Method for replacing lifting ropes of multi-rope frictional geared winch

A technology of hoisting ropes and friction wheels, which is applied to lifting equipment, transportation, and packaging in mines. It can solve problems such as high labor intensity for workers, falling objects in shafts, and long replacement operations, so as to improve the level of mechanized operations and reduce The effect of changing rope time and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

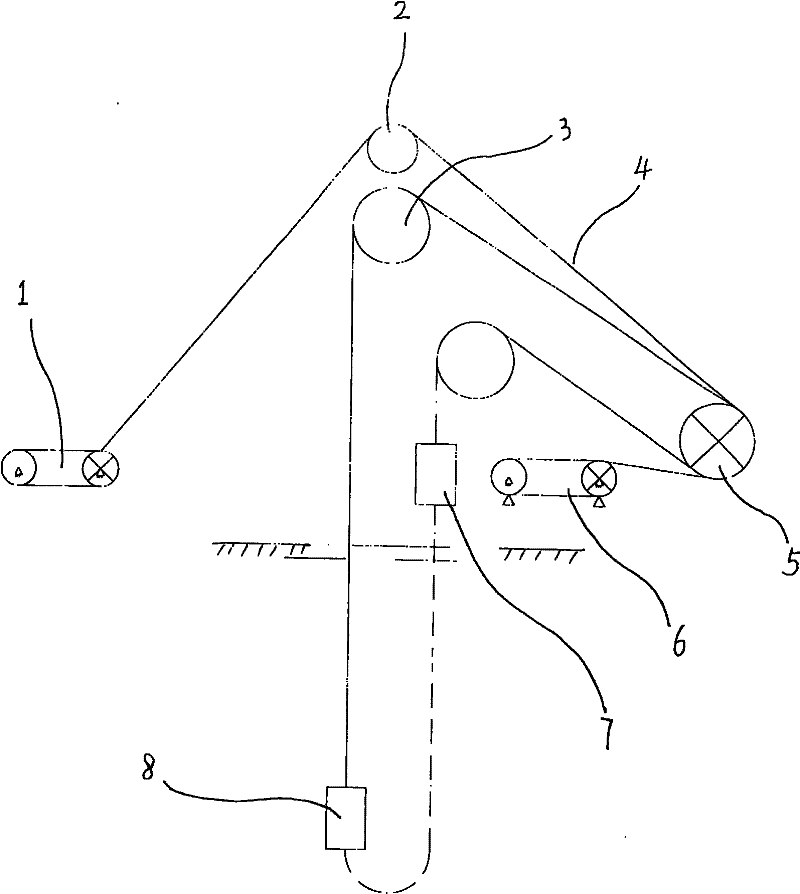

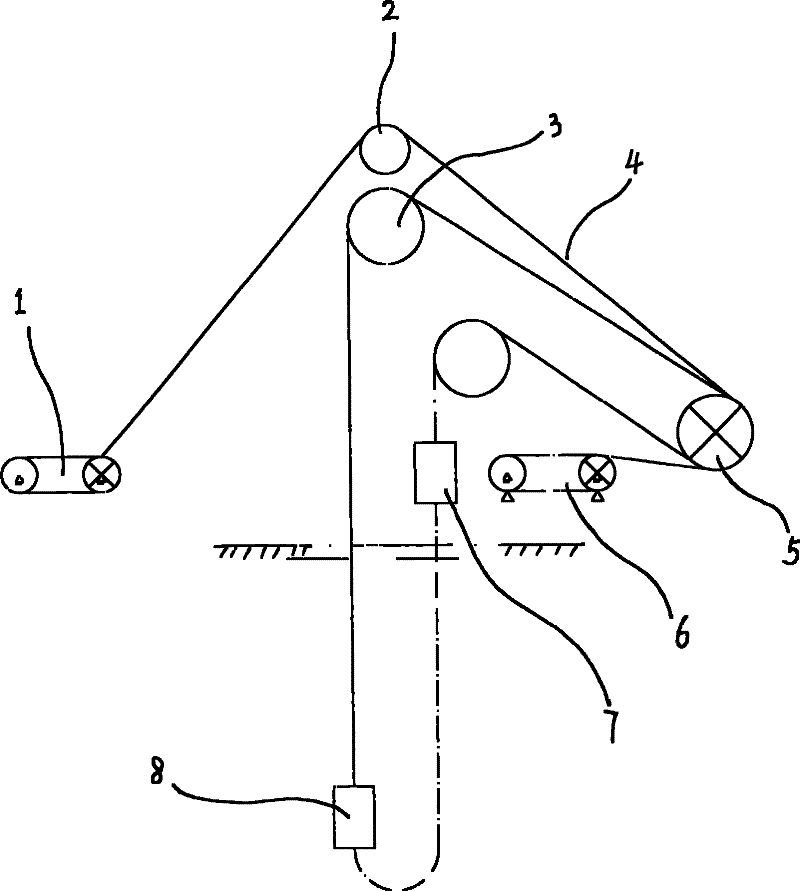

[0014] Depend on figure 1 As can be seen, the present invention comprises: two tension machines, block pulleys, sky wheel, hoisting rope, winch, two tractors, container I, container II. The hoisting ropes are arranged on the winch in order of No. 1, No. 2, No. 3, and No. 4. Lift the container I of the friction wheel winch to the wellhead and stop running. No. 1 and No. 3 of the four old hoisting ropes that connect the container I Untie and remove the ends of the two old hoisting ropes, and at the same time connect the removed ends of the old hoisting ropes with the pulleys of the two tractors, and pass the two new hoisting ropes around the pulley block through the two tension machines Join with container I. The specifications of the tensioner match the lifting capacity of the friction wheel winch, and the specifications of the tractor match the length of the hoisting rope. Start the friction wheel winch to lift the container II, and the rope take-up wheels of the two tractor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com