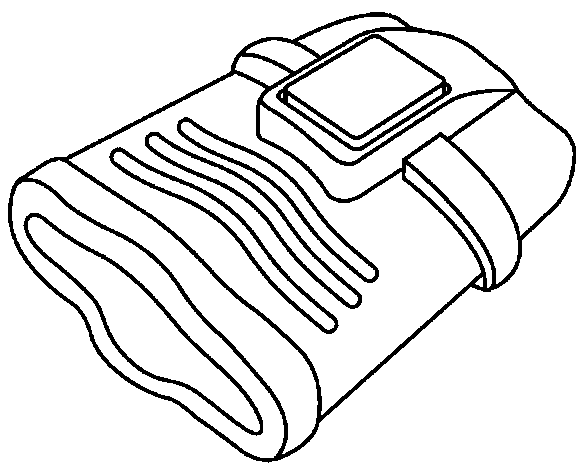

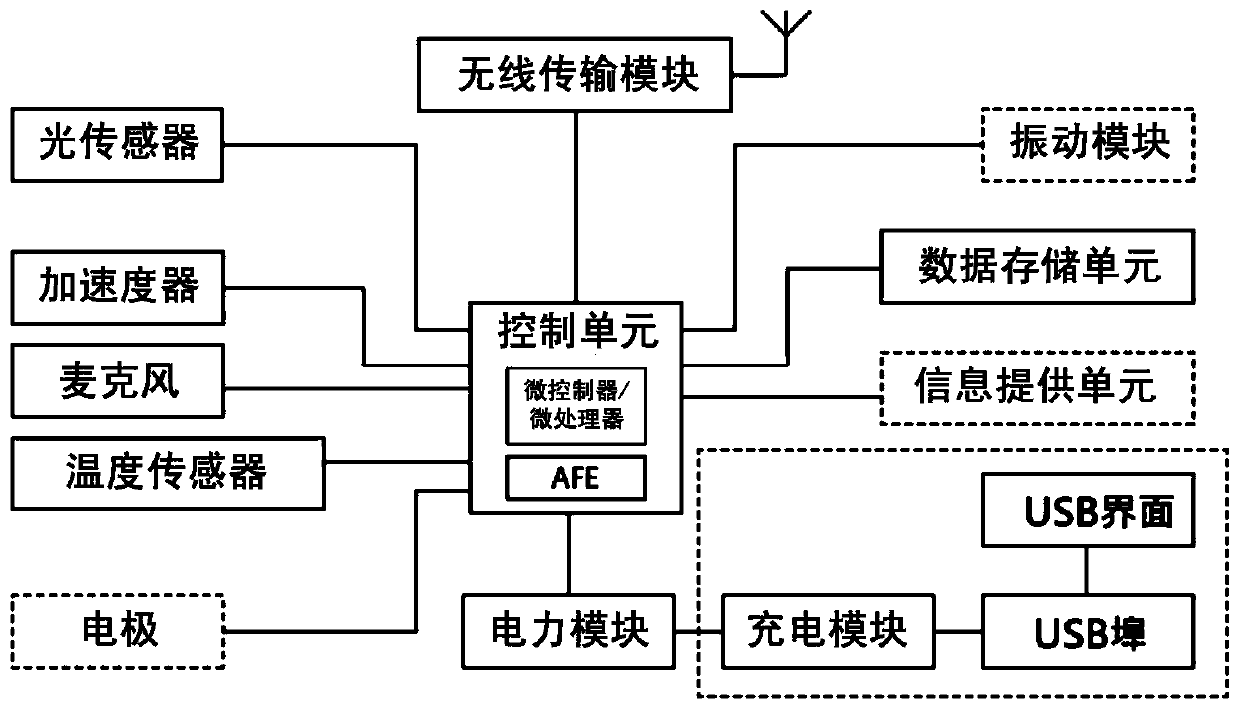

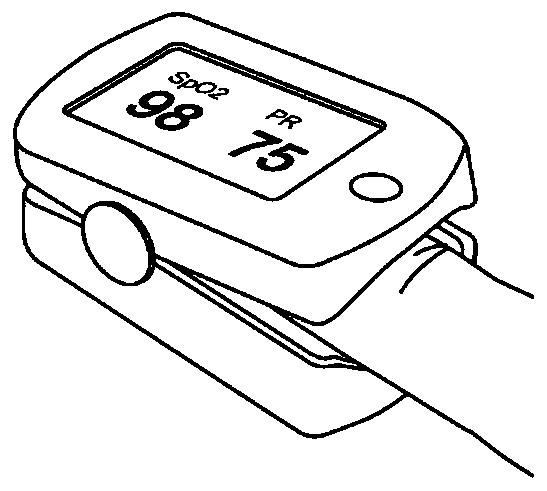

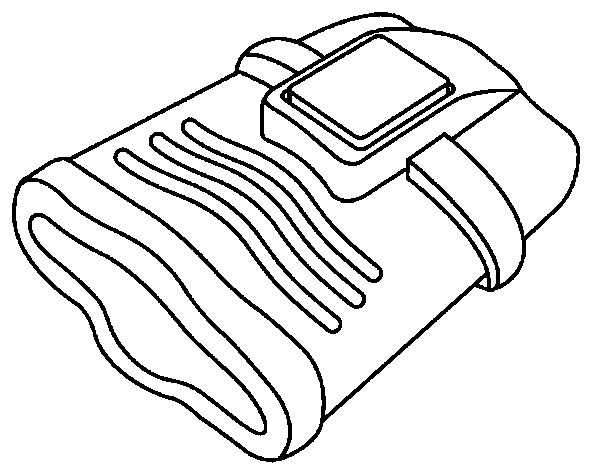

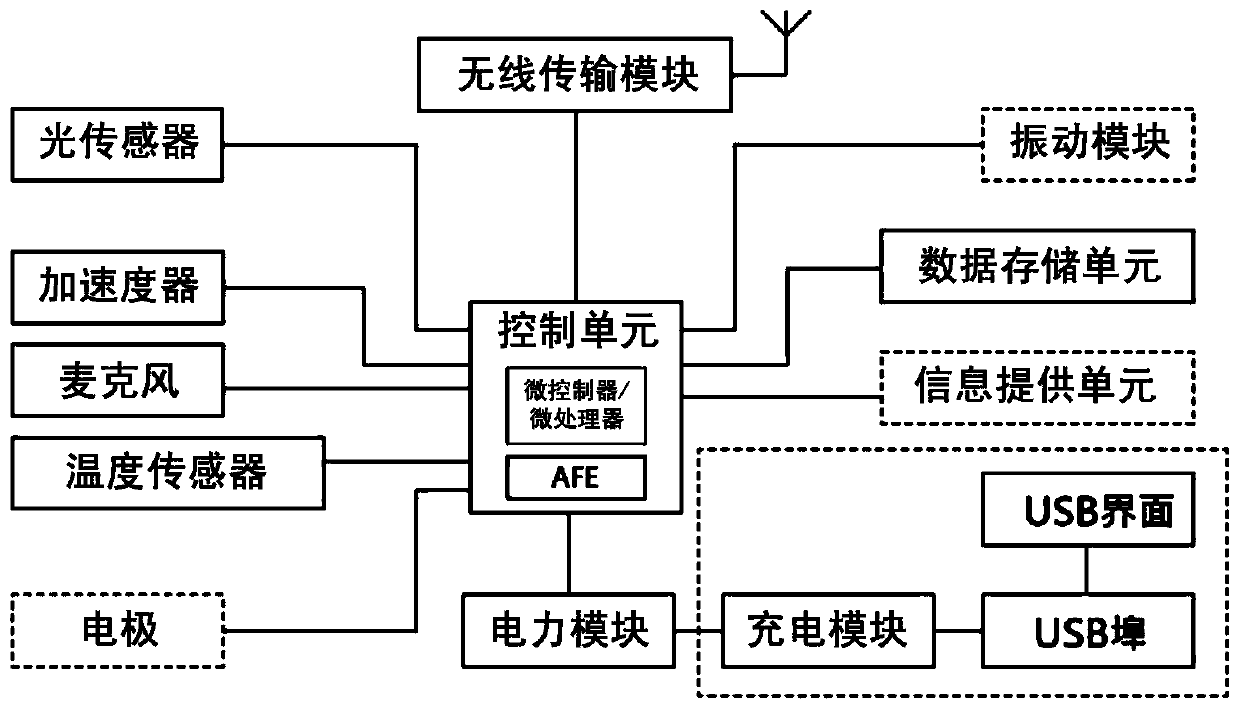

Finger-wearing physiological device and system

PendingCN110251095AAdjustable finger wear structureWith fine-tuning functionSnoring preventionDiagnostic recording/measuringRelevant informationEngineering

The invention relates to a finger-wearing physiological device and system, wherein the finger-wearing physiological device includes a shell, an adjustable finger-wearing structure, a control unit, at least one light source, at least one light detector, and a vibration module. Through the adjustable finger-wearing structure, the finger-wearing physiological device is arranged on a finger of a user to obtain a blood physiological signal of the user during sleep of the user; according to the blood physiological signal, relevant information of a breathing event of the user can be obtained, and the vibration module generates vibration according to the relevant information of the breathing event, so as to generate vibration warning for the user.

Owner:周常安

Artificial intelligence controlled polishing device with fine adjustment function

InactiveCN106944924AApplicable processing requirementsAdjustable angleGrinding carriagesGrinding drivesMotor driveEngineering

The invention relates to the technical field of artificial intelligence, and discloses a grinding device with a fine-tuning function that can be controlled by artificial intelligence. Spring, the opposite side of the support feet is fixedly installed with a slanting block with one end at the bottom of the installation base, the top of the installation base is fixedly installed with a vertical plate, and the front surface of the vertical plate is fixedly installed with a fixing seat. The middle part of the inner cavity is provided with a cavity that runs through the inside of the fixing seat, a motor seat is fixedly installed on the side close to the vertical plate in the cavity, and a driving motor is fixedly installed on the top of the motor seat. The grinding device with fine-tuning function that can be controlled by artificial intelligence is equipped with a forward and reverse motor, and the forward and reverse motor drives the fixed seat to rotate on the front surface of the vertical plate through the rotating shaft, so that the angle of the grinding disc can be adjusted, which is suitable for different workpieces. Processing requirements.

