Patents

Literature

130results about How to "Reduce time spent working at heights" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

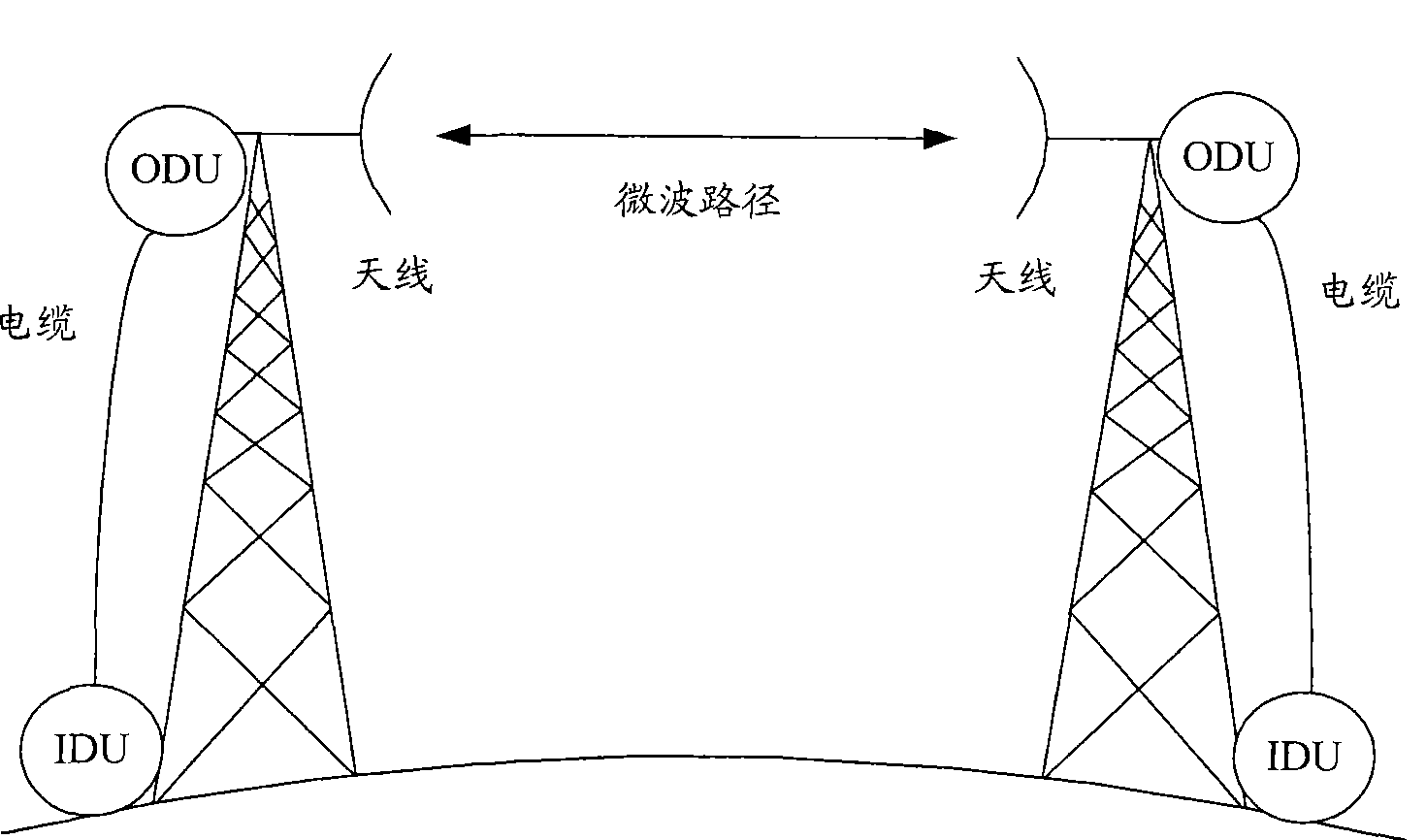

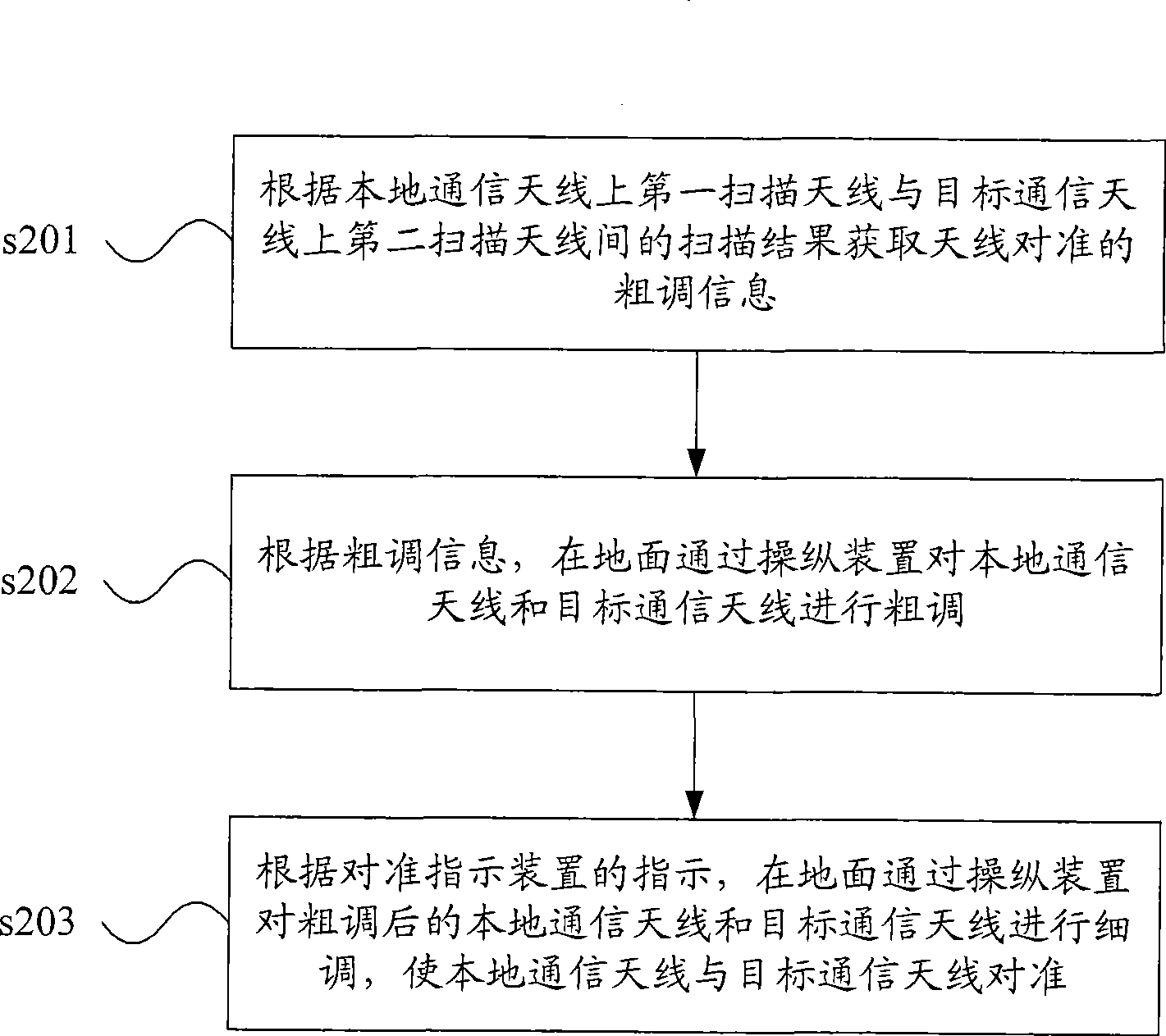

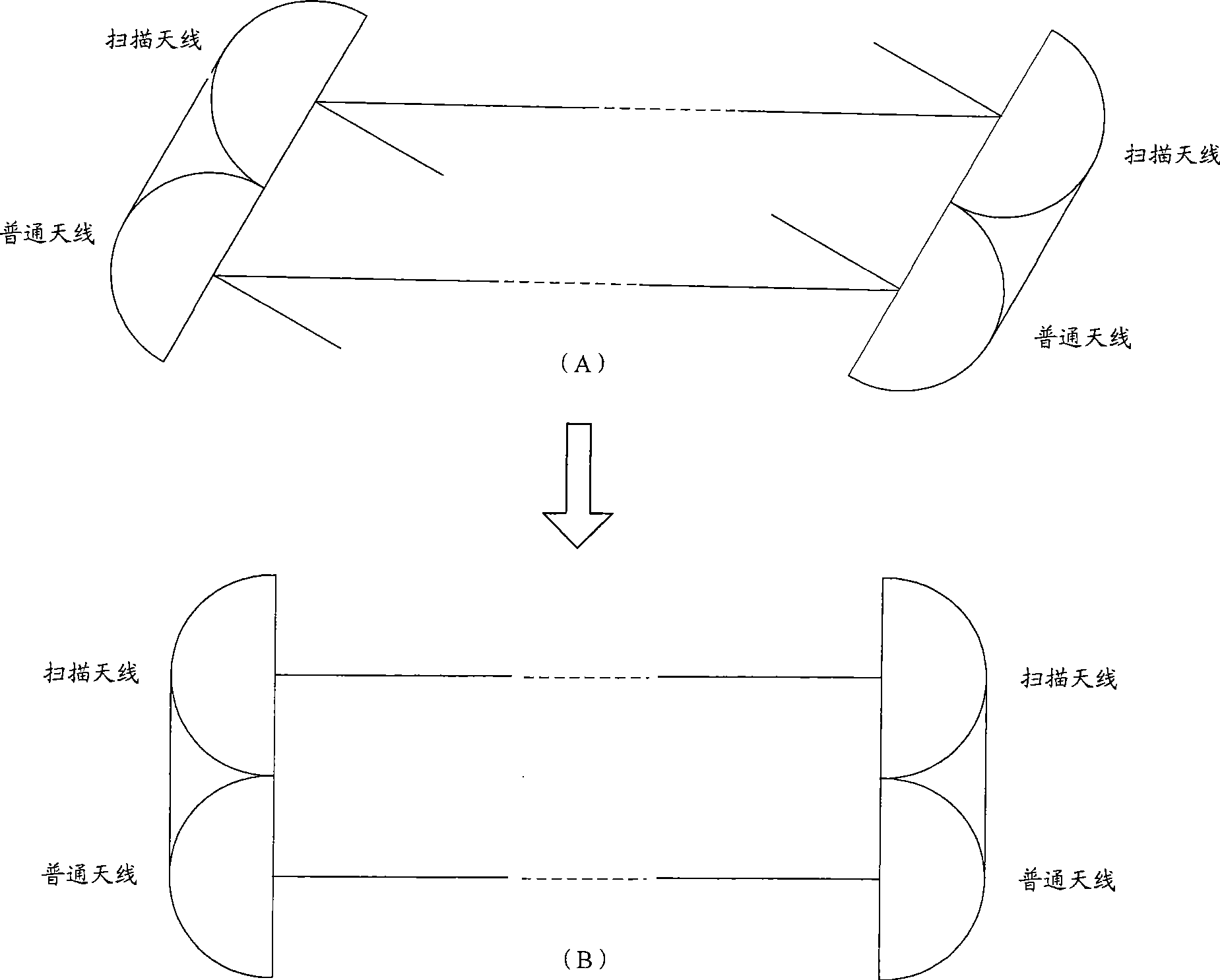

Method, system and device for aligning antenna

InactiveCN101465699AReduce riskImprove alignment efficiencyAntenna supports/mountingsTransmission monitoringTowerElectrical and Electronics engineering

The embodiment of invention discloses an antenna aligning method, a system and a device. The method includes that coarse adjustment information for antenna alignment is obtained according to scanning result between a first scanning antenna of a local communication antenna and a second scanning antenna of a target communication antenna; a control device on ground is adopted to perform coarse adjustment on the local communication antenna and the target communication antenna according to coarse adjustment information; the control device on ground is adopted to perform fine adjustment on the local communication antenna and the target communication antenna after coarse adjustment according to indication from the alignment indicating device, so the local communication antenna is aligned to the target communication antenna. In the embodiment, the control device and the alignment indicating device on ground are adopted to control the antenna direction on the tower top and finish the antenna alignment; the time in high altitude operation is reduced for installation staff, the risk in antenna alignment operation is reduced, and the antenna alignment efficiency is effectively improved; meanwhile, time and labor source are saved.

