Integrated hoisting method for corrugated steel web part

A corrugated steel web and overall hoisting technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve problems such as difficulty in ensuring the welding quality of corrugated steel webs, prolong the construction period, increase the time for high-altitude operations, and reduce construction risks. , Guarantee welding quality and reduce the effect of high-altitude operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

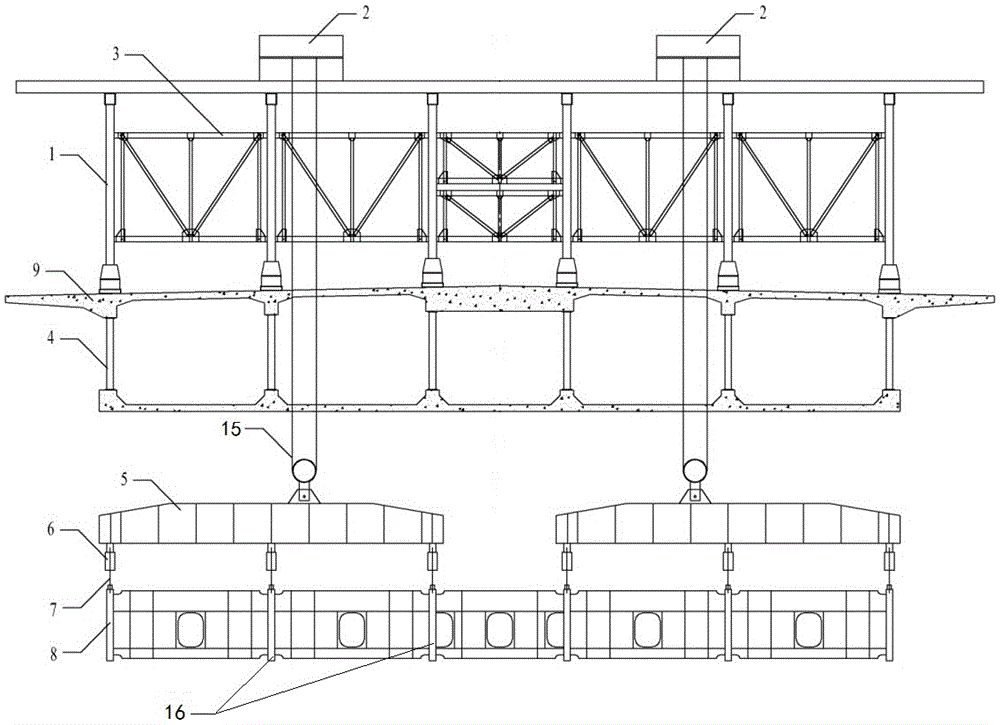

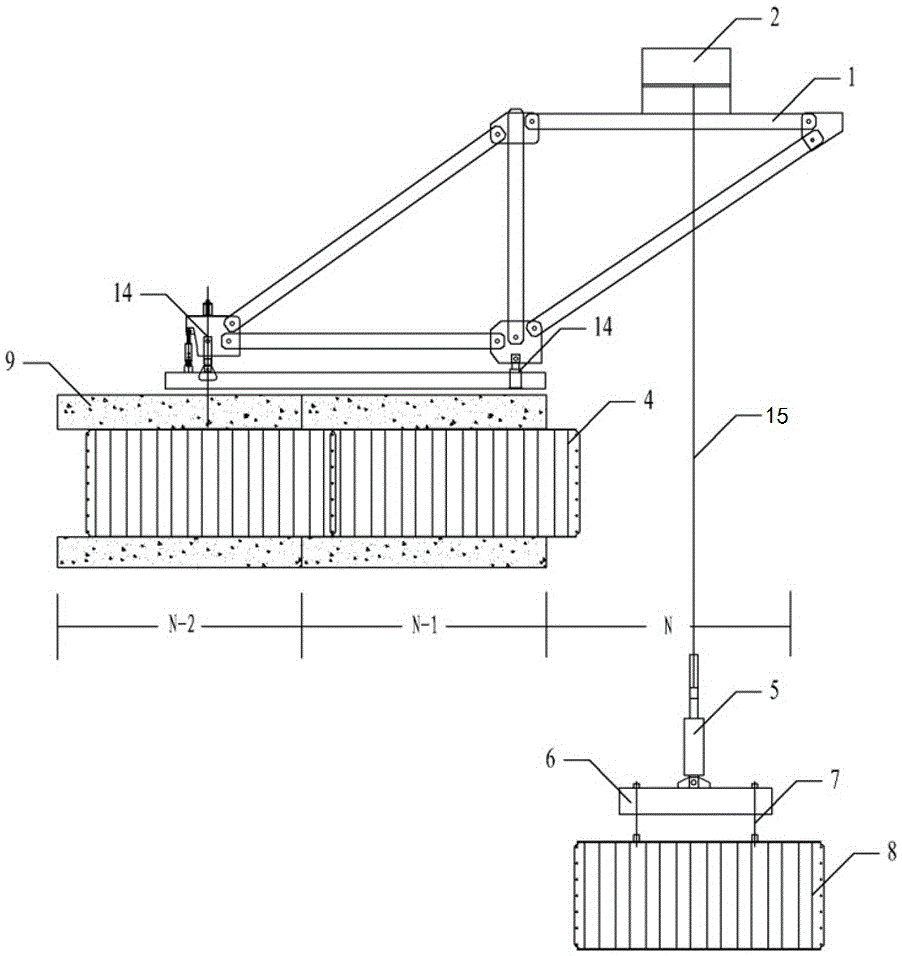

[0017] Example: such as Figure 1-3 As shown, this embodiment specifically relates to an overall hoisting method for corrugated steel web components, which is suitable for PC box girder bridges with corrugated steel webs with single box and multiple rooms and multiple boxes and multiple rooms, and specifically includes the following steps:

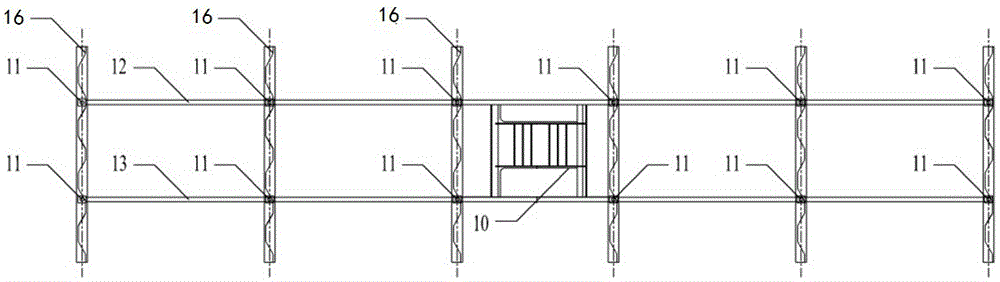

[0018] (1) Prefabricate the No. N corrugated steel web segment 8 to be hoisted in the factory, that is, pass several longitudinal corrugated steel webs 16 evenly spaced above the cross bridge through the steel beam 12, temporary support and reinforcement device 13 and The steel anchor box 10 is welded into a whole, wherein, the upper flange of each piece of corrugated steel web 16 is arranged with two lifting points 11 for hoisting by the crane system, and the corresponding lifting points 11 are welded for lifting connection The temporary lug plate used, one of the hanging points 11 is located at the joint of the corrugated steel web 16 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com