Fabricated bridge substructure and construction method thereof

A prefabricated and bridge technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of great impact on urban traffic, difficult to control the appearance quality, heavy weight of prefabricated piers, etc., to shorten the construction period and weight. The effect of light and reduced investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

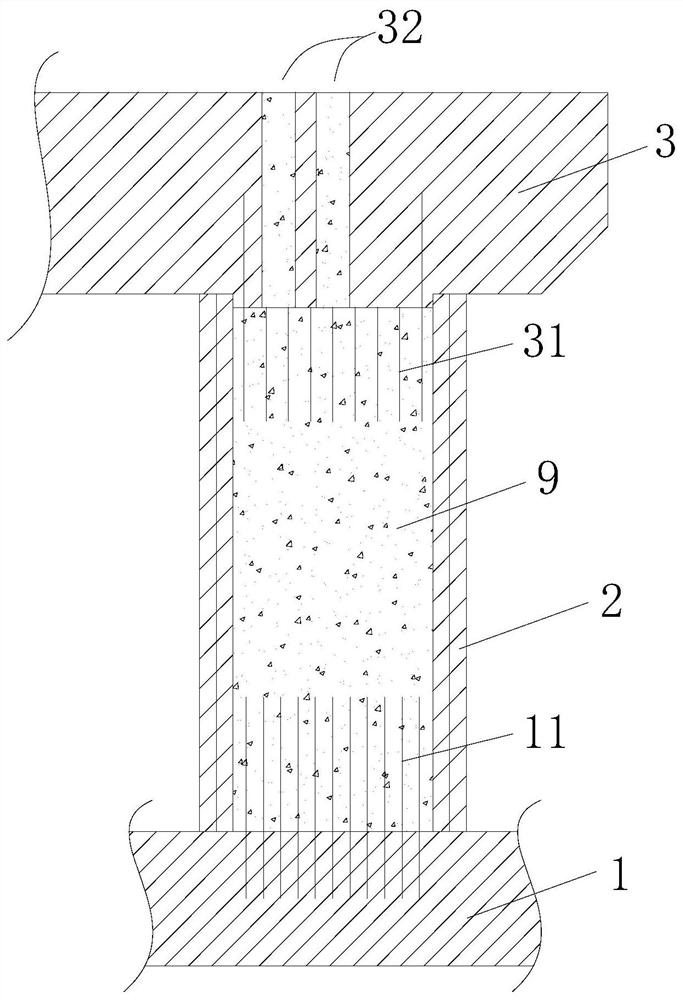

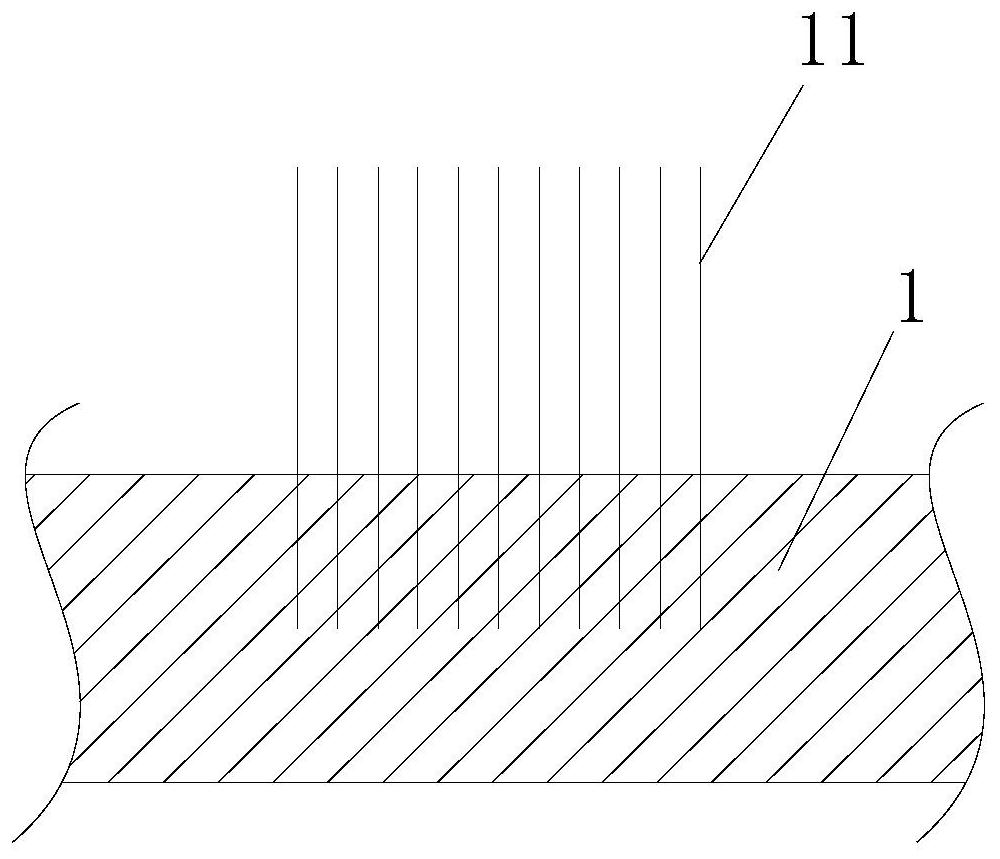

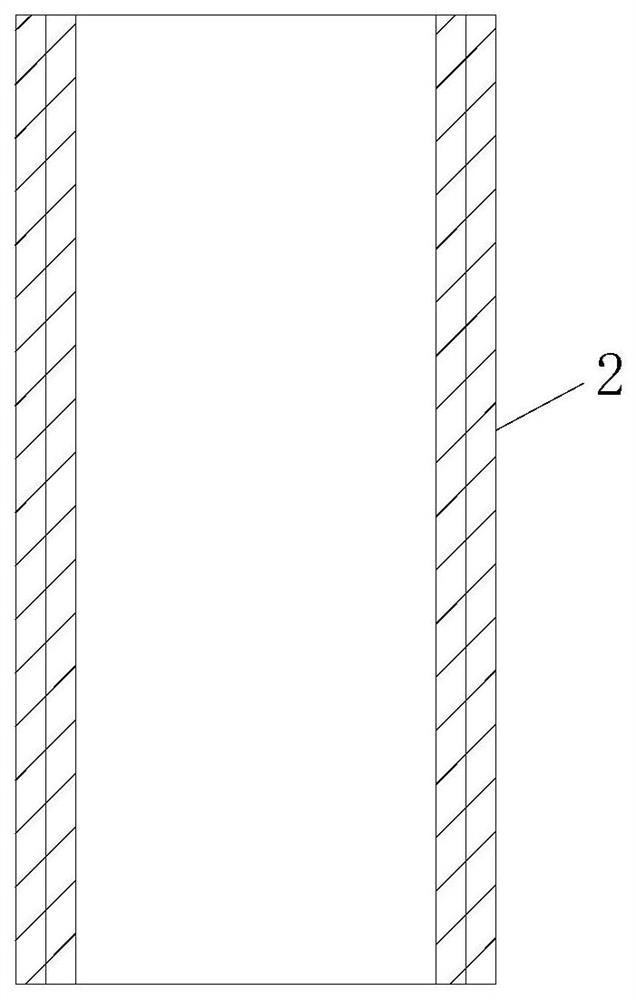

[0057] Such as Figure 1 to Figure 4 As shown, the present invention provides a prefabricated bridge substructure, comprising: a base structure 1, the top of the base structure 1 is annularly arranged with a number of reserved vertical ribs 11 protruding from the top surface of the base structure 1; prefabricated cover beams 3, prefabricated The lower side of the cover beam 3 is circularly arranged with several reserved vertical ribs 31 protruding downwards from the bottom surface of the prefabricated cover beam 3; in the coverage area of the reserved vertical ribs 31 of the cover beam, there is at least one vertically penetrating prefabricated cover beam 3; the base structure 1 and the prefabricated cover beam 3 are connected through the standard prefabricated pier unit 2; the standard prefabricated pier unit 2 is a hollow cylinder with upper and lower openings, and the standard prefabricated pier unit 2 is vertically inserted into the On the top of structure 1, the vertica...

Embodiment 2

