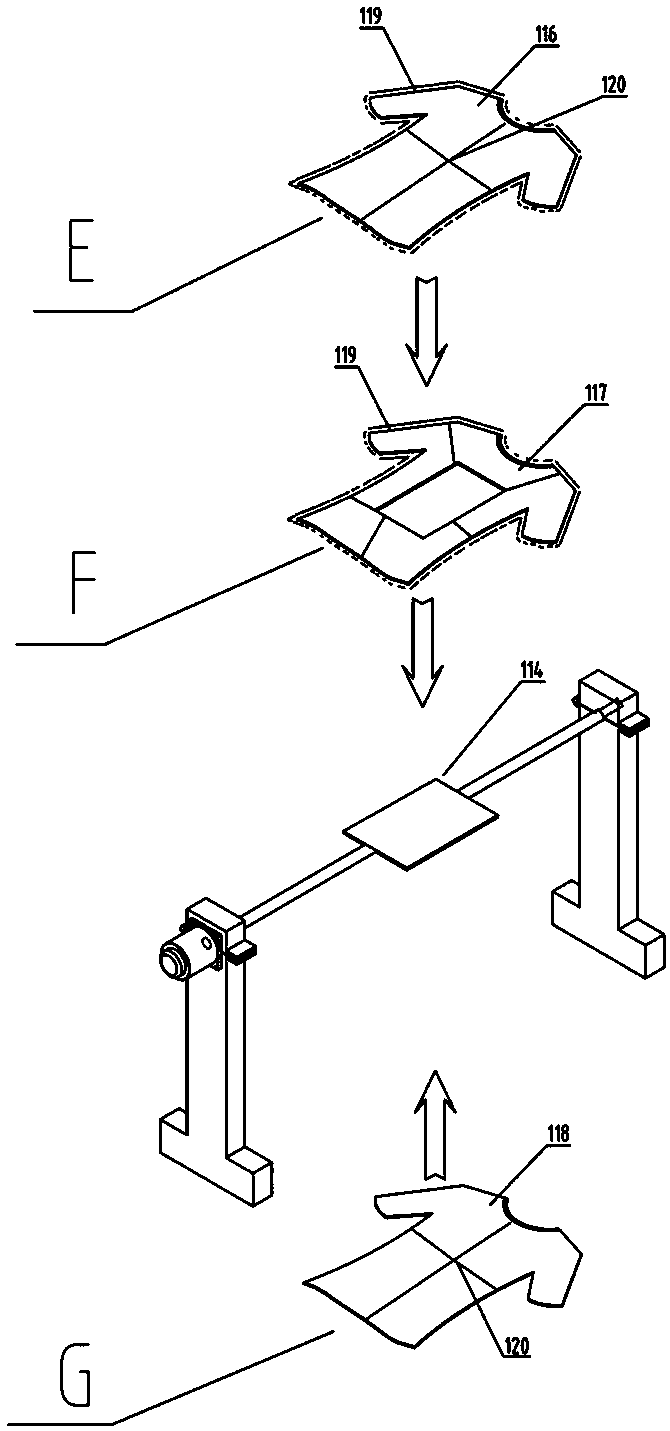

A 3D printing device and double-sided molding method for manufacturing colored plush clothing

A 3D printing and color printing technology, applied in coating devices, manufacturing tools, additive manufacturing, etc., can solve the problems of simultaneous printing of multiple lines, production of fluffy cloth surface layer, and crisscrossing conveniently. Weaving and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

