Manufacturing method for steel ladder around cylinder

A manufacturing method and steel ladder technology, which is applied in the field of steel structure manufacturing, can solve problems such as curvature of finished veneer, poor consistency of helix angle, long time of high-altitude operation, and influence on the manufacturing accuracy of the whole ladder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

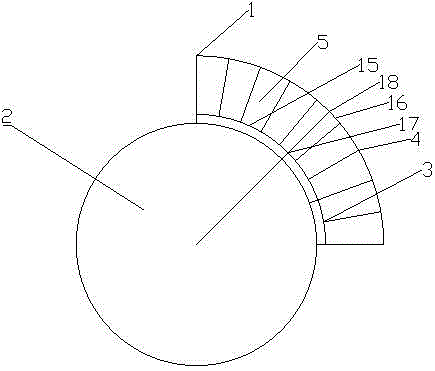

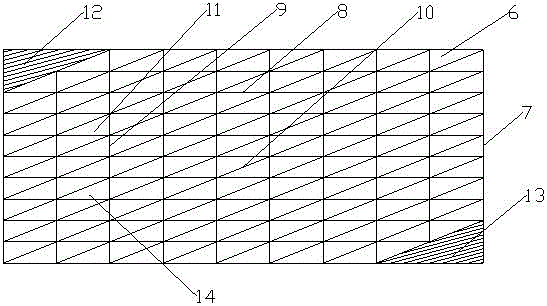

[0033] Below in conjunction with accompanying drawing, the present invention will be further described:

[0034] see figure 1 , figure 2 As shown, the manufacture method of this cylindrical steel ladder 1 comprises the following steps:

[0035] Fabrication of support plates, including the following processes:

[0036] a. Lay at least two plates that meet the design requirements and use them to make the inner support plate 3 and the outer support plate 4 respectively. Because the width of the inner support plate 3 and the outer support plate 4 is the same, but the length of the superimposed drawing method of the outer support plate 4 is greater than the length of the superimposed drawing method of the inner support plate 3, so the effective length for making the outer support plate plate should be greater than that of the outer support plate. In order to make the effective length of the inner support board plate 6, the effective width of the two plates is the same.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com