Owner:HUAWEI TECH CO LTD

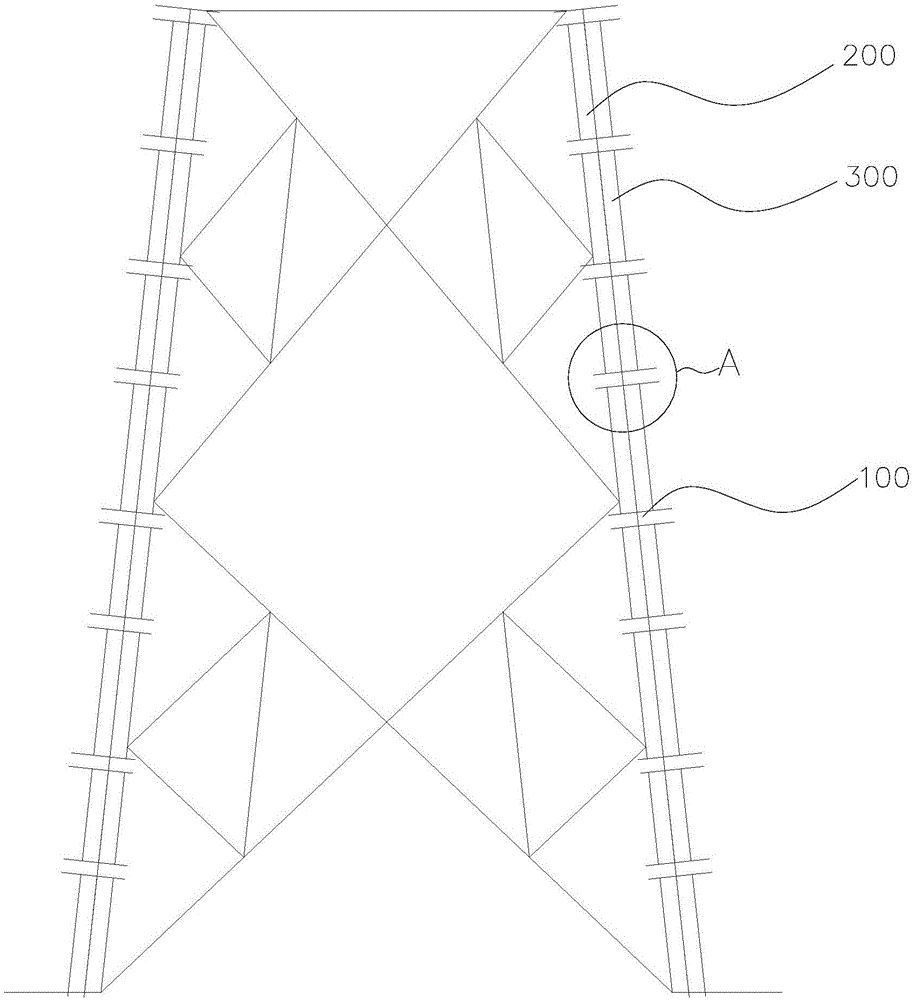

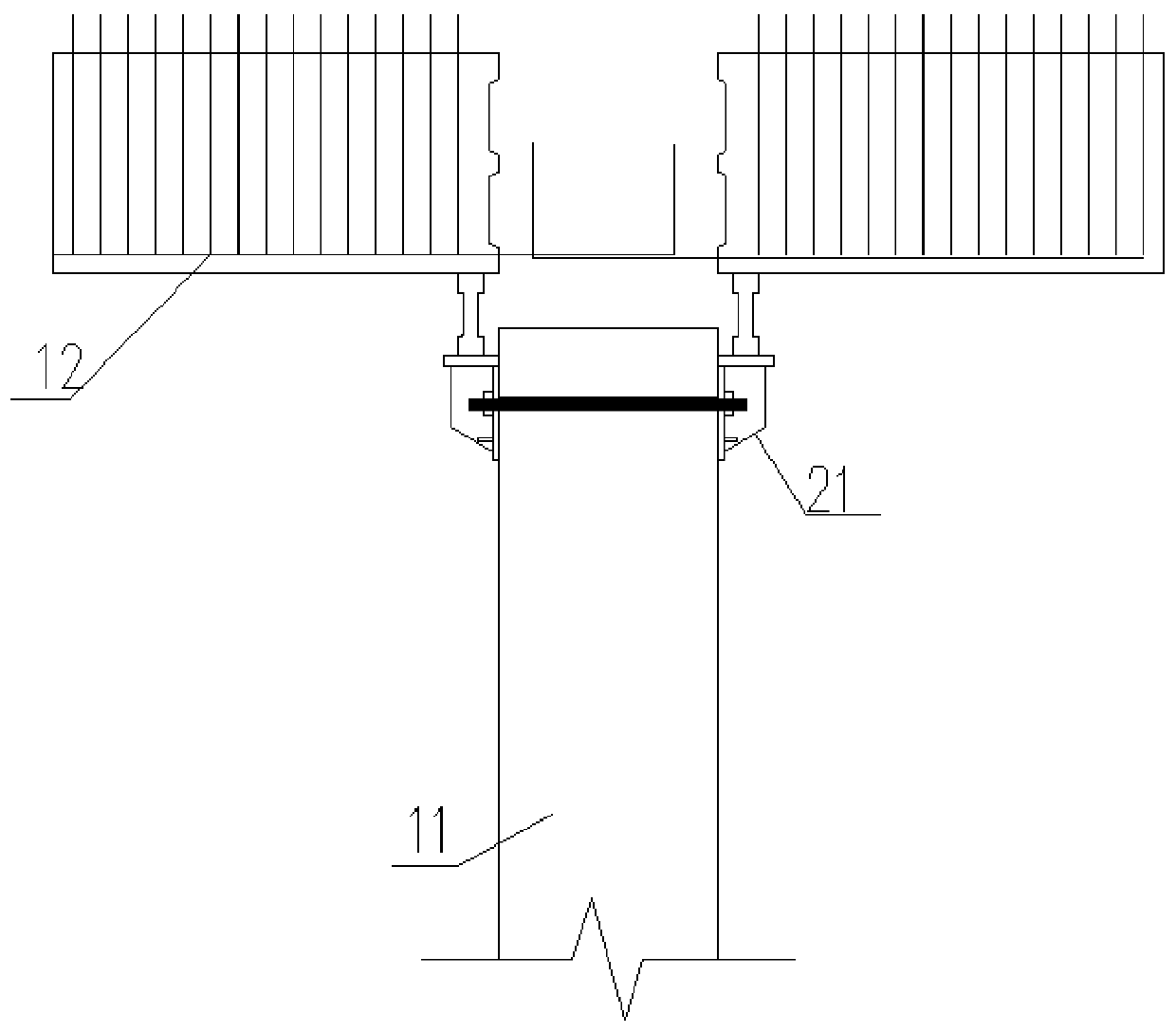

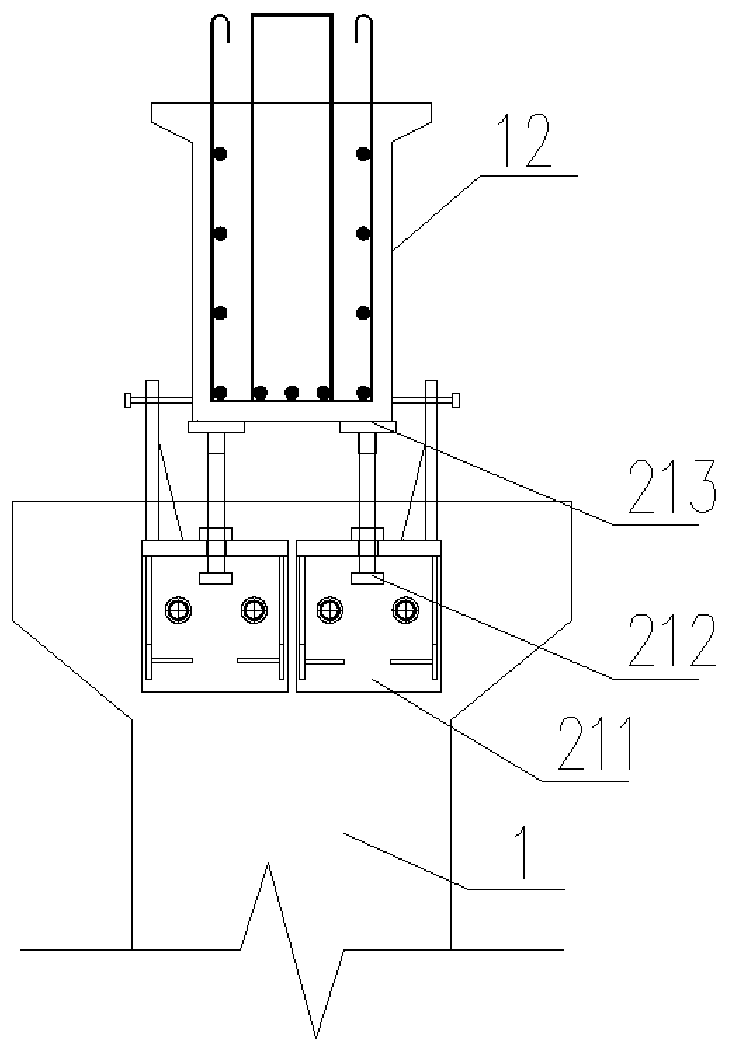

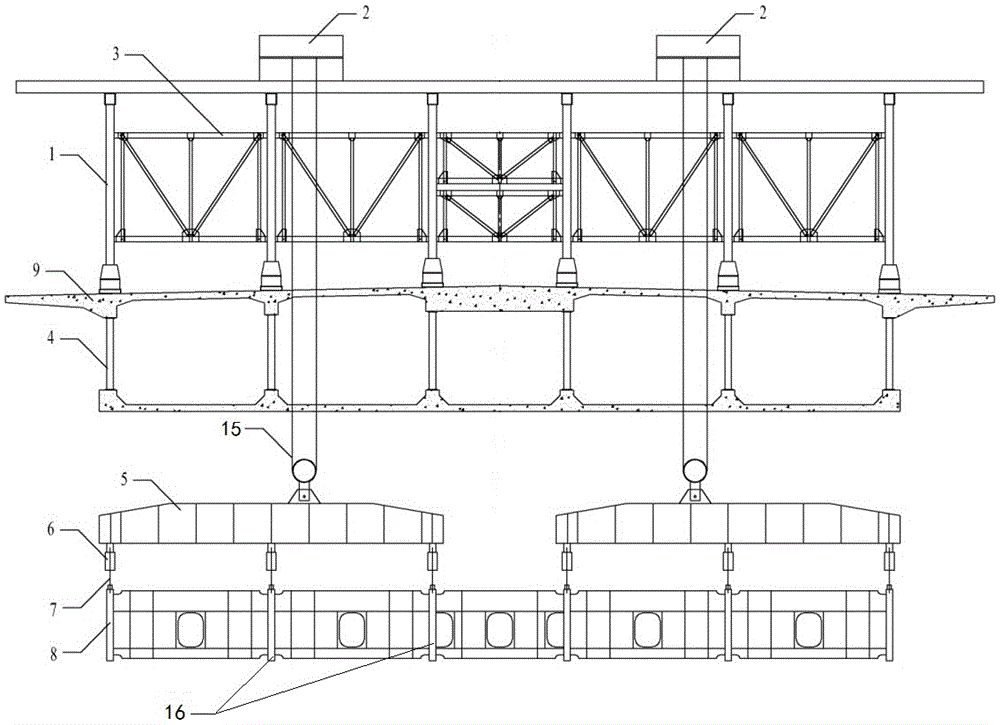

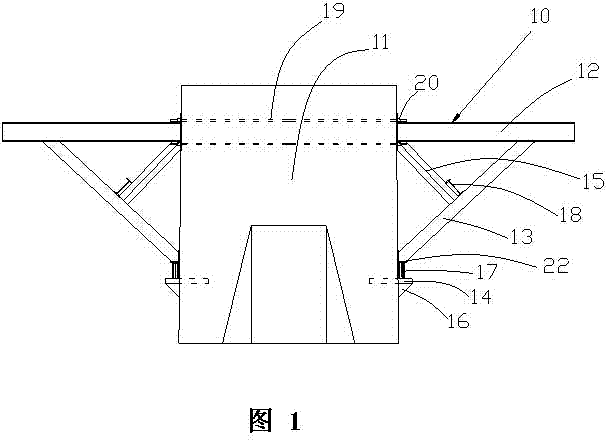

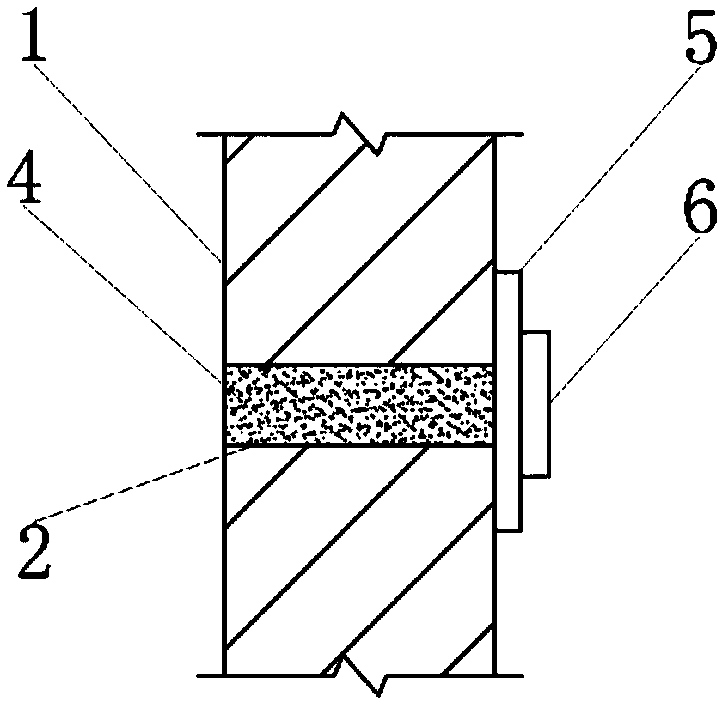

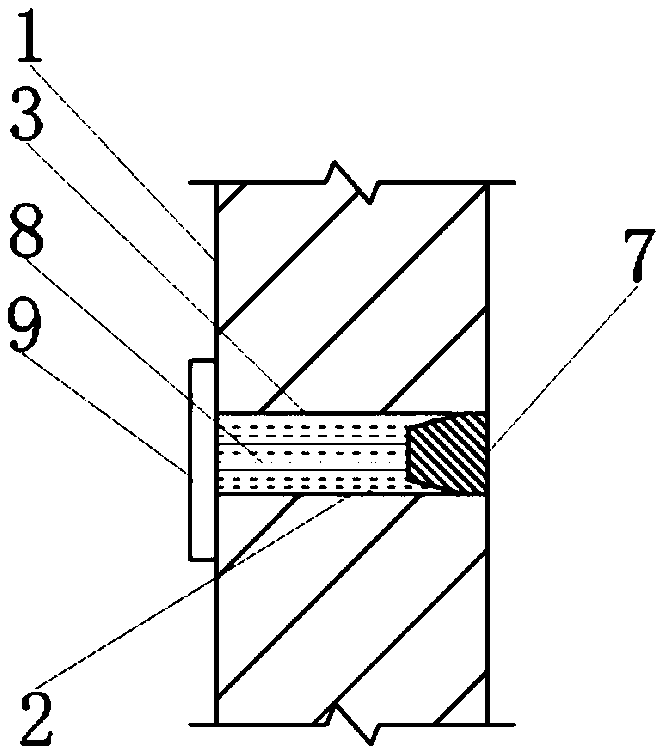

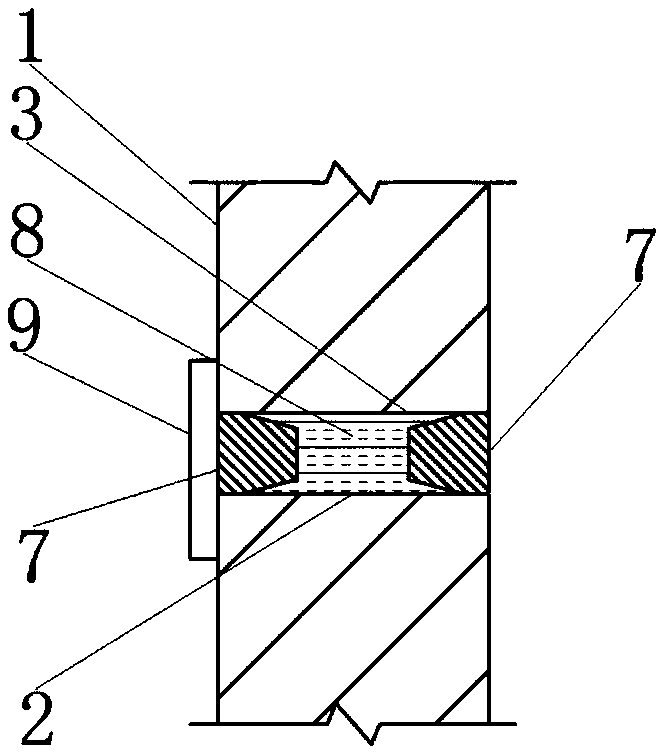

Power transmission tower reinforcing clamps, power transmission tower reinforcing device and power transmission tower reinforcing method

InactiveCN106567599AHigh strengthReduce intensityGeometric CADBuilding repairsTransmission towerElement analysis

The invention discloses power transmission tower reinforcing clamps, a power transmission tower reinforcing device and a power transmission tower reinforcing method. Each power transmission tower reinforcing clamp comprises a main body and a matched part, wherein the main body comprises a clamping part and a connection part which are connected; the clamping part and the matched part are matched to clamp a power transmission tower main material; the joint of the clamping part and the matched part is located in the positions where the clamping part and the matched part extend through the two side edges of the power transmission tower main material. The power transmission tower reinforcing device comprises the multiple power transmission tower reinforcing clamps and a plurality of reinforcing parts. The reinforcing parts are fixed to the power transmission tower main material through the power transmission tower reinforcing clamps, meanwhile, every two adjacent reinforcing parts are in butt joint and are then connected with a shoe plank on a power transmission tower foot plate. The power transmission tower reinforcing method ensures the reinforcing effect of a power transmission tower through combination of finite element analysis and tests. The power transmission tower reinforcing clamps are simple to install, and the power transmission tower reinforcing device and the power transmission tower reinforcing method improve the strength of the power transmission tower.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

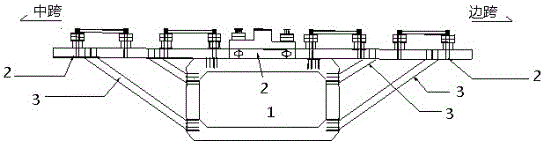

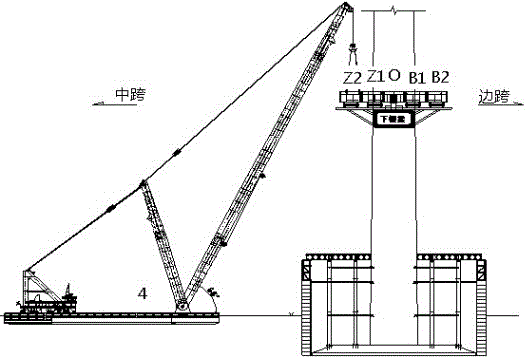

Construction method of superlong cable beam-free sections of cable-stayed bridge

ActiveCN106522101AIncrease the number ofIncrease construction costsBridge erection/assemblyCable stayedTower

The present invention relates to a construction method of superlong cable beam-free sections of a cable-stayed bridge. The first stage refers to the construction of five middle beam sections: the bracket+floating crane installation method is adopted, that is, the five cable beam-free sections in the middle of a tower area are sequentially hoisted up and placed on a lower beam bracket by using a floating crane, and tower beam temporary restraints are installed after the beams are connected into a whole. The second stage refers to the construction of two beam sections at the two ends: the platform+deck crane installation method is adopted, that is, the beam sections at each end are connected together on the backfield in advance and then stored on cofferdam top platforms on the both sides of a main tower, a deck crane above lifts and installs the beam sections, the lifting of the deck crane is conducted by using a midspan-and-then-sidespan asymmetry method, and the counterweight is increased or decreased in the construction process to decrease the unbalanced bending moment in the construction process. The construction method has unique advantages in terms of construction economy, construction cycle and construction safety, and the purpose of not applying floor steel pipe piles is realized.

Owner:ROAD & BRIDGE EAST CHINA ENG +1

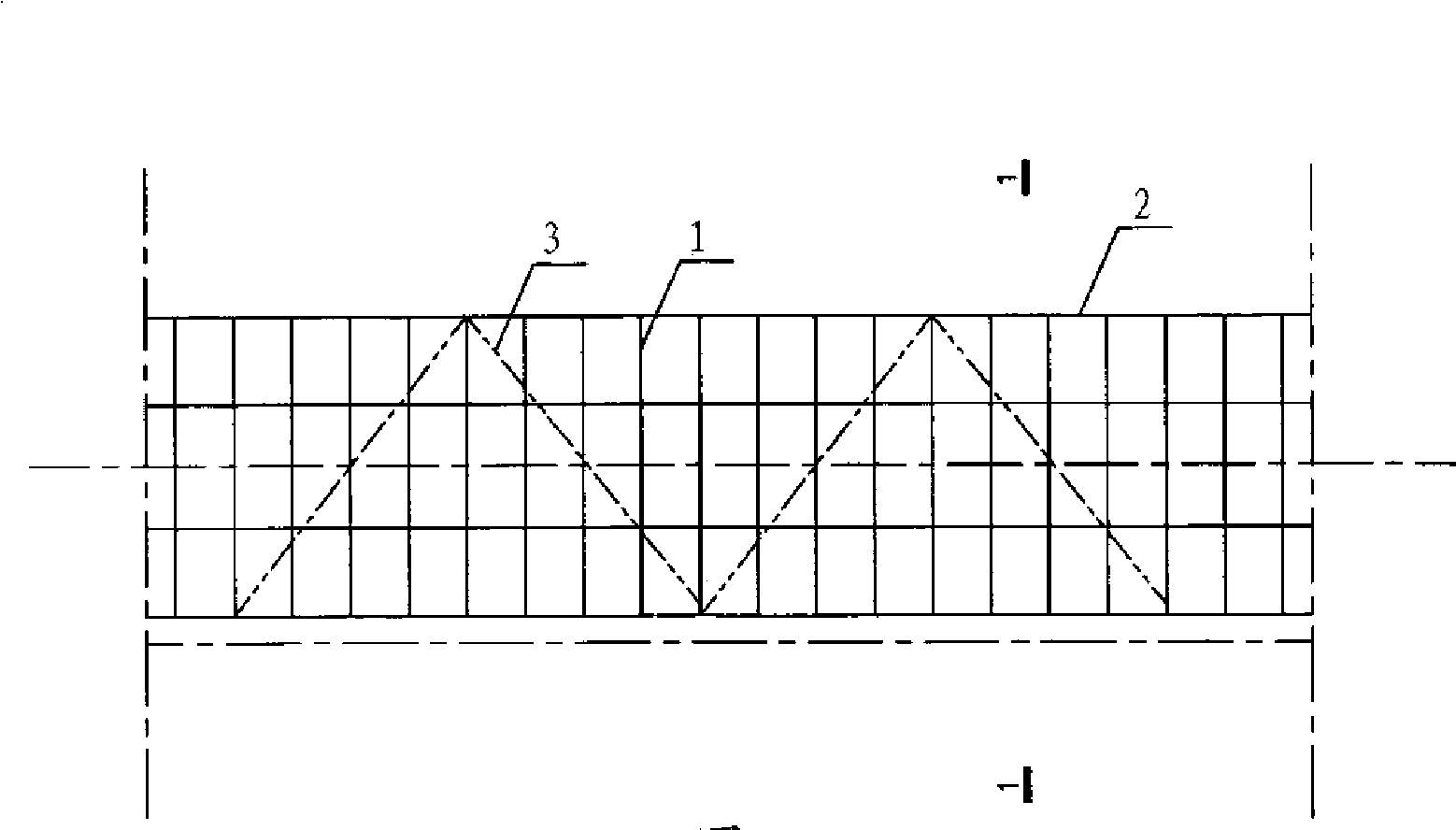

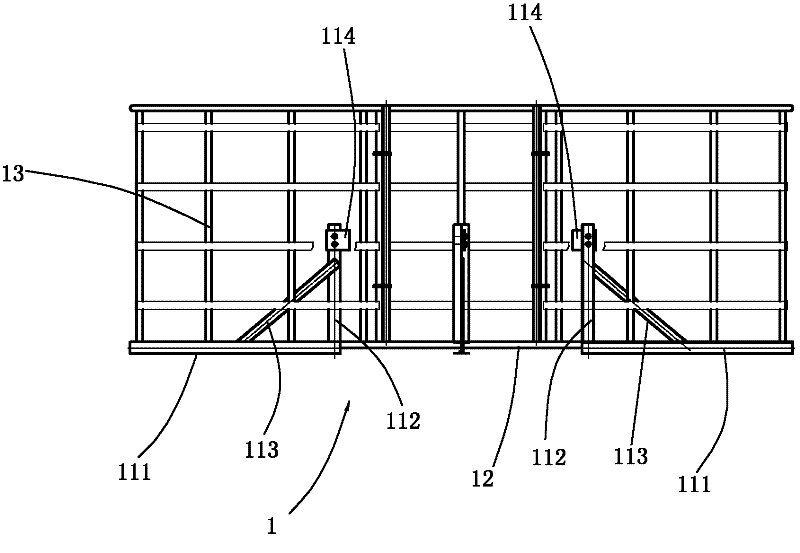

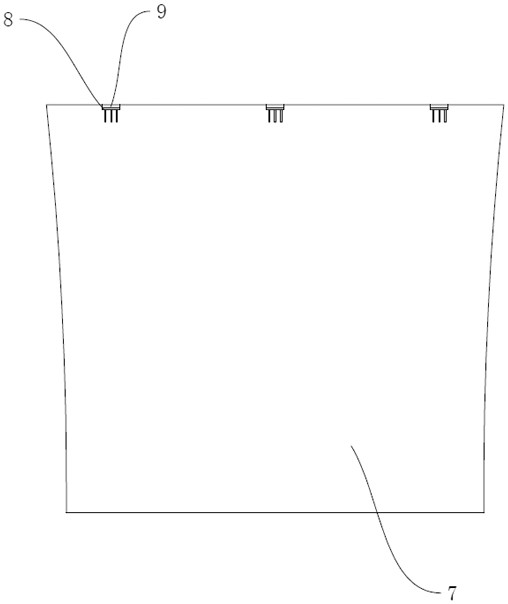

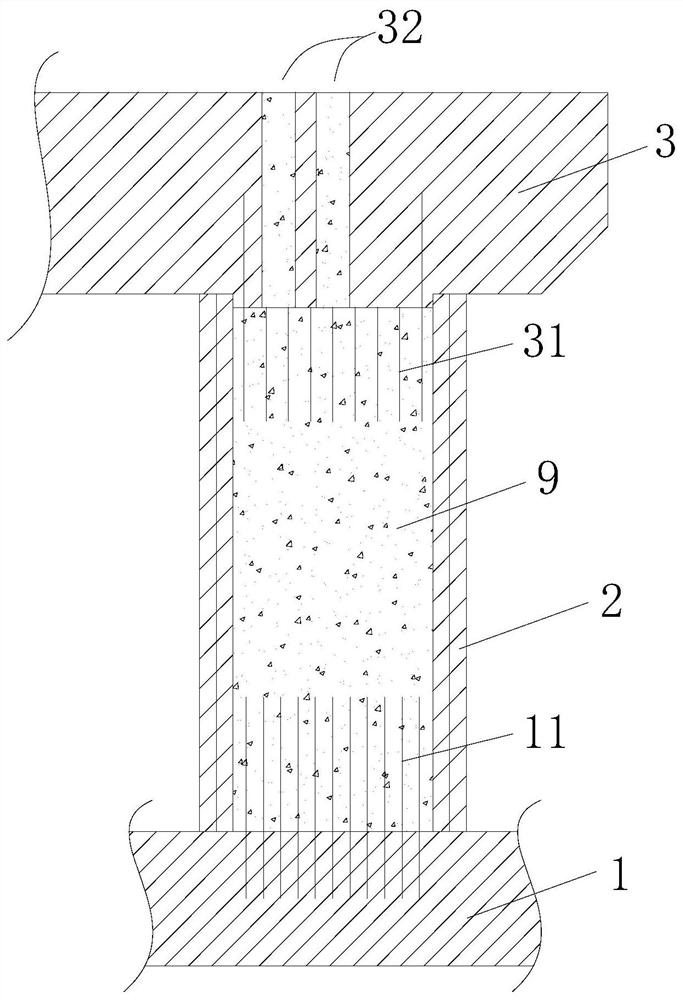

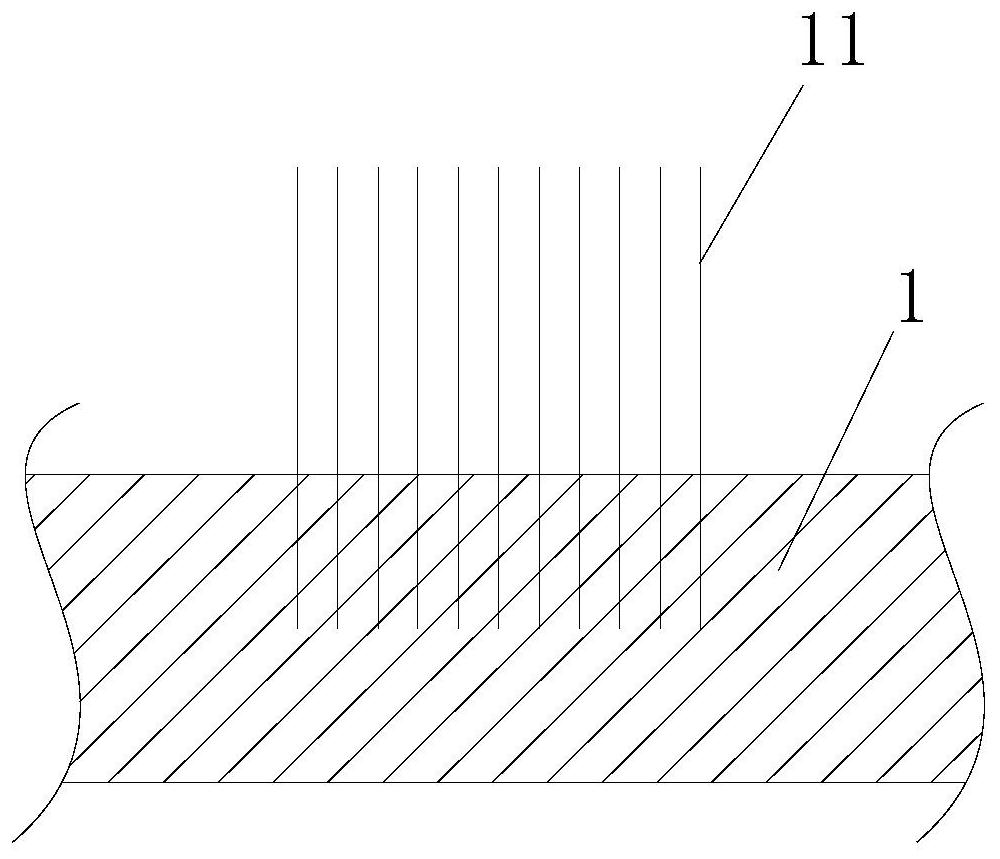

Self-bearing type preprocessing component, self-bearing type preprocessing concrete structure and construction method thereof

InactiveCN101298796AReduce labor intensityReduce construction accidentsFloorsBuilding reinforcementsRebarHigh rise

A self-load preprocessing component, a self-load preprocessing concrete structure and a construction method thereof, the self-load preprocessing component is a stable structure of load bearing by the material of itself, which is made from a preassembled reinforced skeleton connected with a support component. The self-load preprocessing component is manufactured at a processing space of a construction site or in a factory in advance, and the module is supported in site at a construction site; the self-load preprocessing component is hoisted so that structure design is in position, assembled and connected, and a molding board is installed as compensation at a exposed position of the reinforced skeleton; concrete is cast in the molding board, and maintained, so as to solve the technical problem in high rising building or super high rising building such as large aloft work of concrete construction, site operation difficulty, unstable quality, low efficiency, and multiple safety accident.

Owner:姚攀峰

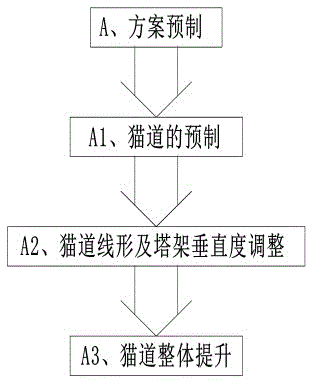

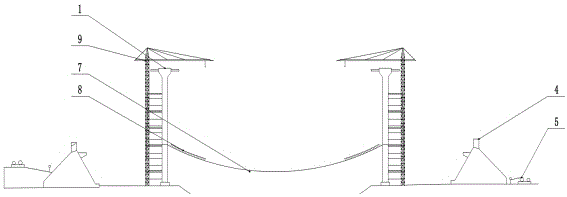

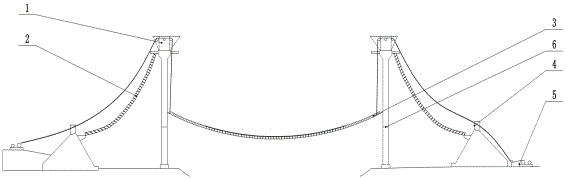

Construction technology for large-diameter pipeline crossing construction catwalk

ActiveCN105603879AImprove the level of installationImprove efficiencyBridge erection/assemblyArchitectural engineeringCross bridge

The invention discloses a construction technology for a large-diameter pipeline crossing construction catwalk, and relates to the technical field of construction of suspension cable type crossing bridges of pipelines. The construction technology for the large-diameter pipeline crossing construction catwalk comprises the steps of pre-making a scheme, prefabricating catwalks, adjusting the catwalk line shape and the tower perpendicularity and lifting the overall catwalks, provides an installation method for a construction passageway (catwalk) for a main cable by adopting aerial prefabricating methods like long-span crossing PPWS, and effectively reduces the overhead installation and overall construction period of catwalks.