Owner:张荣法

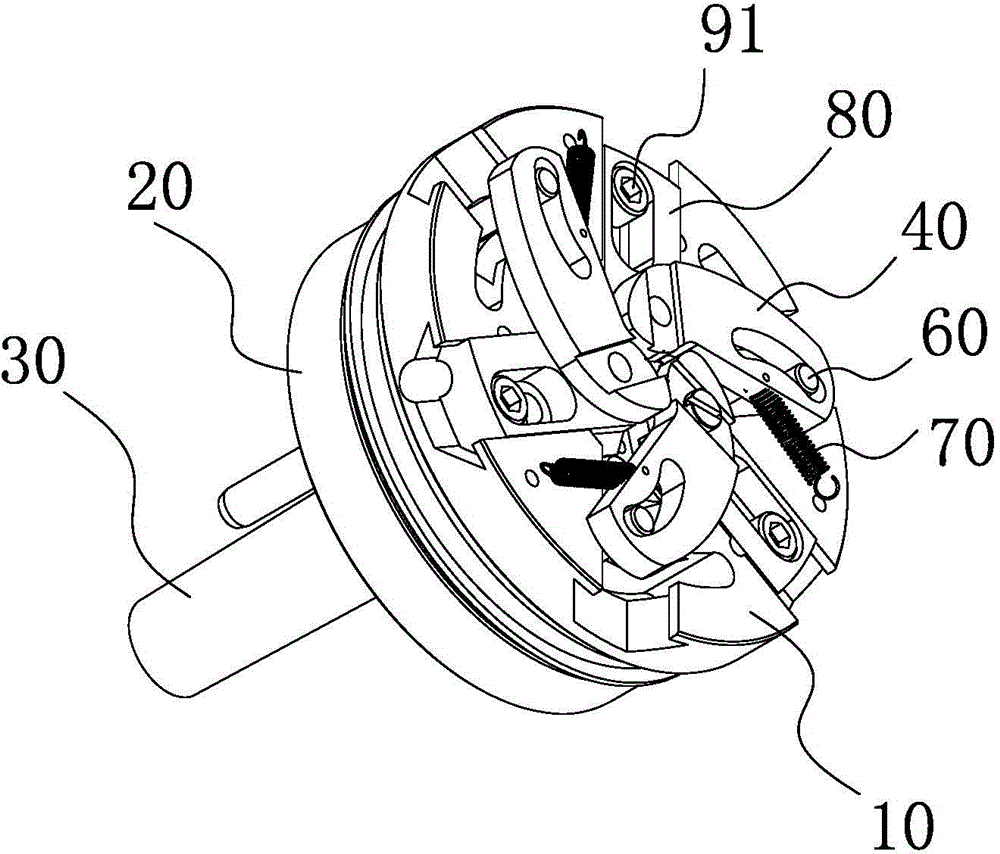

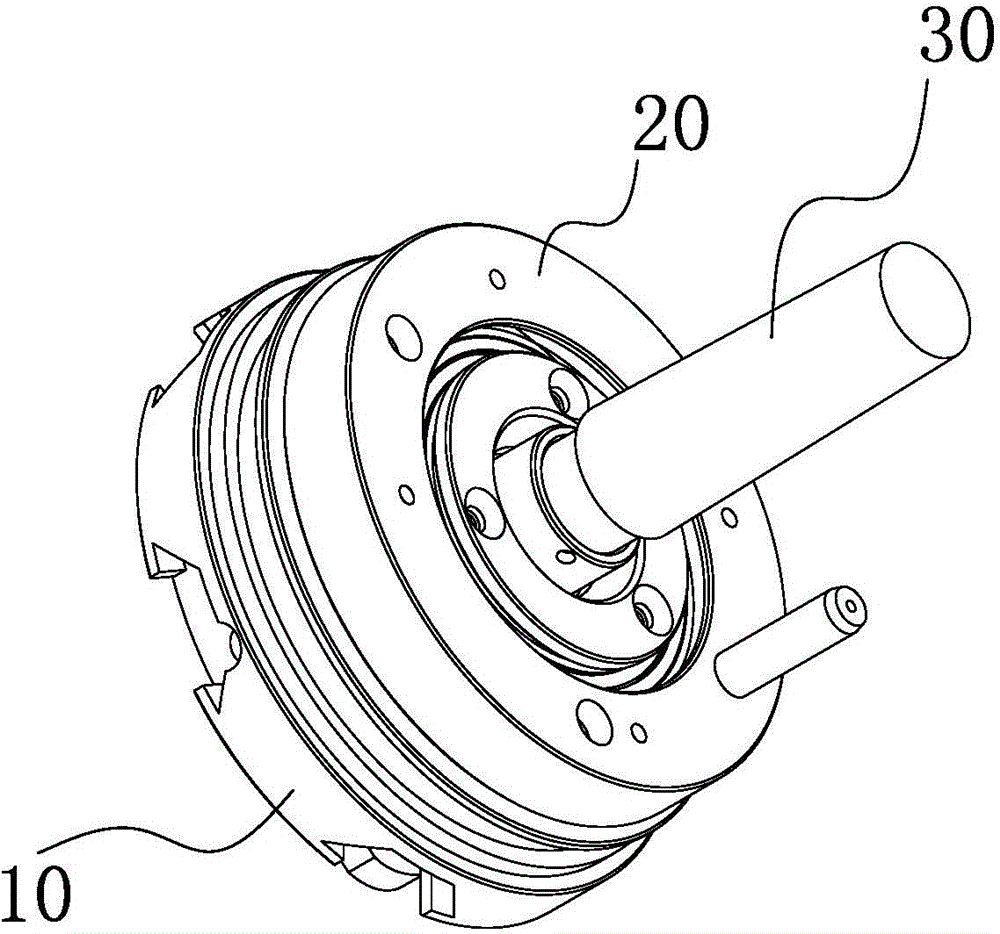

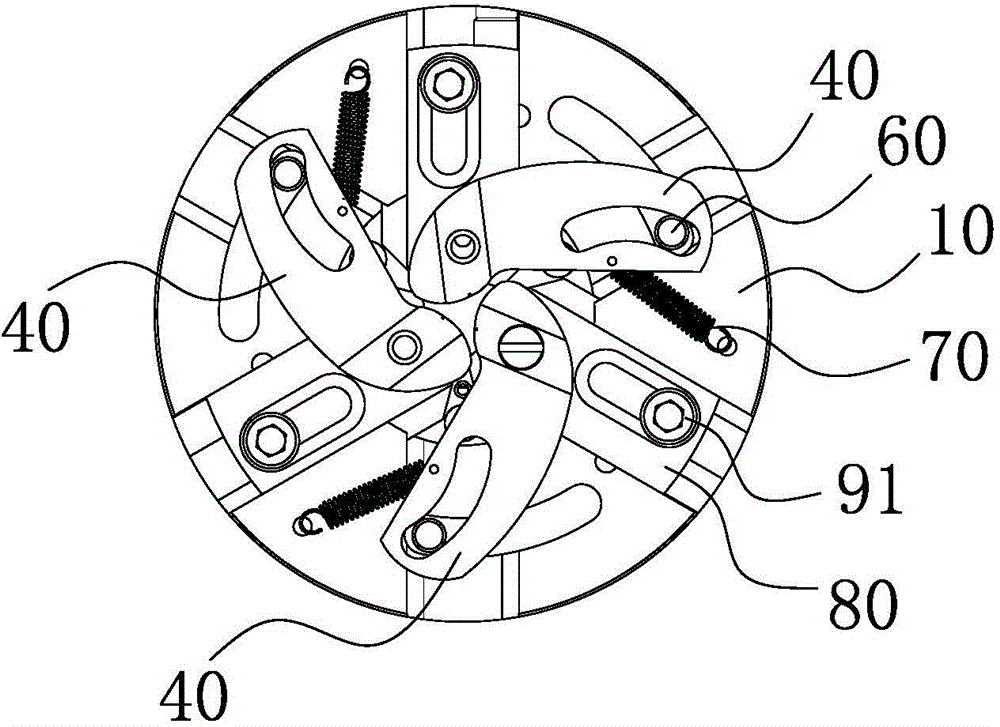

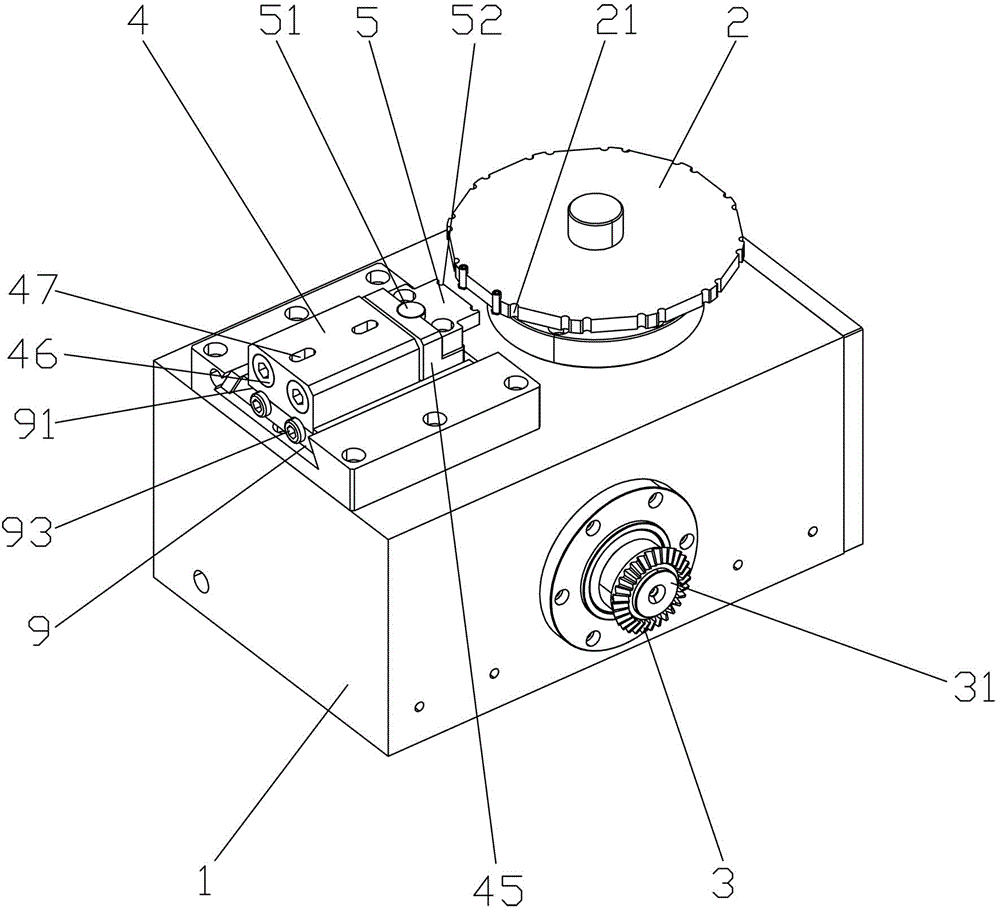

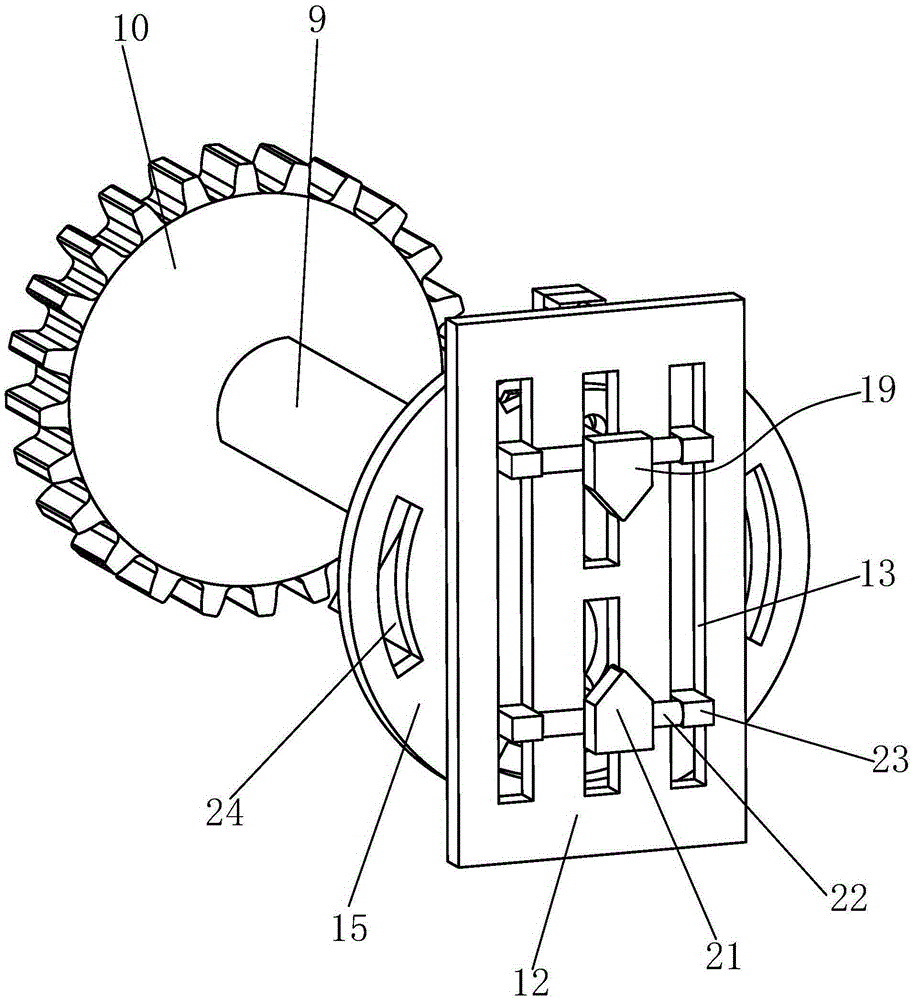

Novel divider

ActiveCN104440018ASimple structureGuaranteed work efficiencyWork holdersMetal working apparatusEngineeringCam