[0060] Further, such as Figure 5 to Figure 7 As shown, the standard prefabricated pier column unit 2 can be improved on the basis of Embodiment 1. In this embodiment, the lower inner wall ring of the standard prefabricated pier column unit 2 is provided with several downwardly extending lower end vertical ribs 22 , the vertical rib 22 at the lower end is connected to the main reinforcement of the prefabricated part of the standard prefabricated pier column unit 2 and is bent inward and downward to extend downwards, and can extend downwards to be flush with the lower end surface of the standard prefabricated pier column unit 2. When the standard prefabricated pier column unit 2 When the unit 2 is vertically inserted on the top of the foundation structure 1, the reserved vertical ribs 11 of the foundation can be inserted into the standard prefabricated pier column unit 2 and correspondingly welded, screwed or bound with the lower vertical ribs 22 to further strengthen the struct...

Embodiment 3

[0066] Further, such as Figure 9 to Figure 11As shown, the standard prefabricated pier column unit 2 can be improved on the basis of the second embodiment. In this embodiment, the first prefabricated pier column 5 further designed on the basis of the standard prefabricated pier column unit 2 is also included. The prefabricated pier column 5 includes a standard prefabricated pier column unit 2 and a plurality of first vertical ribs 51, the plurality of first vertical ribs 51 are integrally formed with the upper end vertical ribs 24 of the standard prefabricated pier column unit 2, and extend upwards out of the standard prefabricated pier The upper end surface of the column unit 2; and the second prefabricated pier column 6 further designed on the basis of the standard prefabricated pier column unit 2, the second prefabricated pier column 6 includes the standard prefabricated pier column unit 2 and some second vertical ribs 61, and some second prefabricated pier columns 61 Two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com