Owner:SICHUAN GASOLINEEUM CONSTR ENG

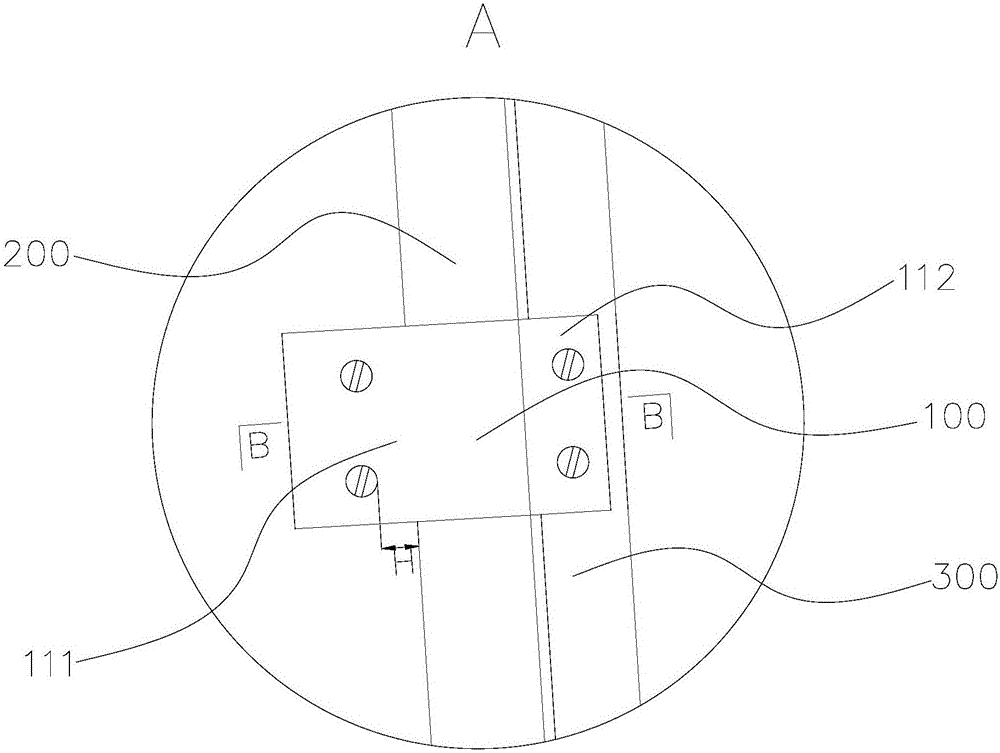

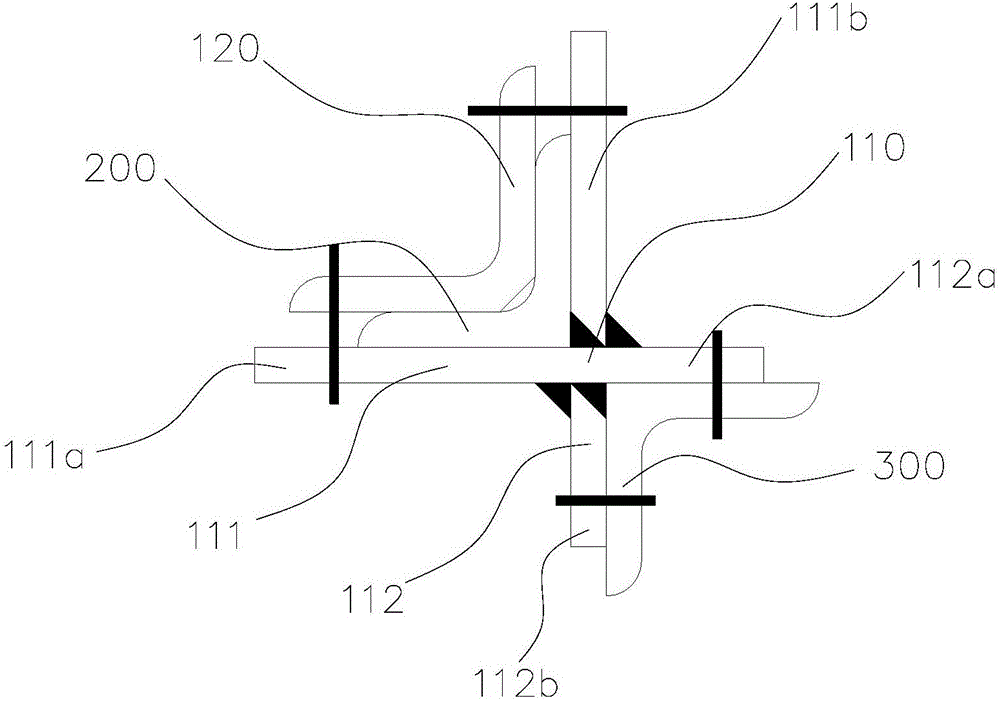

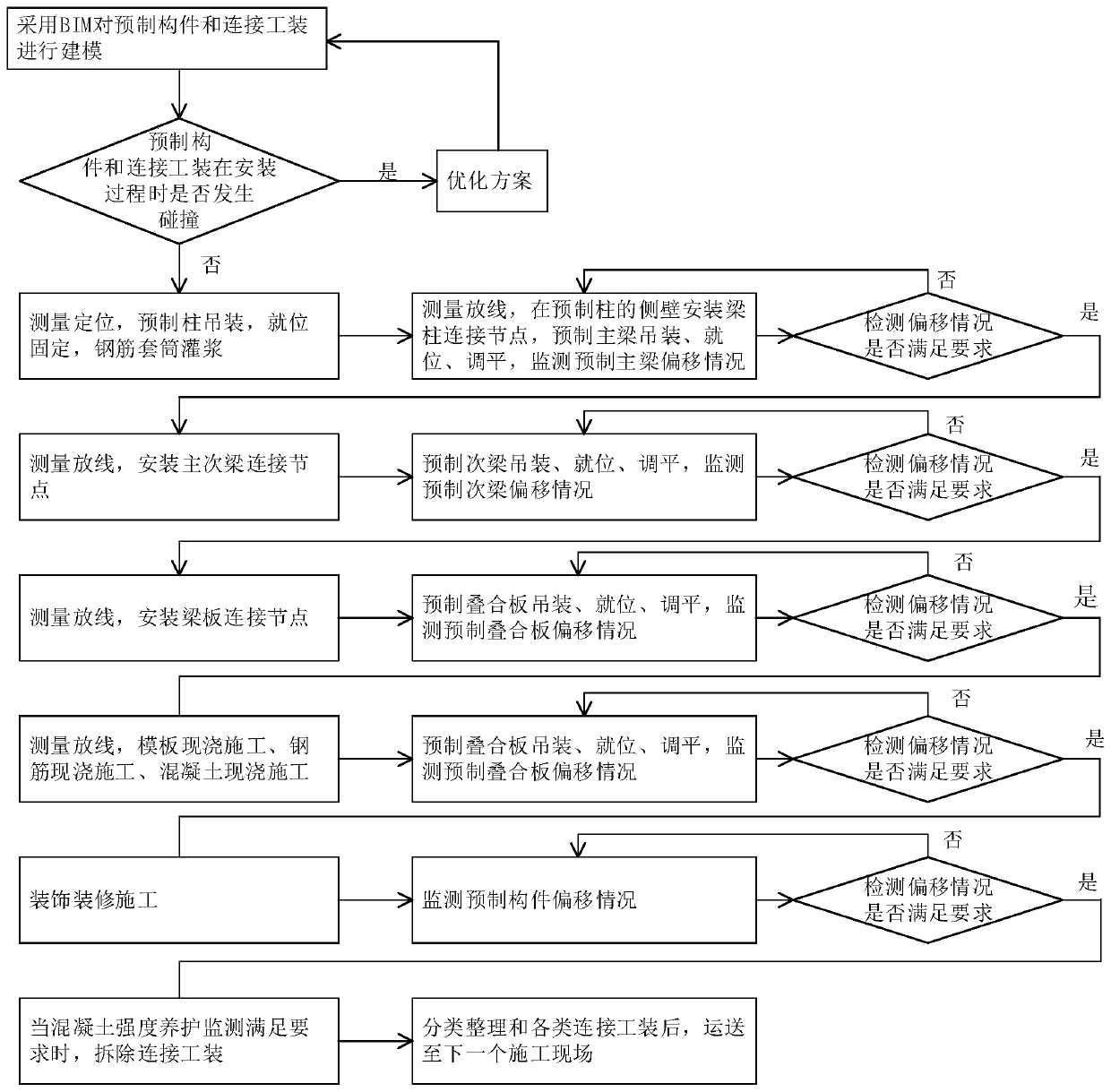

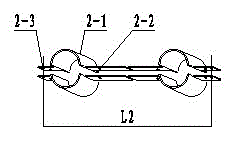

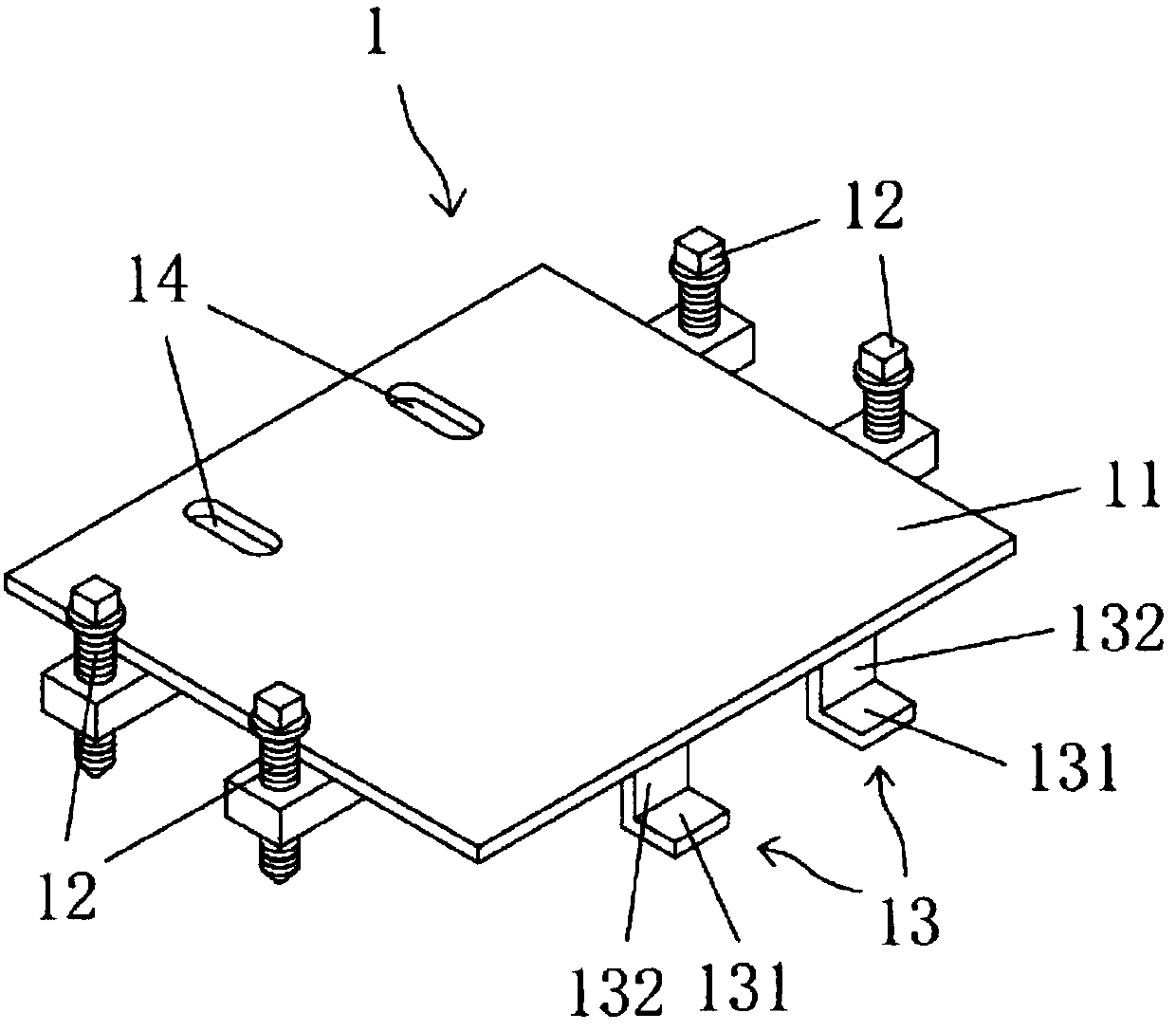

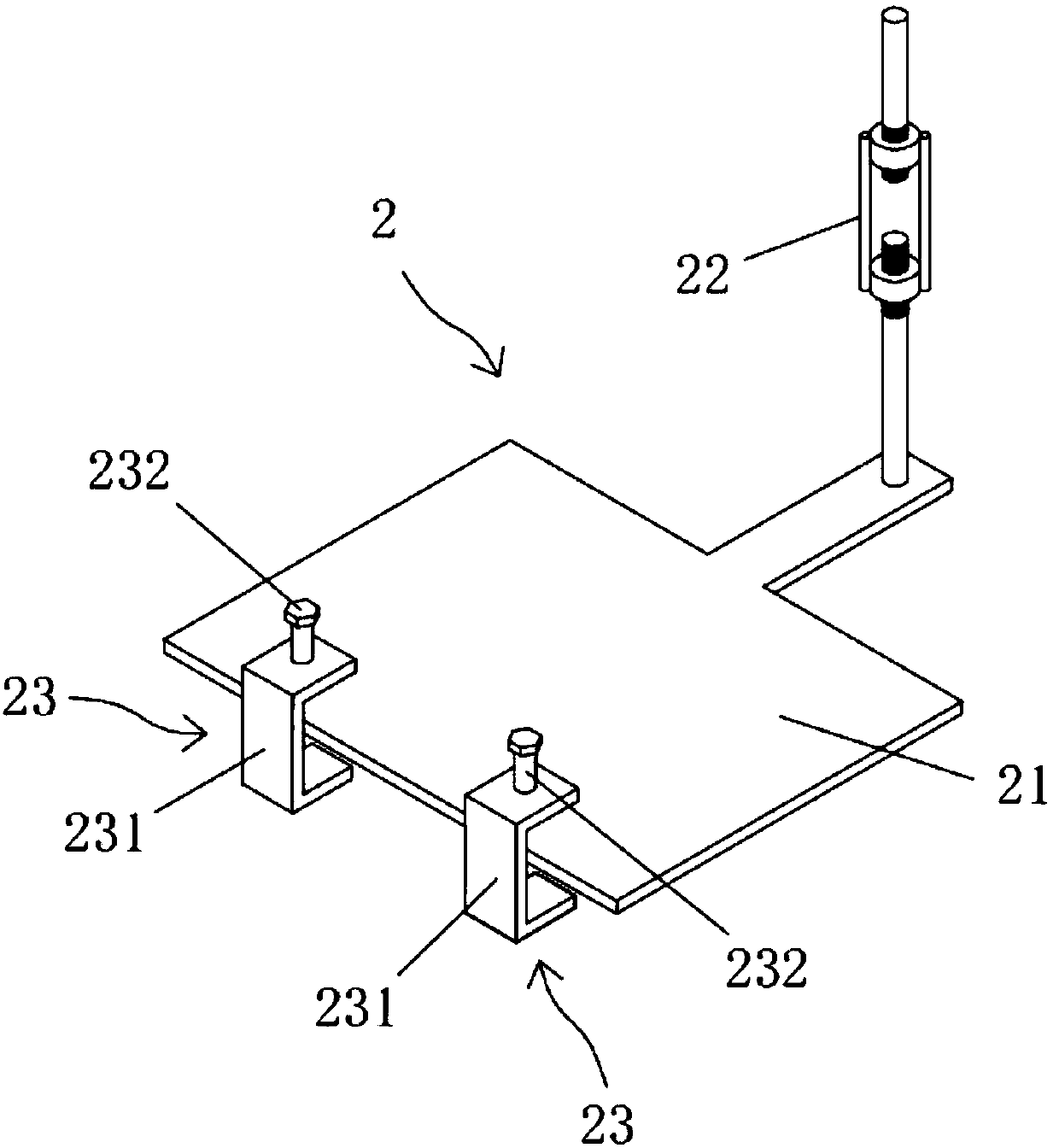

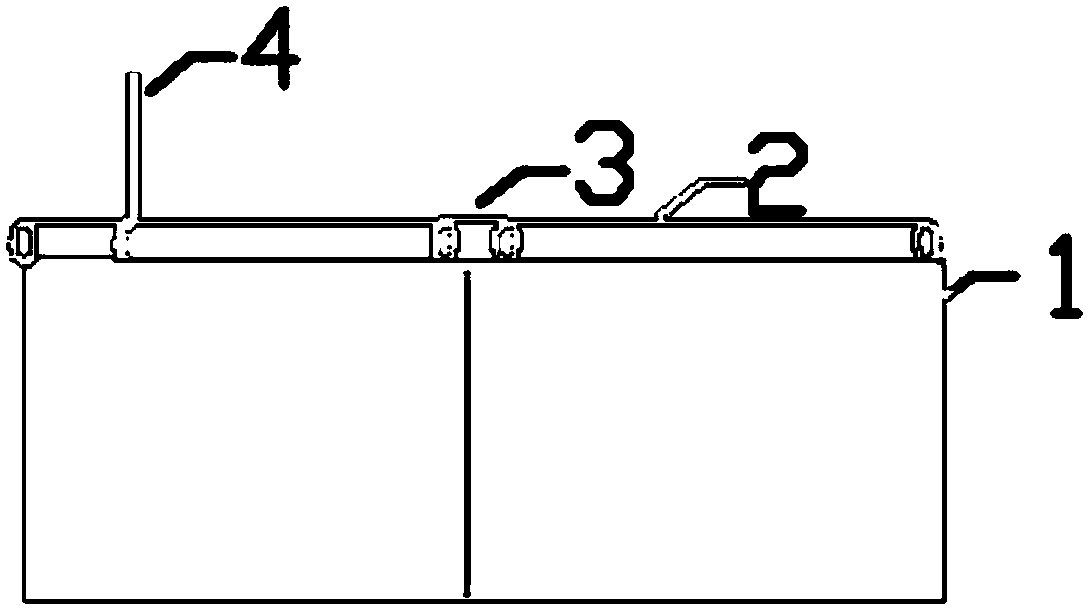

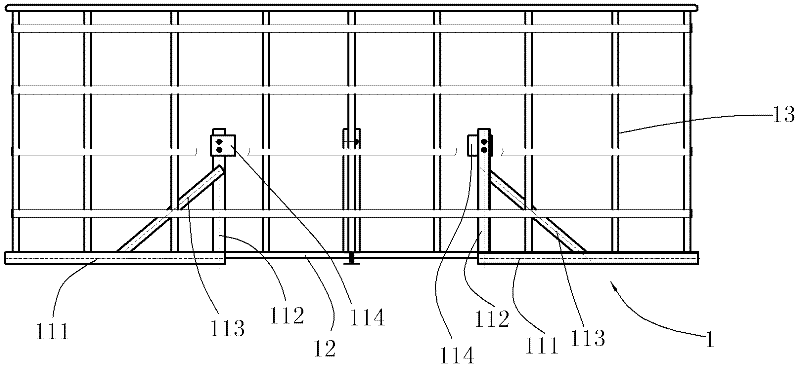

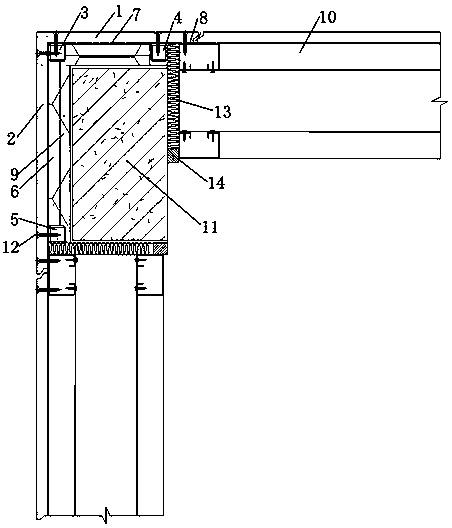

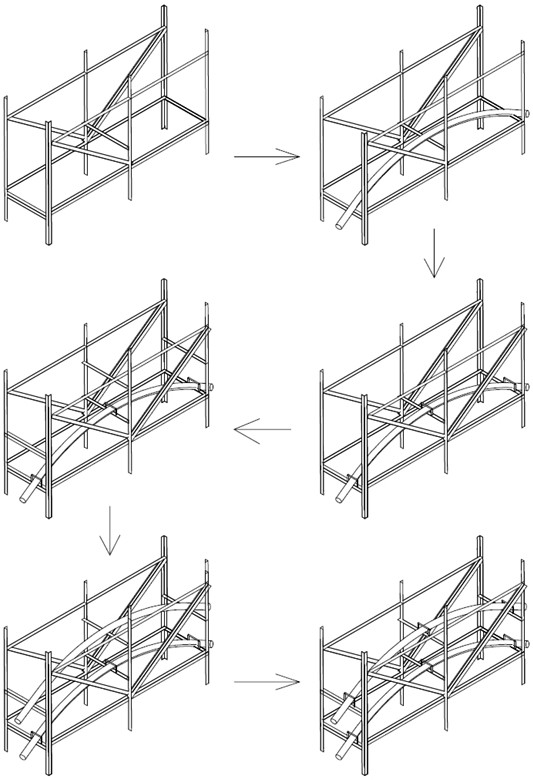

Support-free mounting method of fabricated concrete frame building

InactiveCN111441593AReduce time spent working at heightsMinimize and avoid problemsBuilding material handlingFalseworkConstruction engineering

The invention provides a support-free mounting method of a fabricated concrete frame building. The support-free mounting method comprises the following steps of modeling prefabricated parts and connecting tools by adopting BIM to obtain a mounting scheme of the prefabricated parts and the connecting tools, wherein the prefabricated parts comprise prefabricated columns, prefabricated main beams, prefabricated secondary beams and prefabricated laminated slabs, and the connecting tools comprise beam and column connecting joints, primary and secondary beam connecting joints and beam and plate connecting joints; installing the prefabricated columns, installing the beam and column connecting joints on the prefabricated columns, and placing the prefabricated main beams on the beam and column connecting joints; installing the main and secondary beam connecting joints on the prefabricated main beams and the prefabricated secondary beams, and connecting the prefabricated main beams with the prefabricated secondary beams through the main and secondary beam connecting joints; installing the beam and plate connecting joints on the prefabricated main beams and the prefabricated secondary beams,and placing the prefabricated laminated slabs on the beam and plate connecting joints; conducting cast-in-place construction; and dismounting the connecting tools. By the adoption of the method, a traditional scaffold installation system can be omitted, and the advantages of a fabricated building are brought into full play.

