Mounting structure and method of high-and-large-space clean room

A technology for tall and large spaces and installation structures, applied in building construction, covering/lining, construction, etc., can solve problems such as long-term and high safety hazards, and achieve the effects of improving safety, improving installation efficiency, and reducing connection gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

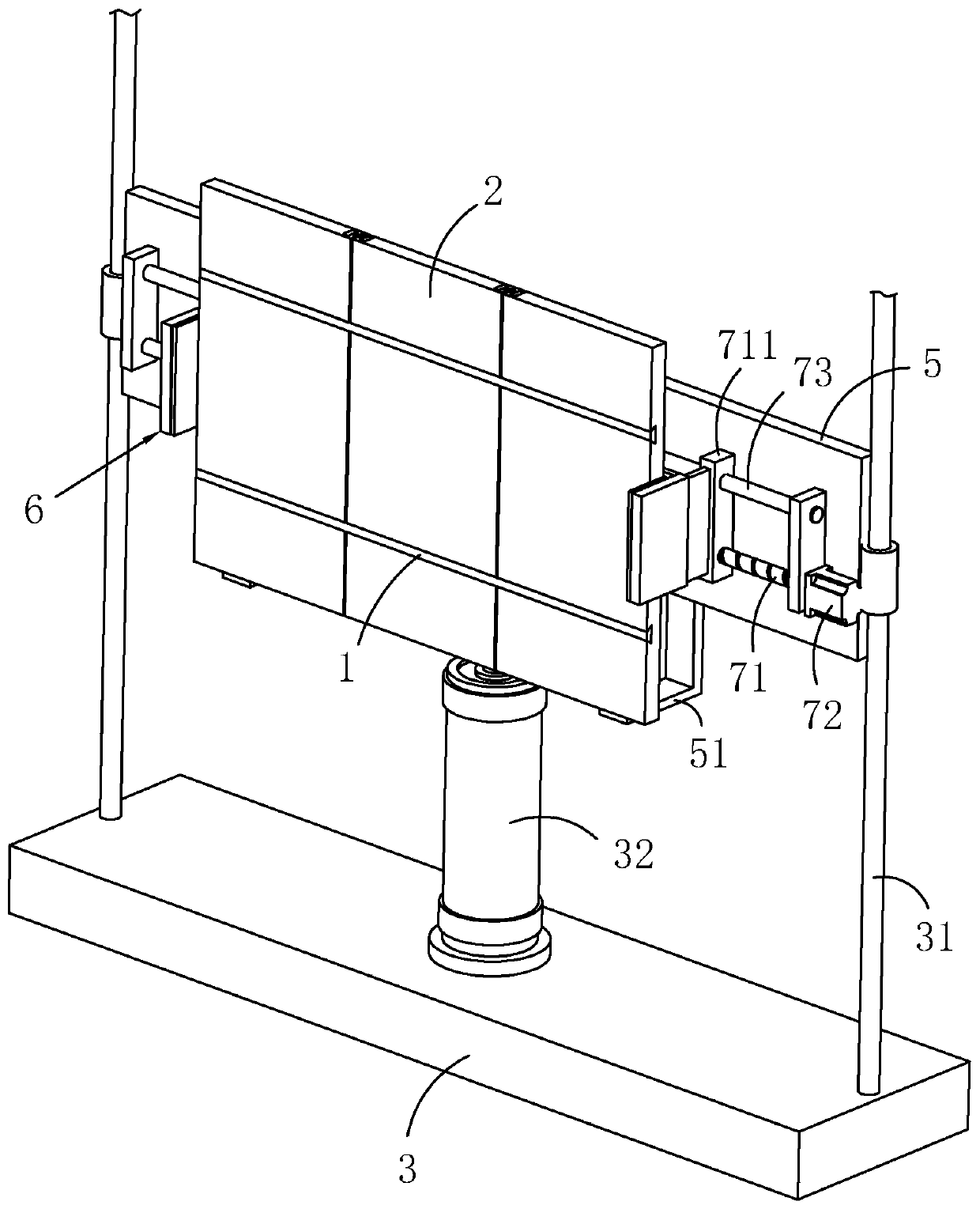

[0043] Such as figure 1 As shown, an installation structure of a clean room in a tall space includes a metal wall plate 2, a fixed rod 1 and a moving seat 3. The moving seat 3 is provided with a lifting plate 5, and the bottom wall of the lifting plate 5 is fixedly provided with two supporting plates. 51, the metal wall plate 2 is placed on the support plate 51. The moving base 3 is provided with a driving source for driving the lifting plate 5 to lift. The moving base 3 is fixedly provided with a column 31 along the vertical direction. Pneumatic cylinder 32, the piston rod of pneumatic cylinder 32 is fixedly connected with lifting plate 5.

