Cable saddle rigidization structure and integral position-fixing and mounting method thereof

A cable saddle, integrated technology, applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., can solve the problems of long positioning time, restricting the construction progress of the cable tower, and high requirements for the positioning accuracy of the cable saddle. The effect of measuring the positioning time and avoiding the influence of bad weather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

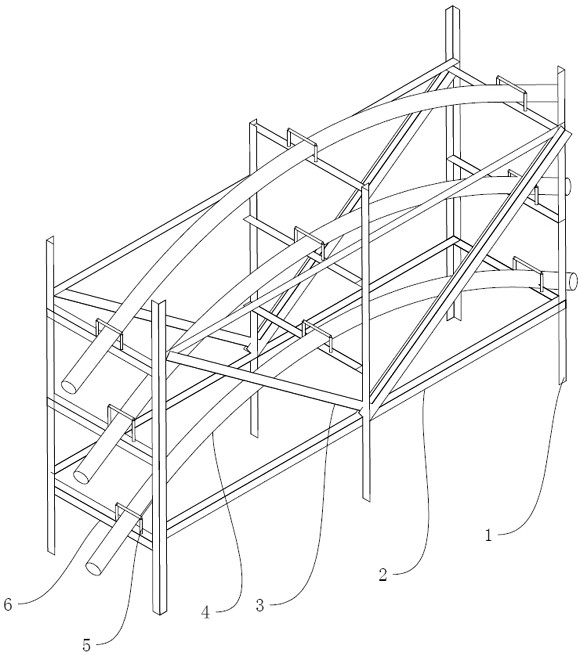

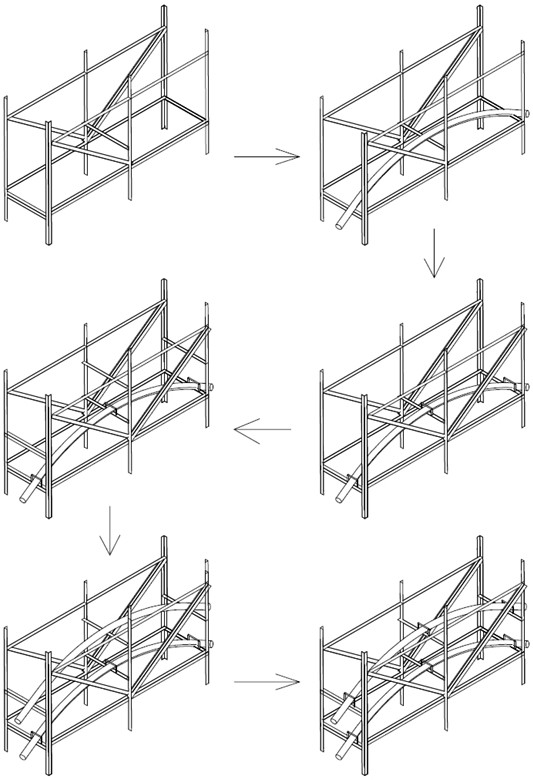

[0039] like figure 1 As shown, a cable saddle rigid body structure 10 includes a shaped steel frame body and a multi-layer cable saddle 4 installed on the shaped steel frame body. The multi-layer cable saddles are positioned with relative coordinates to ensure that the multi-layer The relative spatial angle between the cable saddles corresponds to the relative spatial angle of the cable saddles within the cable tower segment.

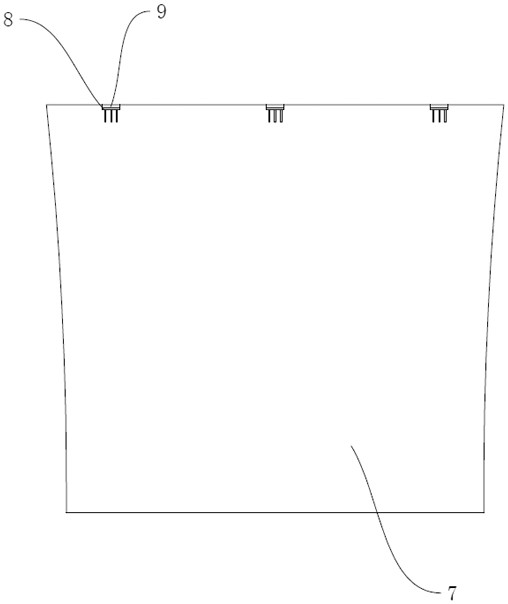

[0040] The shaped steel frame body includes a frame body vertical rod 1 corresponding to the position of the embedded part 8 of the cable tower segment, a positioning flat rod 6 connecting the frame body vertical rod horizontally, and a frame body flat rod 2 longitudinally connecting the frame body vertical rod And connect the frame body slanting bar 3 of the frame body vertical bar, the cable saddle is placed on the positioning flat bar and is positioned and fixed by the limit section steel 5.

[0041]The shaped steel frame has a cuboid structure as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com