Owner:GUANGDONG JIAN YUAN CONSTR ASSEMBLY IND CO LTD +2

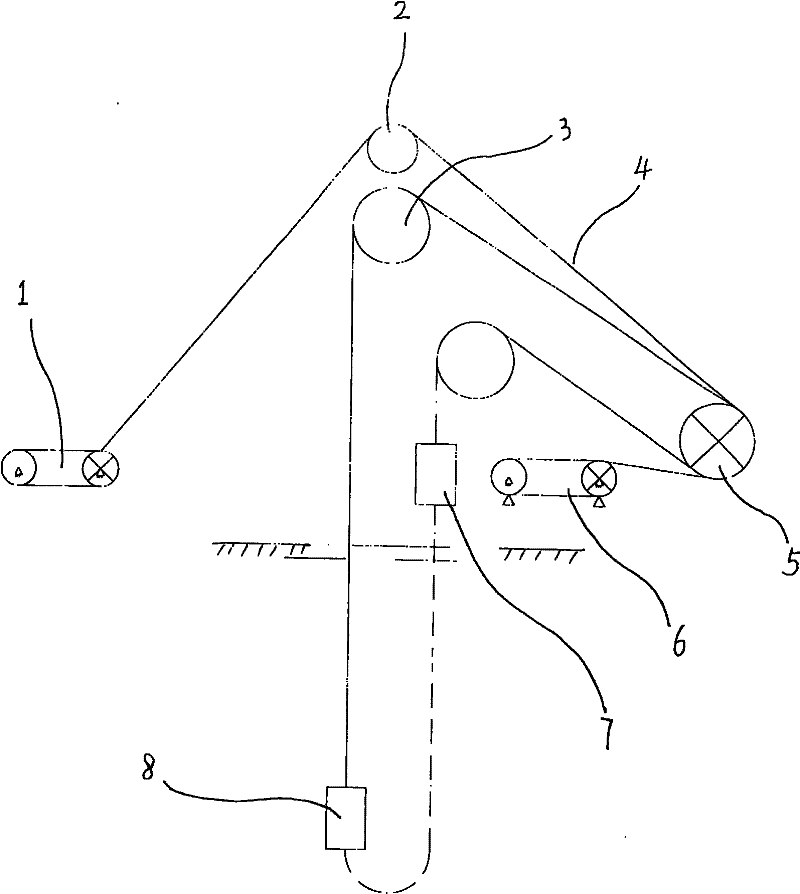

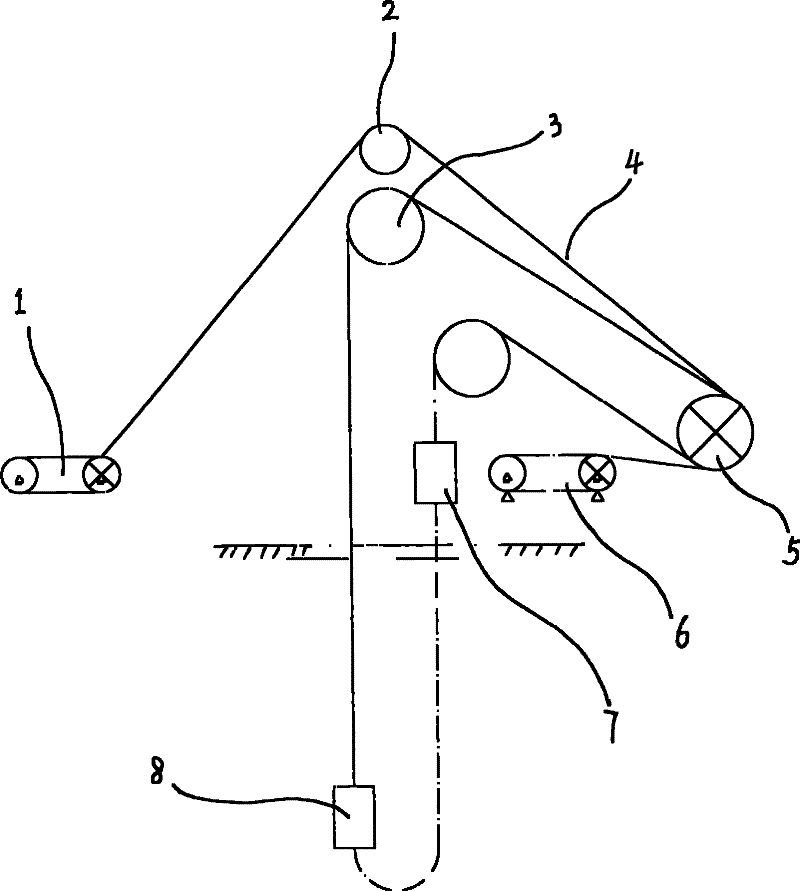

Method for replacing lifting ropes of multi-rope frictional geared winch

The invention discloses a method for replacing lifting ropes of a multi-rope frictional geared winch. A tensioner, a pulley block, a head sheave, the lifting ropes, the winch, a tractor, a container II and a container II are involved; and according to the characteristics of the multi-rope frictional geared winch, the ropes are replaced by effectively using the tensioner and the tractor, at least two ropes are always kept connected with the containers, the winch has enough traction to draw the containers in the rope replacement construction process, the lifting ropes keep enough intensity, themechanical operation level is improved, rope replacement time is reduced, the labor intensity of workers and high-attitude operation time at a wellhead are reduced, the aim of replacing the ropes safely is fulfilled and normal production is guaranteed.

Owner:张万忠

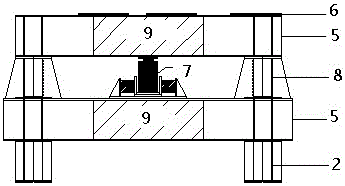

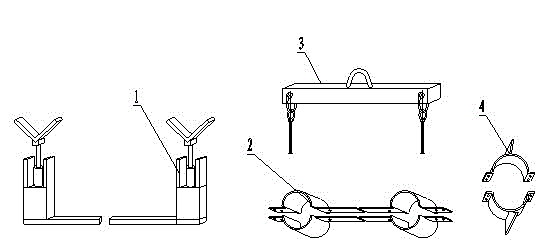

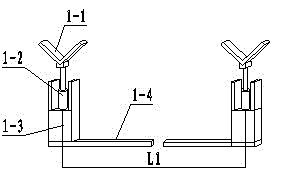

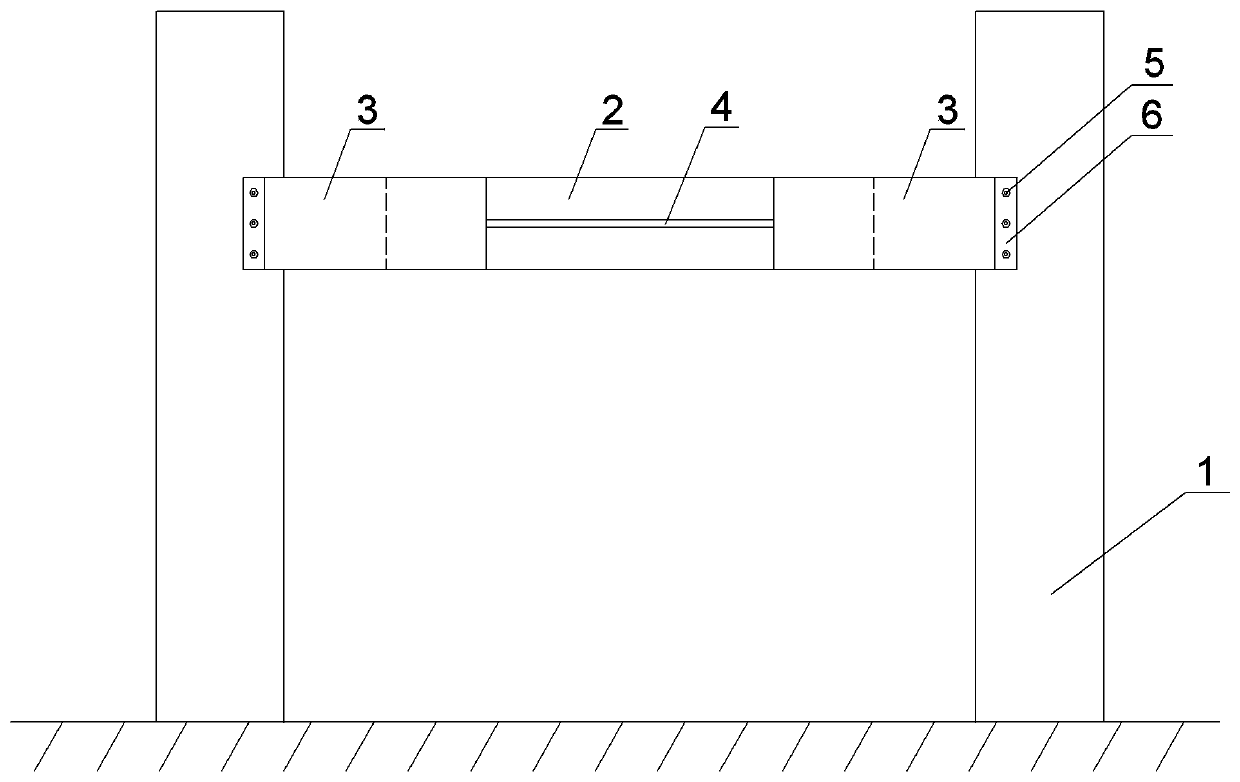

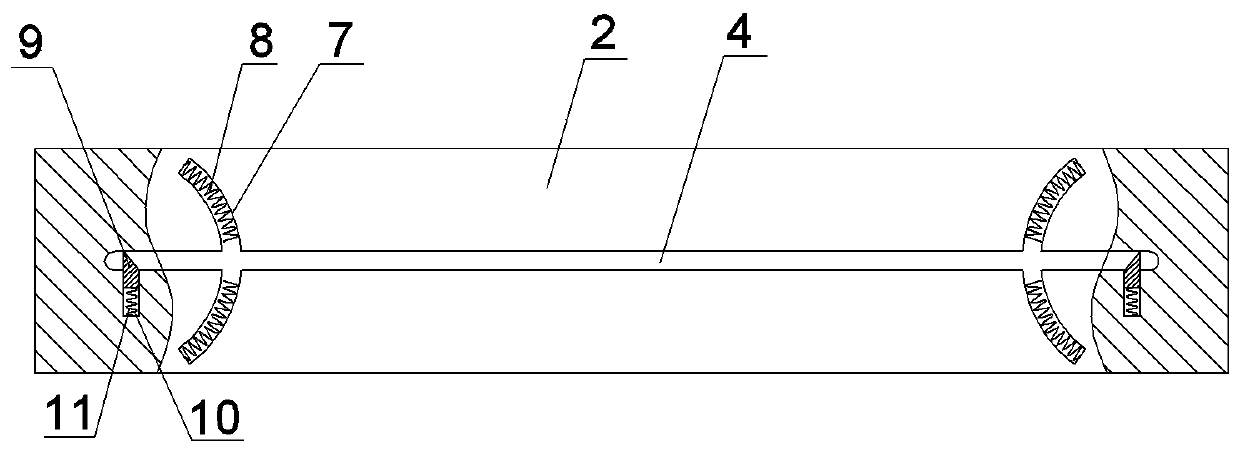

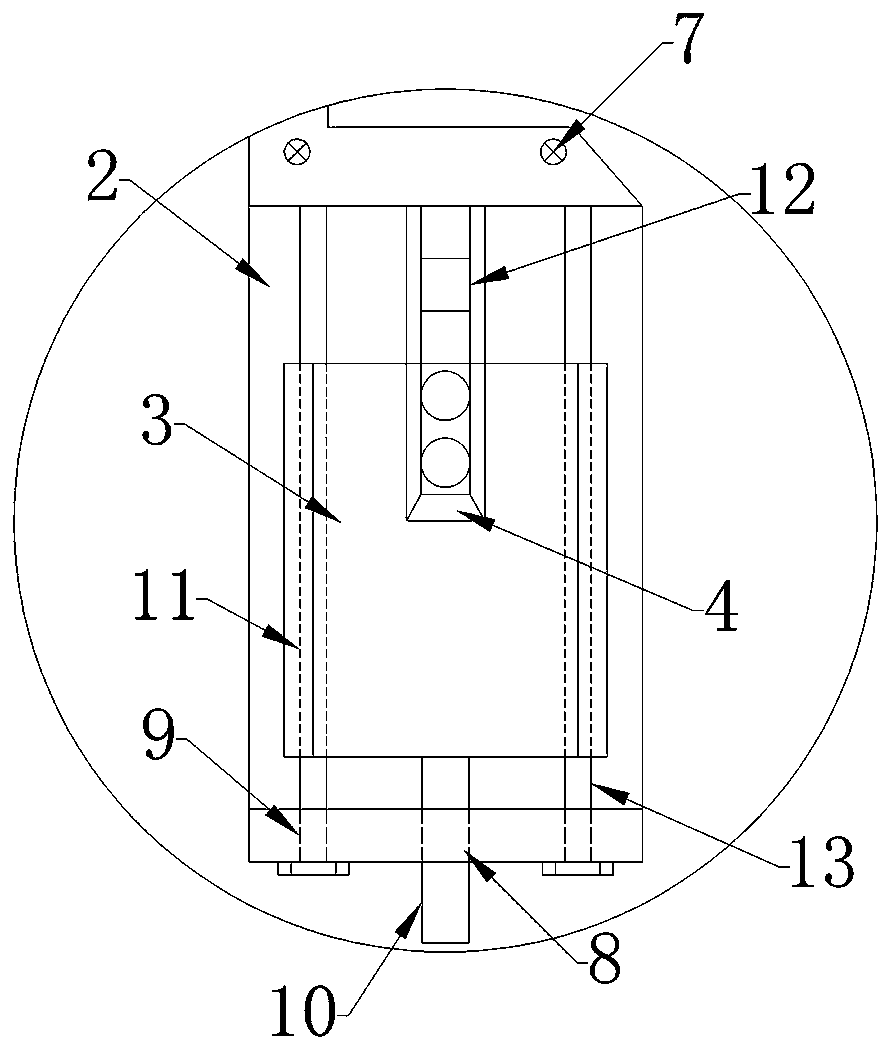

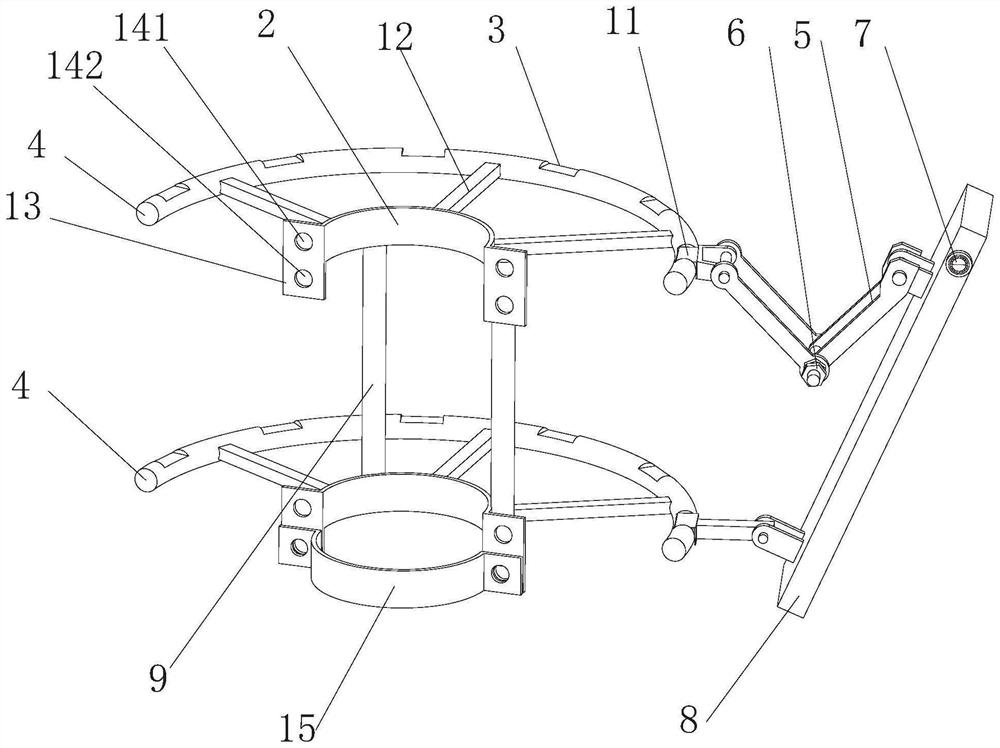

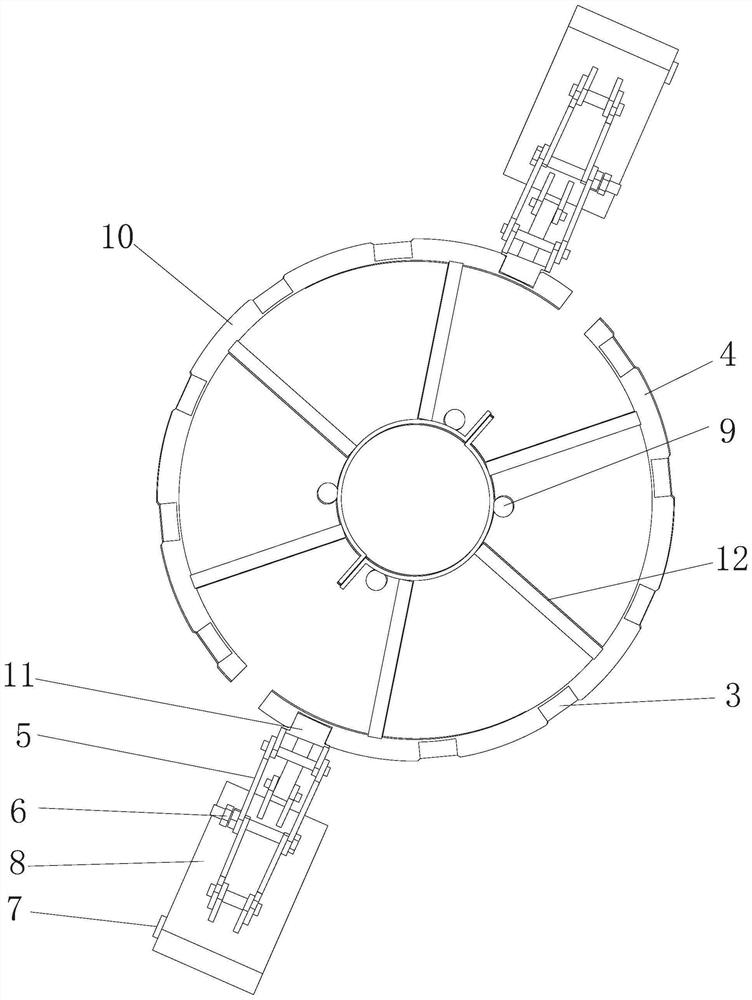

Integral installation device for transformer test bench

InactiveCN102983517AReduce time spent working at heightsReduce labor intensityLoad-engaging elementsSwitchgearHydraulic brakeTest bench

An integral installation device for a transformer test bench is used for integrally installing the transformer test bench and comprises a double-electric-pole horizontal correction mechanism, transformer test bench integral hanging support arms, hoisting transverse arms and a transverse arm adjustment support. The double-electric-pole horizontal correction mechanism is formed by no less than two horizontal correction units, wherein a V-shaped supporting block, a hydraulic jack, a supporting body and a bottom plate are arranged in each horizontal correction unit. The V-shaped supporting blocks are arranged in a bilaterally symmetrical mode and respectively positioned at the ends of the two hydraulic jacks. The spacing L1 of the central axis of the two V-shaped supporting block meets the distance requirement of the standard bench area rod root of the transformer test bench. The hydraulic jacks are fixed on the supporting bodies which are fixed at two ends of the bottom plates, and the bottom plates are arranged on the horizontal ground. By means of the integral installation device for the transformer test bench, time consumed by construction personnel working high above the ground is reduced to the largest extent, labor intensity of the construction personnel is reduced, working efficiency is improved, and the building construction of the 10kV transformer test bench is standardized and normalized.

