Slip form integrated lifting type concrete curing device and method

A kind of concrete and lifting technology, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems of affecting the concrete curing situation, the difficulty of flexible operation of workers, and the poor quality of curing agent painting, so as to achieve the purpose of obtaining materials and Quick and easy to use, flexible styles, reducing the effect of rapid evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

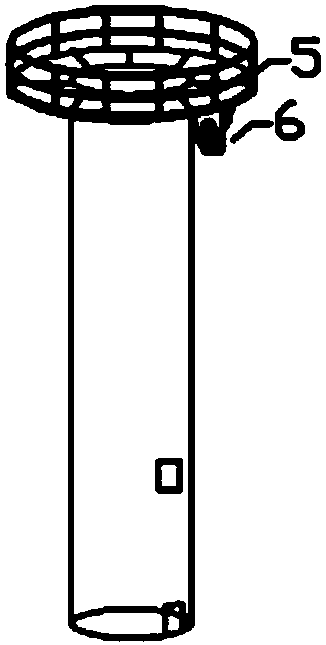

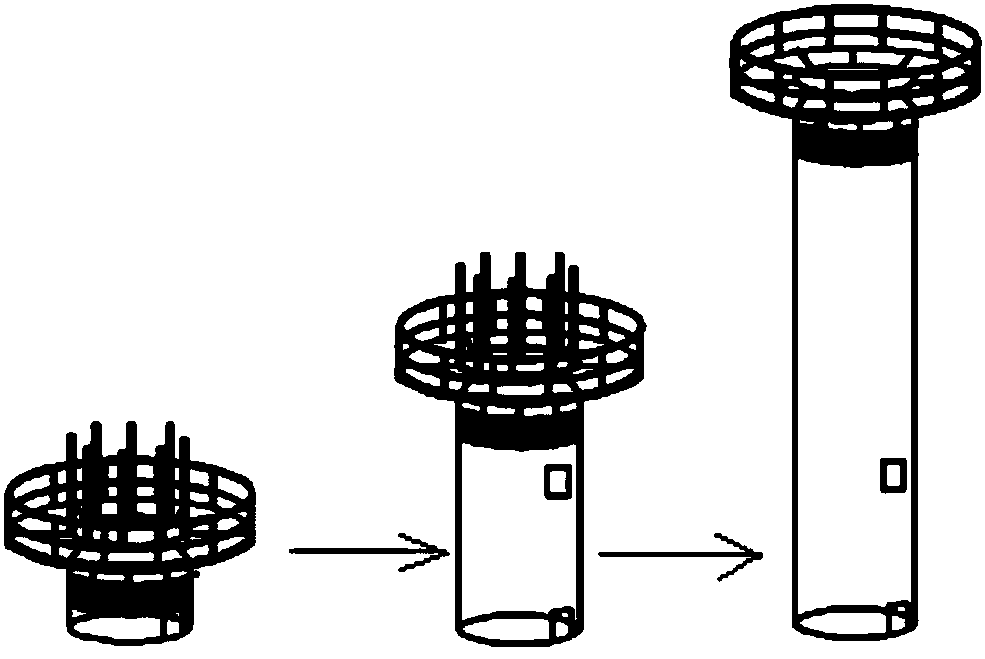

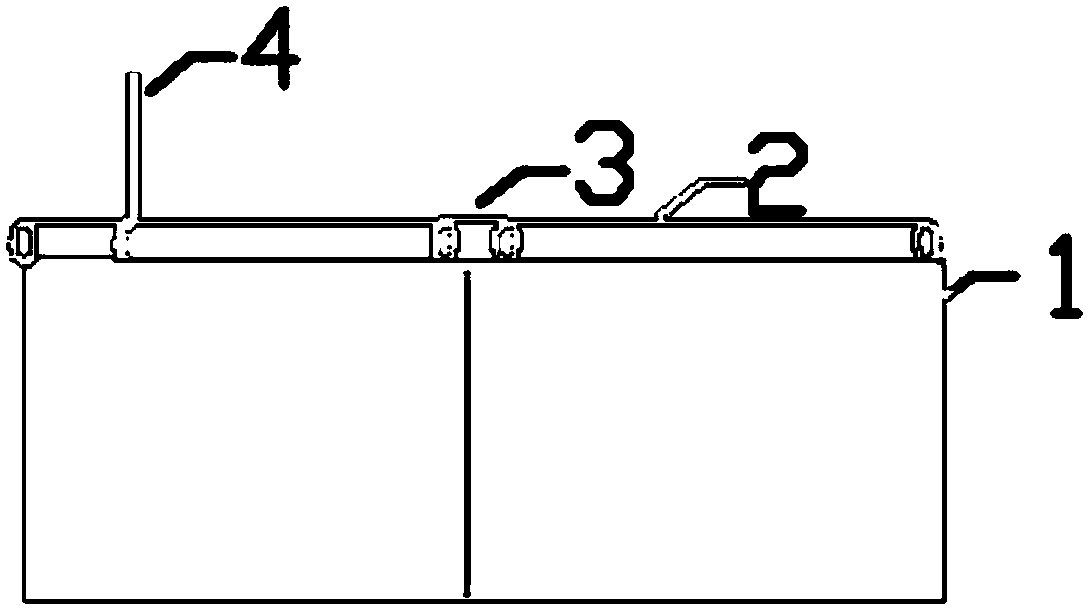

[0026] Such as Figure 2-Figure 5 As shown, the sliding form integrated lifting concrete maintenance device includes a PPR pipe ring 2, a tee 3, a hose 7, a quilt 1, and an iron hook 4. The iron hook 4 is fixed on the lower end of the sliding form operating platform 5, and the iron The hook 4 hooks the PPR pipe ring 2, and the PPR pipe ring 2 is arranged around the structure. Pass 3 to connect flexible pipe 7, and flexible pipe 7 connects water source.

[0027] A concrete curing film is wrapped on the quilt 1 and the PPR pipe ring 2, and water holes are evenly distributed on the concrete curing film inside the quilt 1.

[0028] The small hole 8 is arranged at the lower end of the PPR pipe ring 2 .

[0029] The method for maintaining the concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com