The invention discloses a novel divider which comprises a machine base, a rotary disk arranged on the machine base and a power input end. Positions are distributed on the outer edge of the rotary disk. A push block capable of stretching and retracting forwards and backwards is arranged behind the rotary disk. The end, facing the rotary disk, of the push block is provided with a clamping block. The machine base is also provided with a driving spindle connected with the power input end. A cam is mounted in the middle of the driving spindle in a sleeving mode. An index plate is arranged beside the cam. Indexing rollers capable of clamping a straight flange and an oblique flange are distributed along the circumference of the index plate. The index plate is connected with the rotary disk through an indexing shaft. A movable lever shaft is arranged behind the driving spindle. A lever block facing the rear side of the movable lever shaft is arranged in the middle of the movable lever shaft. The lever block is connected with a push block lever shaft in a rotatable mode. According to the divider, through a reasonable structural improvement and especially through the design of simultaneous linkage of the index plate and the push block, the effect that stepping indexing and stretch and retraction of the push block are controlled simultaneously through one divider is achieved.

Owner:FOSHAN HUIJIE AUTOMATED MACHINERY

Panel overturning and micro-adjusting mechanism

ActiveCN104308441ACompact structureReasonable structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectromagnet

A panel overturning and micro-adjusting mechanism comprises a rack. An oil cylinder base is fixed in the rack through a second pin shaft, the output end of the oil cylinder base is connected with an overturning arm, the overturning arm structurally comprises an overturning arm body, a bottom plate is fixed in the overturning arm body, a jacking oil cylinder is mounted on the bottom plate, and the top of the bottom plate is connected with the side wall of the overturning arm body through a third pin shaft; a movable base of a right-angled structure is fixed on the left side wall in the middle of the overturning arm body through a pressing block, an adjusting washer and bolts, and an electromagnet and a support block are mounted on the long right-angle side of the movable base; the overturning arm further comprises a pull rod oil cylinder connected with a stop pin, and the stop pin and the pull rod oil cylinder which are connected are mounted at the bottom of the short right-angle side of the movable base through driving keys; a support is mounted on the lower portion of the overturning arm body, an optoelectronic switch is mounted on the support, and a bent portion is arranged at the bottom of the overturning arm body. The panel overturning and micro-adjusting mechanism is high in production efficiency and good in safety.

Owner:WUXI HUALIAN SCI & TECH GROUP

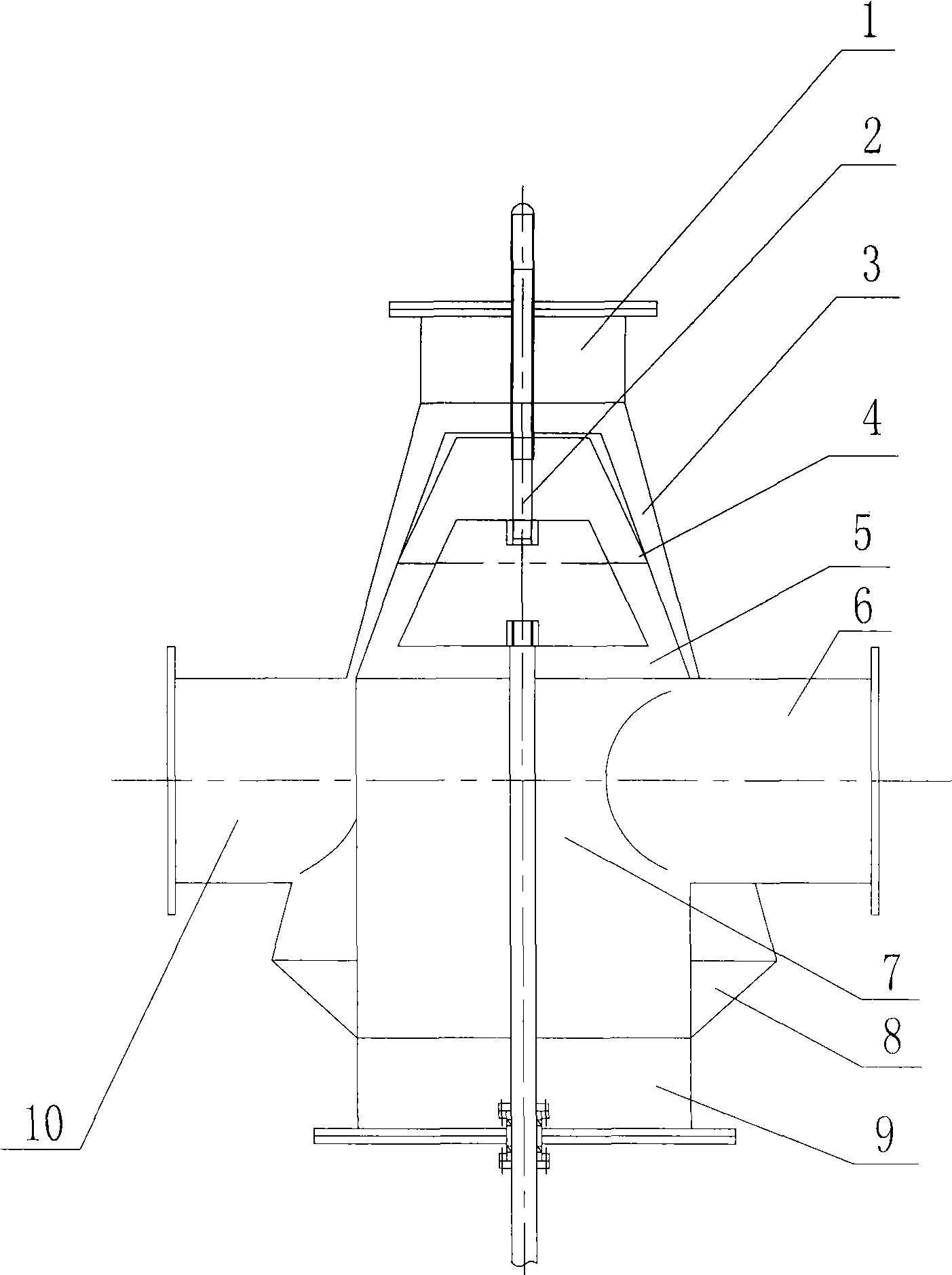

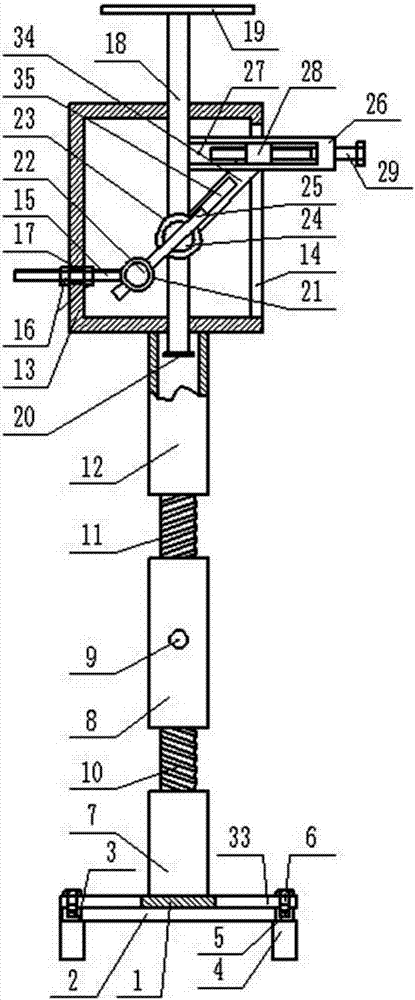

Building support and method of using same

The invention relates to the field of buildings, in particular to a building support and a method of using the same; the building support comprises a bottom plate, a stabilizing device is arranged on the bottom plate, a first adjusting device is arranged on the upper end face of the bottom plate, and a second adjusting device is arranged on an upper support barrel of the first adjusting device. The building support is convenient to operate, the height of the building support can be adjusted from different positions, the building support is applicable to more complex supporting environments, is more convenient to detach, has fine adjustment function, and can provide precise supporting for formworks, preventing breakage occurring to the joints of two formworks.

Owner:济宁弗森机电科技有限公司

Fully-automatic grinder

InactiveCN104493676ADoes not affect workHigh degree of automationGrinding machinesGrinding feedersReciprocating motionEjection Seats

The invention provides a fully-automatic grinder, belongs to the technical field of machinery, and solves the problem that an existing grinder is large in floor area. The fully-automatic grinder comprises a frame, the frame is divided into a conveying area and a machining area sequentially from front to back, an incoming mechanism and a feeding mechanism are arranged in the conveying area, a spindle box and a discharging mechanism are arranged in the machining area, the discharging mechanism and the incoming mechanism are arranged on two sides of the spindle box respectively, the feeding mechanism is arranged over the incoming mechanism and capable of linearly reciprocating between the incoming mechanism and the spindle box, a floating chuck is mounted on the spindle box, and an ejection seat is further arranged on the frame and located right ahead the spindle box. The fully-automatic grinder has the advantages of small floor area and high automation degree.

