Patents

Literature

50results about How to "Reduce job preparation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

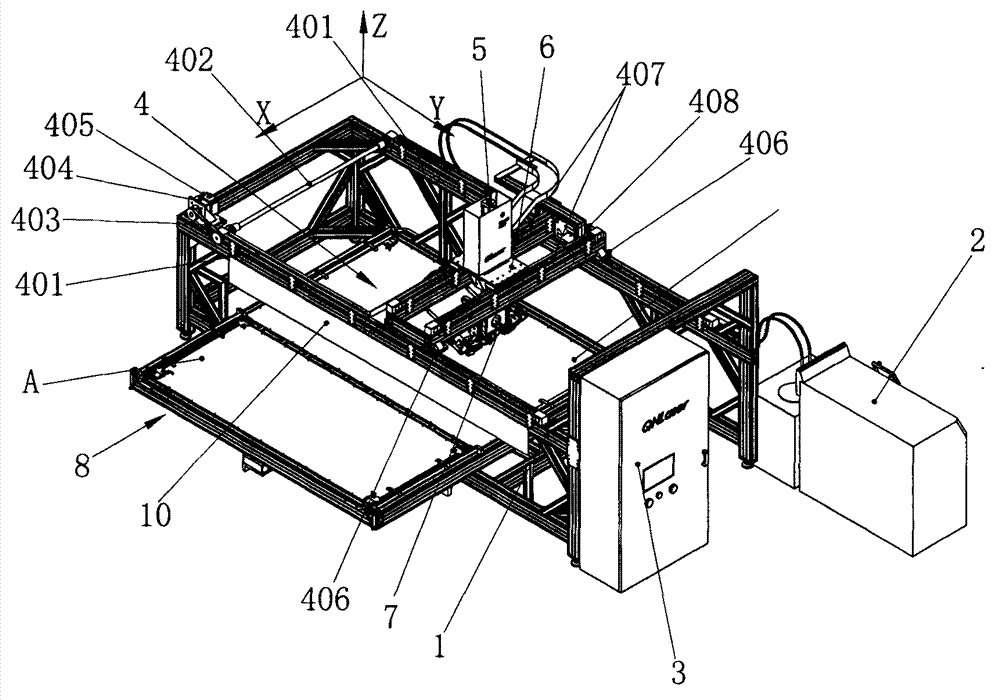

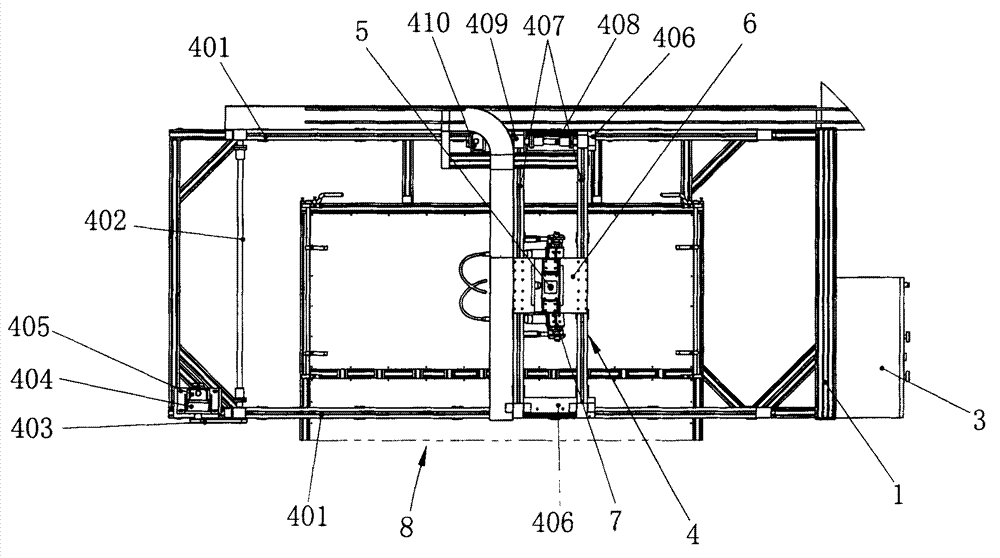

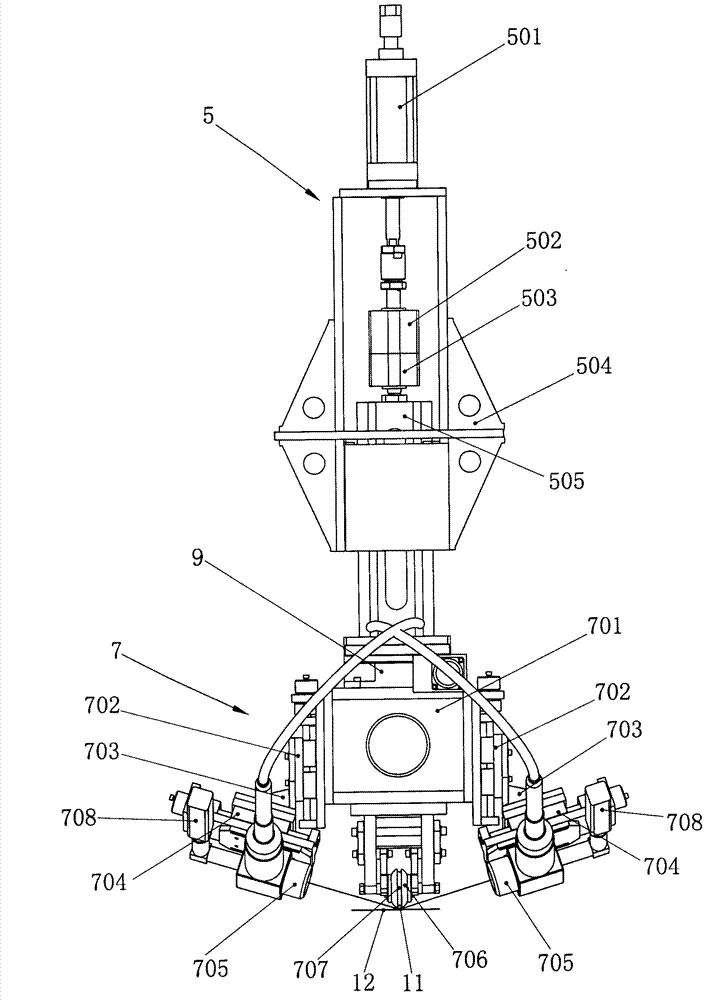

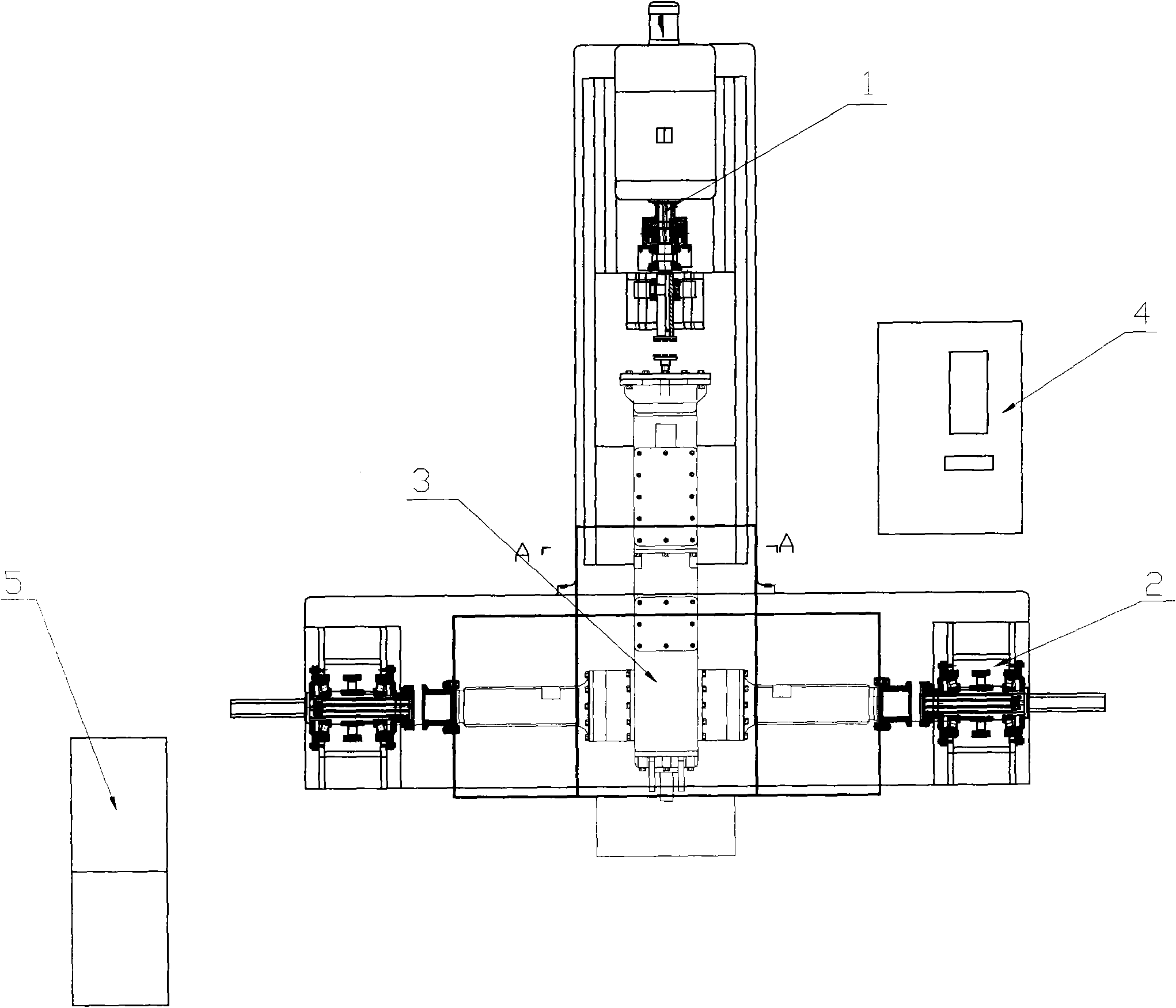

