Support-free mounting method of fabricated concrete frame building

An installation method and a frame building technology, which are applied in the processing of building materials, construction, building construction, etc., can solve the problems of high installation and dismantling costs of scaffolding support systems, high difficulty of scaffolding support systems, and failure to fully utilize them. Achieve the effect of fast and convenient installation and removal of support-free tooling, reduce the time of high-altitude operations, and reduce problems and losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

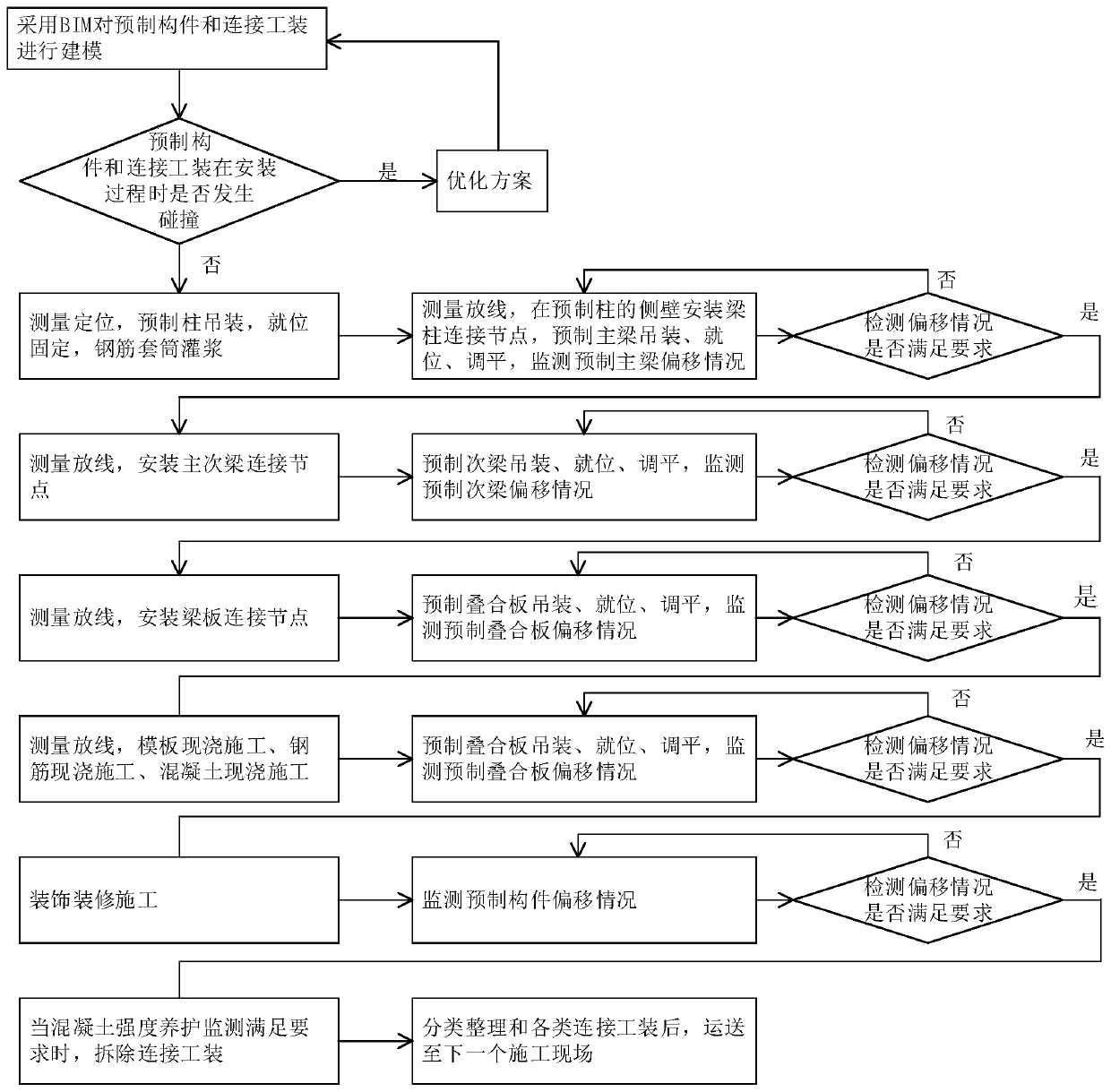

[0048] This implementation provides a support-free installation method for prefabricated concrete frame buildings, and its application to large public buildings, such as libraries, includes the following steps:

