Connecting method of ring crane bearing rail beams and brackets

A corbel connection and rail-bearing beam technology, which is applied in construction, building structure, and building material processing, can solve problems such as low construction efficiency, low connection accuracy, and long hours of high-altitude operations, so as to improve construction efficiency, Effects of improving safety and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

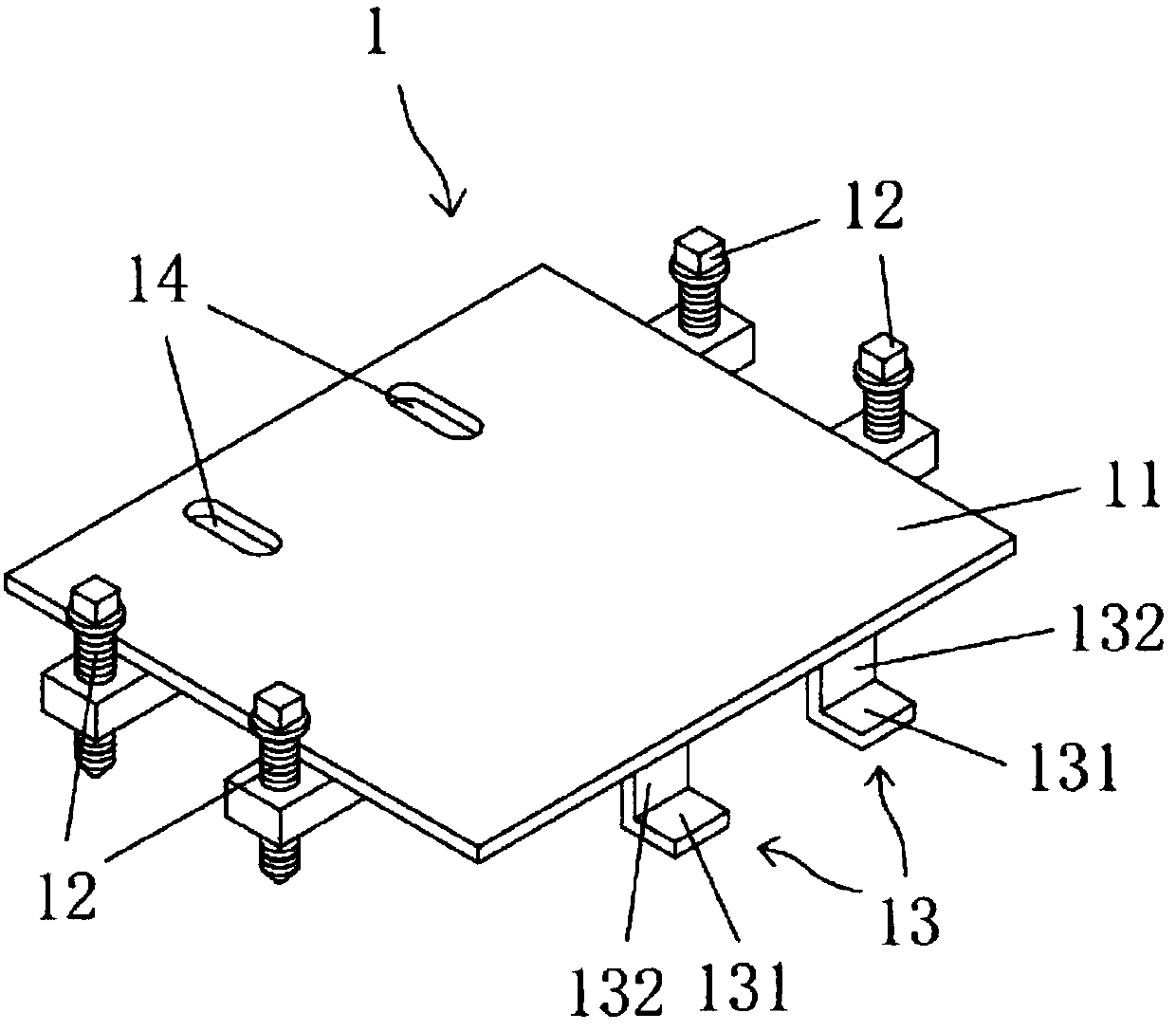

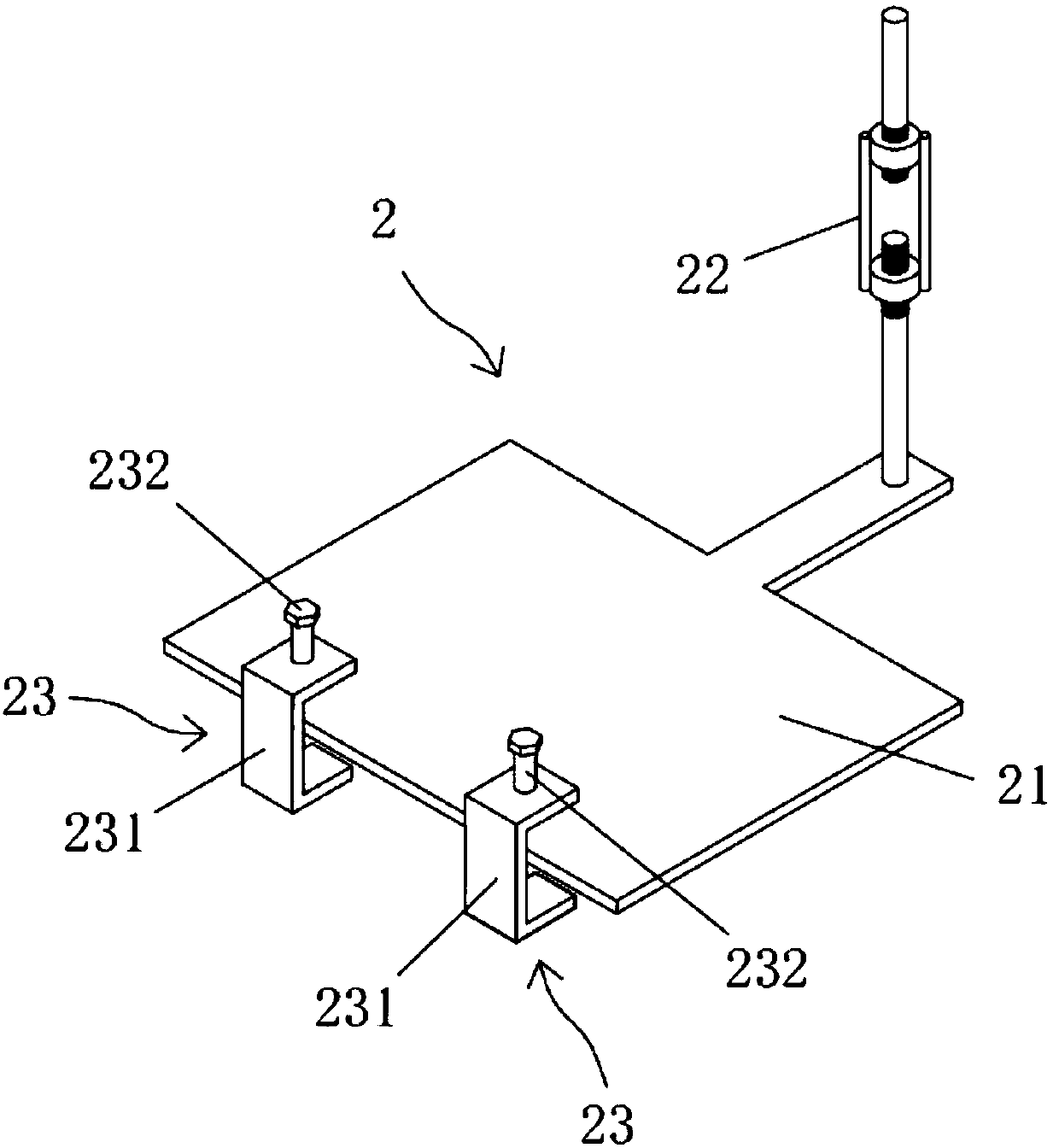

[0037] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

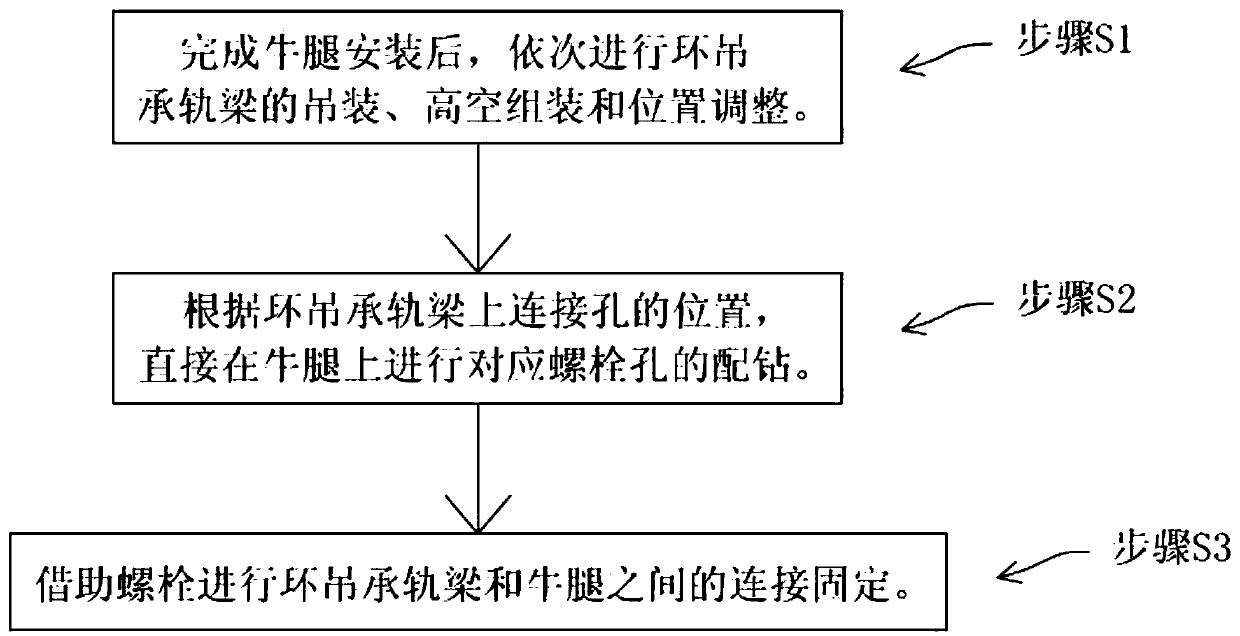

[0038] combine figure 1 As shown, when adopting the method for connecting the ring-hanging rail beam and the corbel of the present invention, when the ring-hanging rail beam and the corbel are fixedly connected, the following steps are specifically included:

[0039] Step S1, after completing the high-altitude fixed installation of the corbel, directly hoist the ring-hanging rail beam to the corbel, and perform assembly and position adjustment of the ring-hanging rail beam on the corbel. Among them, by adjusting the position of the assembled ring-hanging rail beam, all the connecting holes on the ring-hanging rail beam correspond to the corbels.

[0040] In addition, the corbel is a metal component and is fixedly connected to the containment steel-lined cylinder by welding. At the same time, the backing plate of the jack base for installi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com