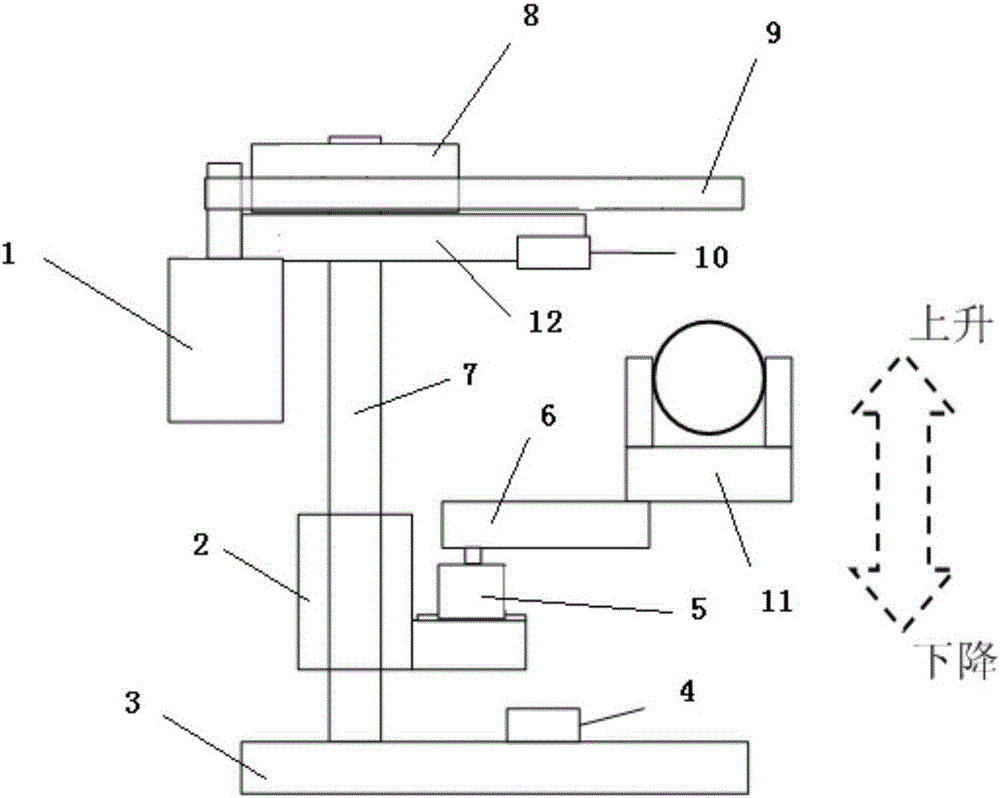

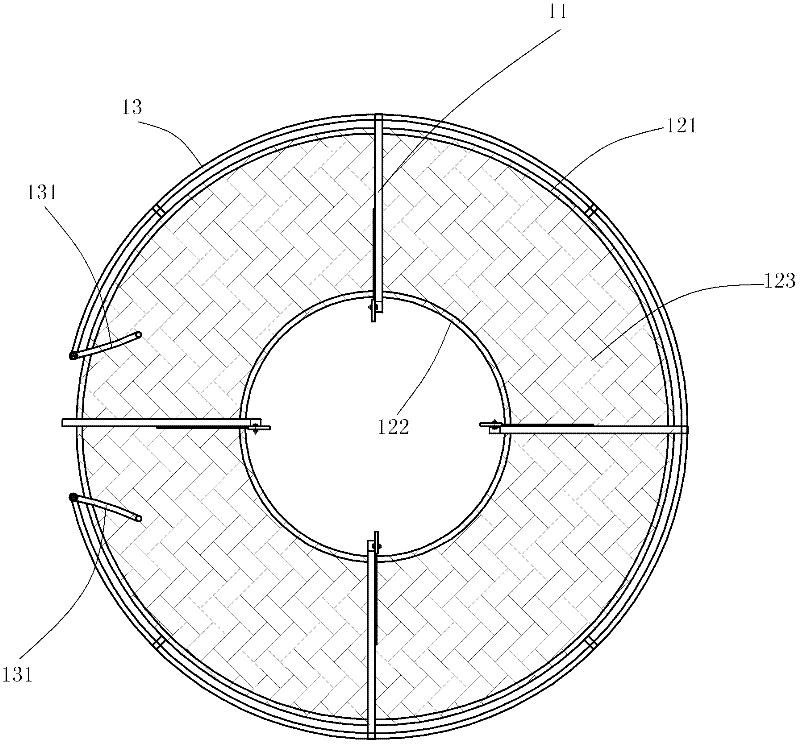

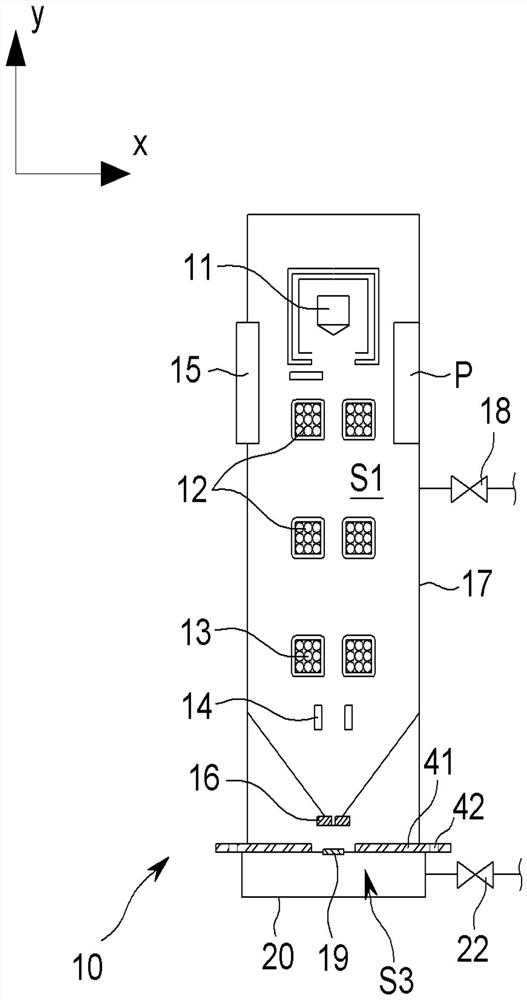

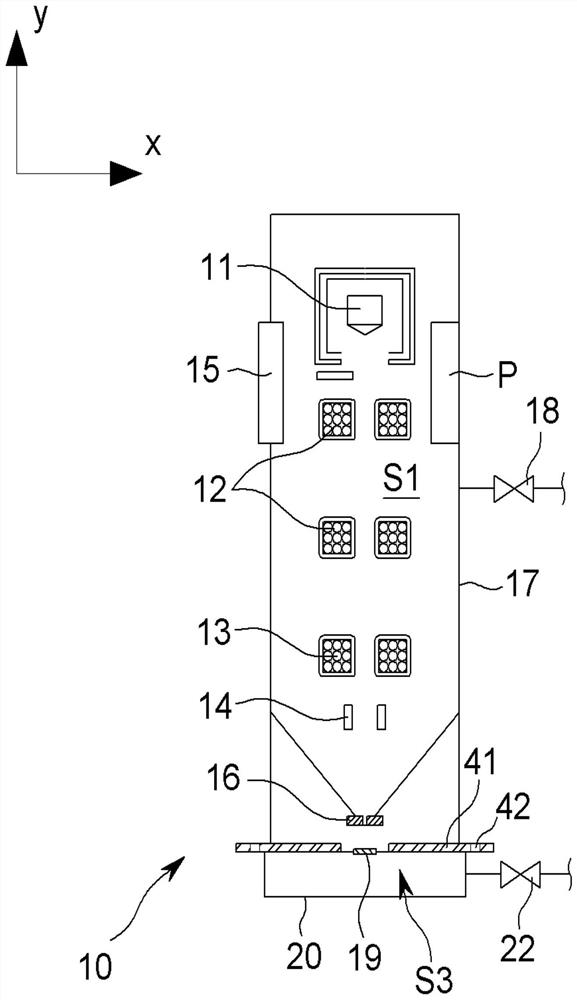

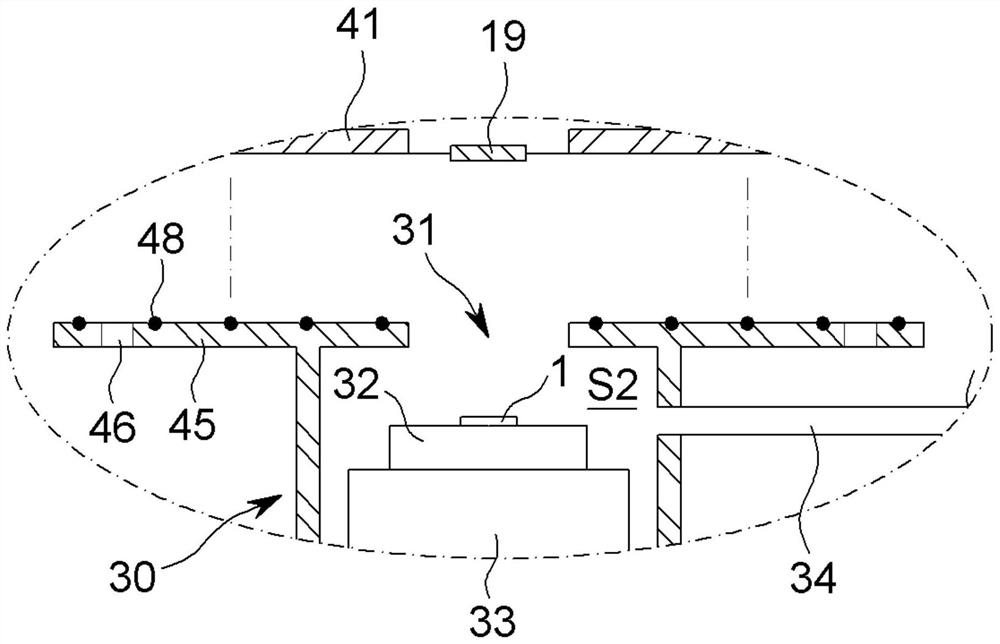

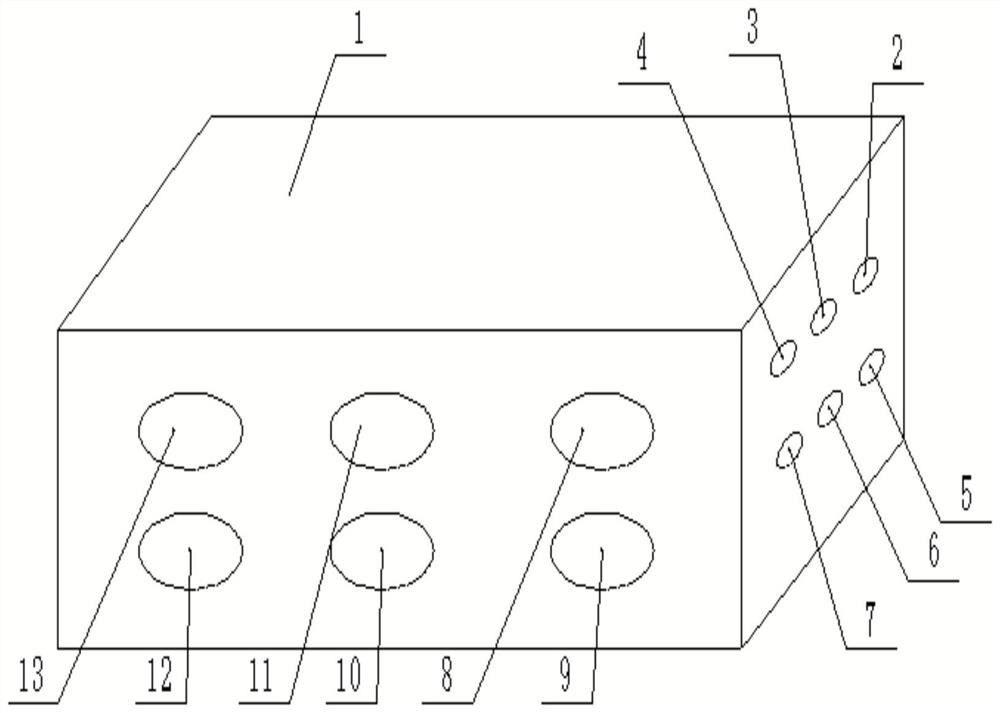