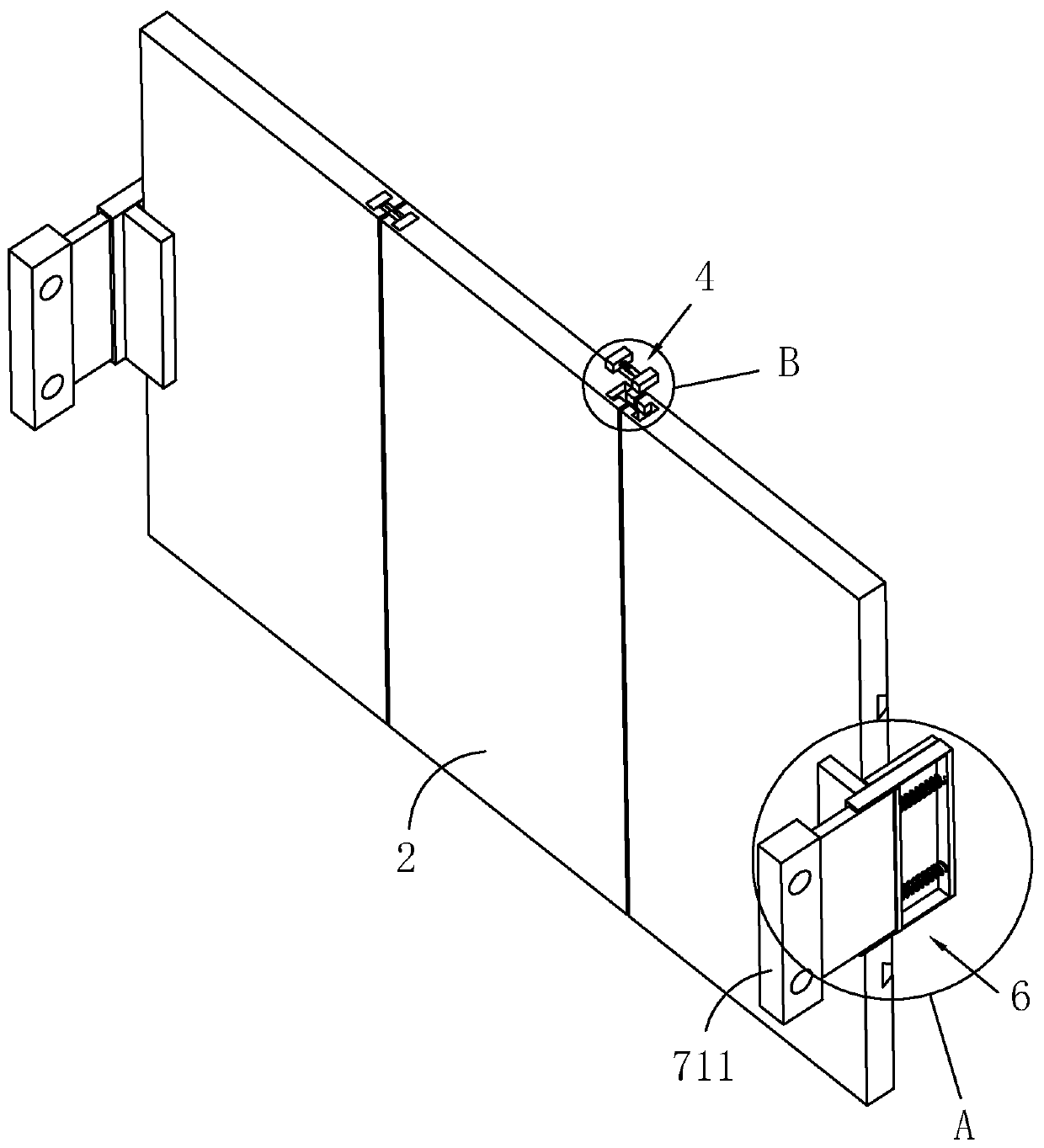

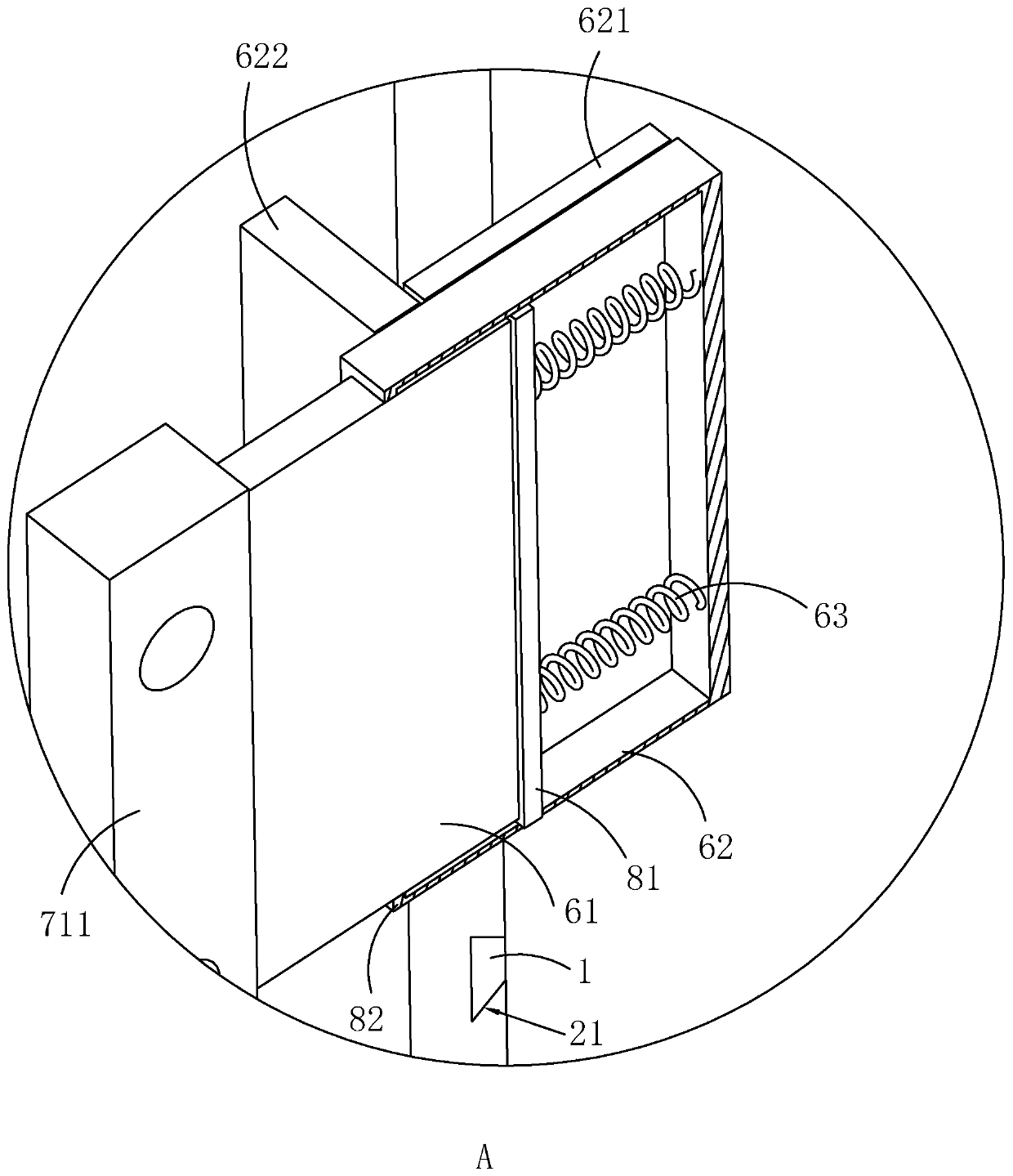

[0044] Such as figure 2 , 3As shown, the side wall of the metal wall panel 2 close to the wall is provided with a card slot 21, the card slot 21 is set as a dovetail groove, and the dovetail groove is arranged along the width direction of the metal wall panel 2, and the fixing rod 1 is clamped on at least two metal walls. In the slot...

Embodiment 2

[0054] An installation method for a clean room in a tall space, comprising the following steps:

[0055] S1. Move the moving seat 3 to the wall where the metal wall panel 2 is to be installed;

[0056] S2. Insert the fixing rod 1 into the slot 21 of the metal wall board 2, and then fix and connect the adjacent metal wall boards 2 through the connector 4, so that multiple metal wall boards 2 are connected side by side as a whole;

[0057] S3. Drive the clamping part 6 to press against the side wall of the metal wall plate 2 through the drive assembly 7, and then drive the lifting plate 5 to move upward through the driving source until the metal wall plate 2 moves to the wall surface to be constructed;

[0058] S4. Fix the metal wall panels 2 on the wall with self-tapping screws, and seal the joints of the adjacent metal wall panels 2 with a sealant.

[0059] A plurality of metal wall panels 2 are fixed as a whole, which is convenient for installation, reduces the time for work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com