Owner:STATE GRID CORP OF CHINA +2

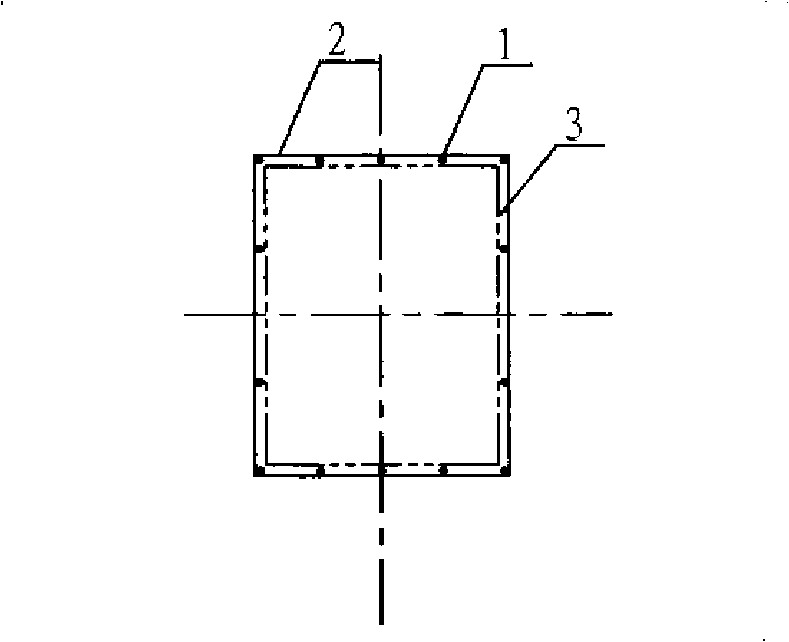

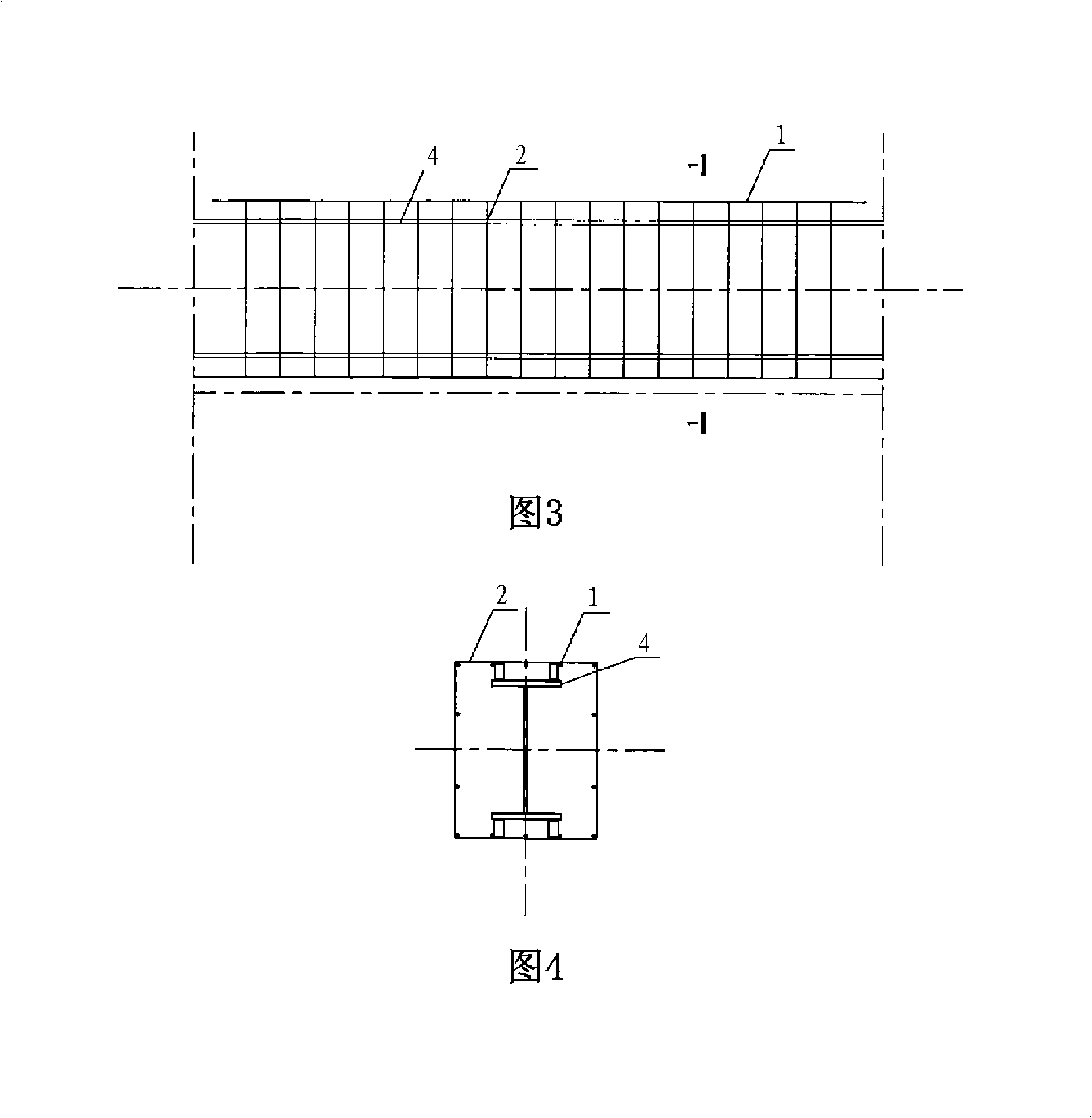

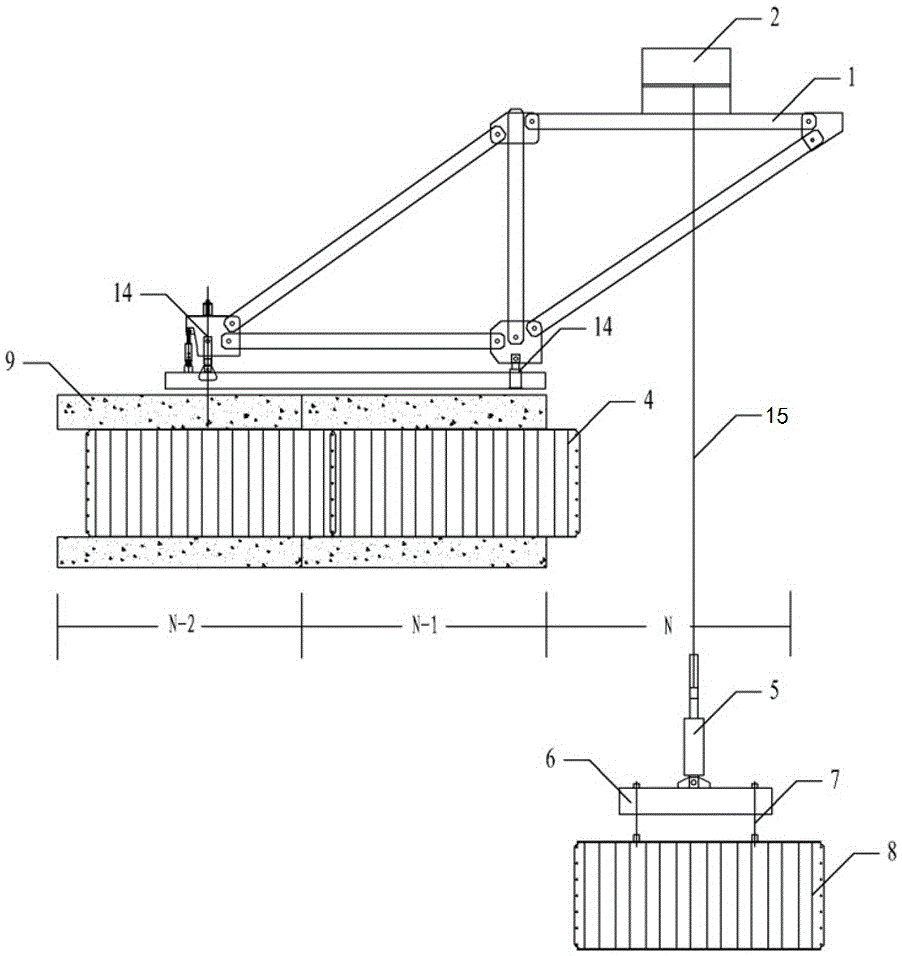

Integrated hoisting method for corrugated steel web part

The invention discloses an integrated hoisting method for a corrugated steel web part. The method includes the following steps that a hanging basket is moved forward in place on the N-1th corrugated steel web section of a corrugated steel web PC box girder bridge, so that the bottom of the hanging basket is fixed to the N-1th corrugated steel web section, and the top of the hanging basket protrudes out of the front end of the N-1th corrugated steel web section; precast splicing of the Nth corrugated steel web section is completed in a factory, the Nth corrugated steel web section is composed of a plurality of longitudinal corrugated steel webs, and the corrugated steel webs are fixedly connected with transverse steel cross beams and temporary supporting and reinforcing devices; by means of a flat plate barge, the Nth corrugated steel web section is conveyed to the position under the design position; by means of a hoisting system located on the top of the hanging basket, the Nth corrugated steel web section is hoisted in place, and the Nth corrugated steel web section and the N-1th corrugated steel web section are connected. The integrated hoisting method has the advantages that the construction period is effectively shortened, construction quality is improved, and aloft work time is shortened.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

Electromechanical oscillating double-click hammer

ActiveCN102290768AReduce time spent working at heightsIncrease the effective strike surfaceOverhead installationPortable percussive toolsPower cableEngineering

The invention discloses an electromechanical swing double-strike hammer, which comprises a rod body and a hammer body, wherein the hammer body is a double-arc hammer body and consists of a vertical section and two arc sections which are symmetric with each other in the vertical direction; the diameter of the inner circular arc of each arc section is greater than that of a cable; and the left end of the rod body is fixedly connected to the middle part of the vertical section of the double-arc hammer body. The hammer is used for manually removing ice and can also be matched with a mechanical deicing device for use. Through the hammer, the existing striking in the tangential direction of the power cable is converted into striking in the circumferential direction of the cable, so that the effective striking area is increased, the deicing efficiency is increased, and the deicing time is shortened.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

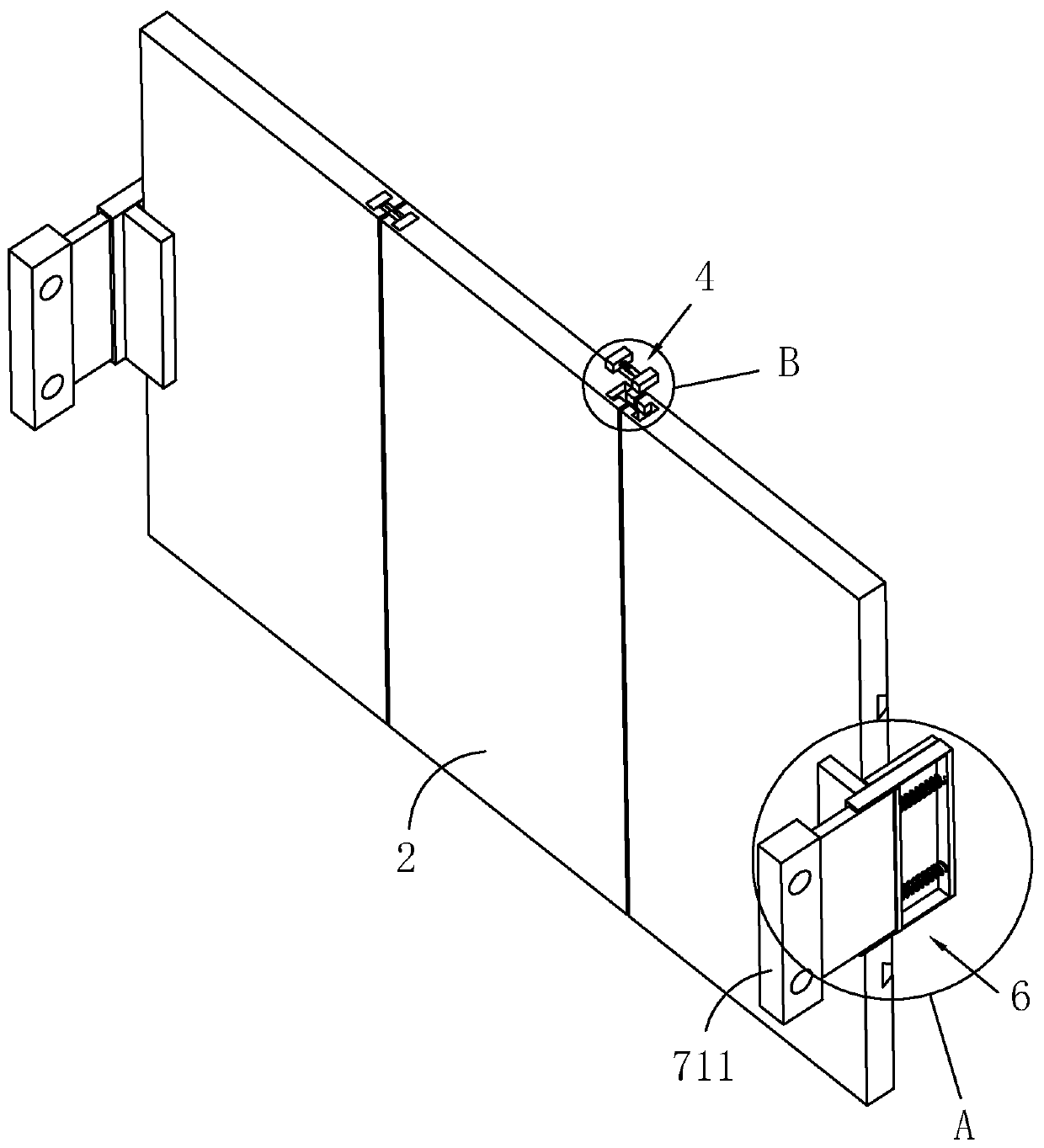

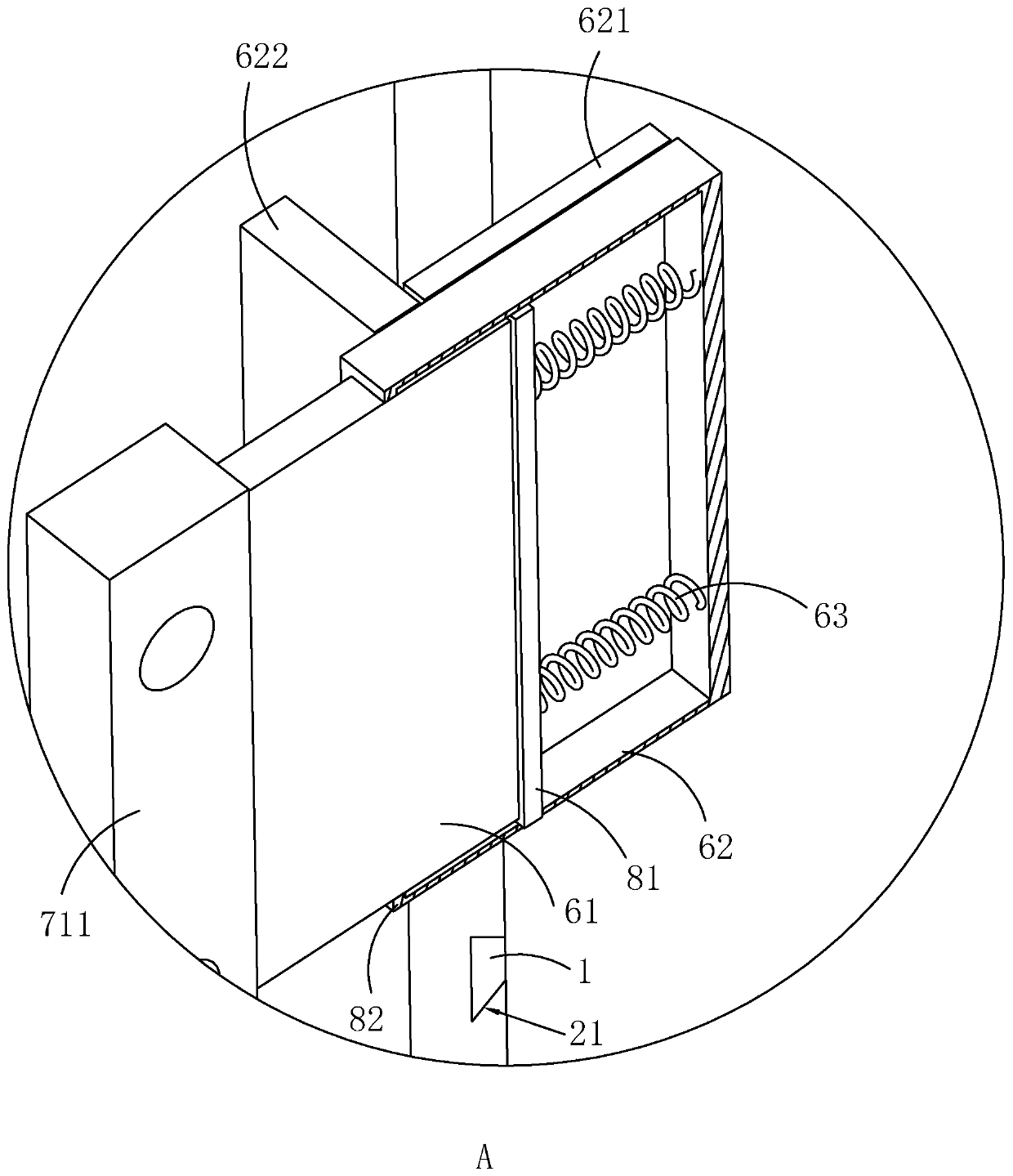

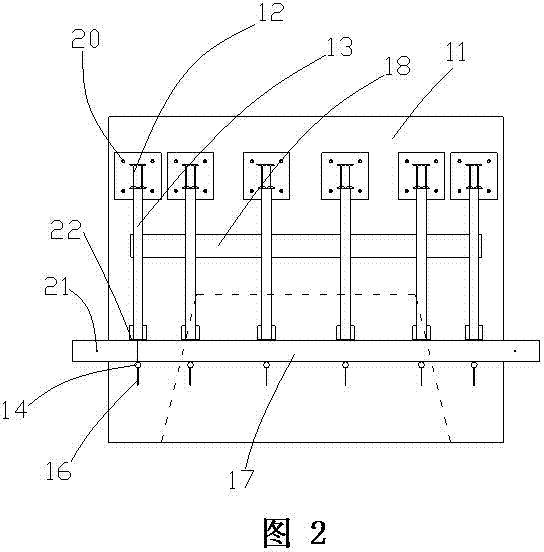

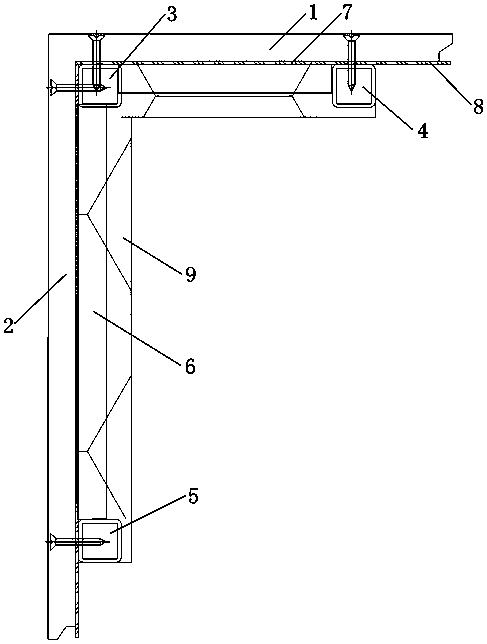

Mounting structure and method of high-and-large-space clean room

InactiveCN110206259AEasy to installReduce time spent working at heightsCovering/liningsEngineeringMechanical engineering

The invention relates to a mounting structure and method of a high-and-large-space clean room, and belongs to the technical field of mounting of cleanroom metal wall plates. The mounting structure comprises metal wall plates, fixing rods and a moving seat; clamping grooves are formed in the side walls, close to a wall, of the metal wall plates, and the fixing rods are clamped in the clamping grooves of the two or more metal wall plates; every two adjacent metal wall plates are fixedly connected through a connecting piece; a lifting plate is arranged on the moving seat, and clamping parts usedfor being clamped in the side walls of the metal wall plates are slidably arranged at the two ends of the lifting plate in the length direction of the lifting plate; and the lifting plate is providedwith a driving assembly for driving the two clamping parts to move in the direction getting close to or away from each other, and the moving seat is provided with a driving source used for driving thelifting plate to ascend and descend. The multiple metal wall plates are fixed into a whole, thus mounting is convenient, the time of working at the high altitude is reduced, and safety is improved.

Owner:川楚联合国际工程有限公司

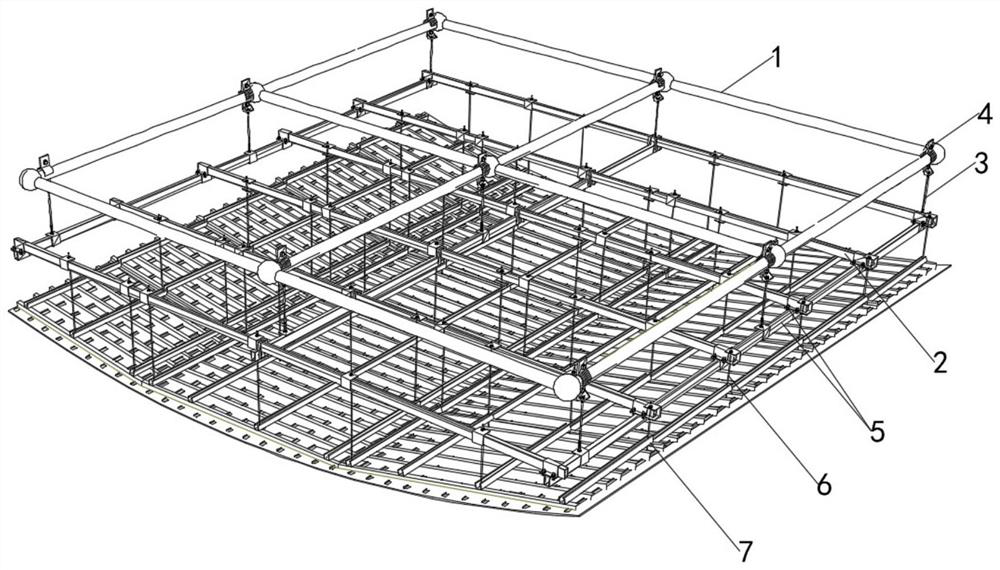

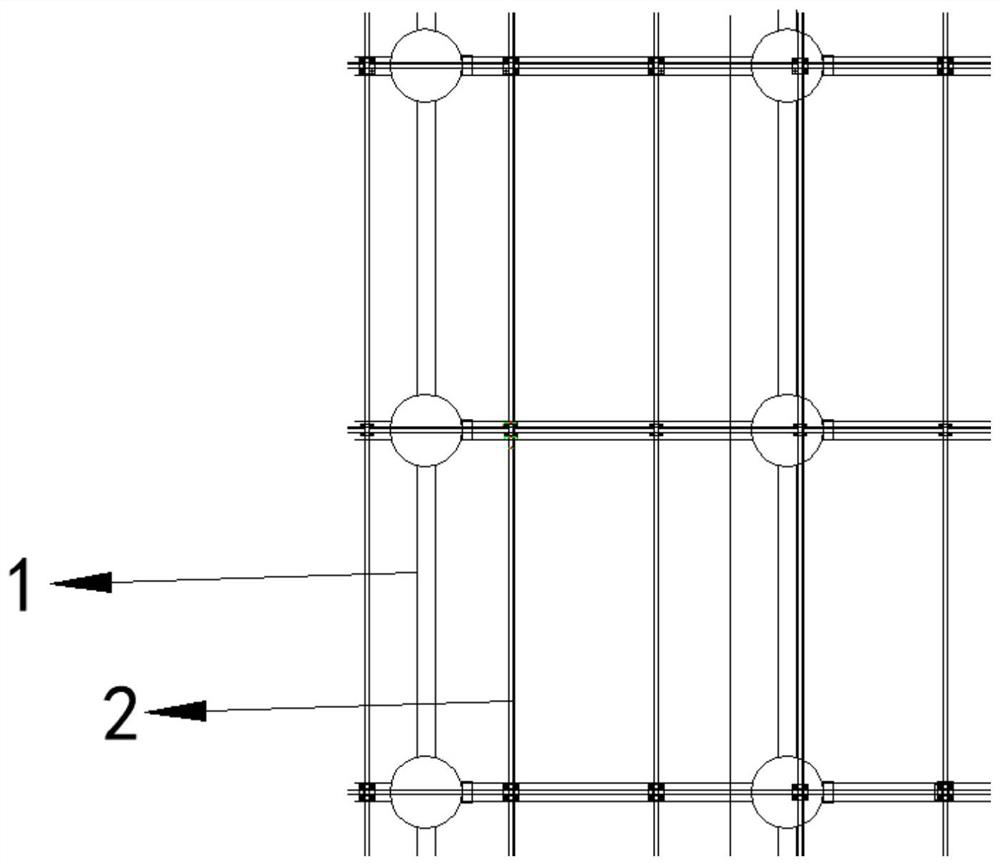

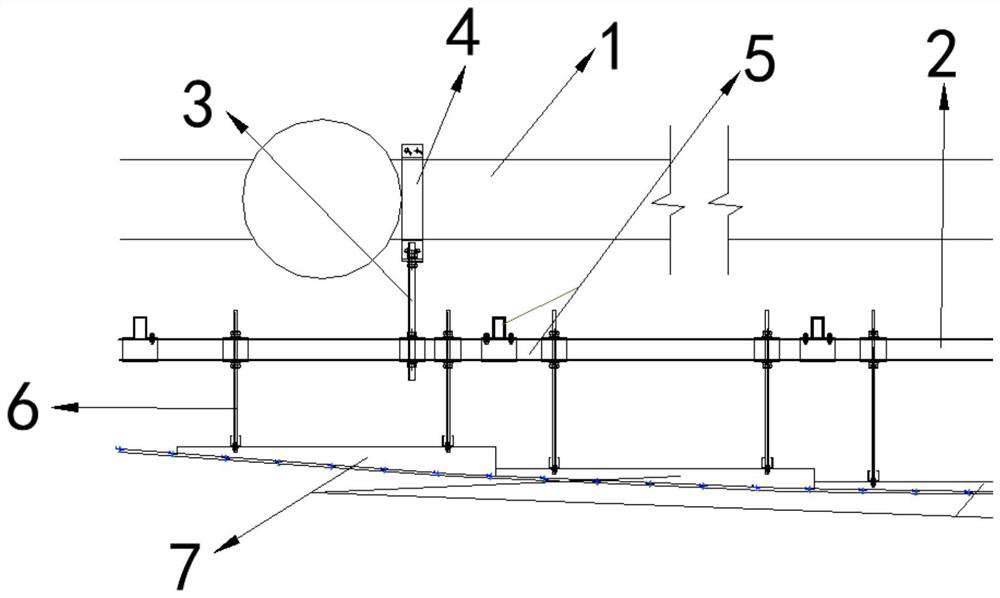

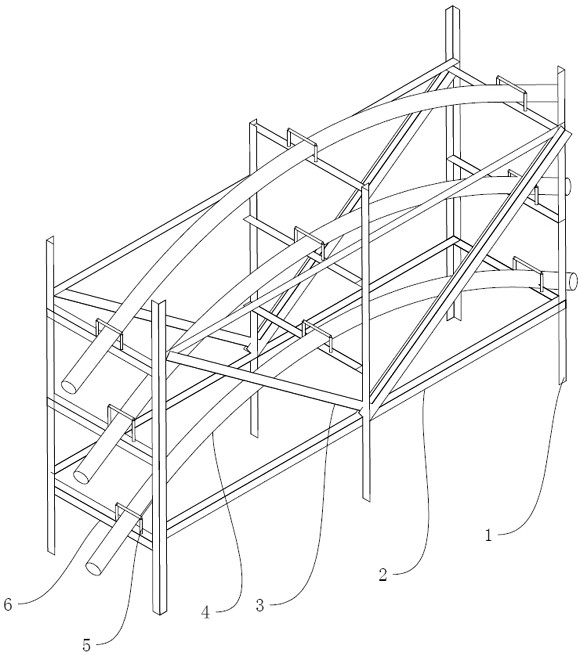

Large-span arc-shaped modeling suspended ceiling construction method

PendingCN113585594AReduce time spent working at heightsImprove construction efficiencyCeilingsCeramic compositeJoist

The invention relates to the technical field of arc-shaped suspended ceiling construction, and particularly discloses a large-span arc-shaped modeling suspended ceiling construction method. The large-span arc-shaped modeling suspended ceiling construction method specifically comprises the following steps that S1, indoor scanning is carried out, and a three-dimensional model is established; S2, according to the three-dimensional model and the indoor actual situation, a suspended ceiling joist is divided into a plurality of ceiling joist units; S3, scaffolds are erected on a construction site, ceiling construction paying-off is carried out, and a supporting frame and the ceiling joist units are mounted in sequence; S4, a silicon ceramic composite board is mounted; S5, putty construction is carried out; and S6, veneer bamboo skin is pasted, and construction is completed. The suspended ceiling joist is divided into the multiple suspended ceiling joist units, and the suspended ceiling joist is mounted in a modularized mode, so that the high-altitude operation time is shortened, the construction efficiency is improved, the labor cost is reduced, and the construction period is shortened.