Owner:NINGBO MEIDE ROBOT

Optical height adjusting device

InactiveCN1521763ADoes not affect degrees of freedomWith coarse tuningInstrumental componentsMechanical engineeringEngineering

Owner:IND TECH RES INST

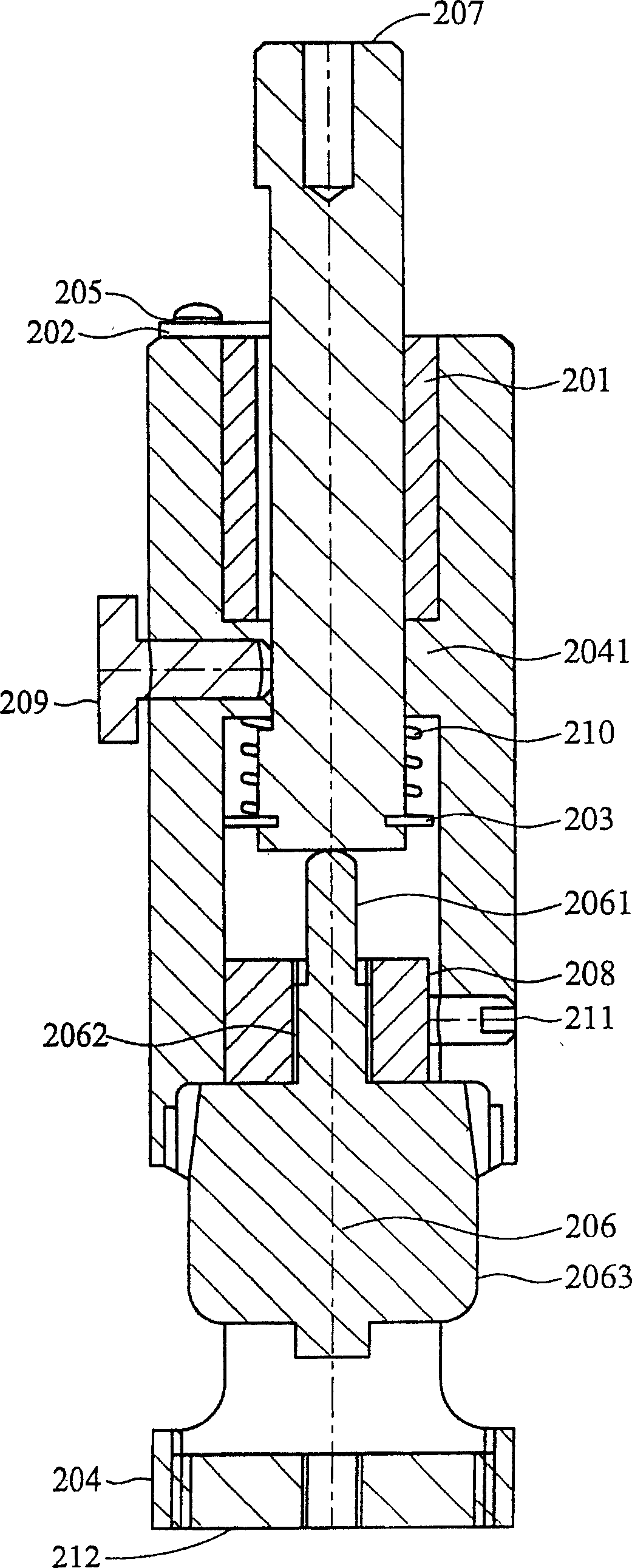

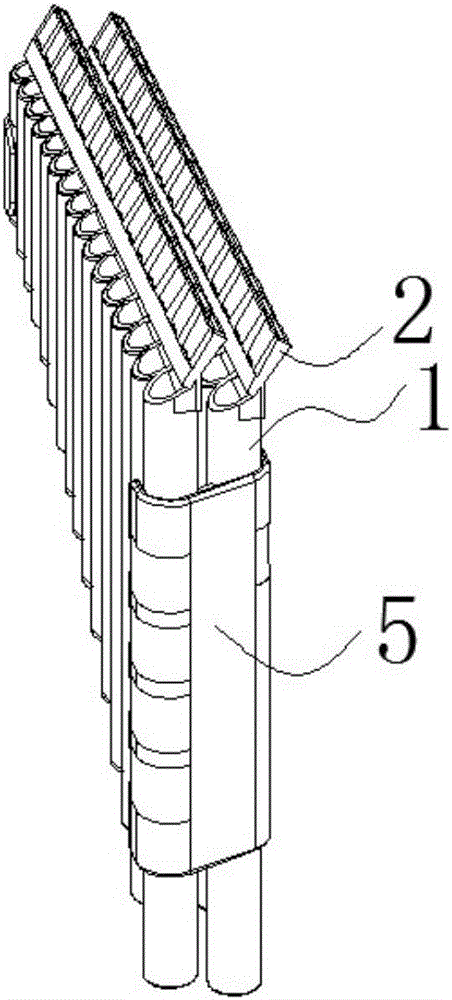

Panpipe

ActiveCN106098033AImprove structural strengthAccurate pronunciationWind musical instrumentsMechanical engineeringTimbre

The invention discloses a panpipe. The panpipe includes tone pipes and a blow nozzle. A plurality of tone pipes are provided and blowing openings of the plurality of tone pipes are arranged at same one ends of the plurality of tone pipes. One blow nozzle is provided and the blow nozzle is a stripe-block-shaped structure which matches the sum lengths of the plurality of tone pipes which are in side-by-side arrangement. The nozzle is in fixed installation to the plurality of tone pipes and the entire body of the blow nozzle is inclined with a lower end directing at the blowing openings. The blow nozzle is provided with blowing through holes communicating the upper end surface and the lower end surface in the inclining direction of the blow nozzle. The blow through holes have the same number as that of the plurality of tone pipes and are arranged in the length direction of the blow nozzle and correspond to the blowing openings of the plurality of tone pipes one by one. The panpipe is characterized in that the external surface in the length direction of the blow nozzle is separately provided with protruding structures formed by the outward protruding of the positions corresponding to respective blow through holes. According to the invention, the panpipe has simple and reasonable structure, enables the finding of tone positions and the best blowing pint required in one music in a rapid and accurate manner, has excellent tone quality fusion, does not require blowing training, lowers difficulty of playing and studying, and enables panpipe playing simply by putting the panpipe in the mouth.

Owner:重庆云雀音乐器材有限公司

Welding jig for IP body lower middle installation support assembly

ActiveCN103934621AMake up for the defect of poor adjustabilityAvoid repeated disassemblyWelding/cutting auxillary devicesAuxillary welding devicesAcute angleFixed frame

The invention relates to a welding jig for an IP body lower middle installation support assembly. The welding jig comprises a small angle seat, wherein the included angle between the upper lateral side of the small angle seat and the horizontal plane is an acute angle, an oblique fixing frame is fixed on the upper lateral side of the small angle seat, a driving and guiding device is fixedly installed on the oblique fixing frame, a lateral vertical plate is connected to the upper side of the driving and guiding device, a front connecting plate is arranged at the front end of the lateral vertical plate, two-freedom-degree hole setting distance adjustment devices are symmetrically connected to the front side of the front connecting plate, and a clamping device is connected to the rear end of the lateral vertical plate. The welding jig has the advantages of being reasonable in structural design, convenient to operate and control, high in positioning and clamping efficiency and the like. By the adoption of the welding jig, automatic clamping and positioning are realized, the location dimension can be adjusted according to the type and size of a part of the IP body lower middle installation support assembly, the defect of an existing welding jig for the IP body lower middle installation support assembly that adjustability is poor is overcome, operation time is saved, and positioning and clamping efficiency is improved.

Owner:ANHUI DACHANG TECH

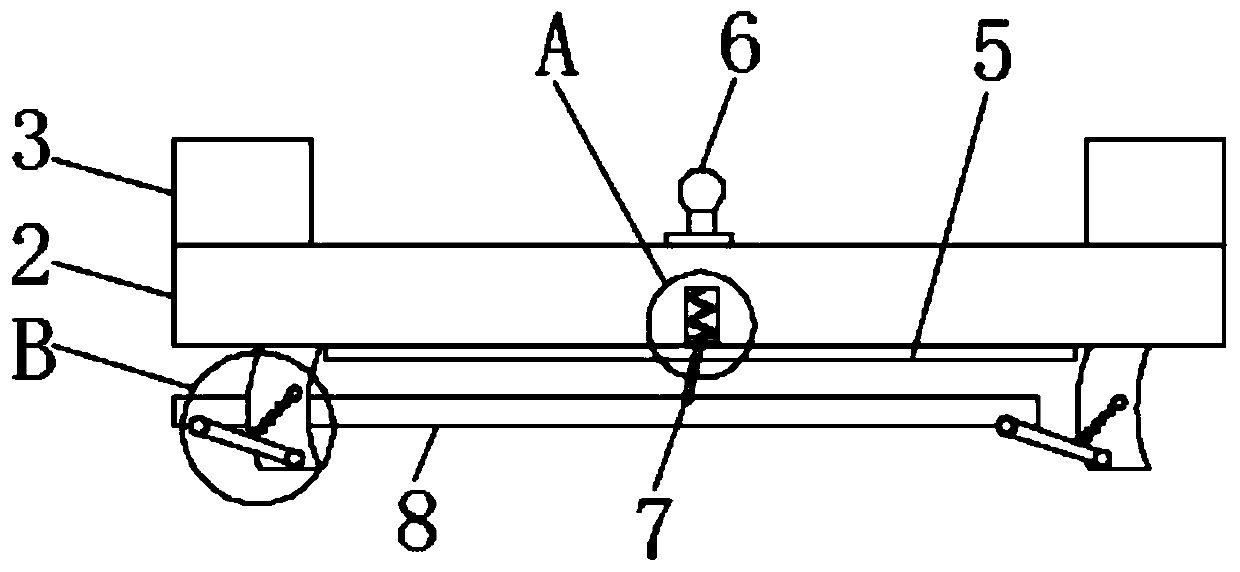

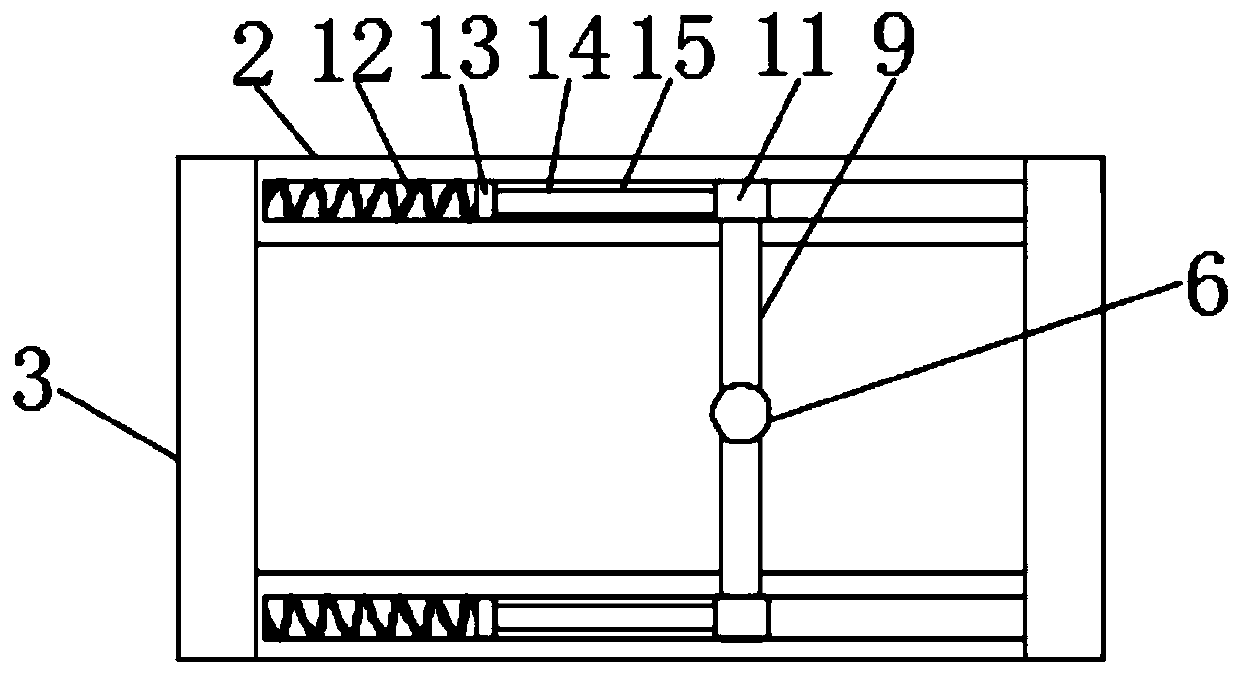

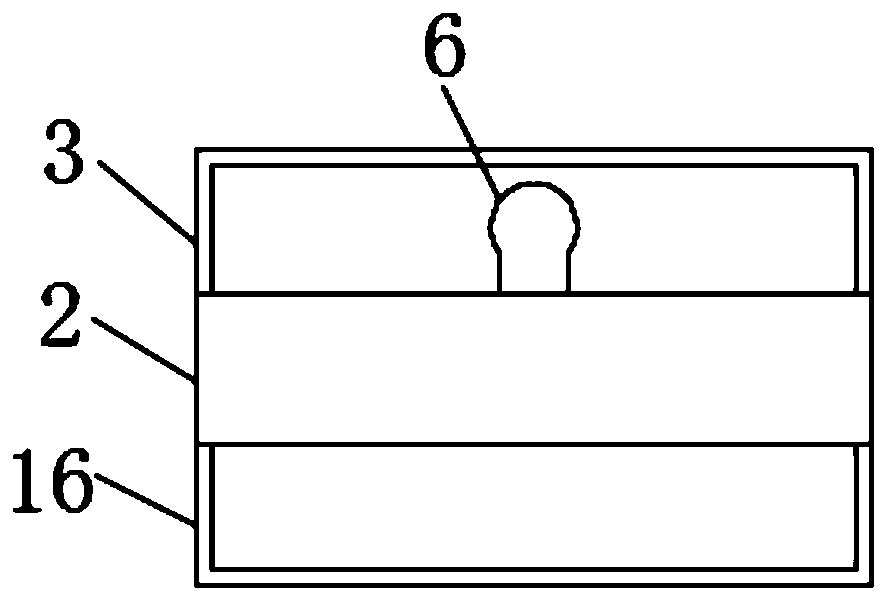

Automatic tightness adjusting type belt fastener capable of automatically adjusting tightness of belt