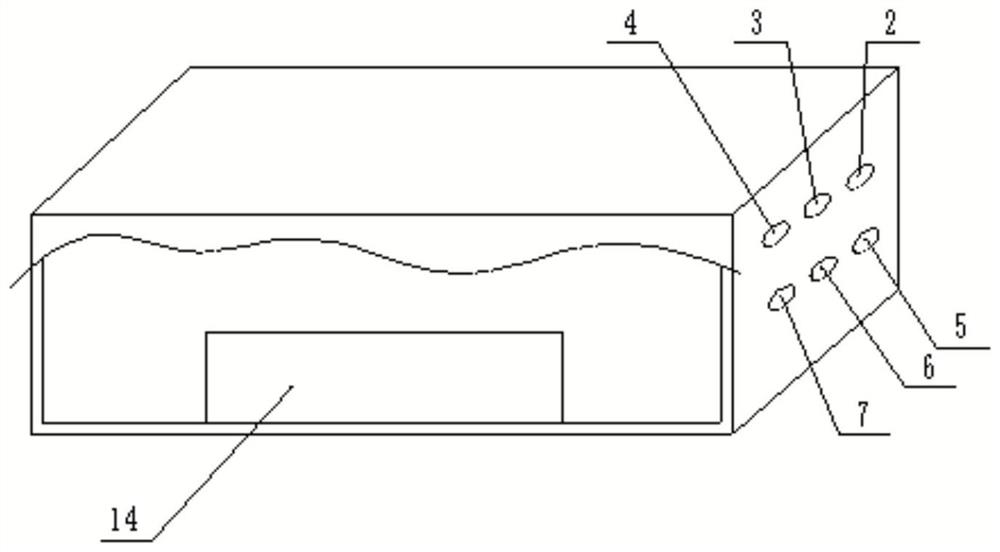

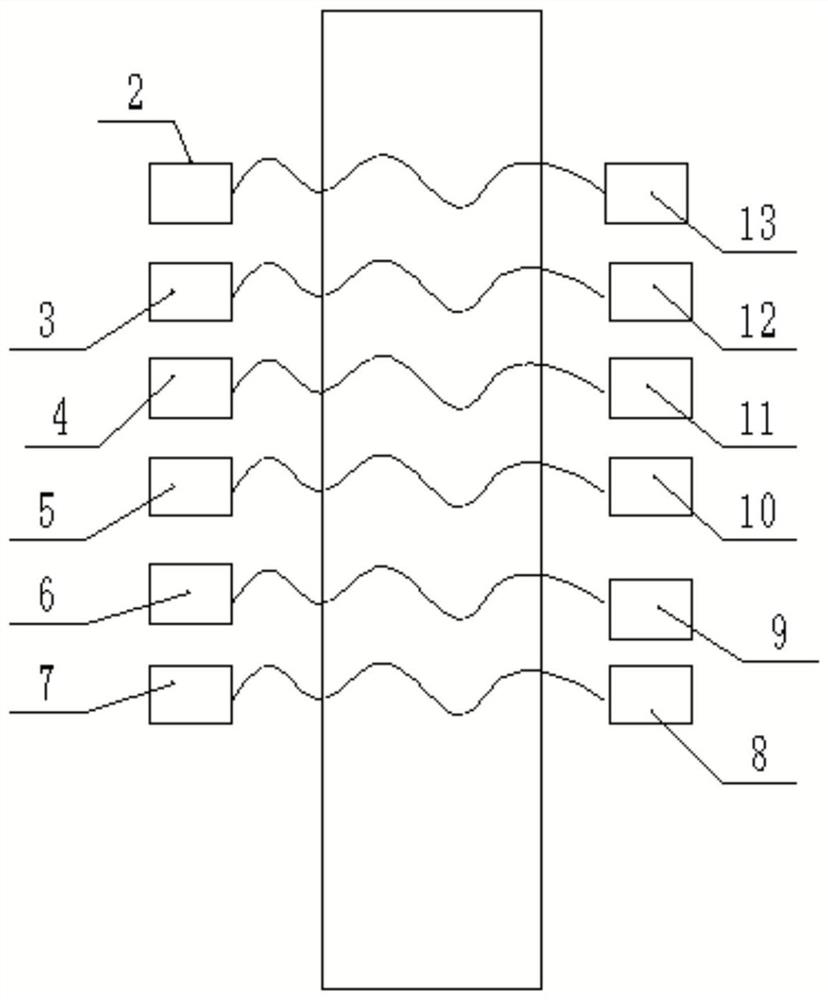

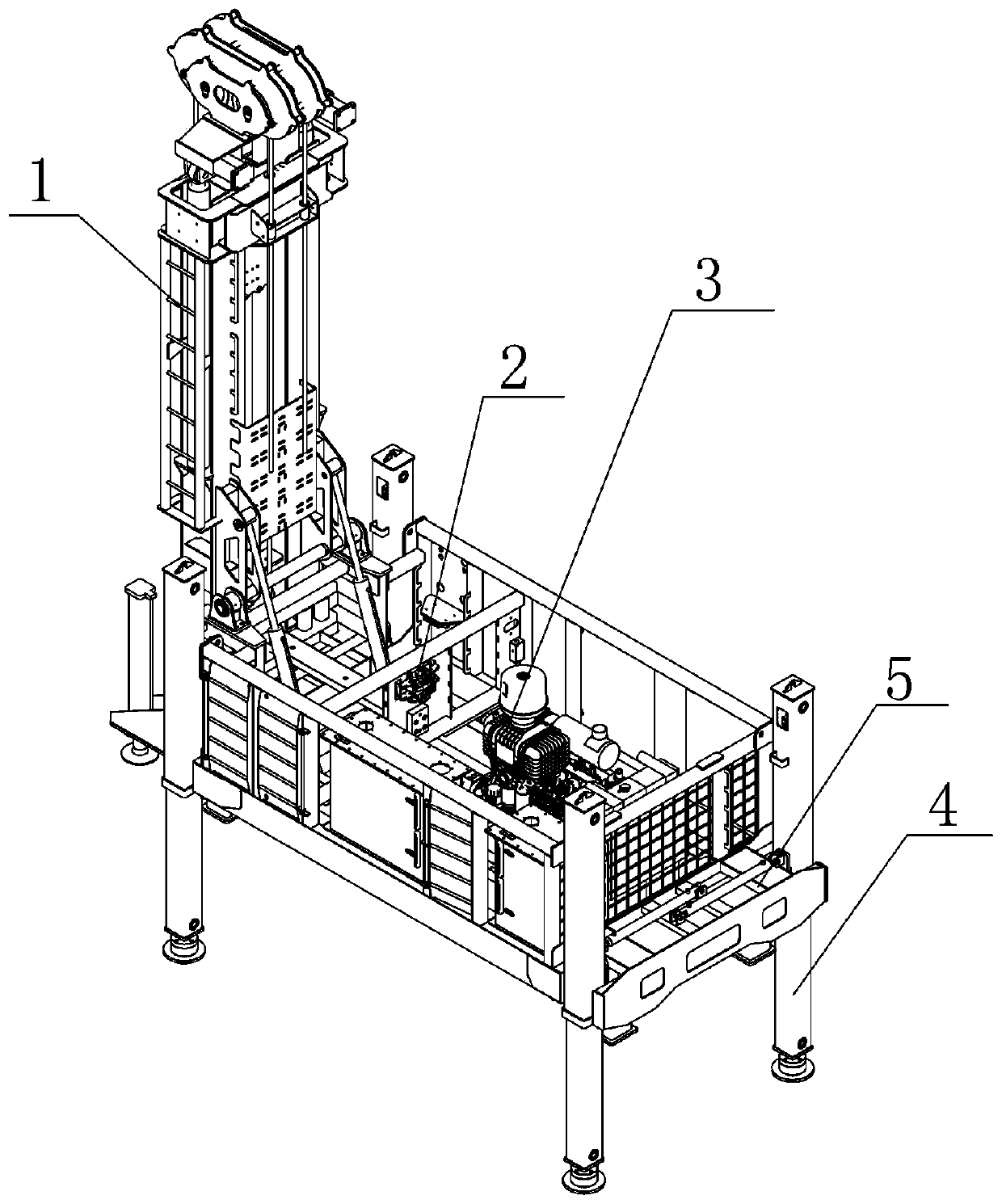

Laser welding device of solar flat plate collector

InactiveCN102756210AImprove heat transfer effectAvoid damageLaser beam welding apparatusPoint densityControl system