Owner:CHINA MCC5 GROUP CORP

Triangular supporting bracket of suspended cast bridge block 0

ActiveCN104233961AStable supportImprove bearing capacityBridge erection/assemblyStructural engineeringUltimate tensile strength

The invention relates to engineering machinery, in particular to a triangular supporting bracket of a suspended cast bridge block 0. The triangular supporting bracket comprises at least one set of supporting frames, wherein the supporting frames comprise horizontal girders installed on bridge pier bodies and further comprise diagonal bracing beams, wherein the upper portions of the diagonal bracing beams are connected with the horizontal girders, the lower portions of the diagonal bracing beams are connected with reinforcing steel plates, the bottom faces of the reinforcing steel plates are connected with transverse beams, the lower portions of the transverse beams are connected with bolt rods, and the bolt rods are inserted into reserved holes in the bridge pier bodies. The fixing operation of the lower ends of the diagonal bracing beams can be completed only by inserting the bolt rods into the bolt rod reserved holes in the bridge pier bodies, the triangular supporting bracket is convenient to use, operation work types are few, cross operation and mutual interference are decreased, and labor intensity of workers is reduced. The triangular supporting bracket is low in installation technology difficulty, can be installed by adopting a common work type and does not need special workers, and manpower resource configuration is optimized. In conclusion, cost is effectively saved, efficiency is improved, and the triangular supporting bracket is safe and provides a guarantee.

Owner:福建第一公路工程集团有限公司

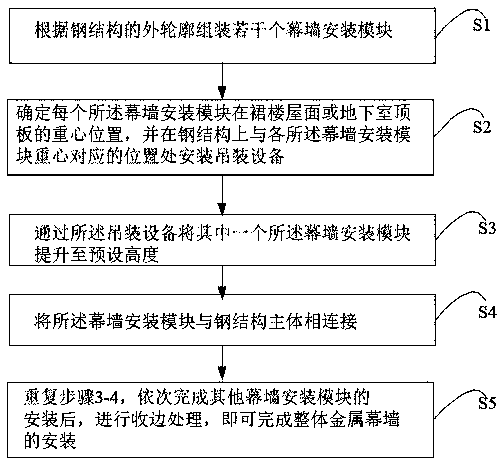

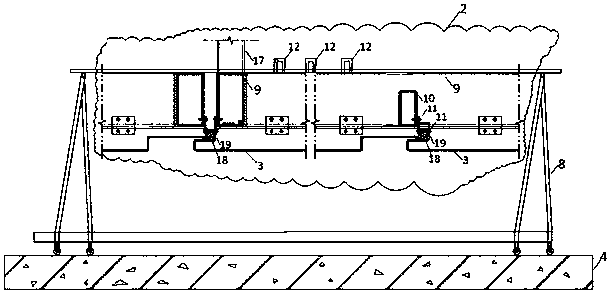

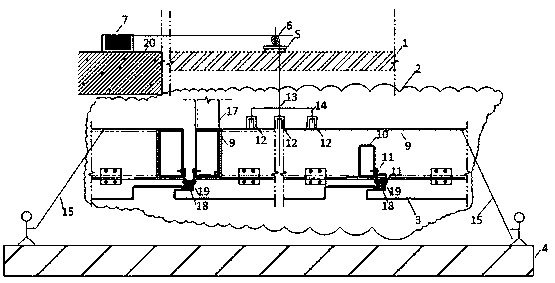

Construction method of metal curtain wall at bottom of high altitude steel structure

InactiveCN110130644AAchieve installationReduce time spent working at heightsWallsBuilding material handlingBasementComputer module

The invention provides a construction method of a metal curtain wall at the bottom of a high altitude steel structure. The construction method comprises the steps that a plurality of curtain wall mounting modules are assembled according to the outer contour of the steel structure; the gravity center positions of all the curtain wall mounting modules on the roof of a podium building or the top plate of a basement are determined, and hoisting equipment mounted on the positions corresponding to the gravity centers of all the curtain wall mounting modules on the steel structure; one of the curtainwall mounting modules is lifted to the preset height through the hoisting equipment; the curtain wall mounting modules are connected with the steel structure main body; the step 3 and the step 4 arerepeated, after mounting of other curtain wall mounting modules is sequentially completed, edge closing treatment is conducted, and namely mounting of the whole metal curtain wall can be completed. According to the construction method, the curtain wall mounting modules serve as hoisting units, the hoisting equipment is mounted on a mounting layer, the curtain wall mounting modules are fixedly connected with the steel structure main body after all the curtain wall mounting modules are integrally and sequentially hoisted and take place, the whole metal curtain wall is mounted, the mounting difficulty is greatly lowered, the construction speed is accelerated, and the construction period is shortened.

Owner:CHINA MCC20 GRP CORP

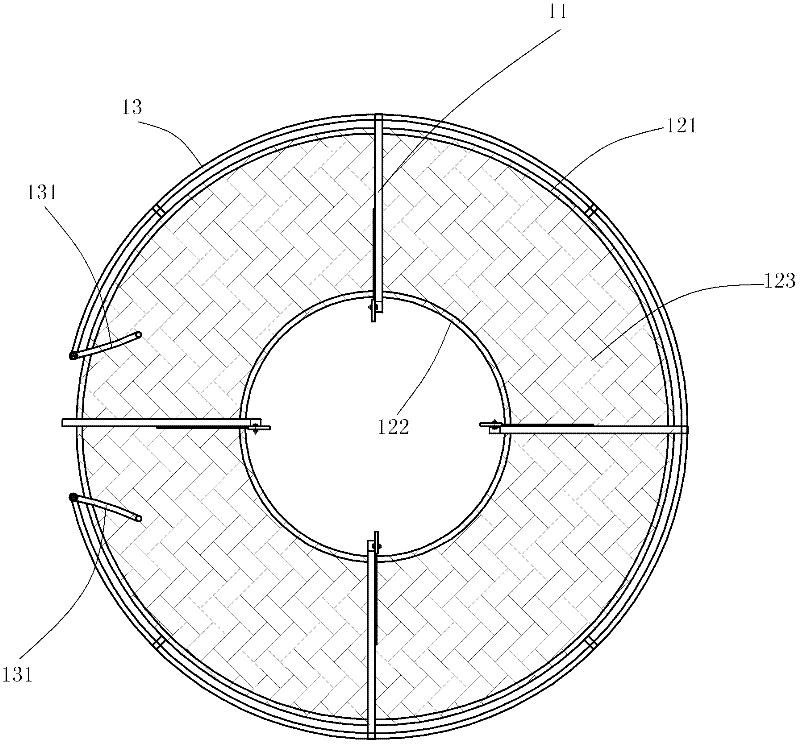

Manufacturing method for steel ladder around cylinder

ActiveCN106271409AImprove consistencyGuaranteed accuracySafety coefficientElectrical and Electronics engineering

The invention relates to the field of steel structure manufacturing, and provides a manufacturing method for a steel ladder around a cylinder. When the manufacturing method for the steel ladder around the cylinder is used for manufacturing the steel ladder around the cylinder, the accuracy of the steel ladder around the cylinder can be better guaranteed, the time for working high above the ground is shortened, and safety factors are improved; a method that an unfolding line of a ladder beam is marked on an overall panel, and interrupted cutting and overall plate curling are carried out is adopted, ladder sections are assembled on the ground according to the size of a real sample, and steps and guard bars are installed according to needs; and step plates are installed on a stacking support plate according to sets from the upper layer to the lower layer on the ground, and a method that cutting separation is carried out on one layer once installation is completed on the layer is adopted for manufacturing.

Owner:CHINA 19TH METALLURGICAL CORP

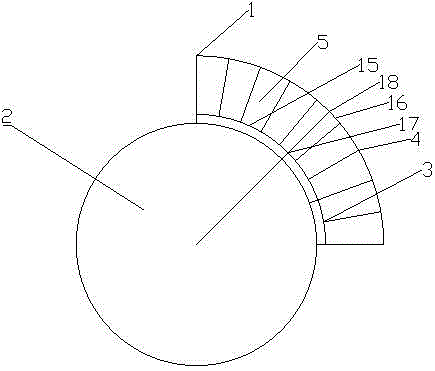

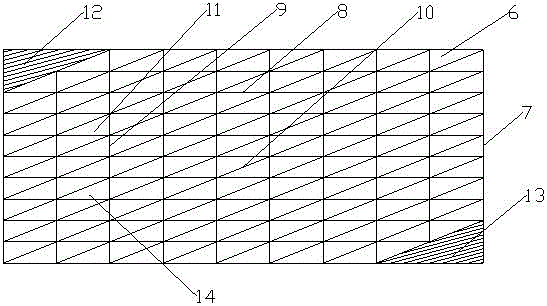

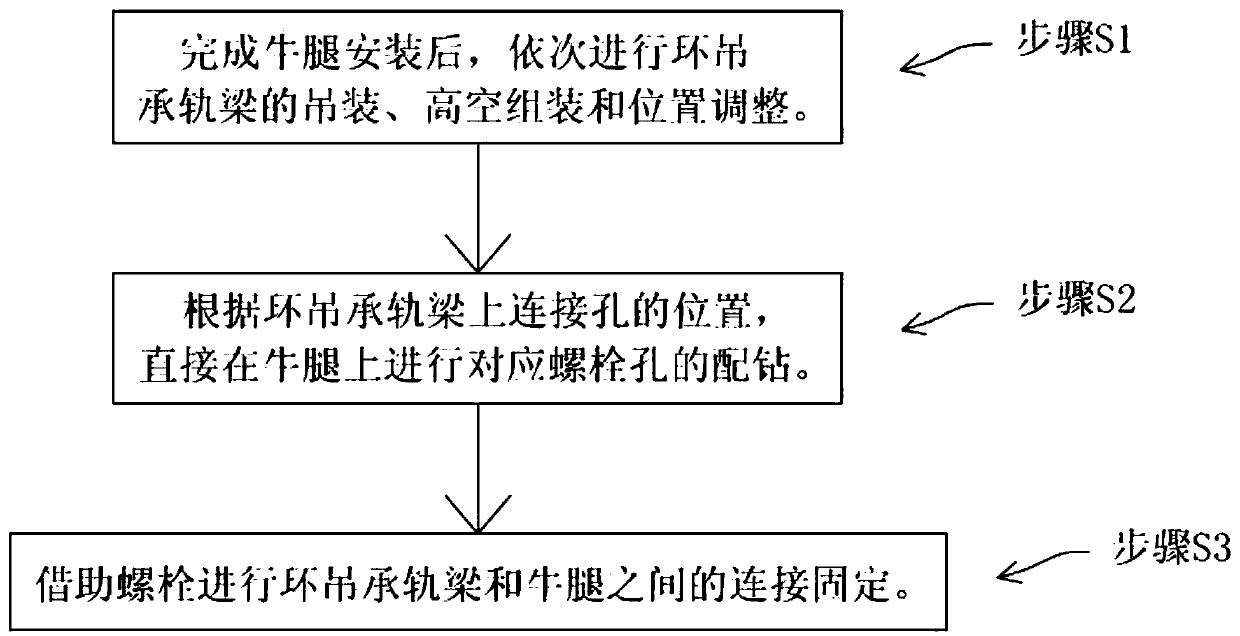

Connecting method of ring crane bearing rail beams and brackets

ActiveCN108049639AEasy positioningReduce machining errorsBuilding material handlingBuilding construction

The invention belongs to the technical field of nuclear power construction and particularly relates to a construction method for connecting ring crane bearing rail beams and brackets. The problems that in the prior art, when the ring crane bearing rail beams and the brackets are connected, the construction efficiency is low, and connecting accuracy is low are solved. The connecting method of the ring crane bearing rail beams and the brackets comprises the steps that S1, after the brackets are fixedly mounted in the high place, the ring crane bearing rail beams are directly hoisted to the brackets, and the ring crane bearing rail beams are assembled and adjusted in position on the brackets; S2, according to the positions of connecting holes in the ring crane bearing rail beams, corresponding bolt holes are directly drilled in the brackets in a matched mode; and S3, after the bolt holes are drilled and machined in the brackets in the matched mode, the ring crane bearing rail beams and the brackets are connected for fixing directly through bolts. The ring crane bearing rail beams and the brackets are connected through the method, the construction period can be shortened, the construction efficiency is improved, and the connecting accuracy can be improved.

Owner:CHINA NUCLEAR IND 23 CONSTR

Slip form integrated lifting type concrete curing device and method

InactiveCN108149940AFlexible stylesSimple and fast operationBuilding material handlingGrain elevatorWater source

The invention provides a slip form integrated lifting type concrete curing device and method. The slip form integrated lifting type concrete curing device includes PPR pipe rings, tee joints, hoses, cotton quilts and iron hooks, the iron hooks are fixed to the lower end of a slip form operating table, the PPR pipe rings are hooked by the iron hooks, and the PPR pipe rings are arranged around structures; and the cotton quilts are hung on the PPR pipe rings which are provided with a plurality of small holes in the circumferential direction, the PPR pipe rings are connected with the hoses throughthe tee joints, and the hoses are connected with water sources. The slip form integrated lifting type concrete curing device and method are mainly applied to the outer wall concrete curing of grain elevators, water towers and other structures, and less manpower and fewer materials are invested to achieve the purposes of real-time curing, energy conservation and environmental protection, safety factor improving and the like.

Owner:鞍钢房地产开发集团有限公司

Sealing structure and method for wall hole

InactiveCN109488036ASimple construction processImprove efficiencyBuilding repairsBuilding construction

The invention discloses a sealing structure and method for a wall hole. The sealing structure comprises a wall and a hole formed in the wall, and comprises a waterproof sealing plug, and the waterproof sealing plug is plugged into the wall hole from the outer side and / or the inner side of the wall. The waterproof sealing plug is in a circular truncated cone shape, the diameter of the top face of the waterproof sealing plug is smaller than the diameter of the wall hole, and the diameter of the bottom face of the waterproof sealing plug is larger than the diameter of the wall hole. When the sealing structure is installed, the top face of the waterproof sealing plug is inserted into the wall hole firstly, and is rapidly embedded into the wall through hammering, the technology is simple, and the efficiency is high. The waterproof sealing plug is formed by waterproof and elastic vinyl plastic, and has the good waterproof performance. According to the sealing structure and method for the wall hole, the technology is simple, the efficiency is high, the construction period is short, time of work high above the ground of constructors is shortened, hidden danger is reduced, the sealing effect is good, and leakage of an outer wall is effectively prevented.

Owner:玉田县长春建筑工程有限公司

Removing method of lifting cover for hoisting

ActiveCN102583149AShorten demolition preparation timeReduce job preparation timeLoad-engaging elementsMarine engineeringFlange

The invention relates to a removing method of a lifting cover for hoisting. The removing method is characterized by comprising the following steps of: installing the lifting cover and an operating platform on equipment to be hoisted; connecting hoisting ropes, starting a main hoist to hoist the equipment to be hoisted to an equipment installing foundation in position; hoisting operators to the operating platform by using an auxiliary hoist, loosening double-head studs and nuts for fixing the lifting cover and equipment flanges, and then returning the operators to the ground by using the auxiliary hoist; lifting a hoisting hook of the main hoist, separating the operating platform and the lifting cover from a top flange of the equipment; rotating an arm rod of the main hoist, and falling the hoisting hook, till the operating platform and the lifting cover fall to the ground; and disassembling the operating platform and the lifting cover on the ground. The removing method has the advantages that by specially-designed matching of the operating platform and the lifting cover, the lifting cover and the operating platform can be quickly disassembled from the equipment after the hoisting is finished, and then the operating platform is separated from the lifting cover on the ground, so that the working efficiency and the hoisting safety are greatly improved, and meanwhile the hoisting construction cost is also reduced.

Owner:CHINA PETROLEUM & CHEM CORP +2

Double-limb thin-wall super high-pier temporary steel collar beam construction method

ActiveCN110067208AReduce time spent working at heightsImprove construction efficiencyBridge erection/assemblyReinforced concreteBranch collar

The invention belongs to the technical field of bridge construction, and particularly discloses a double-limb thin-wall super high-pier temporary steel collar beam construction method. The double-limbthin-wall super high-pier temporary steel collar beam construction method includes the following steps that first, an assembling partis pre-buried in a pier stud; second, a steel collar beam is assembled on site; third, the steel collar beam is lifted to an assembling position; and fourth, a branch collar beam is made to slide to make the outer side of the branch collar beam stick to the pier stud, and then is connected with the assembling part and a hanging part. According to the double-limb thin-wall super high-pier temporary steel collar beam construction method, the construction method ofsteel collar beam field assembling and then lifting is adopted to solve the problem of long working time of personnel in a high altitude during the construction of an existing reinforced concrete collar beam, and the function of seismic resistance can be achieved.