The invention discloses an automatic tightness adjusting type belt fastener capable of automatically adjusting the tightness of a belt. The belt fastener comprises a fastener body, wherein the two edges of the upper end of the fastener body are symmetrically, vertically and fixedly connected with two upper fixing sleeves, the upper end face of the fastener body are laterally and symmetrically provided with two sliding grooves, each sliding groove is internally and slidably connected with a sliding block respectively, the sides, protruding from the sliding grooves, of the two sliding blocks arejointly connected with a sliding plate, and the middle of the sliding plate is fixedly connected with a lug. The automatic tightness adjusting type belt fastener capable of automatically adjusting the tightness of the belt has the advantages that through the cooperative action of a first spring, a second rotating rod, a lower friction plate, a third spring, a limiting plate, a first rotating rodand an upper friction plate, one end of the belt is tightly clamped between the lower friction plate and the upper friction plate, so that the belt is fixed, the damage to the surface of the belt is avoided, and the integrity of the belt is ensured; the fine adjustment of the tightness of the belt is achieved through the cooperative action of a second spring, a pressing piece, an abutting rod, thesliding blocks, the sliding plate and the lug.

Owner:QING CAN XING HARDWARE CRAFTS CO LTD

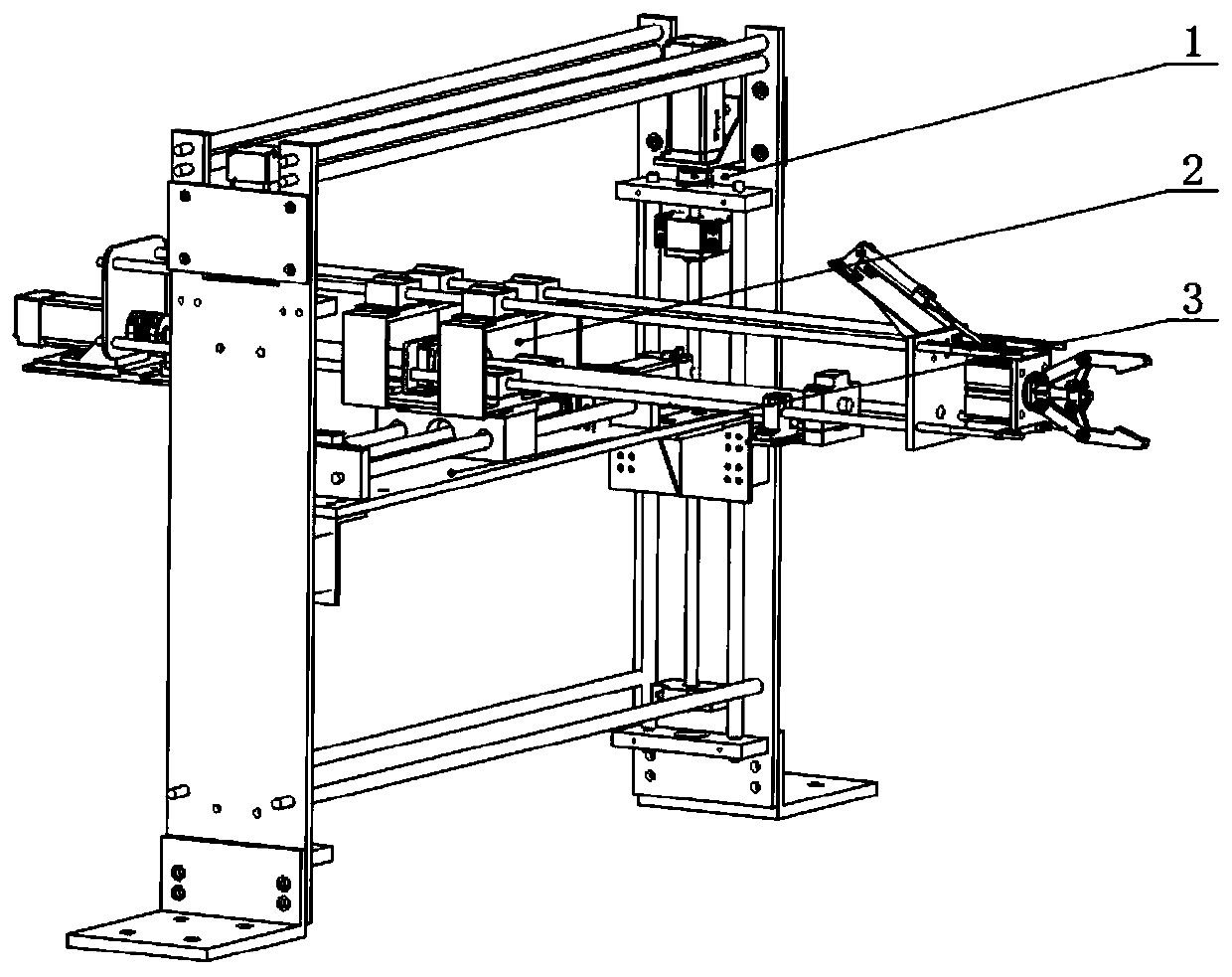

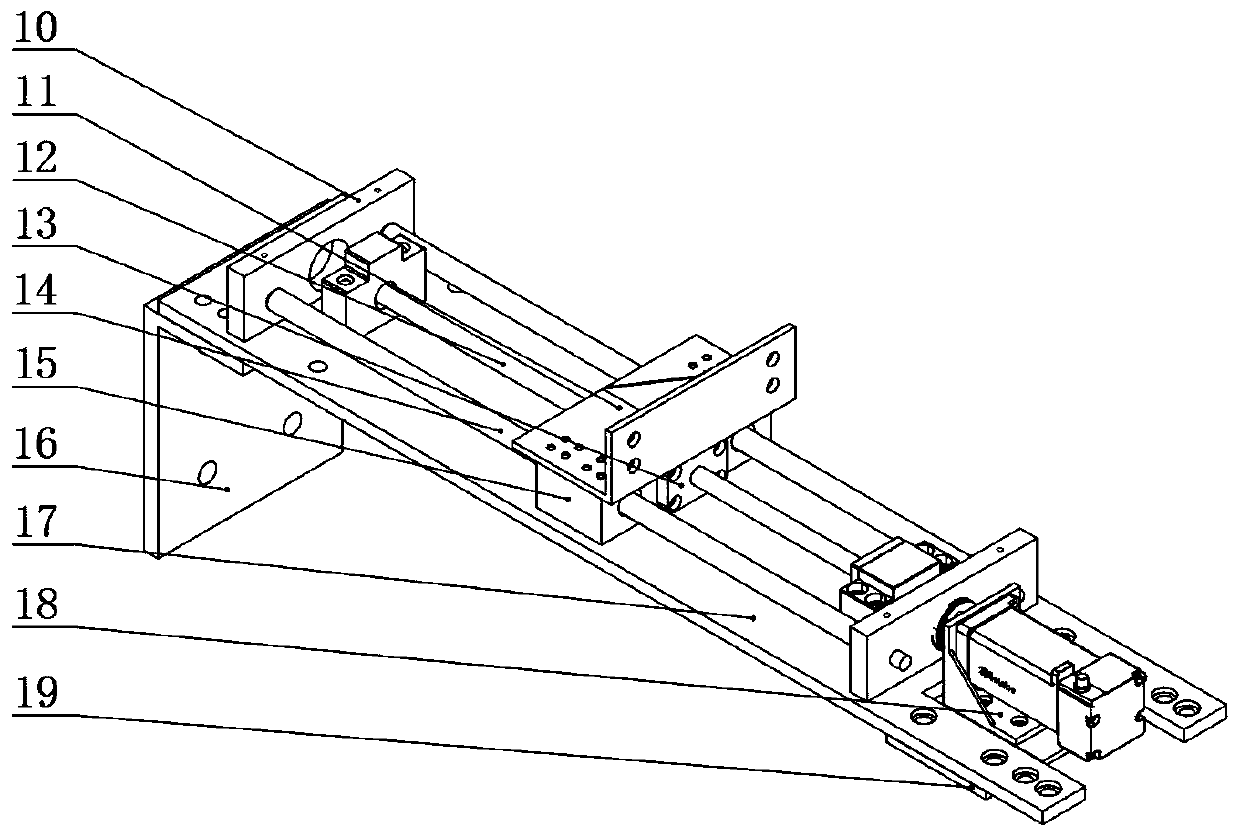

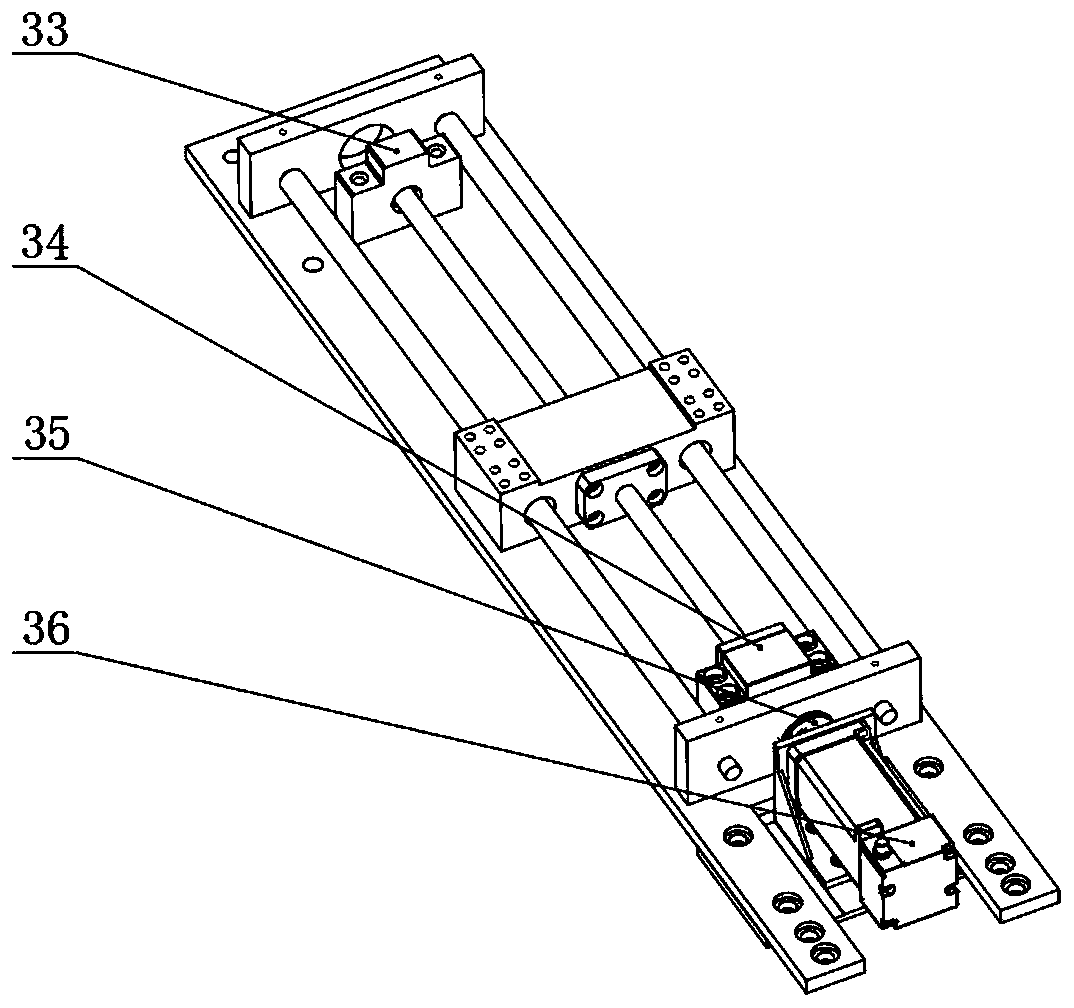

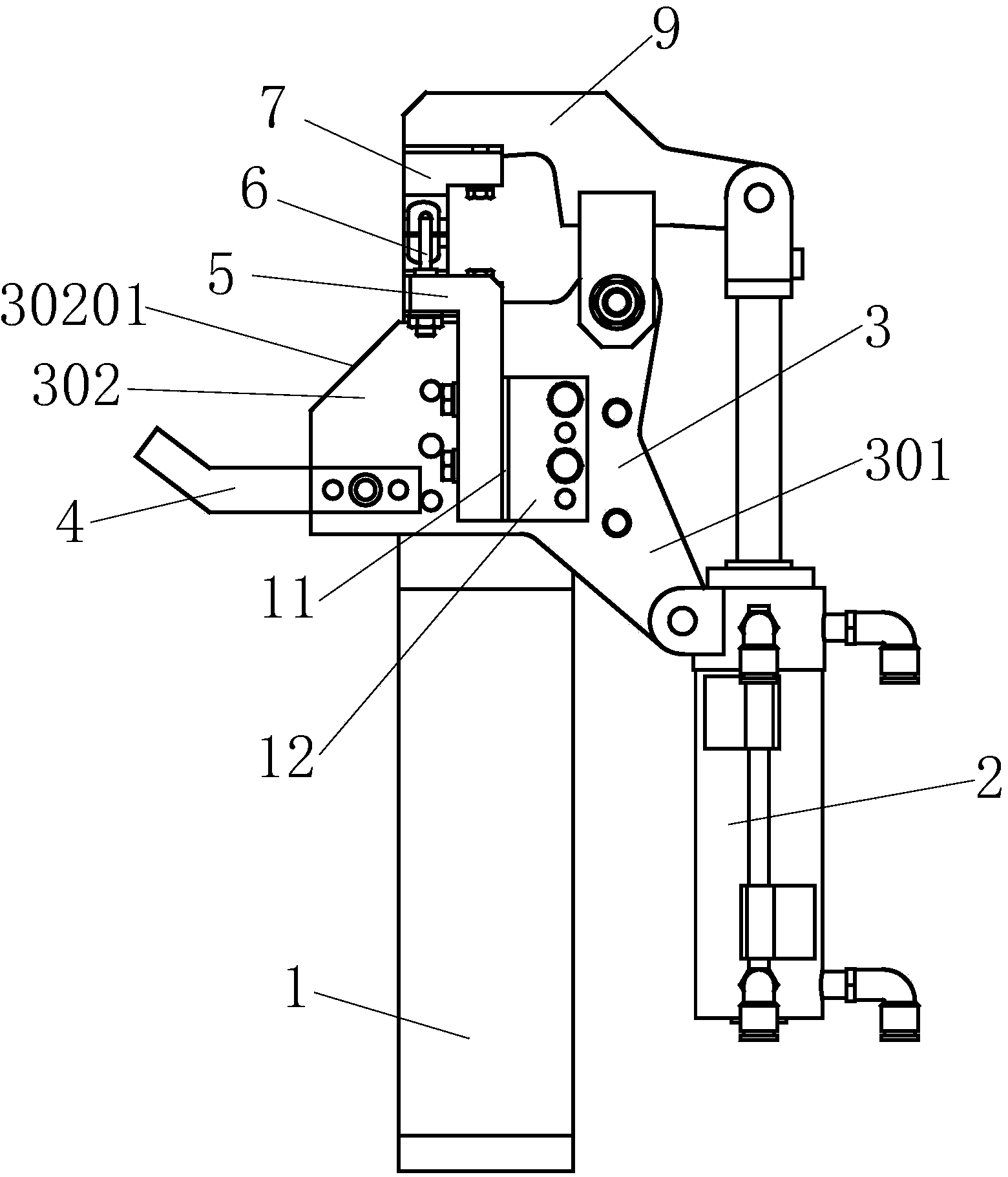

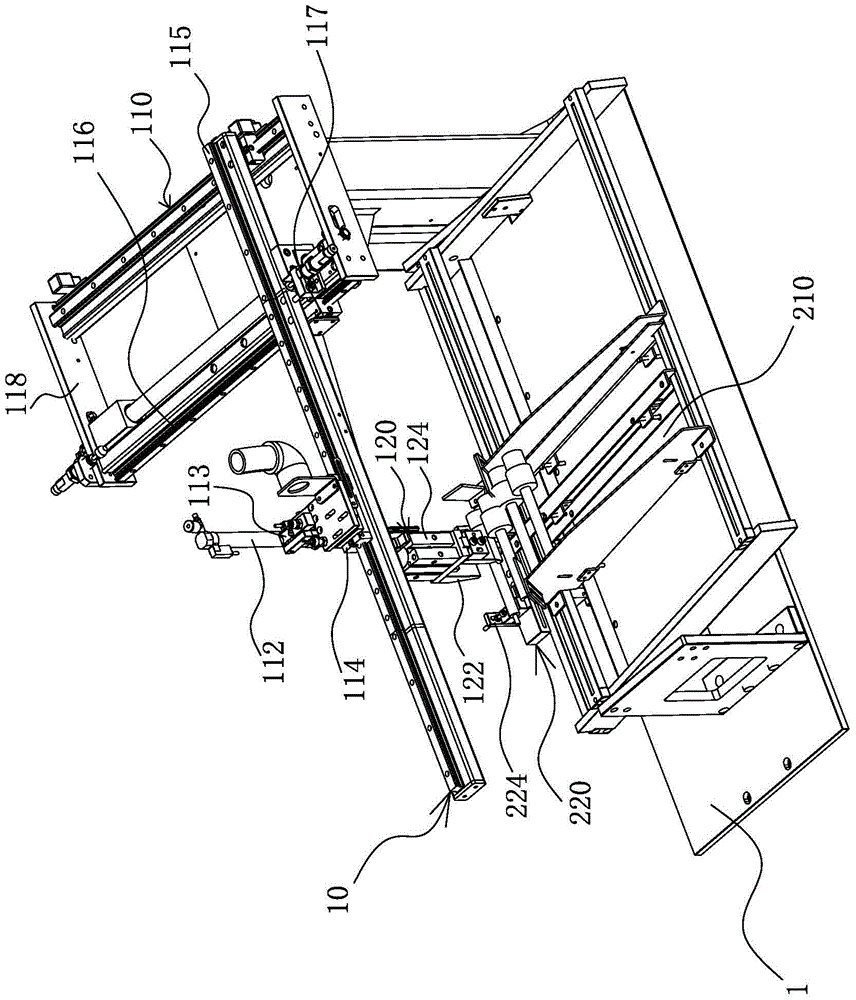

Three-degree-of-freedom fine-adjustment automatic grabbing device

ActiveCN110253548AFully automatedSimple structureProgramme-controlled manipulatorGripping headsThree degrees of freedomStructural composition

The invention provides a three-degree-of-freedom fine-adjustment automatic grabbing device. The device comprises a z-direction sliding table, an x-direction sliding table and a y-direction mechanical arm. The z-direction sliding table comprises a first lead screw, a first lead screw nut, a supporting plate, positioning rods and a positioning rod fixing seat; the structural composition of the x-direction sliding table is the same as that of the z-direction sliding table; the y-direction mechanical arm comprises a y-direction sliding table device, a guide block, a supporting side base, a fine adjustment device, a mechanical gripper device and a power device; and the fine adjustment device