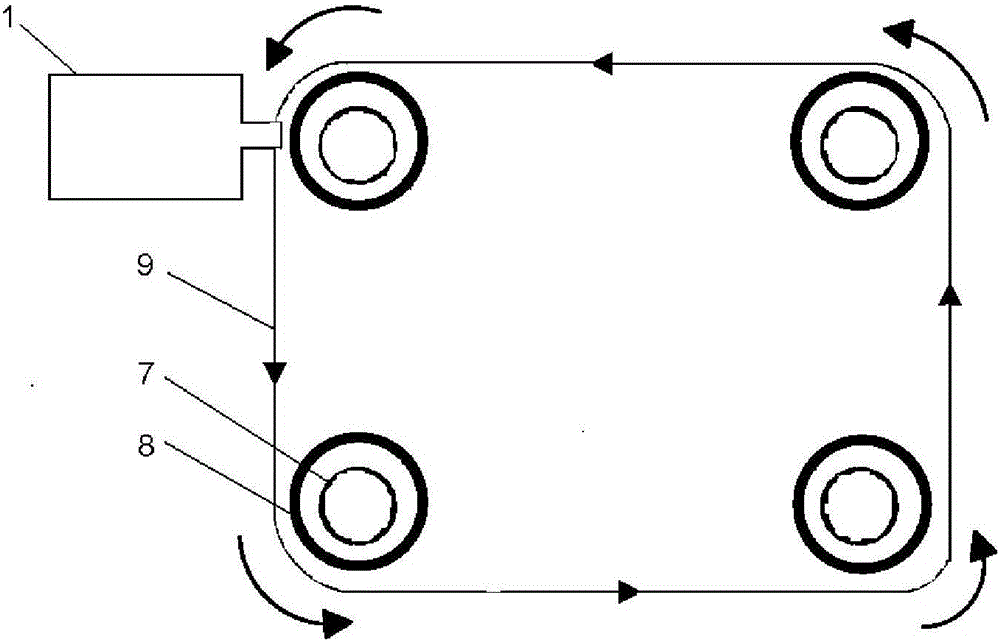

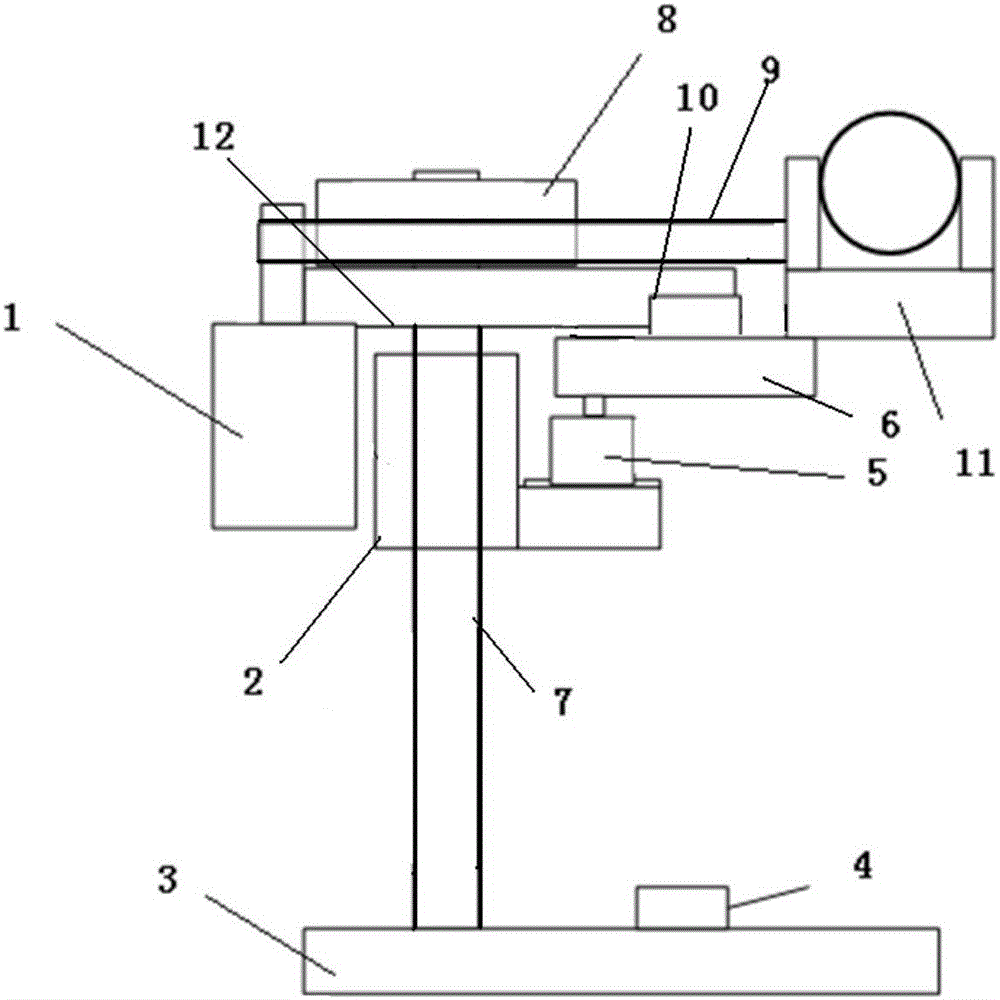

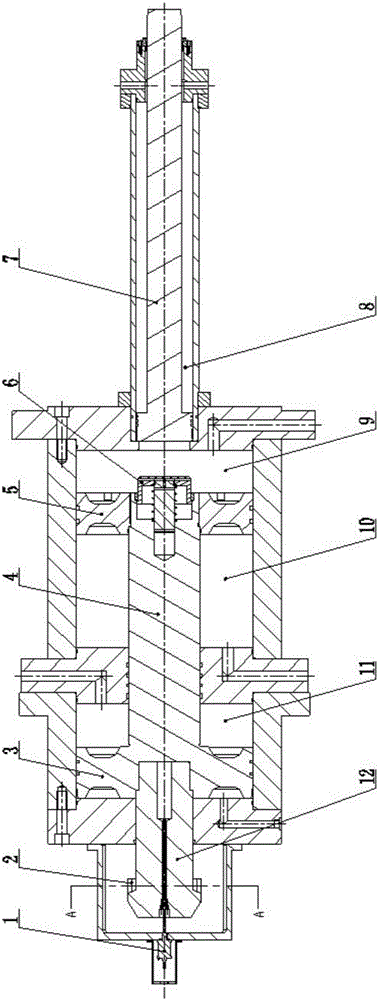

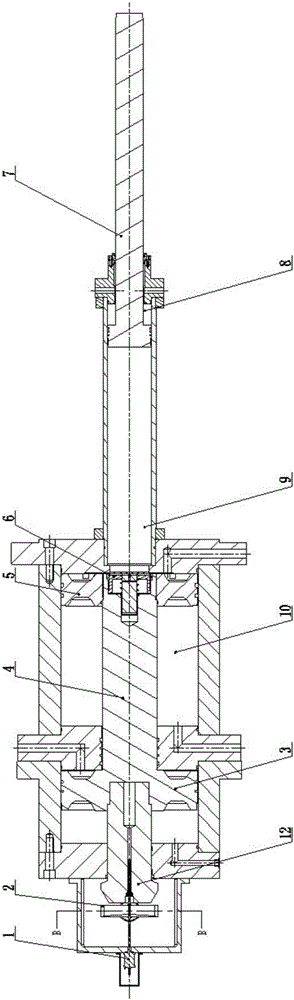

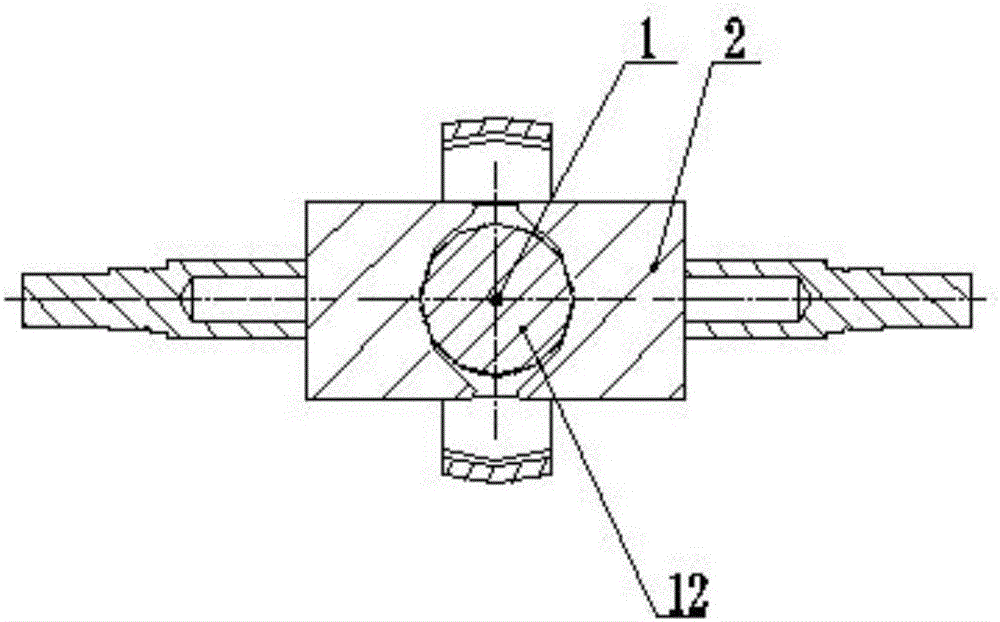

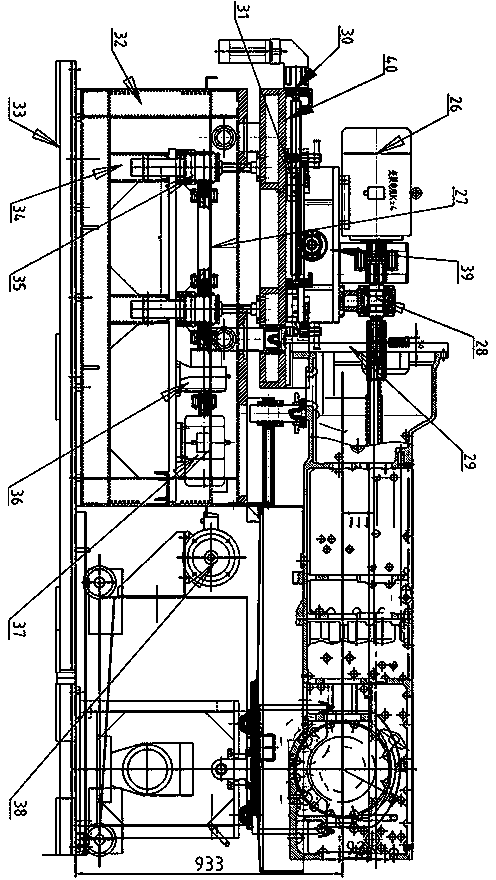

The invention relates to a laser welding device of a solar flat plate collector. The laser welding device is characterized by comprising a frame, a solid pulse laser system and a control system. An XY-axis servo driving mechanism is arranged on the frame, a Z-axis lifting mechanism and a laser welding head are arranged on the XY-axis servo driving mechanism through a dragging plate, and a rotating table is arranged below the laser welding head. The laser welding device adopts a high-power solid pulse laser system, a high-speed precise linear module is used as an XY-axis transmission guiding component, the device operates stably, device welding speed is increased, welding point density is increased, welding quality is improved, and heat transmission effect of the solar flat plate collector is improved. The Z-axis lifting mechanism adopts a series connection structure of three cylinders, the laser welding head is lifted and lowered stably in subsection mode, damage such as copper pipe dent is reduced, product quality is improved, and production cost is reduced. A double-station rotating table structure is adopted, operators do not need to walk back and forth, labor intensity is lowered, and production efficiency is increased.

