Suspension device on built net frame steel ball

A suspension device and steel ball technology, applied in the direction of buildings, building components, building structures, etc., can solve problems such as danger, achieve the effect of simple installation process, distributed force, and solve safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Acoustic wind tunnels are widely used in the inspection fields of various automobiles and their main components, aerospace equipment and nautical ships, and are used to simulate the influence of different wind speed environments on the measured objects. High wind speeds will produce high noise. Therefore, the acoustic wind tunnel is a combination of acoustic anechoic chamber and aerodynamic equipment. Install an acoustic wind tunnel anechoic room with a length x width x height of 50 x 35 x 28m in a large factory building. The sound-proof floor, four walls and the roof are assembled by metal sound-proof modules. The inner surface is installed with 1.2 long metal orifice sound-absorbing wedges according to the design frequency. The total weight of the roof is 135 tons. Due to the large span of the laboratory, it needs Hoist the roof on the original grid structure of the factory roof.

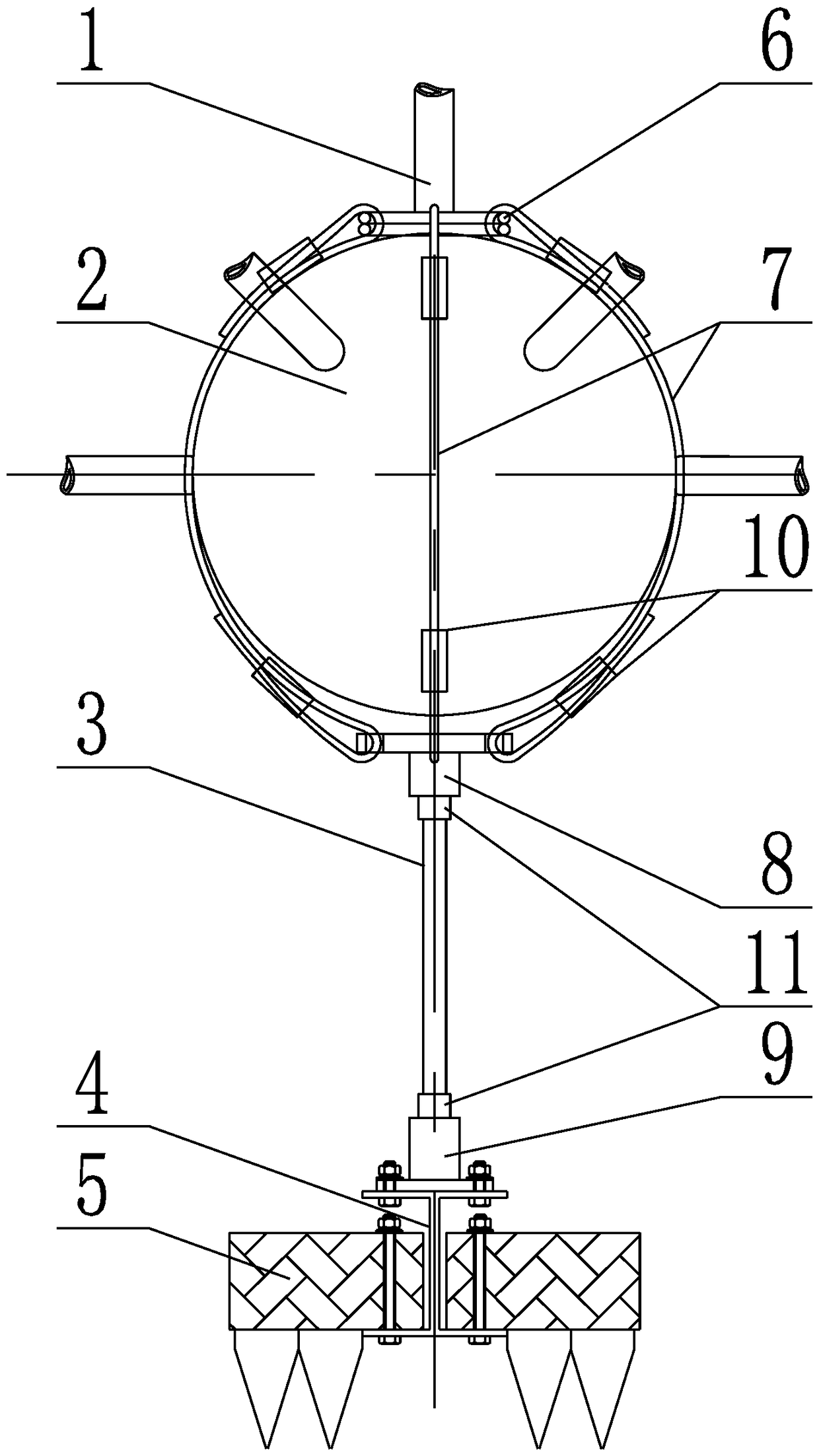

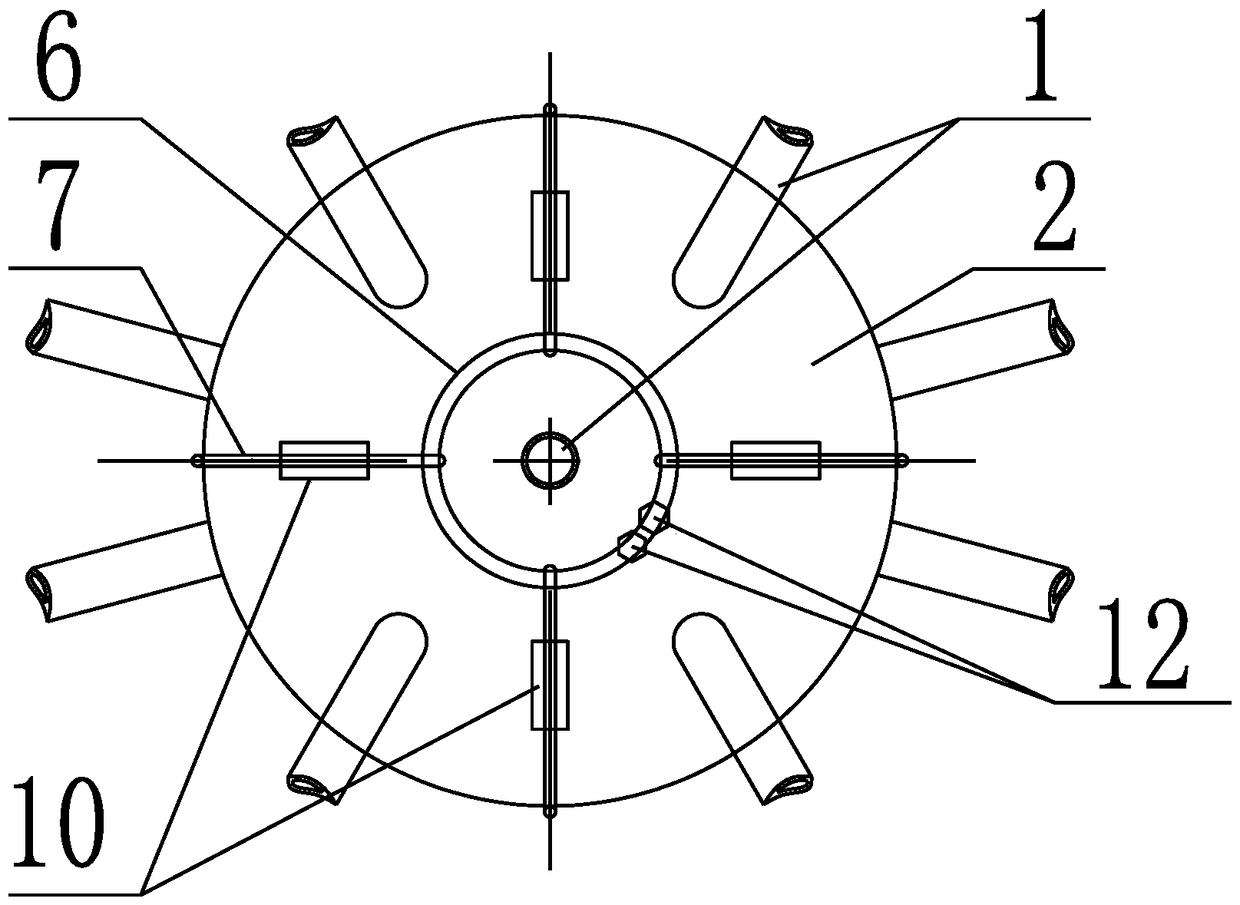

[0020] Such as figure 1 , figure 2 As shown, a suspension device on t...

Embodiment 2

[0025] Example 2: Build a passenger car detection sound insulation room in a large factory building. The volume is length × width × height = 60 × 30 × 8m. Modular metal sound insulation and sound absorption panels are used to make the four walls and the roof, and the part under the roof Ventilation, air conditioning and some testing equipment are installed, the roof is 100mm thick, the density per square meter is 45 kg, and the sound insulation is 45 decibels. Since the roof is not very heavy, according to the density of the grid steel balls, the hanging points are laid out in a dense and dense manner, and 3 steel wire ropes and 6 steel wire ropes are respectively used on the steel balls according to the load. The local dispersion of the line load of the steel wire rope on the steel ball ensures that the steel ball is evenly stressed and does not deform. When the roof is hoisted, the balance force of the roof is adjusted through the suspender 3, and the others are the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com