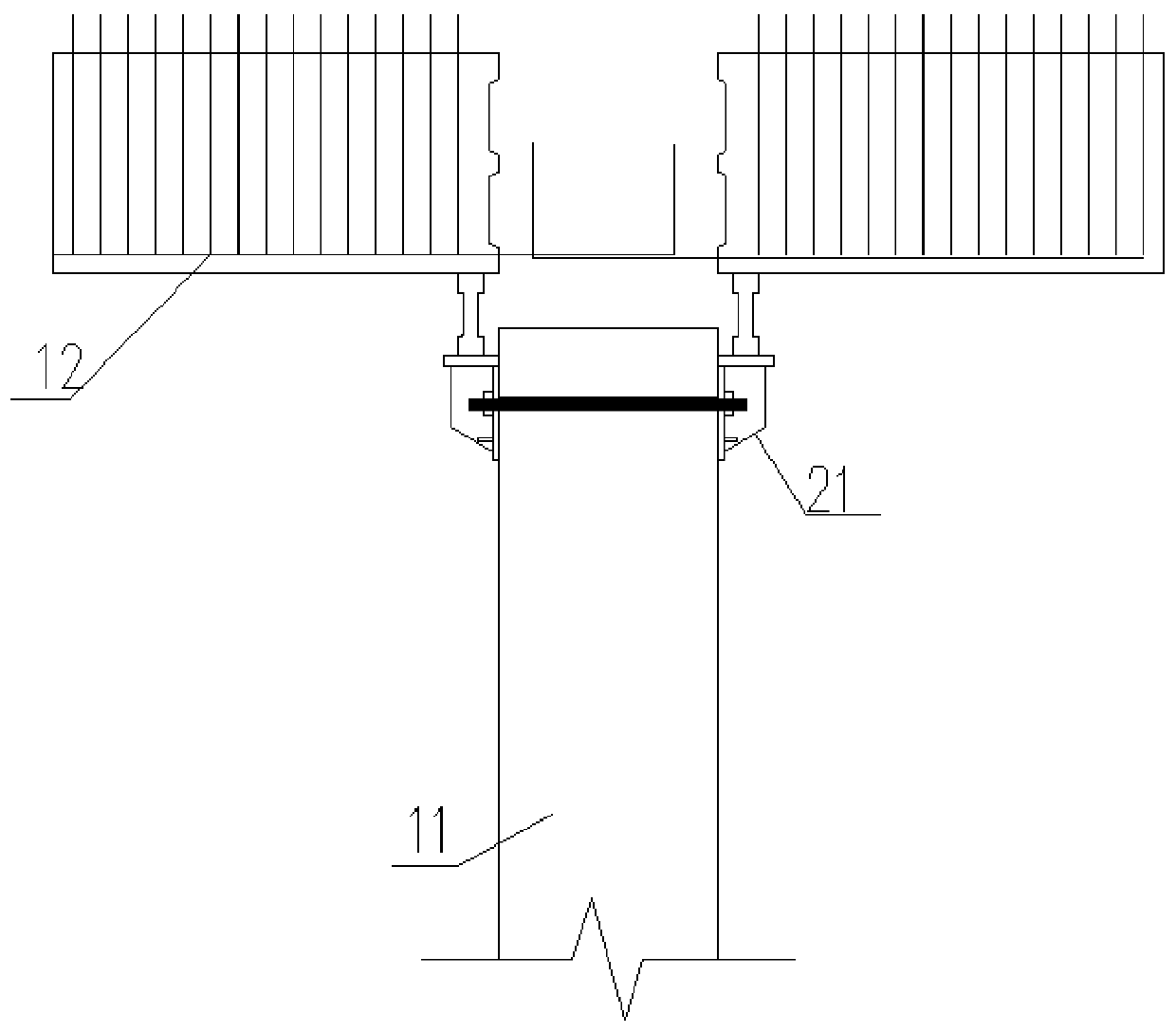

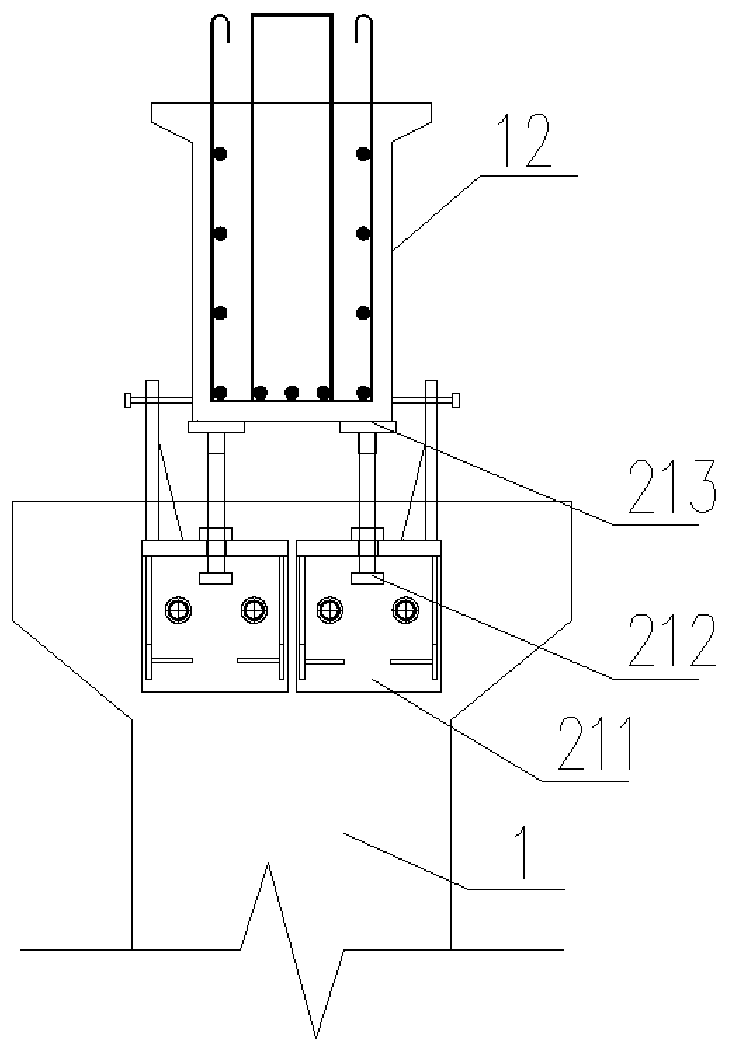

[0049] S1. Use BIM to model the prefabricated components and connecting tooling, and obtain the installation plan of the prefabricated components and connecting tooling; the prefabricated components include: prefabricated columns 11, prefabricated main beams 12, prefabricated secondary beams 13 and prefabricated composite panels 14; the connecting tools include : Beam-column connection node 21, primary and secondary beam connection node 22 and beam-slab connection node 23.

[0050] Specifically, in step S1, the following steps are included:

[0051] S11, modeling according to the actual shape, weight and size of the prefabricated component 1 and the connecting tool 2;

[0052]S12. When the prefabricated component 1 and the connecting tool 2 do not collide during the ...

Embodiment 2

[0078] In recent years, with the development of urban subway rail transit, closely following the pace of construction of the subway network, the comprehensive development of resources such as the above-mentioned properties, underground space, and depots along the subway has become a development zone for the comprehensive utilization of urban subway rails in various places. A new development model to come. The development and operation of superstructure properties along the subway, underground space, and depot superstructure properties are the specific implementation platforms for the development strategy of "subway + property" and also a new growth point for benefits.

[0079] Taking a depot project as an example, the comprehensive development of the superstructure property of the depot has a greater impact on the construction difficulty and construction period compared with the previous construction of the depot, especially the construction of the superstructure property of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com