Owner:WUXI QINENG WELDING EQUIP

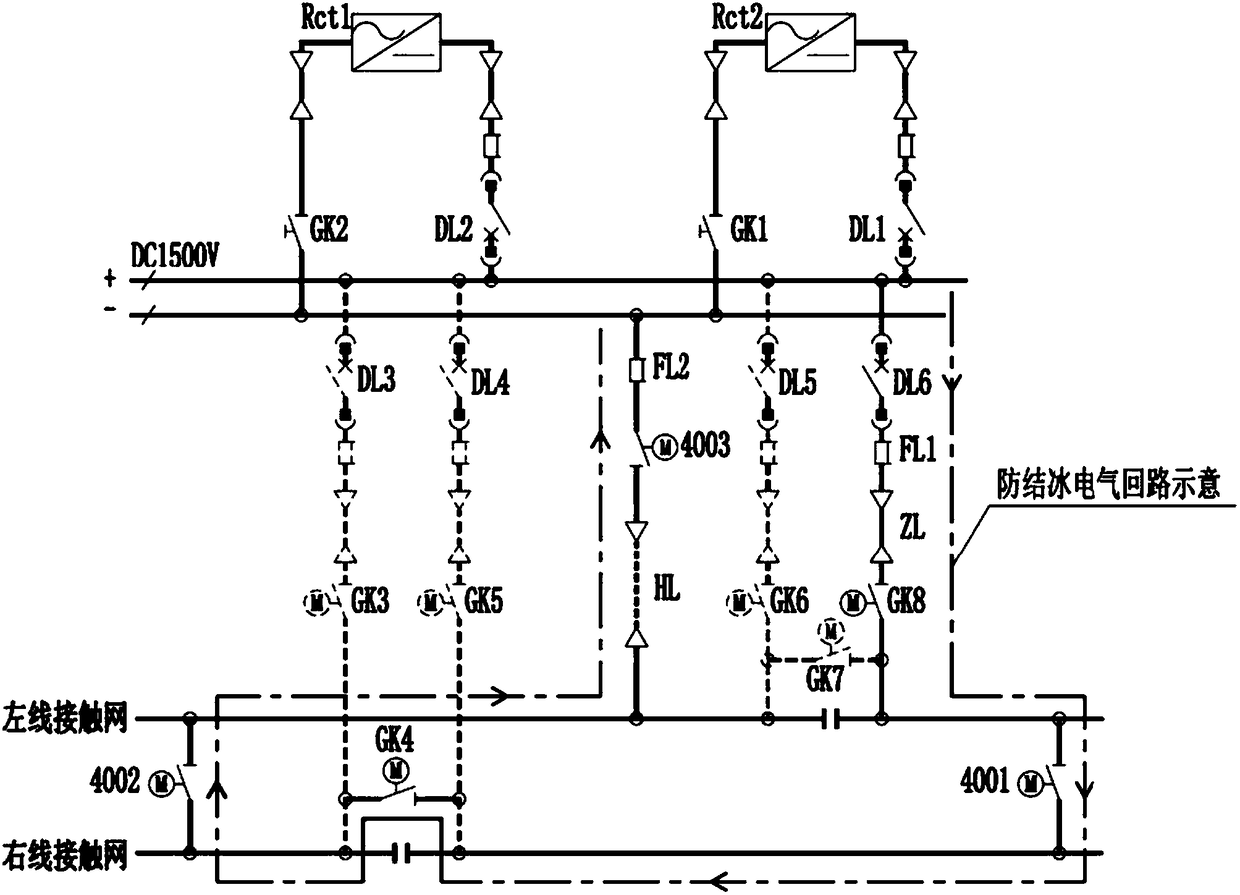

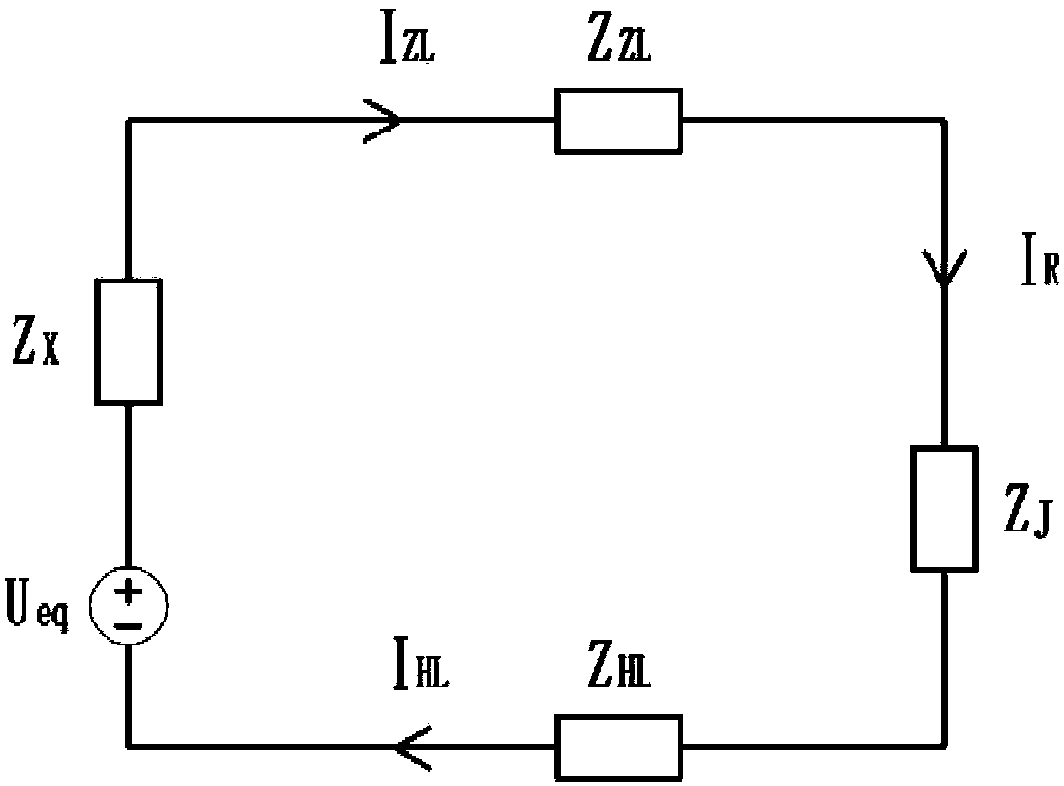

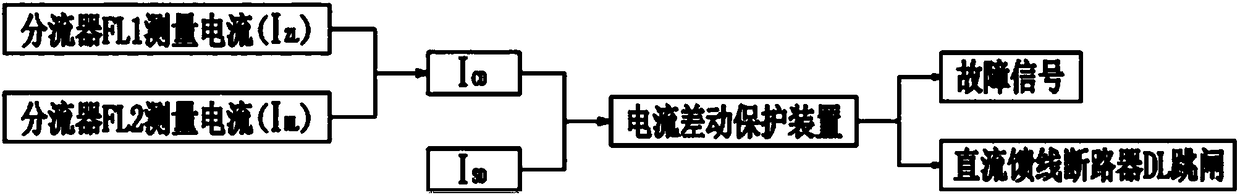

Electrical design method for preventing direct current overhead contact system from being frozen

InactiveCN108790949APrevent freezingImprove anti-icing performanceOverhead installationEmergency protective circuit arrangementsAnti freezingElectrical control

The invention discloses an electrical design method for preventing a direct current overhead contact system from being frozen. The method comprises an electrical circuit design method and an electrical control design method. According to the anti-freezing electrical circuit design method, on the basis of a basic structure of a direct current traction power supply system, a direct current bus of adirect current traction substation continuously outputs a certain amount of current to the overhead contact system, the size of the current is adjusted through adjustment of the circuit input range ofthe overhead contact system, and contact lines are prevented from being frozen through the thermal power of the overhead contact system. An anti-freezing circuit is low in consumption, small in equipment input, free of addition of manpower and mechanical facilities and easy to realize in a project. According to an electrical circuit control method, circuit control logic, action criteria and a control logic principle are proposed, and the control method is simple, effective and reliable.

