Automated magnet assembling device for wind power generator set

A technology for wind turbines and assembling devices, which is used in the manufacture of stator/rotor bodies, etc., can solve the problems of low efficiency and precision of manual assembly, increase the hidden danger of manual operation, and long assembly time, so as to ensure assembly quality, improve accuracy, The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

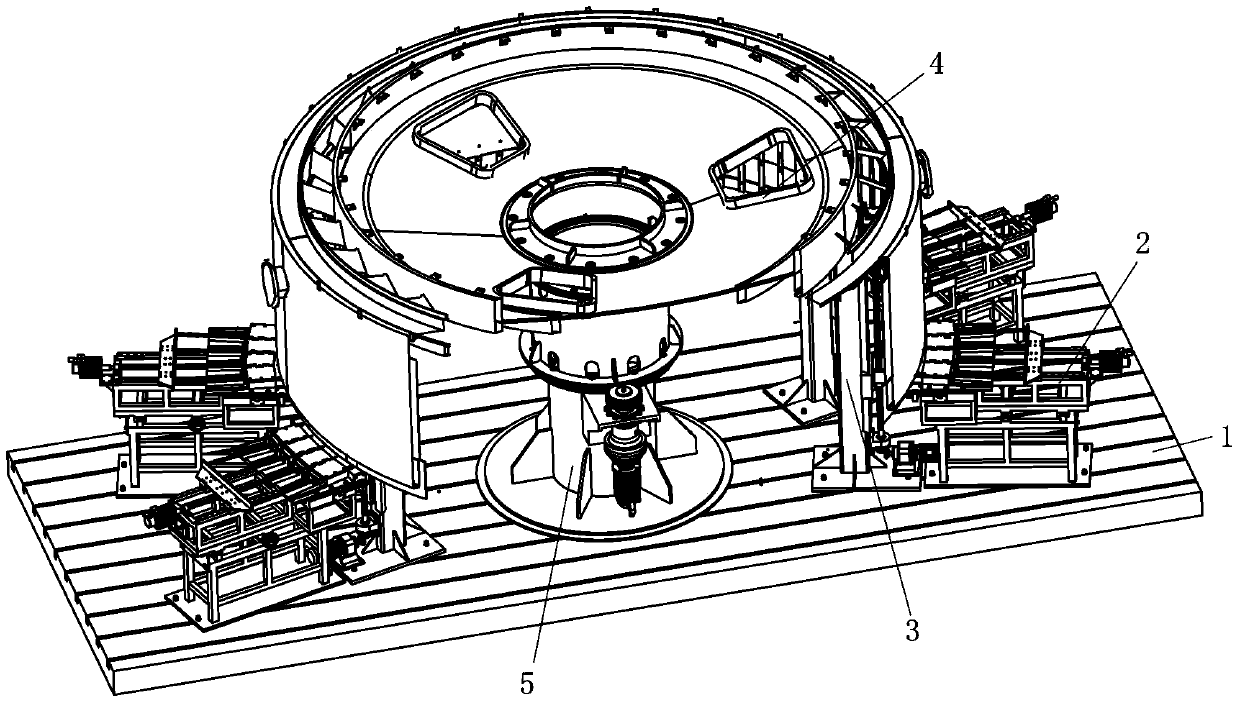

[0033] refer to figure 1 , figure 1 is a structural schematic diagram of an automatic magnet assembly device according to an embodiment of the present invention.

