Ultrosonic wave concerted biological adsorption water treating method

A biological adsorption and ultrasonic technology, applied in the field of water treatment, can solve the problems of high energy consumption and high production cost, and achieve high mass transfer efficiency, high removal rate and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

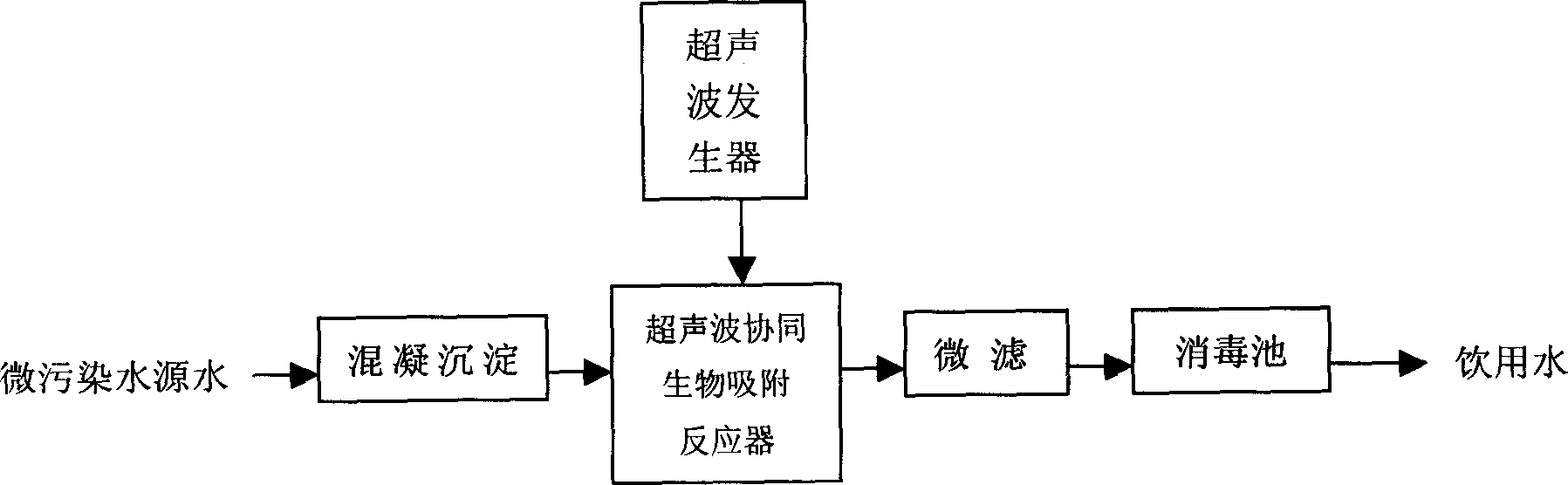

[0012] Such as figure 1 As shown, under the condition that the water temperature is normal temperature, the polluted surface water whose index concentration of potassium permanganate is less than 12mg / l is lifted by the water pump to the sedimentation tank for coagulation and sedimentation, and the water is mixed with FeCl 3 As a coagulant, the effluent after coagulation and sedimentation flows into the ultrasonic synergistic biosorption reactor under pressure. The effective volume of the reactor is 11 cubic meters. The residence time in the reactor was 30 minutes. Fill the reactor with 1 ton of powdered activated carbon with a particle size of 200 meshes, microorganisms are attached to the surface and pores of the activated carbon, and a blower is used to blow air to the porous aeration pipe installed in the reactor, and the activated carbon and water are discharged. Aeration, the ratio of the aeration volume to the influent flow rate is 8:1. Use a liquid whistle ultrasonic...

Embodiment 2

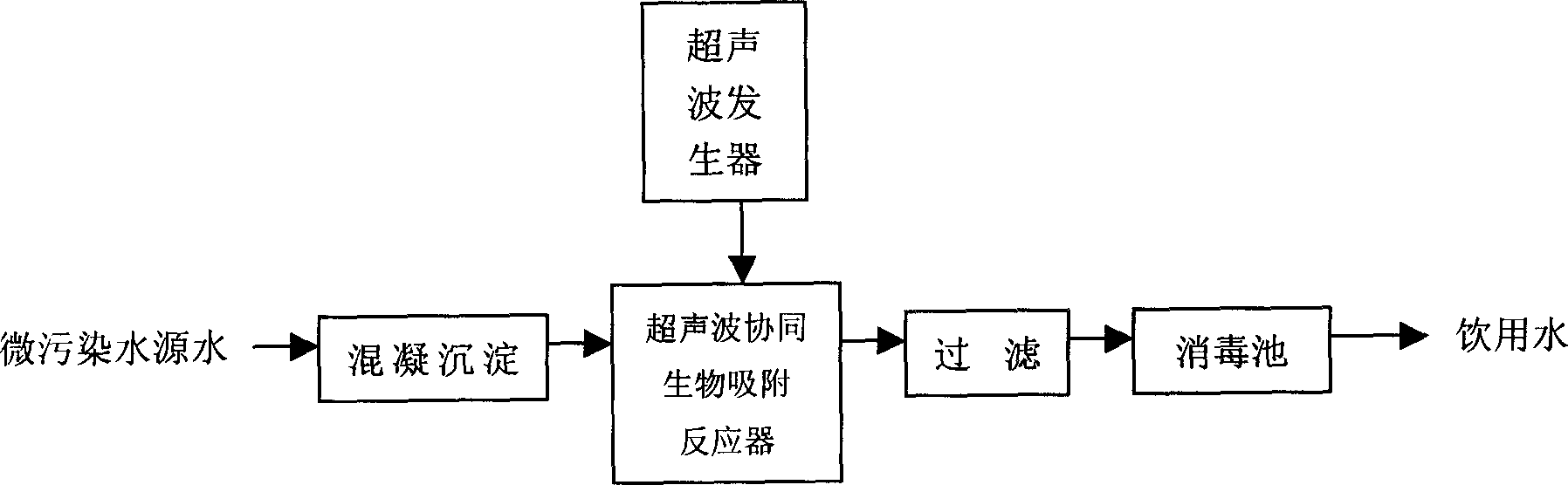

[0014] Such as figure 2 As shown, under the condition that the water temperature is lower than 15°C, the polluted surface water whose index concentration of potassium permanganate is less than 12 mg / l is lifted by the water pump to the sedimentation tank for coagulation and sedimentation, and is treated with FeCl 3 As a coagulant, the effluent after coagulation and precipitation flows into the ultrasonic synergistic biosorption reactor under pressure. The effective volume of the reactor is 11 cubic meters. The residence time of water in the reactor was 30 minutes. Fill the reactor with 1 ton of granular activated carbon with a particle size of 3mm. Microbes are attached to the surface and pores of the activated carbon, and the air compressor is used to blow air to the microporous aeration head installed in the reactor. and water for aeration, the ratio of the aeration volume to the influent flow rate is 10:1. Corresponding to the granular activated carbon, use the probe-typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com