Owner:CHINA RAILWAY ELECTRIFICATION SURVEY DESIGN & RES INST

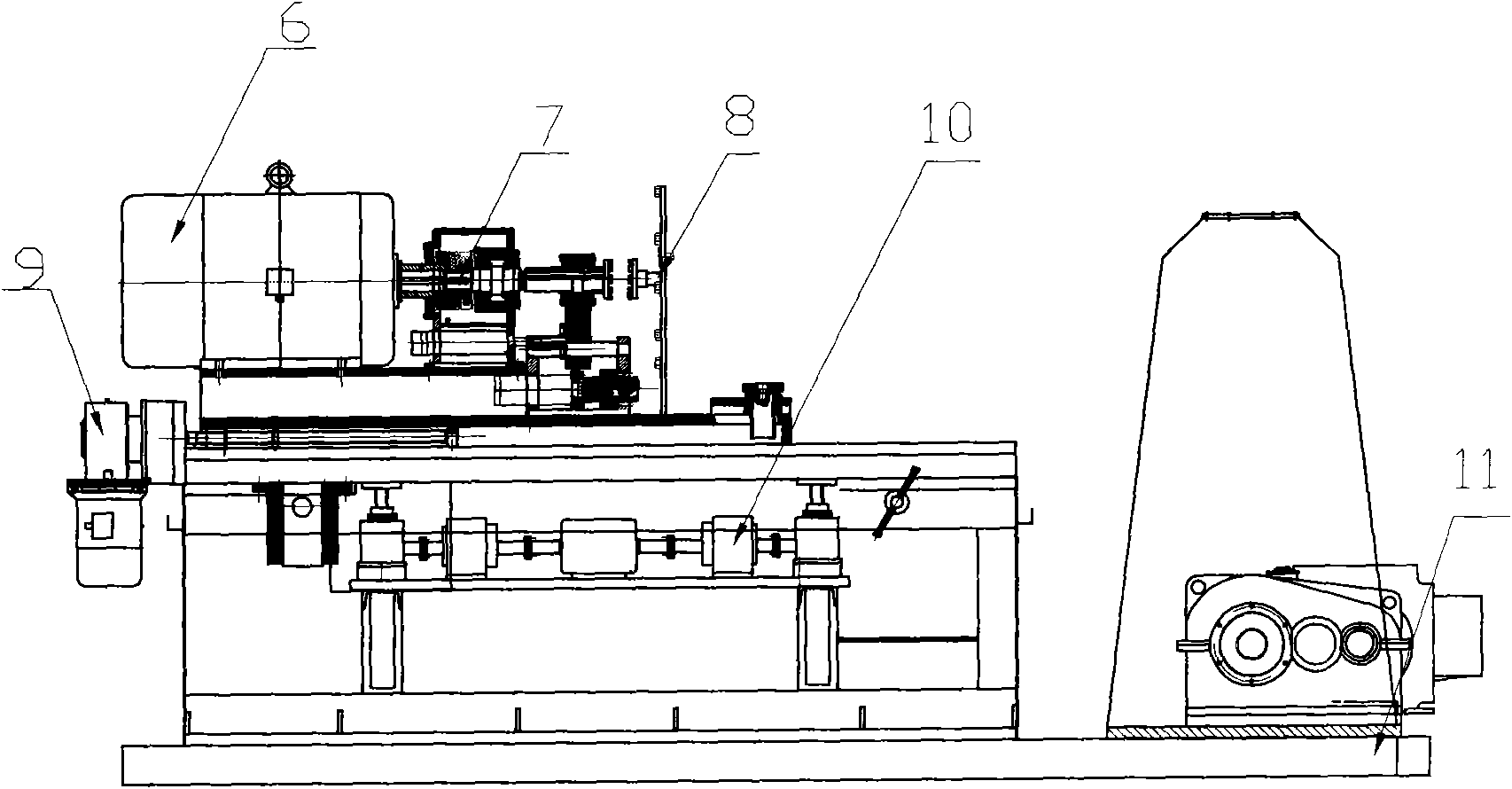

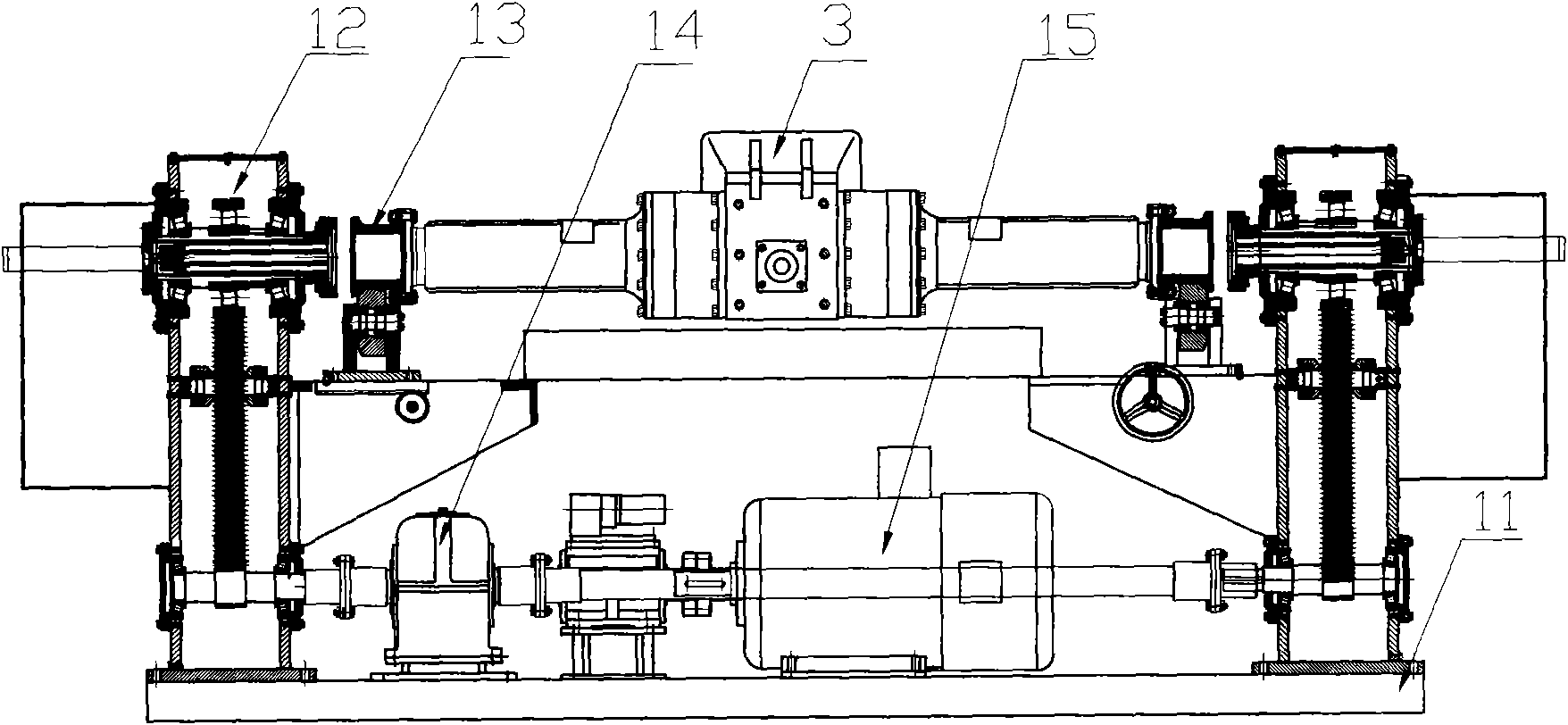

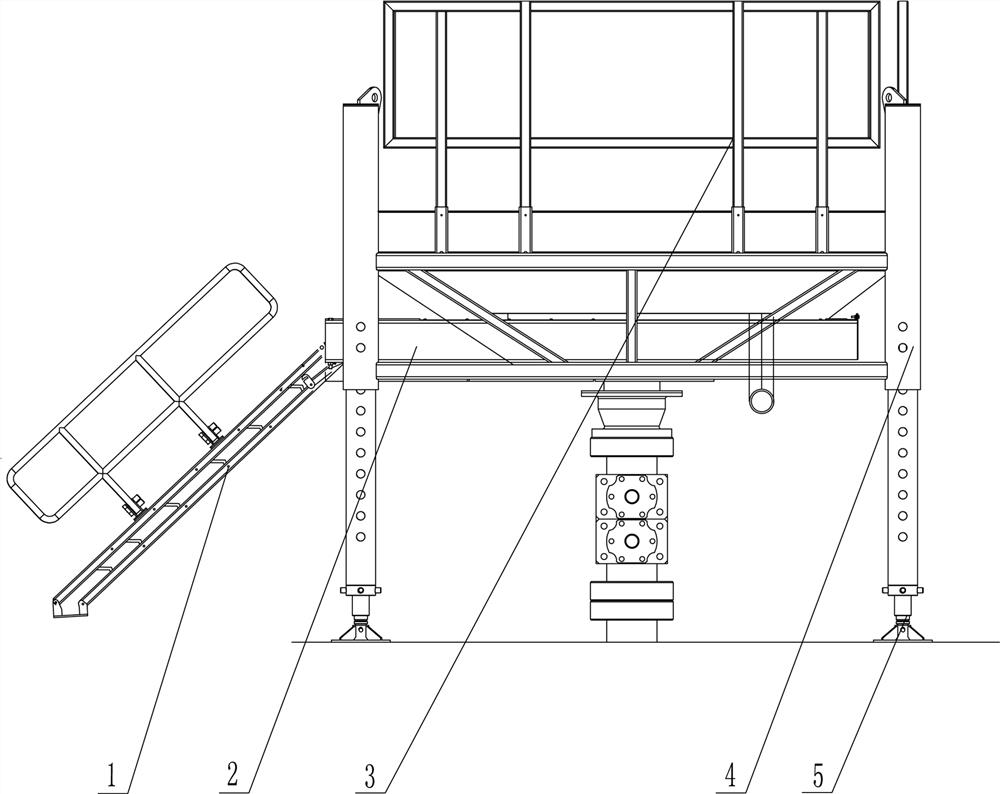

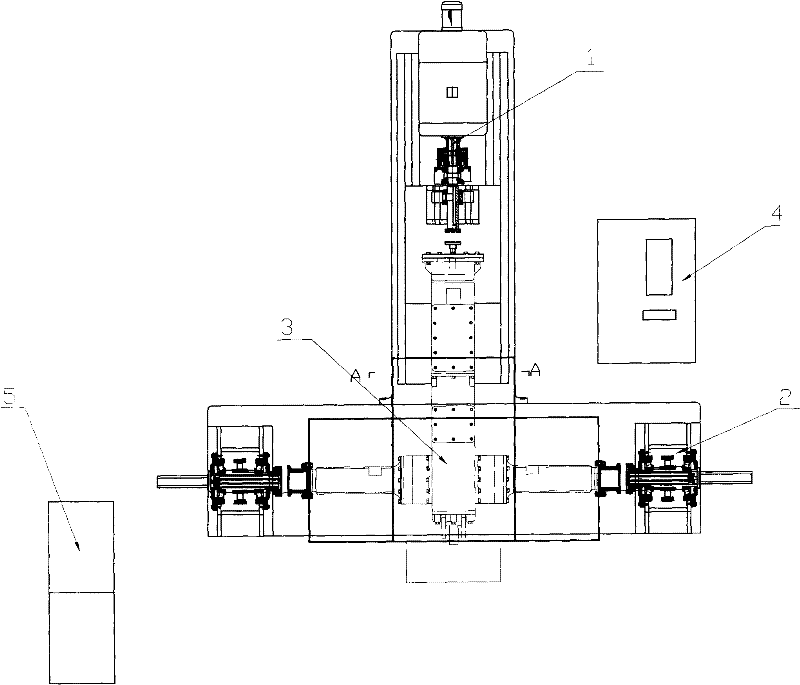

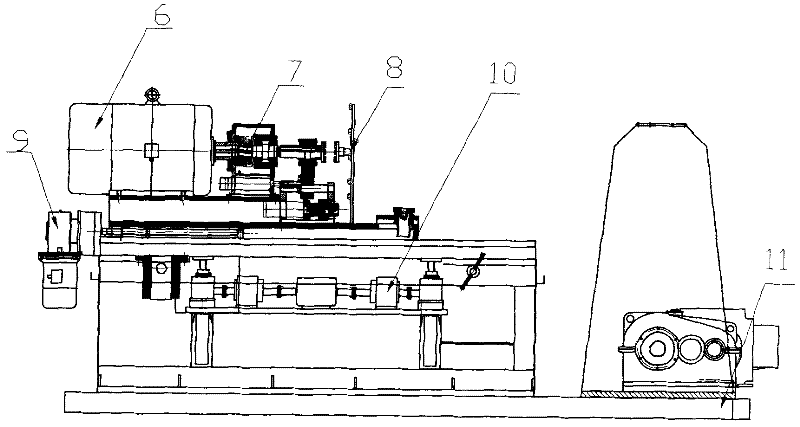

Load running-in test bench for tractor and auto chassis and running-in technology thereof

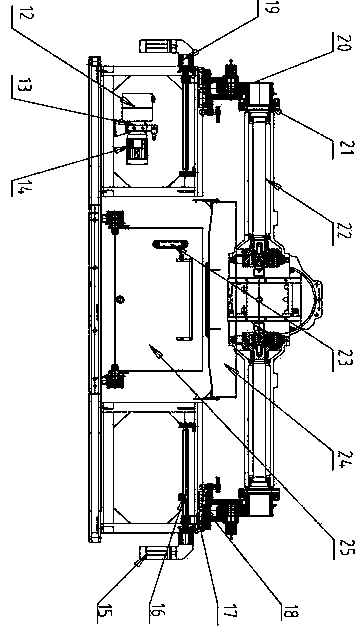

The invention relates to the electrical and mechanical field and discloses a load running-in test bench for tractor and auto chassis and a running-in technology thereof, wherein, the running-in test bench comprises an input mechanism, a lifting mechanism, an output mechanism, a loading mechanism, a base, a hydraulic purification system and an automatic control system; the input mechanism is positioned at one end of the base, and the lifting mechanism is arranged between the input mechanism and the base; the output mechanism and the loading mechanism are positioned at the other end of the base,and the loading mechanism is positioned below the output mechanism and connected with the output mechanism through a coupling; and the automatic control system is electrically connected with the input mechanism and the loading mechanism. When a running-in test is carried out, the input mechanism, the output mechanism and the hydraulic purification system are respectively connected with a test piece of the tractor chassis or the auto chassis. The running-in technology mainly adopts the loading running-in purification technology. The running-in test bench has the beneficial effects of improvingthe quality of a whole vehicle, saving energy, time and occupied space, improving the production efficiency, reducing the ex-factory back repair rate of products and realizing the automatic control.