Owner:CHINA CONSTR FOURTH ENG DIV

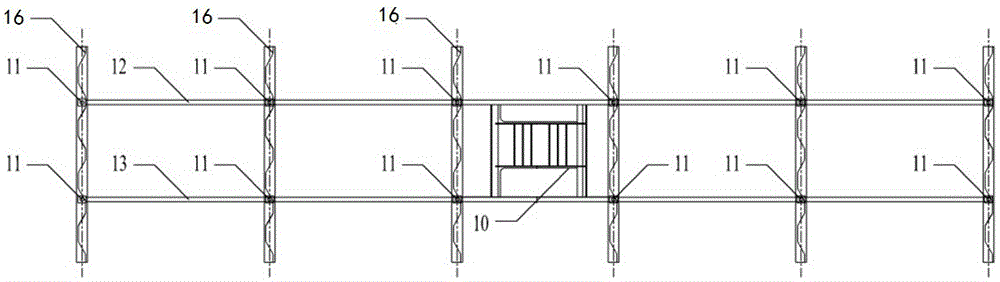

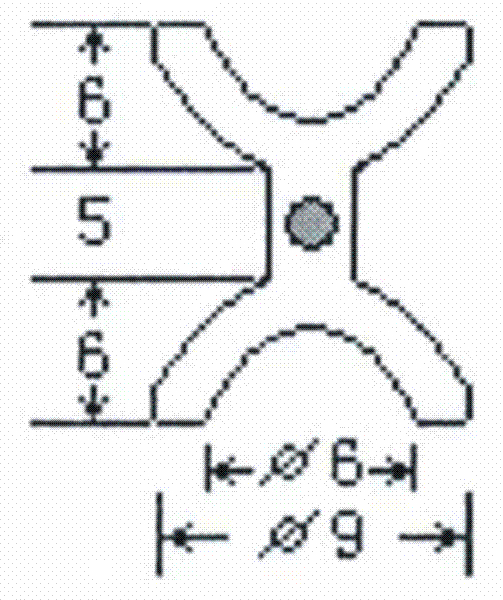

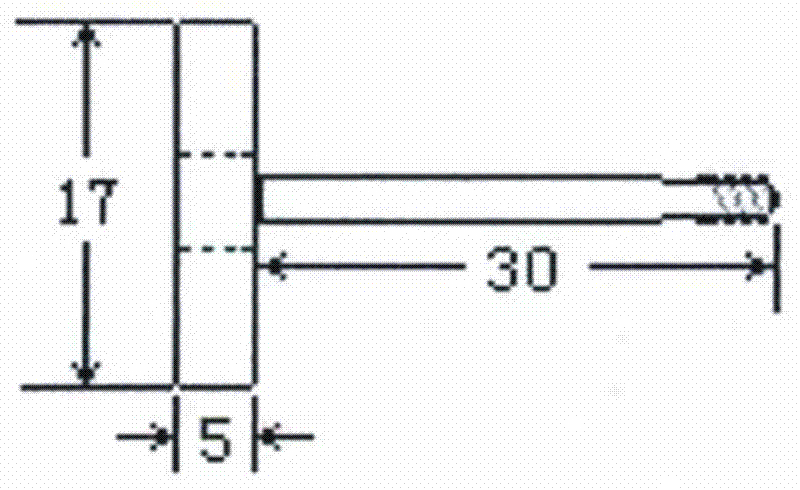

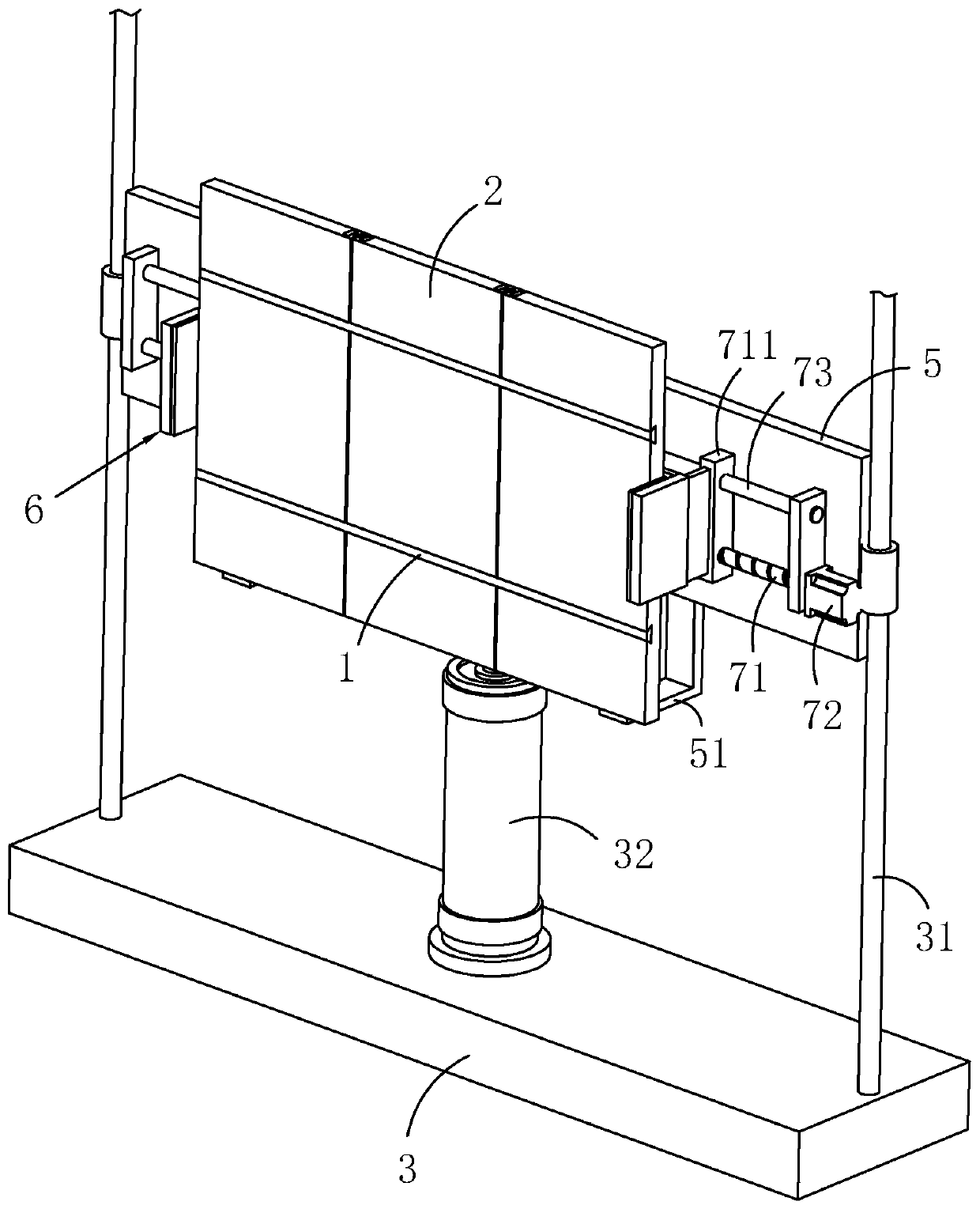

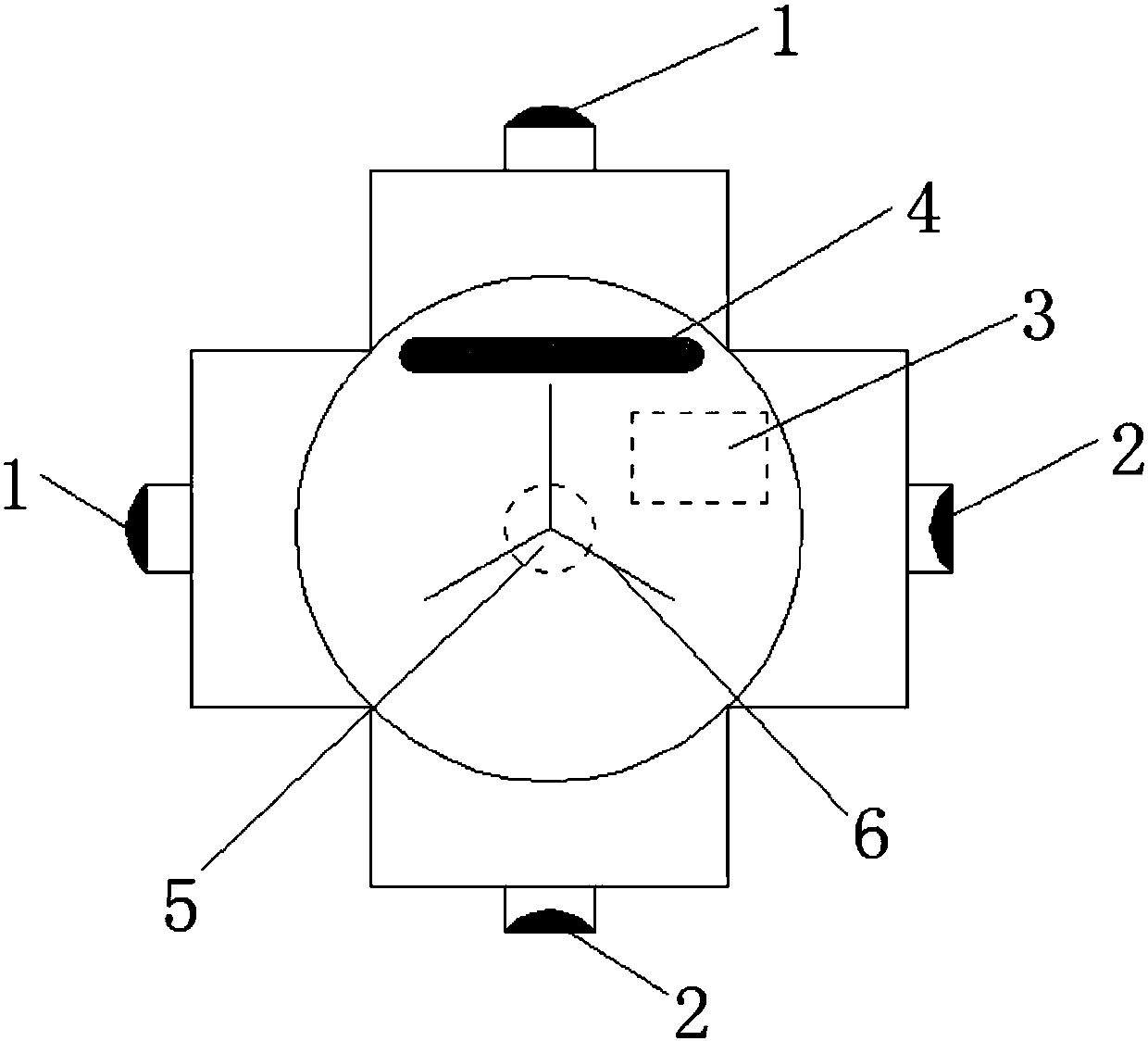

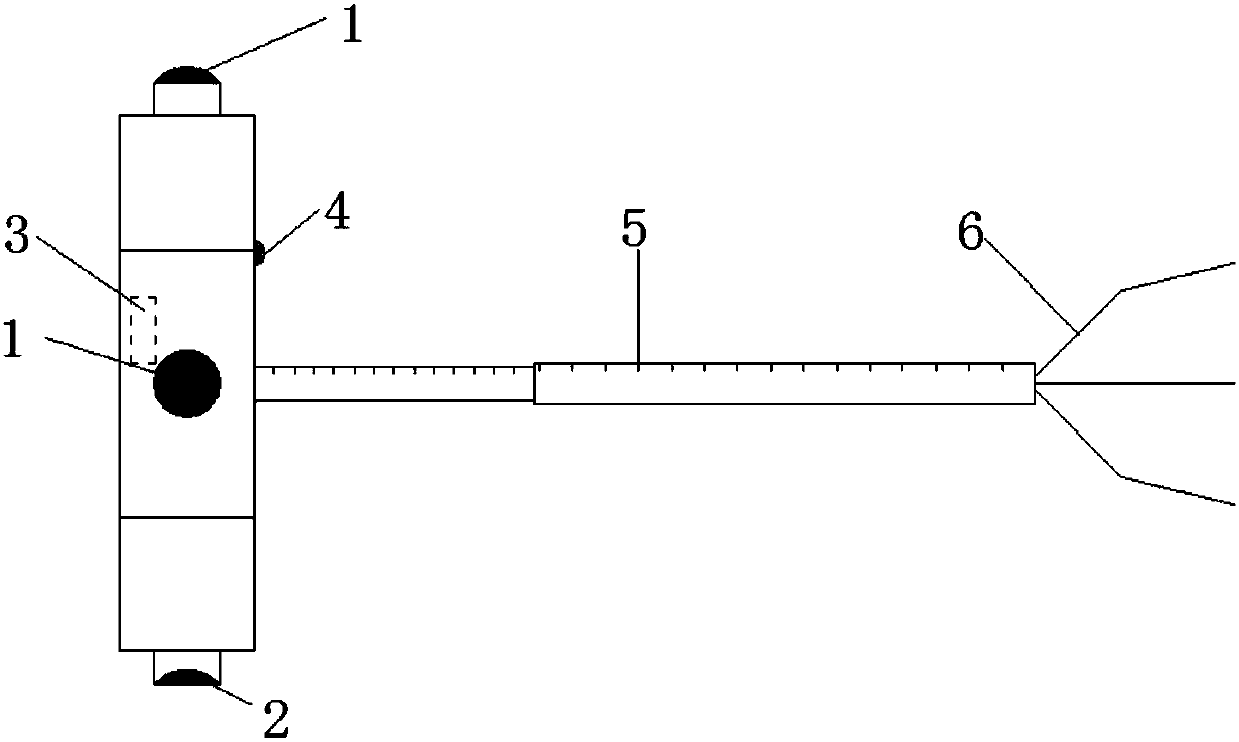

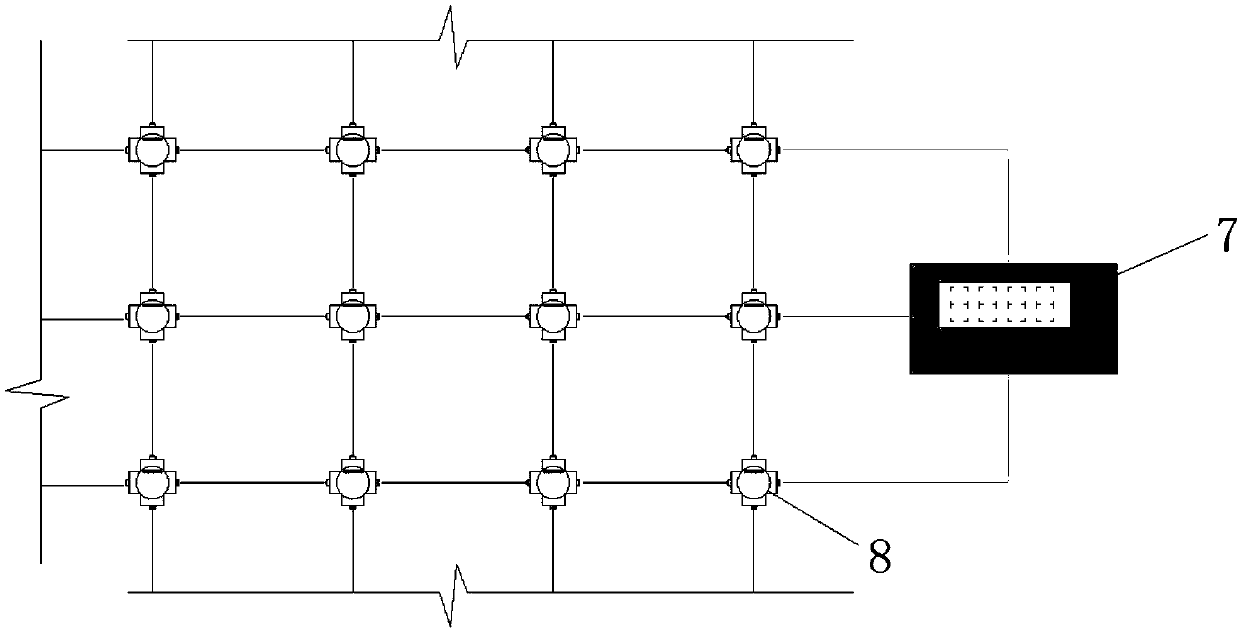

Laser measurement correction system and method for external wall of high-rise building

ActiveCN107843243ASolve the difficulty of measurement controlSolve the accuracy problemReference line/planes/sectorsFixed frameComputer module

The invention discloses a laser measurement correction system and method for an external wall of a high-rise building. The system comprises a control unit, a standard measurement correction unit and aplurality of measurement correction units, wherein the standard measurement correction unit and the measurement correction units are mounted on the same plane and are mutually networked to form a grid structure; the structure of the standard measurement correction unit is the same as that of each measurement correction unit; each unit comprises a cross-shaped structure main body, an adjusting rodand a fixed frame; each cross-shaped structure main body comprises two laser emitting devices, two laser receiving devices, a signal sending module and a horizontal pointer, wherein the two laser emitting devices are arranged at positions of two adjacent cross-shaped tips on the cross-shaped structure main body respectively, and the two laser receiving devices are arranged at positions of the other two adjacent cross-shaped tips on the cross-shaped structure main body respectively. The laser measurement correction system disclosed by the invention has the advantages that the measurement precision is high, the labor cost of construction can be effectively reduced, the system can be circularly utilized for a plurality of times and energy saving and environment protection are realized.

Owner:CHINA FIRST METALLURGICAL GROUP

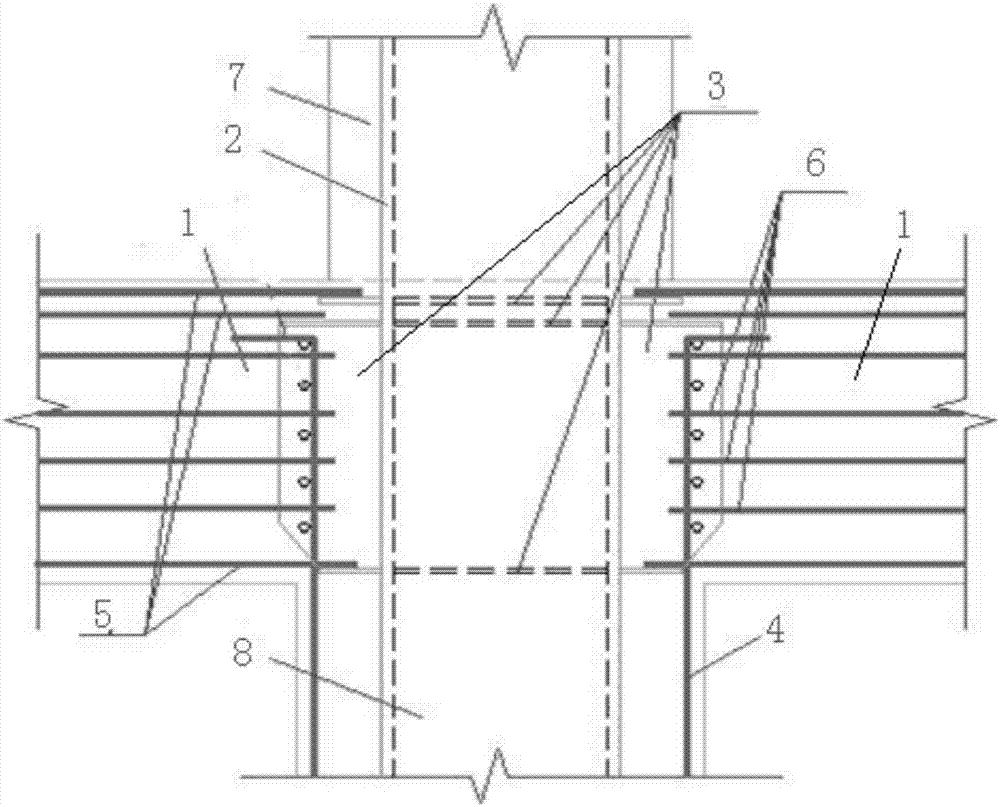

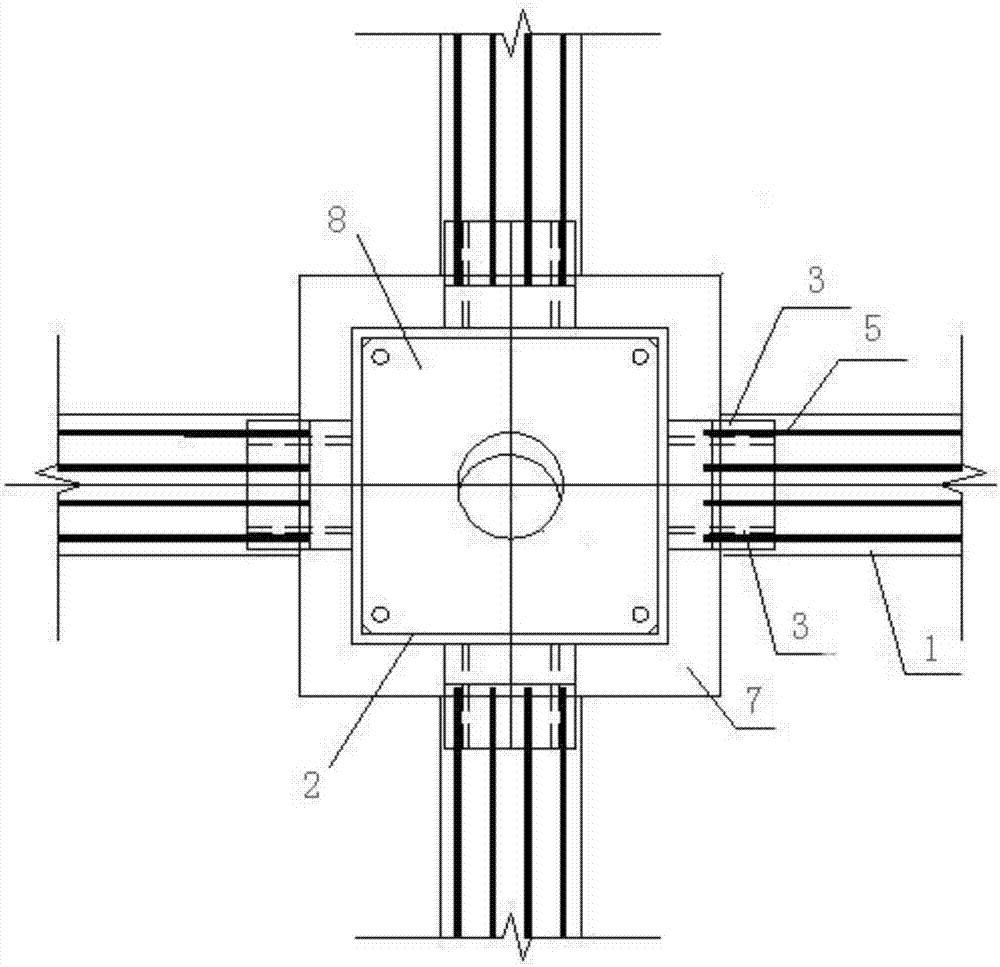

Novel steel-concrete beam-column joint construction structure and comprehensive construction method

PendingCN107489277AIncrease profitSolve the deficiencies of deepeningBuilding material handlingConcrete beamsArchitectural engineering

The invention provides a novel steel-concrete beam-column joint construction structure and a comprehensive construction method. A joint three-dimensional model is established by utilizing a BIM technology before main body structure construction, connecting joints of concrete beams and steel reinforced columns are deepened, rebar putting plate integrated processing is conducted by utilizing BIM data, the BIM technology is utilized to simulate joint construction before on-site construction, and an optimal scheme is determined; the steel reinforced columns are transported to a construction site for being installed, column longitudinal bars are fixed to the outer sides of the steel reinforced columns through rebar putting plates in the vertical direction, and beam longitudinal bars and torsional bars are fixed in the transverse direction; and concrete pouring is conducted. Joint deepening, three-dimensional expressing, construction simulating are conducted by utilizing the BIM technology, so that conciseness and efficiency are achieved. The rebar putting plates are precisely welded to the steel reinforced columns in advance, on-site construction is extremely convenient, and the construction period is shortened. The invention belongs to the technical field of building construction.

Owner:CCFED THE FIRST CONSTR & ENG +1

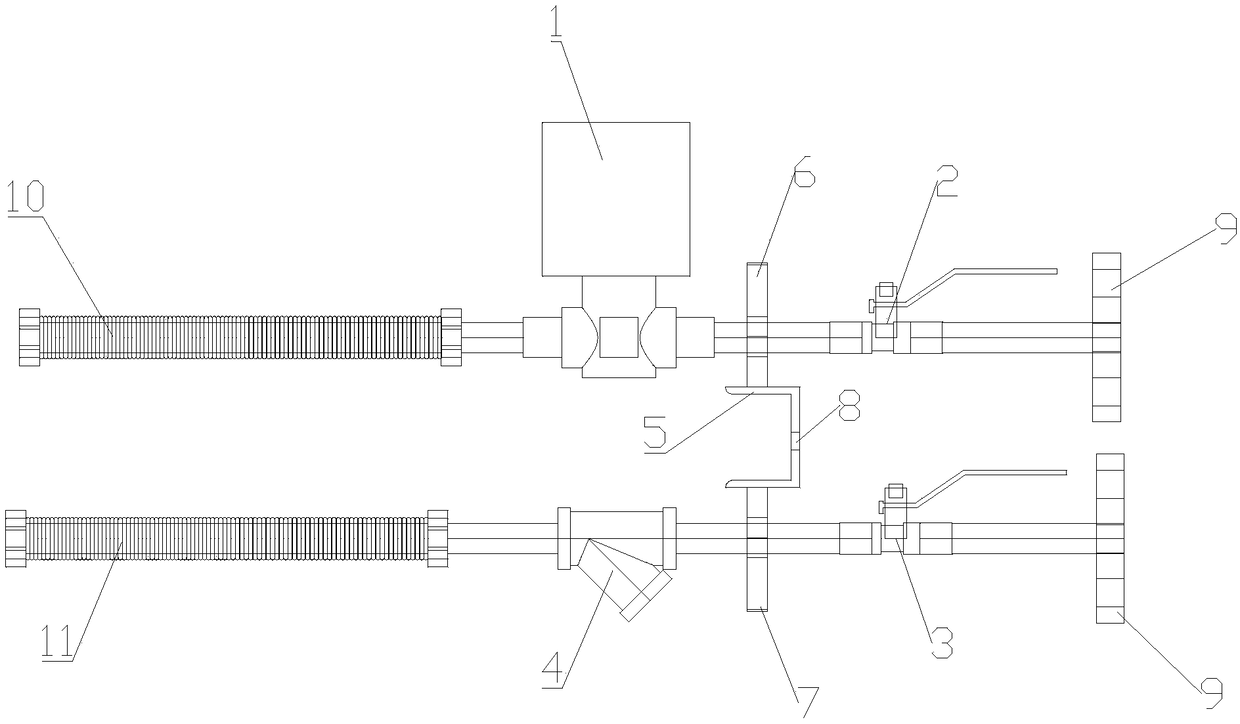

Prefabricated valve set for four-pipe fan coiler

InactiveCN108825839AImprove the quality of engineering constructionThe quality and appearance are neat and beautifulPipe supportsFlanged jointsEngineeringVALVE PORT

The invention provides a prefabricated valve set for a four-pipe fan coiler. The prefabricated valve set comprises a support, an electric two-way valve, a first ball valve, a second ball valve and a filter. The support comprises a steel channel, first supporting plates and second supporting plates. Multiple first supporting plates are fixedly connected to the outer side of the first side wall of the steel channel. Multiple second supporting plates are fixedly connected to the outer side of the second side wall of the steel channel. The first side wall and the second side wall are parallel. Thefirst end of the electric two-way valve is connected with the first end of the first ball valve through a first pipe section. The first end of the filter is connected with the first end of the secondball valve through a second pipe section. The first pipe section penetrates through holes in the first supporting plates, and the second pipe section penetrates through holes in the second supportingplates. According to the prefabricated valve set, the project construction quality is improved greatly, the prefabricated valve set has integrality and compactness, and is easy to install, and unnecessary potential safety hazards of high-altitude operation are avoided.

