Integral installation device for transformer test bench

An integral installation and transformer technology, applied in the field of transformers, can solve the problems of safety risks, high labor intensity, long hours of construction workers working at heights, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

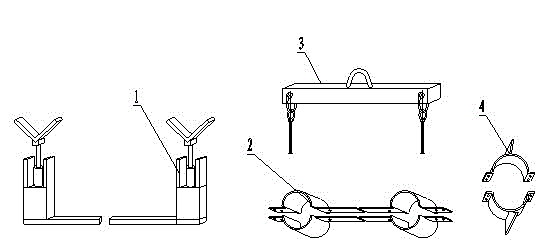

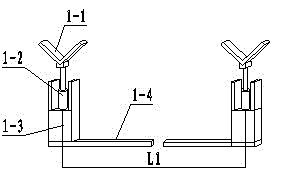

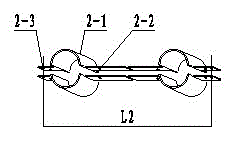

[0020] Referring to Fig. 1 and Fig. 2, the present invention includes a double electric pole level correction mechanism 1, an integral hoisting support 2 of a transformer stand, a lifting cross arm 3 and a cross arm adjustment support 4, and the double electric pole level correction mechanism 1 has different numbers. It is composed of less than two groups of horizontal correction units, and a pair of V-shaped support blocks 1-1 arranged symmetrically on the left and right are arranged in each group of horizontal correction units, and the V-shaped support blocks 1-1 are installed on the hydraulic jack 1-2 At the end, the distance between the central axes of the two V-shaped support blocks is L1=2.5 meters, which meets the requirements for the distance between the pole roots of the standard platform area of the transformer stand. The hydraulic jack 1-2 is fixed on the support body 1-3, and the support body 1- 3 is fixed on the two ends of the bottom plate 1-4, and the bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com