Owner:湘潭科达电工专用成套设备有限责任公司

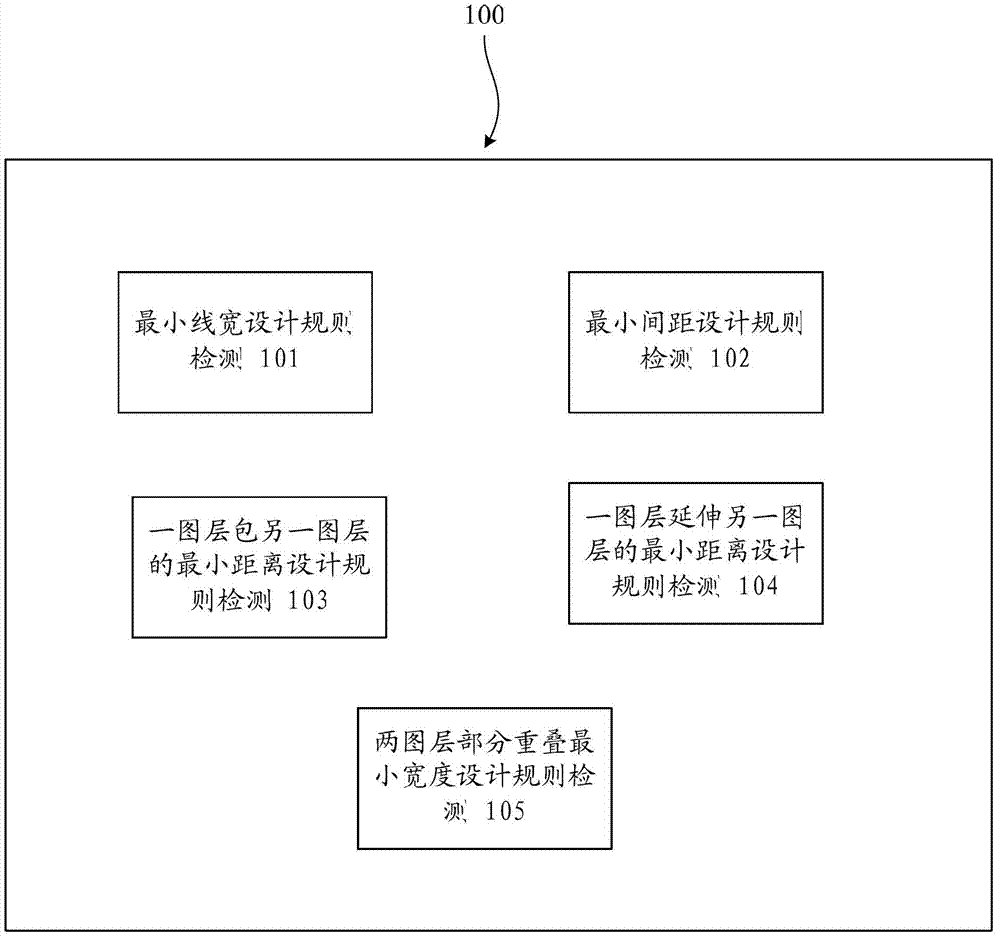

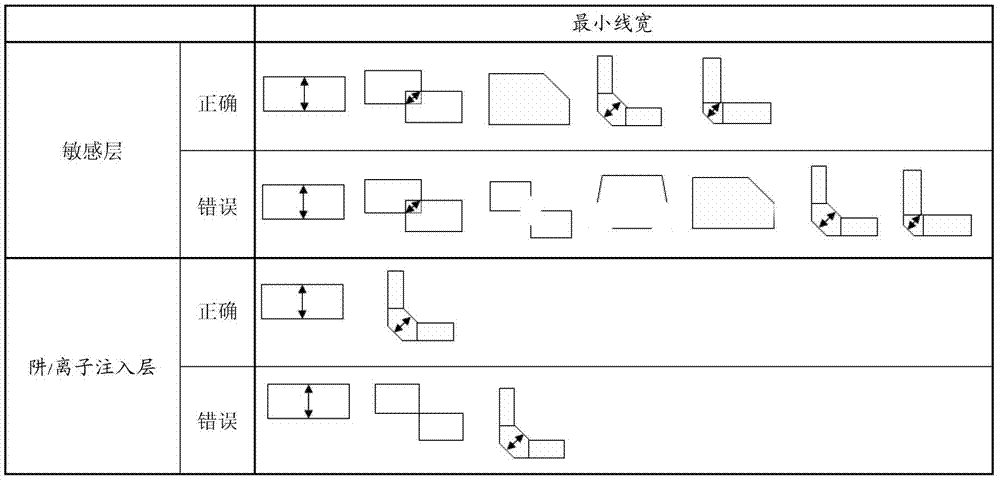

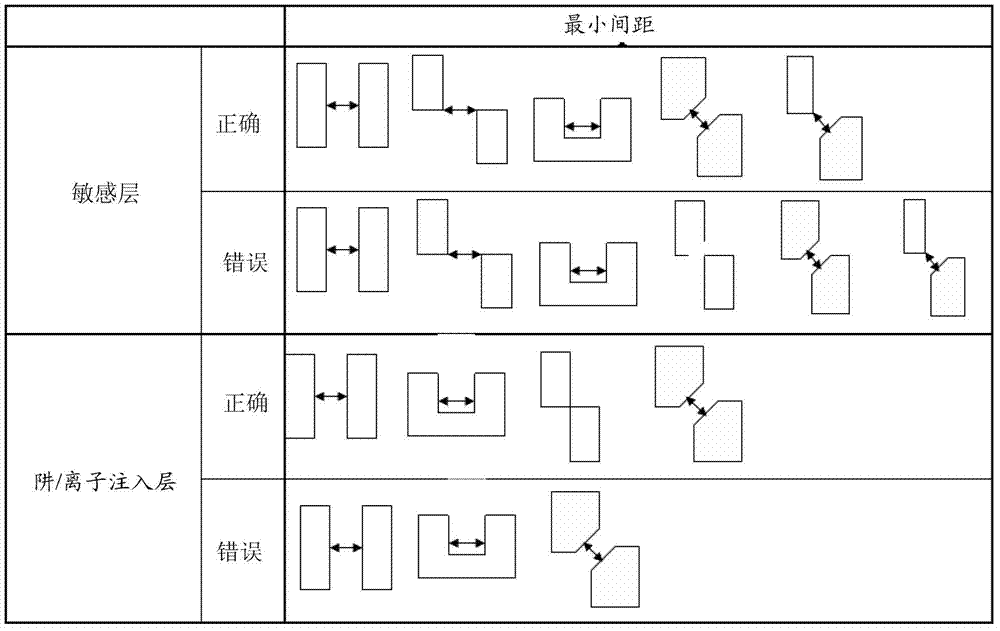

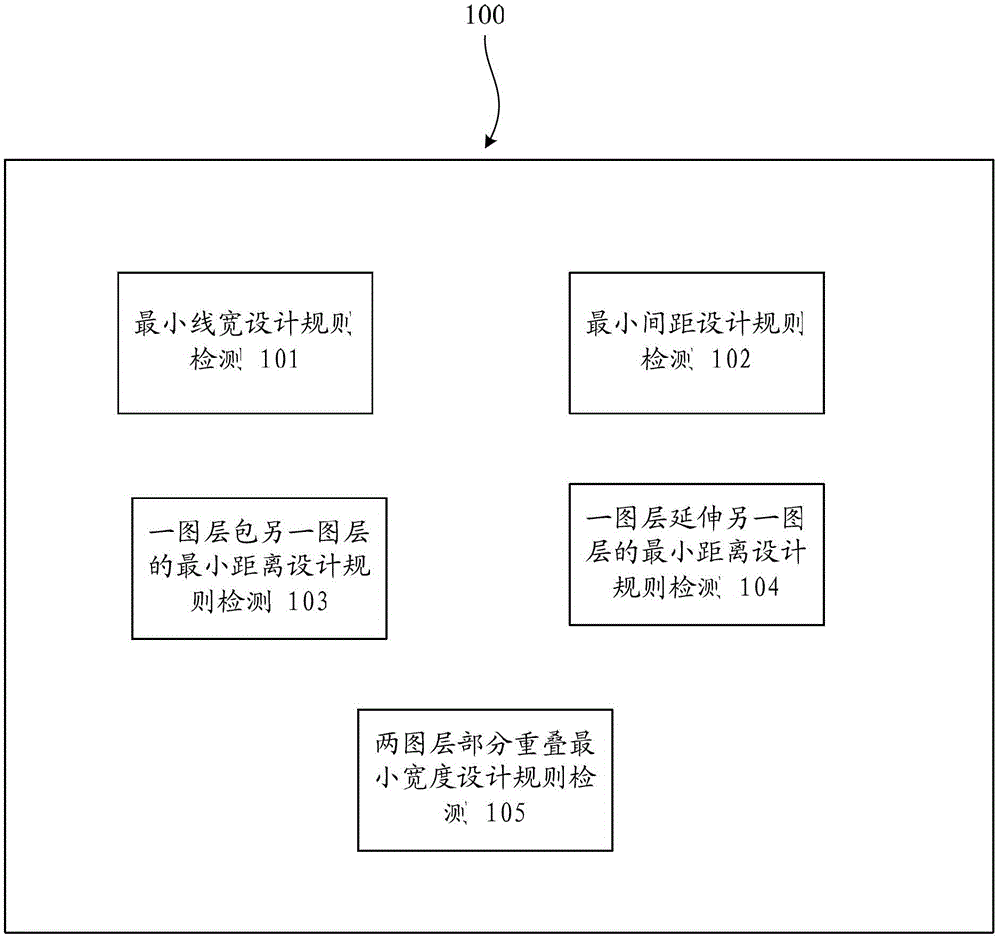

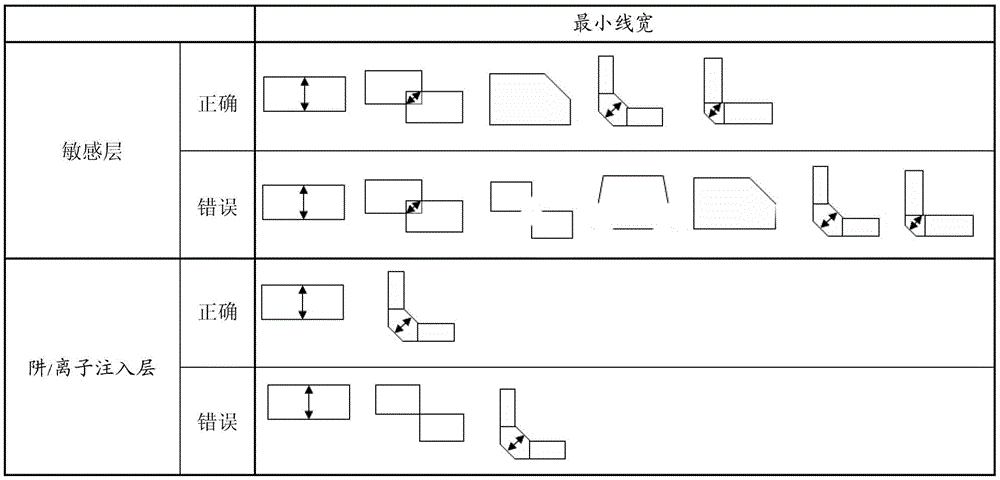

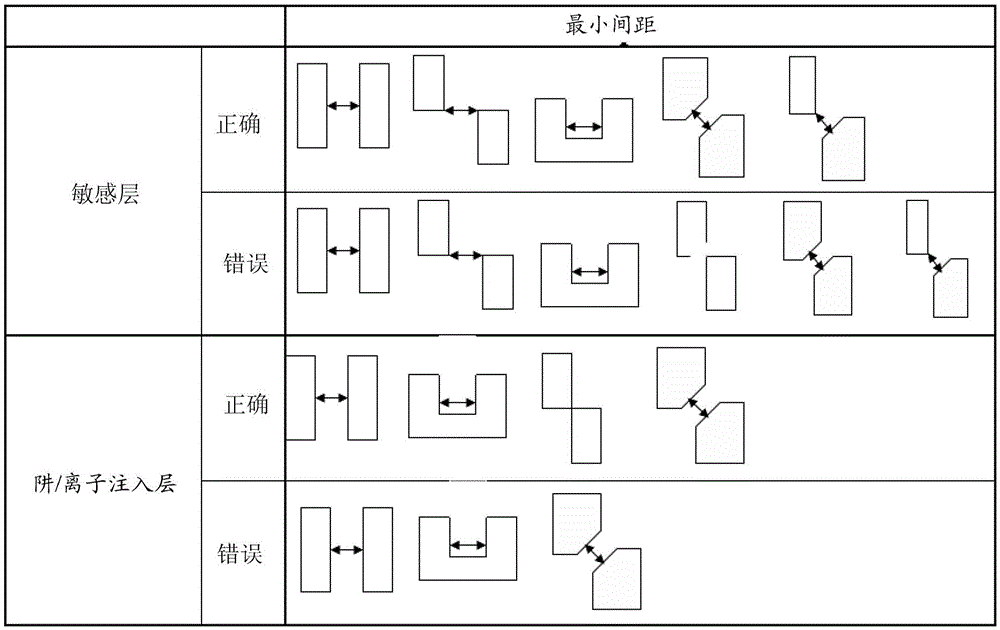

Layout design rule check file verification graphics library and establishment method thereof

ActiveCN103310037AReduce job preparation timeImprove work efficiencySpecial data processing applicationsGraphicsComputer architecture

The invention discloses a layout design rule detection file verification graphics library and an establishment method thereof. The layout design rule check file verification graphics library comprises a minimum line width, a minimum space, a minimum distance enclosing another graphic layer by one graphic layer, a minimum distance extending to another graphic layer from one graphic layer, a single-layer graph with the minimum width overlapped by two graphic layer parts, and design rule