comprises a cylinder, a cylinder piston rod, a first connecting rod, a second connecting rod, a third connecting rod and a fixing plate, the cylinder piston rod is connected with the middle of the second connecting rod, the two ends of the second connecting rod are connected with the first connecting rod and the third connecting rod correspondingly, and the fixing plate is used for fixing guide rods. The three-degree-of-freedom fine-adjustment automatic grabbing device is simple in structure, low in cost and high in flexibility and is provided with the fine adjustment device.

Owner:ZHEJIANG UNIV OF TECH

Crossbeam support pole mechanism

InactiveCN1858374AWith telescopic functionWith fine-tuning functionStrutsPillarsAgricultural engineeringSelf locking

The present invention discloses a kind of low cost crossbeam supporting column mechanism with screws and trimming nuts. The low cost crossbeam supporting column mechanism possesses telescoping function, trimming function and self locking function. It has easy assembling and disassembling, flexible use and low cost.

Owner:李博

a splitter

ActiveCN104440018BSimple structureGuaranteed work efficiencyWork holdersMetal working apparatusEngineeringCam

The invention discloses a novel divider which comprises a machine base, a rotary disk arranged on the machine base and a power input end. Positions are distributed on the outer edge of the rotary disk. A push block capable of stretching and retracting forwards and backwards is arranged behind the rotary disk. The end, facing the rotary disk, of the push block is provided with a clamping block. The machine base is also provided with a driving spindle connected with the power input end. A cam is mounted in the middle of the driving spindle in a sleeving mode. An index plate is arranged beside the cam. Indexing rollers capable of clamping a straight flange and an oblique flange are distributed along the circumference of the index plate. The index plate is connected with the rotary disk through an indexing shaft. A movable lever shaft is arranged behind the driving spindle. A lever block facing the rear side of the movable lever shaft is arranged in the middle of the movable lever shaft. The lever block is connected with a push block lever shaft in a rotatable mode. According to the divider, through a reasonable structural improvement and especially through the design of simultaneous linkage of the index plate and the push block, the effect that stepping indexing and stretch and retraction of the push block are controlled simultaneously through one divider is achieved.

