Pure air gap arrester

A lightning arrester, pure air technology, applied in the direction of overvoltage arrester, spark gap, electrical components, etc. using spark gap, can solve the problem of wire burn, can not guarantee effective discharge distance, can not play lightning protection effect, etc. Strong corrosion resistance and radiation resistance, solve the maintenance cost, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

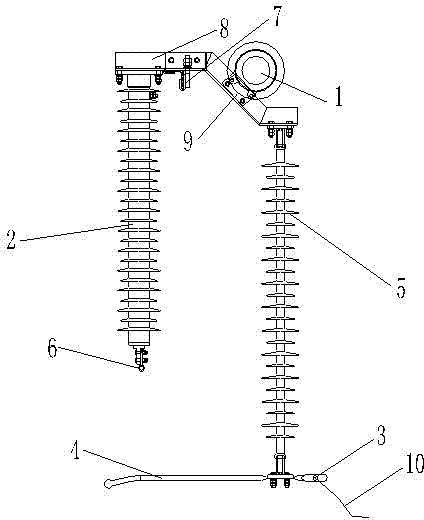

[0009] Refer to figure 1 As shown, a pure air gap arrester includes a discharge counter 1, and a discharge counter frame 9 arranged below the discharge counter 1, a suspension beam 8 arranged below the discharge counter frame 9, and a surge arrester body 2 arranged below the suspension beam 8. , And the upper gap rod 6 arranged under the arrester body 2, and the fixed universal hook 7 arranged under the suspension beam 8 side by side with the arrester body 2, and the lower gap rod 4 arranged under the upper gap rod 6, and arranged in the lower gap The insulator 5 above the rod 4, and the connecting wire mounting hole 3 arranged below the insulator 5 and on the same plane as the lower gap rod 4; the upper gap rod 6 and the lower gap rod 4 are made of carbon fiber, high carbon graphite, and copper powder , Made of white steel powder and conductive resin; among them, the weight percentage of carbon fiber is 20%, the weight percentage of high carbon graphite is 40%, the weight perc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com