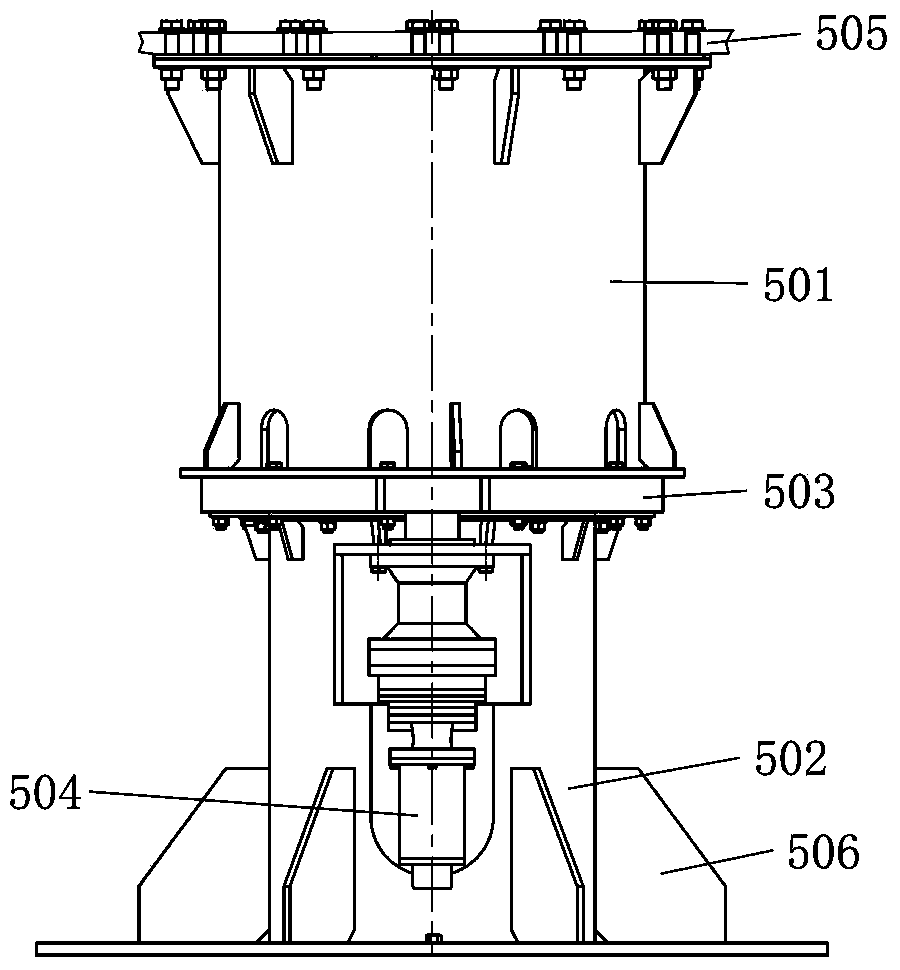

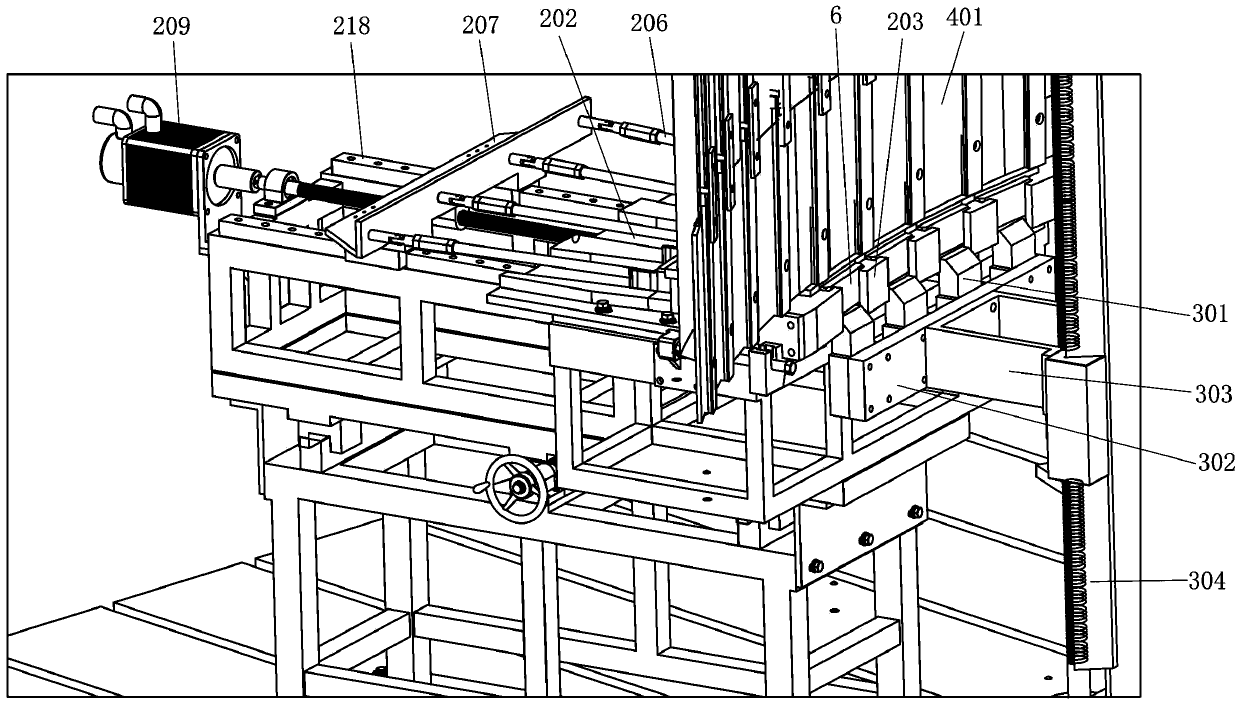

[0034] According to an embodiment of the present invention, the provided magnet automatic assembly device is used for performing magnet assembly work on the rotor 4 of the wind power generating set. The rotor 4 of the wind power generating set has a yoke, which is generally cylindrical, and a plurality of vertical magnet fitting slots 401 for installing magnets are formed on the yoke wall (see image 3 ), the magnet automatic assembly device is used to place the magnet 6 from bottom to top (see image 3 ) is pushed into each vertical magnet assembly slot 401 to a predetermined position. Gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com