Owner:FOSHAN HUIJIE AUTOMATED MACHINERY

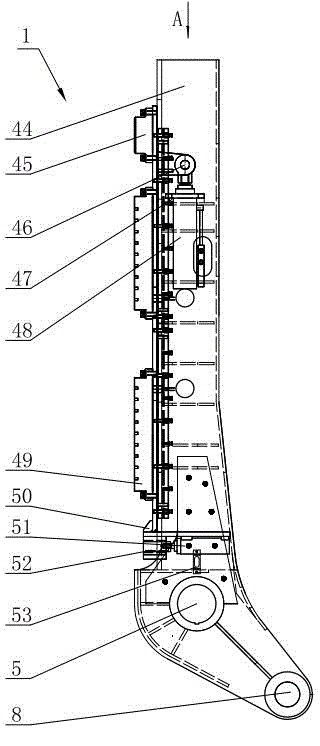

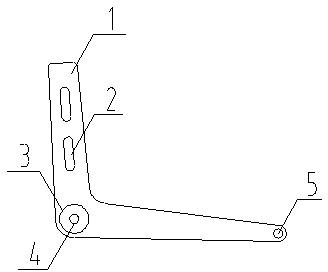

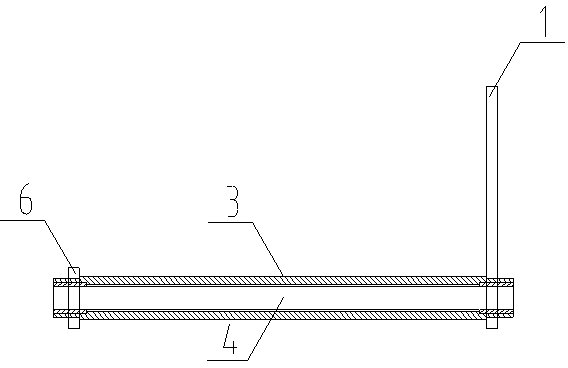

Driving swing arm rack

InactiveCN104192455AWith fine-tuning functionAvoid size errorsLarge containersDrive shaftEngineering

The invention discloses a driving swing arm rack which comprises a swing arm rack body. The driving swing arm rack is characterized in that two kidney-shaped holes are formed in the upper end of one side of the swing arm rack body, a driving shaft is connected to the part of the rotating shaft of the swing arm rack body in the Z-axis direction, the driving shaft is provided with a fixing shaft hole, the other end of the swing arm rack is provided with a connecting hole, the driving shaft is provided with a locating plate, and the swing arm rack body is of an L-shaped structure. The driving swing arm rack has the advantages that the arm swing action around the driving shaft on the single aspect is achieved in an optimized mode, meanwhile, the driving shaft is used for driving other connecting mechanisms to run, the structure has the fine adjustment function, the size error in the mounting process is avoided, the structure is simple, mounting is convenient, production efficiency is improved, and production cost is reduced.

Owner:HEFEI SANGUAN PACKING SCI & TECH

Multi-shaft parallel-connection cutting machining device

ActiveCN105234432AImprove processing efficiencyIncreased processing flexibilityLarge fixed membersTurning machinesEngineeringDrive shaft

The invention relates to a multi-shaft parallel-connection cutting machining device. The multi-shaft parallel-connection cutting machining device comprises a sliding rail. The sliding rail is provided with a sliding supporting frame and a sliding rotary disc in a matched mode. A bearing sleeve is installed in the sliding supporting frame, and a transmission shaft is arranged in the bearing sleeve. A driving gear is installed at the front end of the transmission shaft. An arc slideway is arranged on the sliding rotary disc, the inner side and the outer side of the arc slideway are each provided with an arc positioning slideway, and two turning cutter frames can move on the arc slideway. Each turning cutter frame comprises a rotary shaft penetrating through the arc slideway. The rear end of each rotary shaft is provided with a driven gear matched with the driving gear. The front side of each rotary shaft is sleeved with a positioning block located in front of the sliding rotary disc. A plurality of bolts are installed on each positioning block, penetrate through the arc positioning slideway on the corresponding side and are matched with nuts. A plurality of parallel shafts can be machined simultaneously through the multi-shaft parallel-connection turning cutter frames. All turning cutters can be adjusted independently. The machining efficiency and machining flexibility are improved. Two shafts in different distances can be turned.

Owner:HENAN FEILONG WUHU AUTOMOBILE PARTS

Finger-wearing physiological detection device

InactiveCN110251094AAdjustable finger wear structureWith fine-tuning functionSnoring preventionDiagnostic recording/measuringBiomedical engineeringLight detector

The invention relates to a finger-wearing physiological detection device including an inflexible part and a flexible part. Through the flexible part, the inflexible part can be arranged on a finger to obtain an application force toward the circle center of the cross section of the finger and achieve stable contact of at least one light source and at least one light detector on the inflexible part with the finger. Moreover, through the flexible part, the inflexible part can also be arranged on the upper half part or the lower half part of the cross section of the finger according to different needs to obtain different blood physiological information.