Owner:CHINA CONSTR THIRD ENG BUREAU INSTALLATION ENG CO LTD +1

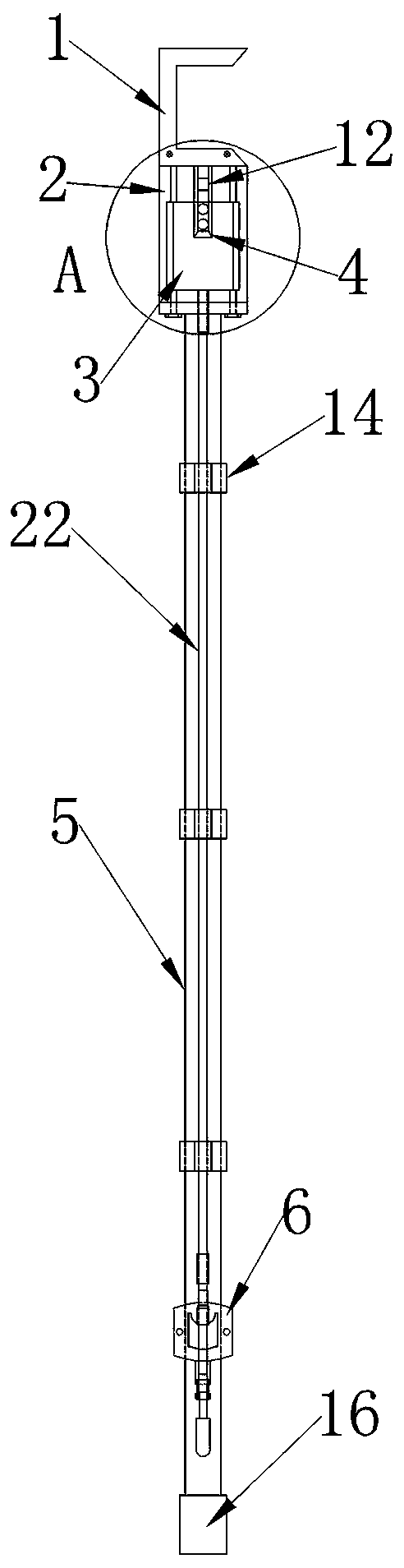

An insulating rod that shortens the working time of replacing the suspension insulator of the grounding electrode with power

ActiveCN109103809BFirmly connectedEasy to useApparatus for overhead lines/cablesEngineeringMaterials science

Owner:国网河南省电力公司超高压公司 +1

Prefabricated corner wall and construction method

PendingCN110295690AGuaranteed to be verticalReduce time spent working at heightsWallsHeat proofingEngineeringWall plate

The invention discloses a prefabricated corner wall. The prefabricated corner wall is provided with a first wallboard and a second wallboard which are connected vertically, and the inner sides of theconnection ends of the first wallboard and the second wallboard are both connected with the side face of a first vertical square pipe; the inner side of the first wallboard is connected with the sideface of a second vertical square pipe, and the inner side of the second wallboard is connected with the side face of a third square pipe; the horizontal distance between the second vertical square pipe and the end of the first wallboard, and the horizontal distance between the third vertical square pipe and the end of the second wallboard are 45-70 mm separately; a plurality of transverse square pipes are arranged between the first vertical square pipe and the second vertical square pipe as well as between the first vertical square pipe and the third vertical square pipe at intervals; the inner sides of the first wallboard and the second wallboard are fixedly provided with transverse steel belts connected with the transverse square pipe, the first vertical square pipe, the second verticalsquare pipe and the third vertical square pipe; and the two ends of each transverse steel belt are each provided with an extension segment, and the inner sides of the first wallboard and the second wallboard are coated with first insulating layers with the thickness of 35-40 mm.

Owner:ZHONGKE QIYE (DALIAN) TECH CO LTD

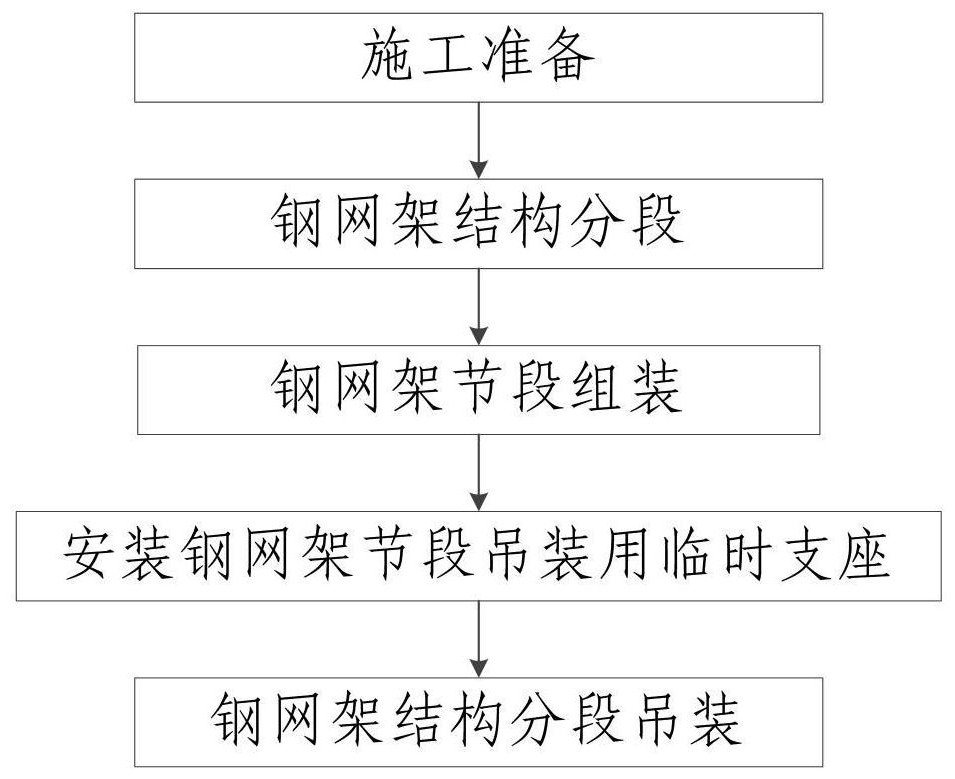

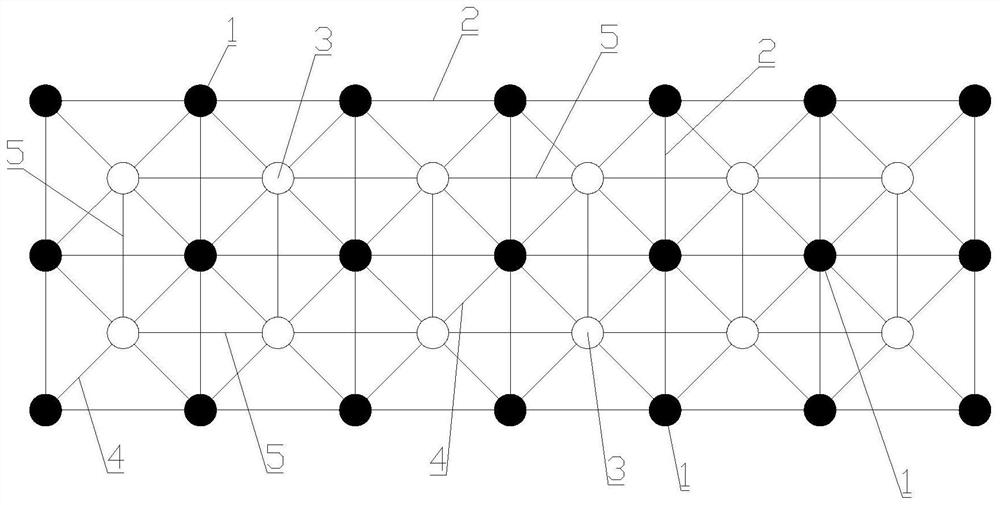

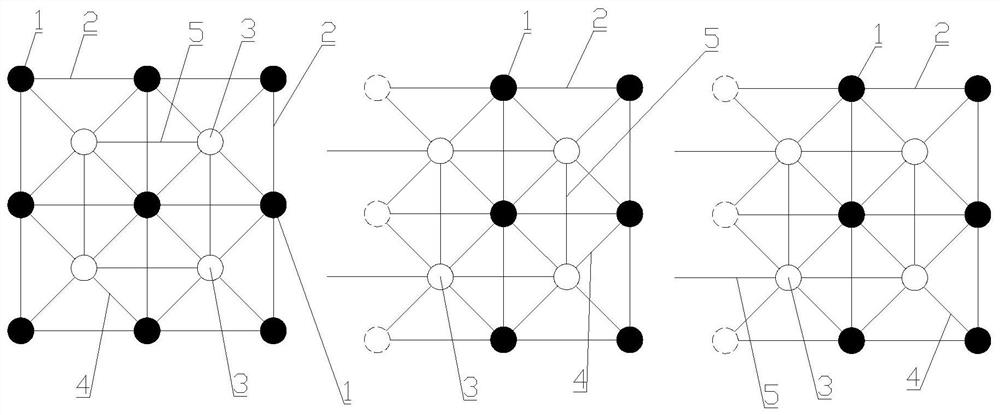

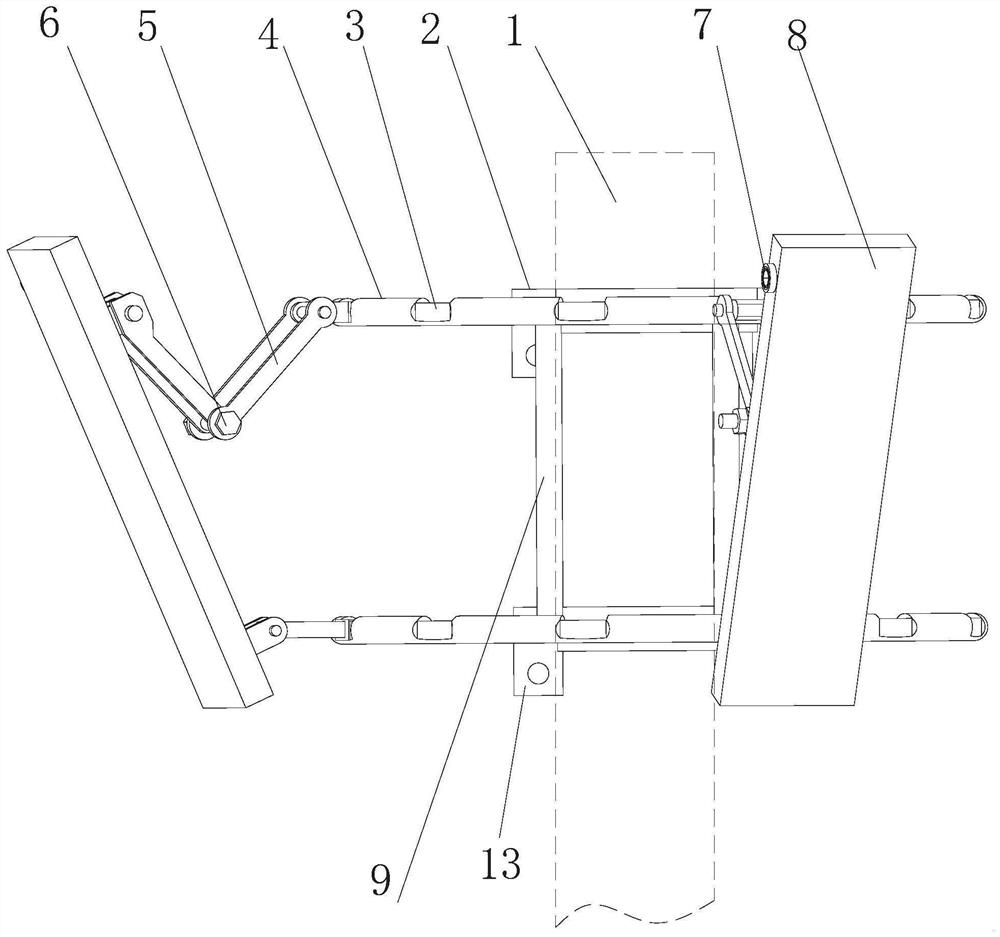

Segmented hoisting construction method for steel grid frame structure

ActiveCN112267568AReduce time spent working at heightsEasy to operateBuilding material handlingStructural engineeringControl theory

The invention discloses a segmented hoisting construction method for a steel grid frame structure. A steel grid frame structure to be hoisted comprises a lower layer grid frame and an upper layer gridframe, the lower layer grid frame and the upper layer grid frame are each formed by assembling four chord balls and chord members, and the lower layer grid frame and the upper layer grid frame are connected through web members. The segmented hoisting construction method comprises the following steps: 1, construction preparation is conducted; 2, the steel grid frame structure is segmented; 3, thesteel grid frame segments are assembled; 4, a temporary support for hoisting the steel grid frame segments is mounted; and 5, the steel grid frame structure is segmentally hoisted. The construction operation is convenient and fast, the steel grid frame structure is divided into the multiple steel grid frame segments, the method that the steel grid frame segments are assembled on the ground, and then the assembled steel grid frame segments are hoisted one by one is adopted, thus the assembling quality and the assembling efficiency of the steel grid frame segments can be effectively improved; and the temporary support is adopted for temporary supporting in the hoisting process of the steel grid frame segments, the installation precision of the steel grid frame segments can be effectively guaranteed, the aerial work time during hoisting of the steel grid frame structure is shortened, and the safety risk is small.

Owner:中铁二十局集团市政工程有限公司

Portable 5G base station antenna and base station

ActiveCN113659303AReasonable arrangementReduce bumpsAntenna supports/mountingsStructural engineeringMechanical engineering

The invention relates to a portable 5G base station antenna and a base station. The portable 5G base station antenna comprises a first mounting rack, a holding clamp capable of fixing the first mounting rack on a holding pole, and an antenna body mounted on the first mounting rack; the first mounting rack comprises two first clamping plates which are arranged at intervals in a vertical direction, outer rods arranged on the outer rings of the first clamping plates, middle rods connected between the first clamping plates and the outer rods and a plurality of connecting plates for connecting the two first clamping plates, and the first mounting rack can be locked and prop against the holding pole through a locking piece after being matched with the holding clamp; and the antenna body is installed on the outer rods through angle positioning structures, and the side surface of the antenna body is provided with an angle indicator for naked eyes to see degrees. According to the portable 5G base station antenna and the base station of the invention, manual carrying and manual installation can be conveniently carried out, and the installation of an installation bracket can be carried out by a lifting rope for several times, so that the installation bracket can be suitable for various remote installation places with inconvenient traffic.

Owner:北京鑫昇科技有限公司

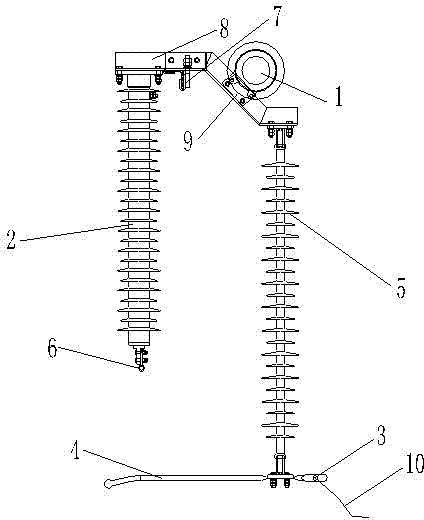

Pure air gap arrester

ActiveCN103701038APermanent useFixed discharge distance is accurateSpark gap detailsOvervoltage arrestors using spark gapsHigh resistanceFiber

The invention discloses a pure air gap arrester. The pure air gap arrester comprises a discharge counter, a discharge counter frame, a suspension beam below the discharge counter frame, an arrester main body, an upper gap rod, a fixing universal hook, a lower gap rod, an insulator, and a connection wire mounting hole, wherein the arrester main body and the insulator are arranged in parallel; both the upper gap rod and the lower gap rod are made of, by weight, carbon fiber 40%, high-carbon graphite 40%, copper powder 5%, white steel powder 5% and conductive resin 30% by pressing, wherein the carbon fiber is in a bar-like, round, octagonal, elliptical or ovale shape. The pure air gap arrester provided by the invention has the advantages of long service life, high stability, high strength, low specific gravity, light weight, and high resistance to heat, corrosion and radiation.

Owner:吉林市能兴电力设备有限公司

Cable saddle rigidization structure and integral position-fixing and mounting method thereof

InactiveCN112064514AGuaranteed positionDoes not affect constructionBridge structural detailsBridge erection/assemblySteel frameTower

The invention relates to a cable saddle rigidization structure and an integral position-fixing and mounting method thereof. The cable saddle rigidization structure comprises a section steel frame bodyand multi-layer cable saddles mounted on the section steel frame body, wherein the position fixing of the multi-layer cable saddles relative to each other is achieved through relative coordinates; relative space angles of the multi-layer cable saddles are ensured to be in accordance with relative space angles of cable saddles in cable bent tower segments; the section steel frame body comprises frame body vertical rods corresponding to embedded parts in the cable bent tower segments in position, position-fixing horizontal rods transversely connected to the frame body vertical rods, and frame body horizontal rods longitudinally connected to the frame body vertical rods; the cable saddles are placed on the position-fixing horizontal rods; and the positions of the cable saddles are fixed through position-limiting section steel. The multi-layer cable saddles are controlled through the relative coordinates during rigidization, so that the relative positions of the multi-layer cable saddlesare guaranteed. The multi-layer cable saddles are integrally hoisted to the tower after rigidization and then controlled through absolute coordinates. The position fixing is fast, and the position fixing precision is high. In addition, position fixing performed aloft is not needed, and the construction of a cable bent tower is not affected, so that the overall construction progress is accelerated.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD +1

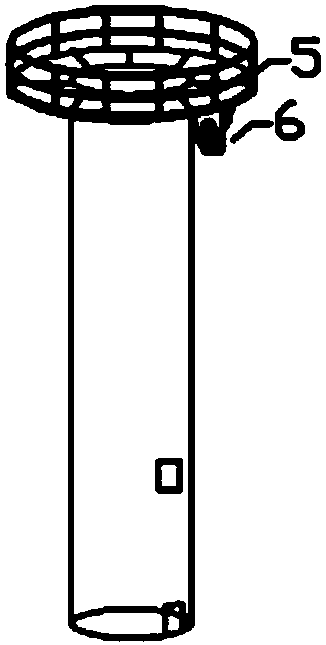

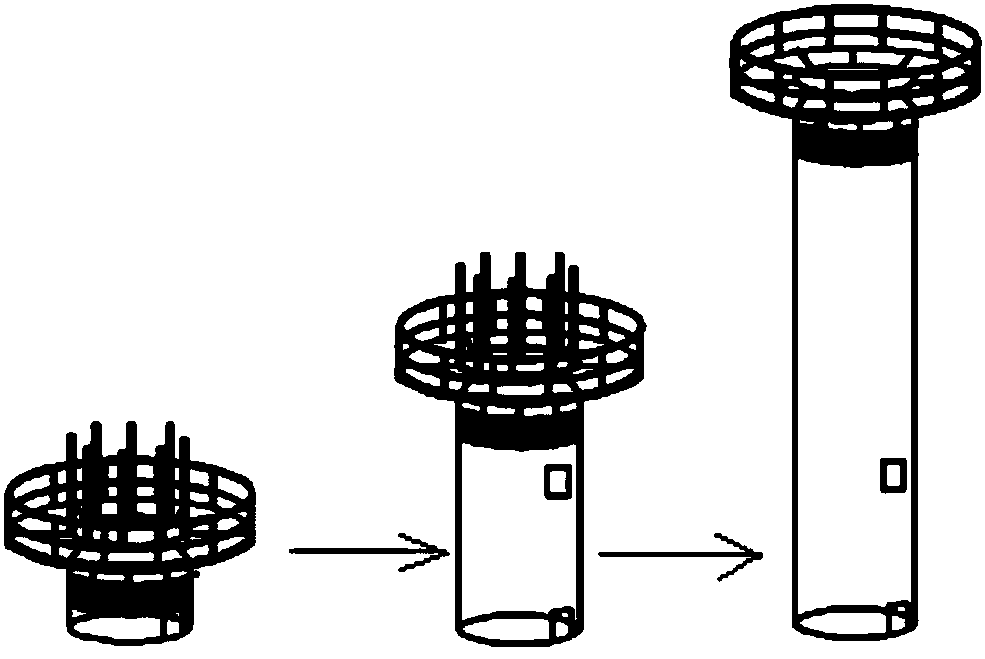

Fabricated bridge substructure and construction method thereof

PendingCN112609562AReduce investmentReasonable designBridge structural detailsBridge erection/assemblyArchitectural engineeringLap joint

The invention discloses a fabricated bridge substructure which comprises a foundation structure, a prefabricated bent cap and a quasi-prefabricated pier column unit, and foundation reserved vertical ribs are arranged at the top of the foundation structure; cover beam reserved vertical ribs are arranged on the lower side of the prefabricated bent cap. At least one sprue gate vertically penetrating through the prefabricated bent cap is arranged in the area covered by the reserved vertical ribs of the bent cap; a standard prefabricated pier column unit is a hollow cylinder with openings in the upper portion and the lower portion and penetrates through the foundation reserved vertical ribs to be vertically inserted into the top of the foundation structure; the prefabricated bent cap is in lap joint with the top of the standard prefabricated pier column unit and extends into the hollow area of the standard prefabricated pier column unit through the cover beam reserved vertical ribs to be connected in an inserted mode. Expansion concrete is cast in situ in the sprue gate and the hollow area of the standard prefabricated pier column unit. The construction quality can be controlled in a cast-in-place and prefabricating combined mode, investment of formworks is omitted, the weight is low, installation is convenient and rapid, the aerial work time can be effectively shortened, the construction efficiency is improved, and the construction period is shortened.

Owner:SICHUAN JIAOTOU CONSTR ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com