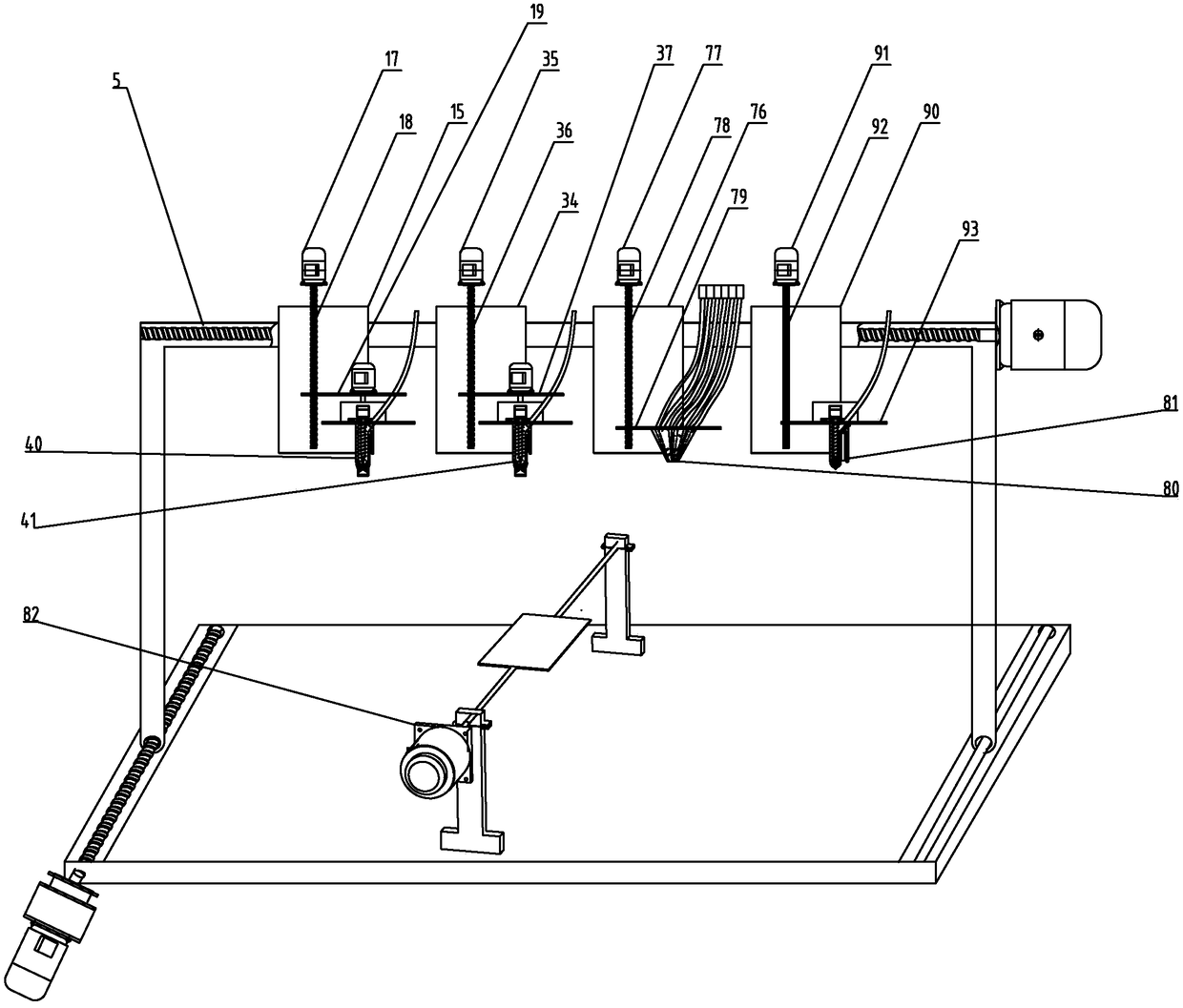

[0069] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings.

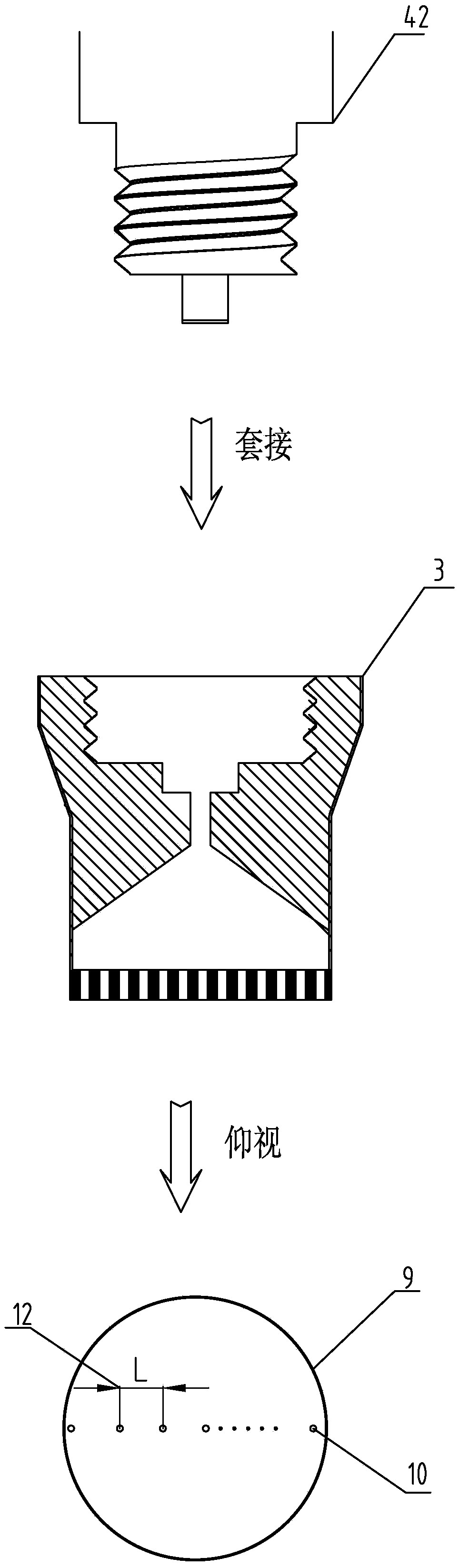

[0070] A 3D printing device for manufacturing colored plush clothing, comprising: a long-distance porous printing head 40 or Figure 8 , flat print head 41 or Figure 10 , color printing spray head 80, single nozzle print head 81, 360° reversible platform 82, three-layer sandwich plate ( Figure 9 ). The 3D printer realizes three-dimensional printing by three-dimensional positioning of the X-axis, Y-axis, and Z-axis. Four Z-axis lifting tables are set on the X-axis, and the four Z-axis lifting tables are respectively equipped with long-distance porous printing heads 40 or Figure 8 , flat print head 41 or Figure 10 , a color printing spray head 80, a single nozzle print head 81, and a 360° reversible platform 82 configured in the 3D printer.

[0071] The long-distance porous print head 40 or Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com