Owner:周常安

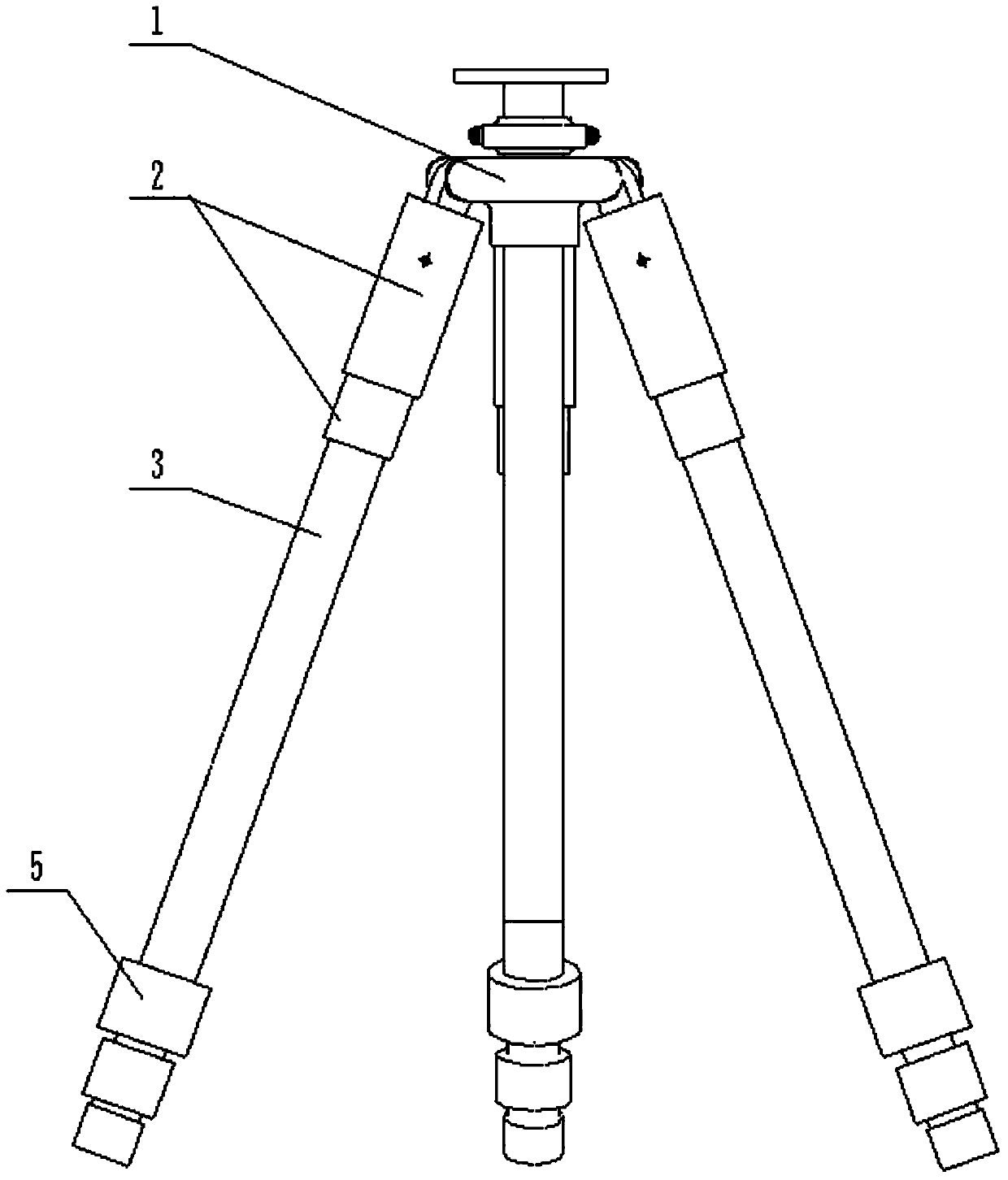

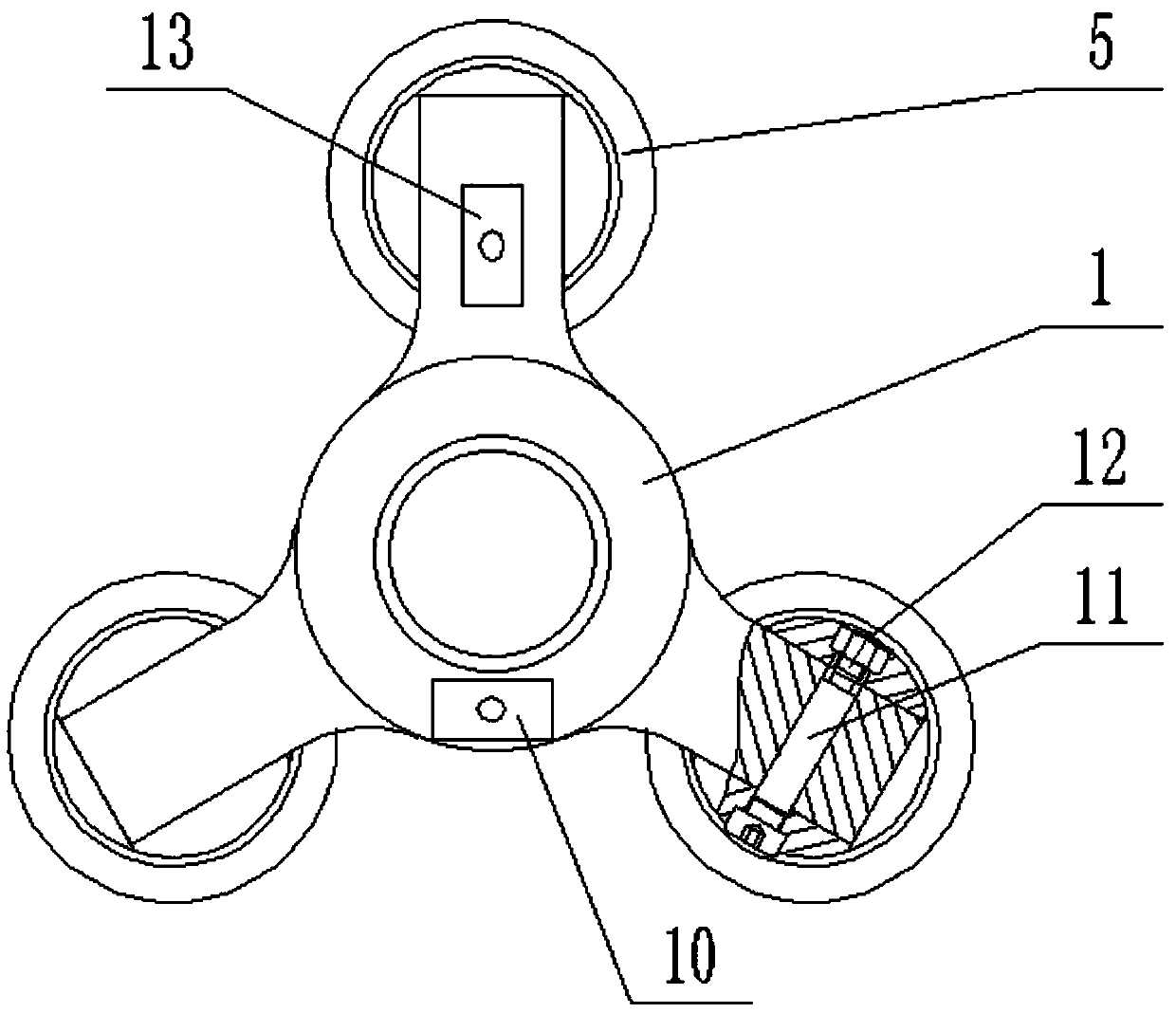

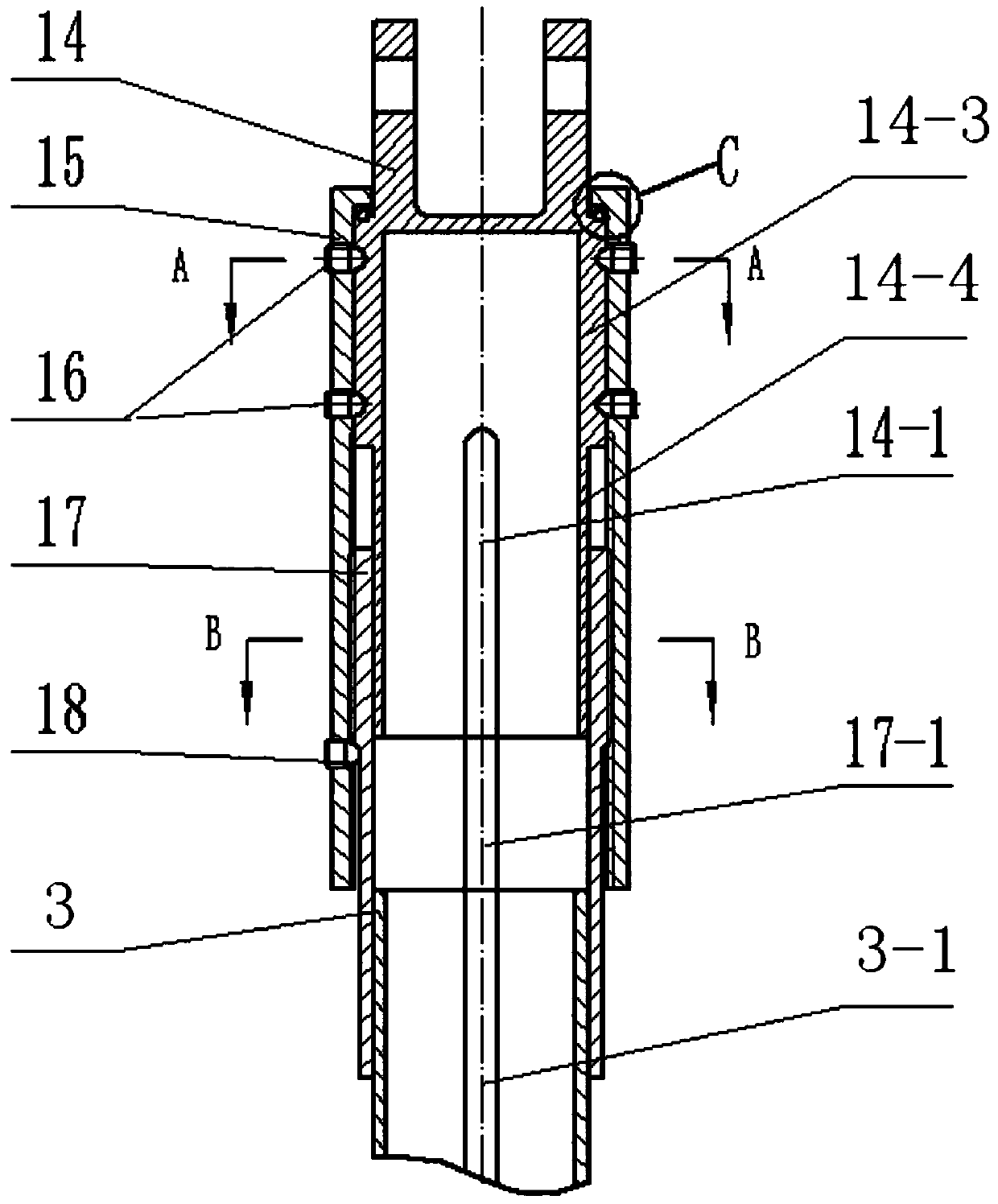

Fine-adjustment level tripod

InactiveCN104215273ARealize scaling fine-tuningEasy to adjustMeasurement apparatus componentsEngineeringScrew thread

The invention discloses a fine-adjustment level tripod. The fine-adjustment level tripod comprises a foot stand, a connecting piece and a connecting end tip, wherein a fine-adjustment mechanism is arranged between the foot stand and the connecting piece and comprises a fine-adjustment coiled pipe and a fine-adjustment guiding pipe; the upper end of the fine-adjustment coiled pipe movably sleeves an outer peripheral wall of an upper connecting head of the connecting end tip; the lower end of the fine-adjustment coiled pipe sleeves the upper end of the fine-adjustment guiding pipe; the fine-adjustment coiled pipe is connected with the fine-adjustment guiding pipe through inner threads and outer threads; a lower connecting head of the connecting end tip is placed in the fine-adjustment guiding pipe; the outer peripheral wall of the lower connecting head is in sliding fit with the inner peripheral wall of the fine-adjustment guiding pipe; a guiding screw is arranged on the fine-adjustment coiled pipe; a guiding annular groove is formed in the outer peripheral wall of the connecting end tip; the head of the guiding screw is inlaid in the guiding annular groove; and when the fine-adjustment coiled pipe rotates, the fine-adjustment guiding pipe drives the foot stand to downwards or upwards move in the axial direction, so that stretching and retracting fine-adjustment on the foot stand is realized. The fine-adjustment level tripod has the advantages of convenience in adjustment, high in accuracy and the like. The fine-adjustment mechanism is simple and compact in structure; and by the fine-adjustment mechanism, a common tripod can be improved and has a fine-adjustment function.

Owner:SOUTH CHINA UNIV OF TECH

Clamp for lower right mounting bracket assembly of IP body

ActiveCN103949835APromote shakingAvoid shakingWelding/cutting auxillary devicesAuxillary welding devicesFixed frameEngineering

The invention relates to a clamp for a lower right mounting bracket assembly of an IP body. The clamp comprises a vertical base, a connecting frame, an air cylinder, a linkage pressing handle, a biasing head, a biasing base, an L-shaped fixed frame, a two-freedom-degree hole positioning distance adjusting device, a positioning hinge pin and a U-shaped bracket, wherein the connecting frame is fixedly connected with the upper end of the vertical base; the L-shaped fixed frame is fixedly mounted on the connecting frame through the two-freedom-degree hole positioning distance adjusting device; a lower connecting part is arranged at the lower right part of the connecting frame; the middle of the linkage pressing handle is connected with the upper end of the connecting frame; a left baffle is arranged on the left side of the connecting frame; the U-shaped bracket is fixedly connected with the lower part of the left baffle; the lower connecting part is connected with the air cylinder; one end of the linkage pressing handle is hinged to the air cylinder; the biasing head is mounted at the other end of the linkage pressing handle; the positioning hinge pin is connected with the upper end of the L-shaped fixed frame in an inserting manner; the biasing base is mounted at the side part of the L-shaped fixed frame. The clamp has the advantages of reasonable structural design, high automation degree, convenience for adjustment and control and the like, realizes automatic clamping and positioning instead of manpower, guarantees the clamping and positioning precision, has a fine adjustment function, and enlarges the application scope.

Owner:ANHUI DACHANG TECH

Suspension device on built net frame steel ball

PendingCN108625521ASimplify the installation processEasy and quick on-site installationBuilding roofsCeilingsKeelSteel ball

The invention relates to a suspension device on a built net frame steel ball. The suspension device is constituted by a hanging rod, a main keel, a double-layer lantern ring, steel wire ropes, an upper flange plate, a lower flange plate and a supporting plate; the double-layer lantern ring is formed by bending rigid materials and connected to supporting rods of the net frame steel ball in a sleeving mode; the upper ends and the lower ends of the steel wire ropes are locked and fixed into annular shapes through embracing hoops; one end of each of the upper flange plate and the lower flange plate is in a disc shape and is provided with a round hole, the other end of each of the upper flange plate and the lower flange plate is in a cylindrical shape, and a threaded hole is formed in the center of the other end of each of the upper flange plate and the lower flange plate; the upper ends of the multiple steel wire ropes are evenly connected into the double-layer lantern ring in a sleeved mode, and the two ends of connectors are fastened through clamping rings; the lower ends of the steel wire ropes are connected with the round hole in the upper flange plate; threads are arranged at theupper end and the lower end of the hanging rod and are in threaded connection with center holes of the upper flange plate and the lower flange plate through back tightening nuts correspondingly; and the I-shaped steel main keel is in threaded connection with the lower flange plate, and modular roof formworks are fixed to the main keel. The suspension device on the built net frame steel ball has the characteristics that the structure of the net frame steel ball is not damaged, the attractiveness of the net frame steel ball is not affected, force bearing is even, the loading amount is large, andsound insulation performance is good.

Owner:北京科奥克声学技术有限公司

A CNC grinding machine

InactiveCN104493677BDoes not affect workHigh degree of automationGrinding machinesGrinding feedersReciprocating motionElectric machinery

The invention provides a CNC (computer numerical control) grinding machine and belongs to the technical field of machinery. The CNC grinding machine comprises a frame, a grinding tool and a bench movably mounted on the frame. The frame includes a conveying area and a processing area sequentially from front to rear. An incoming mechanism and a conveying mechanism are disposed in the conveying area. A spindle box and a discharging mechanism are disposed in the processing area. The discharging mechanism and the incoming mechanism are disposed on two sides of the spindle box. The conveying mechanism is disposed over the incoming mechanism and can linearly reciprocate between the incoming mechanism and the spindle box. A floating chuck is mounted on the spindle box. The frame is provided with an ejector base arranged right in front of the spindle box. The grinding tool is movably mounted right in rear of the spindle box. The spindle box is fixedly connected with the bench. The ejector base is disposed over the bench. The frame is further provided with a first drive motor and a second drive motor; the first drive motor can control the grinding tool to linearly move in the horizontal direction; the second drive motor can control the bench to linearly slide. The CNC grinding machine has the advantages of high automation level and operational convenience.

Owner:NINGBO MEIDE ROBOT

Magnet automatic assembly device for wind turbines

ActiveCN103633792BFully automatedWith fine-tuning functionManufacturing stator/rotor bodiesControl systemEngineering

The invention discloses an automated magnet assembling device for a wind power generator set. The automated magnet assembling device comprises a support device for being fixed with a rotor of the wind power generator set and driving the rotor to rotate, feeders arranged outside the rotor, pushing-in devices arranged inside the rotor, and a control system for controlling the rotation of the rotor, the operation of the feeders and the operation of the pushing-in devices, wherein the feeders comprise supports, feeding slots arranged on the supports and pushing assemblies for pushing magnets to be assembled along the feeding slots; one end of each feeding slot is positioned below a magnetic yoke of the rotor; the feeding slots correspond to magnet assembling slots on the magnetic yoke to push the magnets to be below the magnet assembling slots; the pushing-in devices can push the magnets to preset positions in the magnet assembling slots. The automation of the magnet assembling process is realized by the automated magnet assembling device, the investment of manpower in the assembling process is reduced, and the assembling efficiency and precision are improved.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com