check among multilayer graphs. According to the layout design rule detection file verification graphics library provided by the invention, on one hand, the incomplete verification graph kinds due to inadequate experience of a verification engineer can be made up; on the other hand, the development cycle of establishing the verification graph can be shortened. The layout design rule detection file verification graphics library can be used for providing the reference for manually establishing the verification graphs by any layout verification engineer and can also be used for an automatic generation tool of the verification graph, directly calling a graphics library file and realizing batch production of the verification graph by using a tool to modify the basic line width, the layer and other variables.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

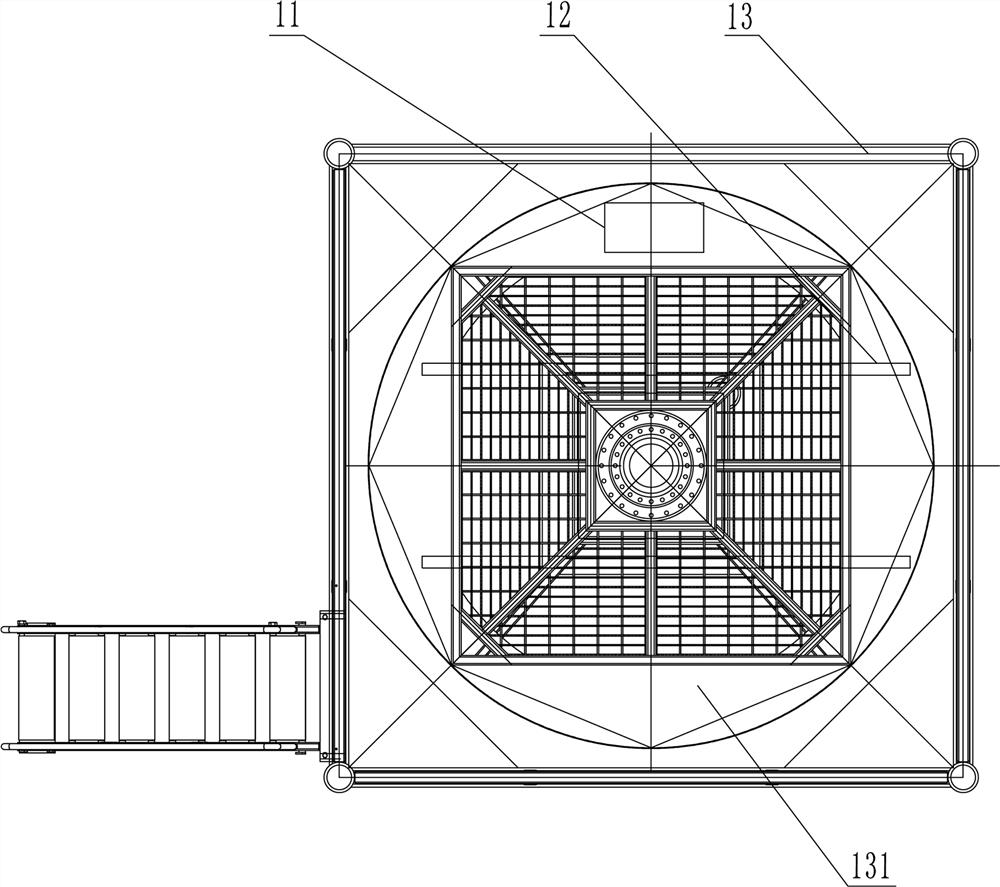

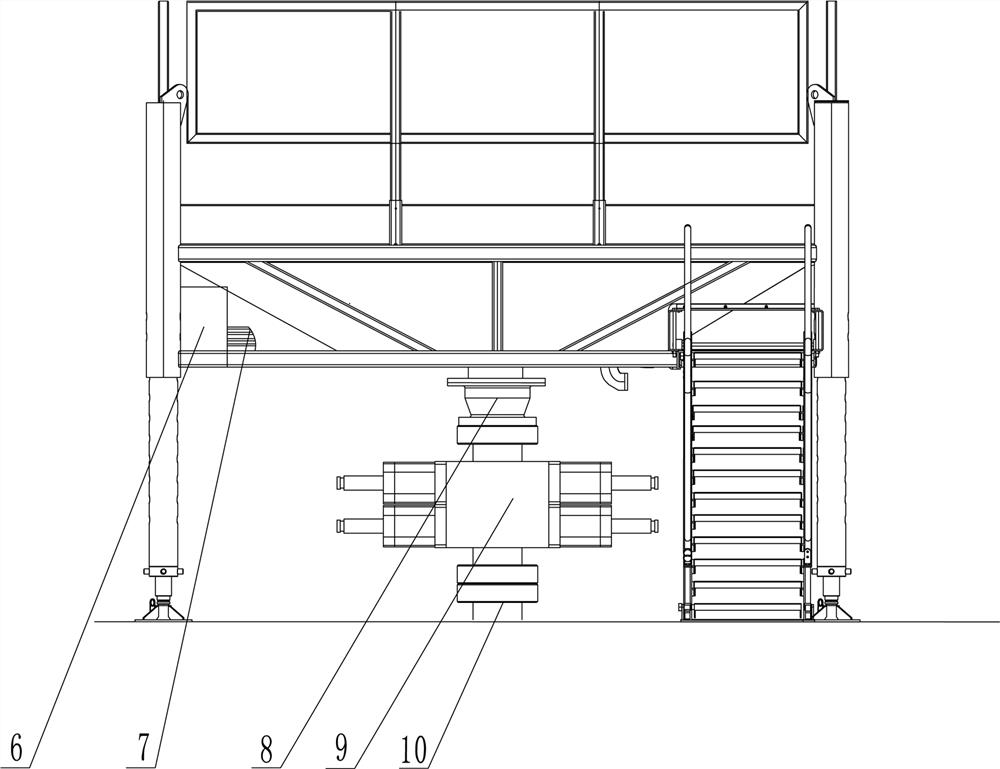

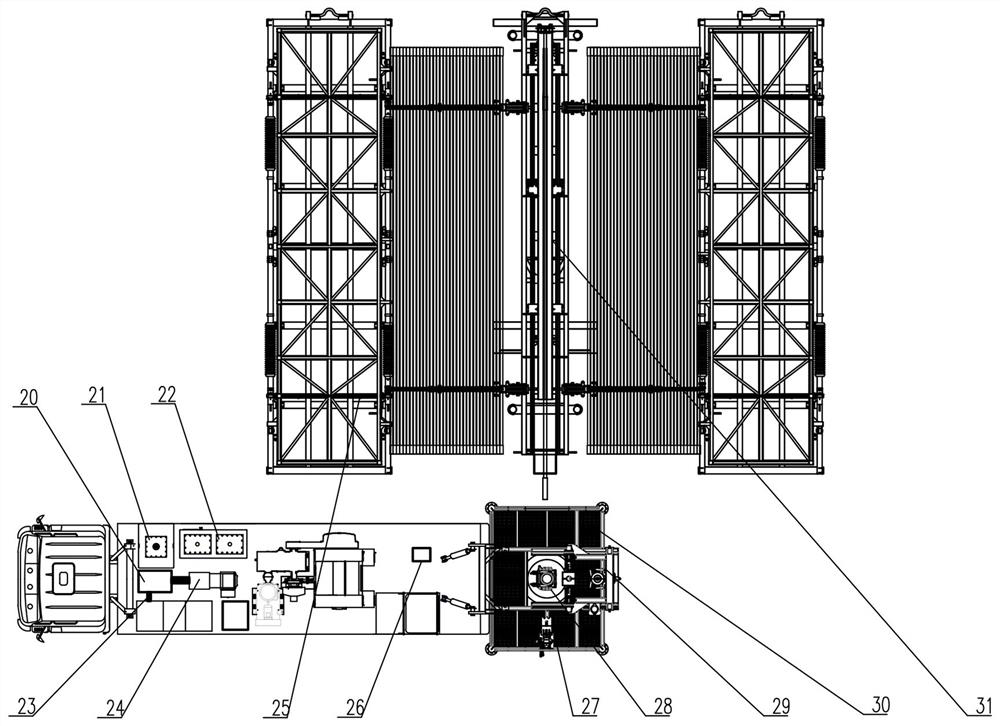

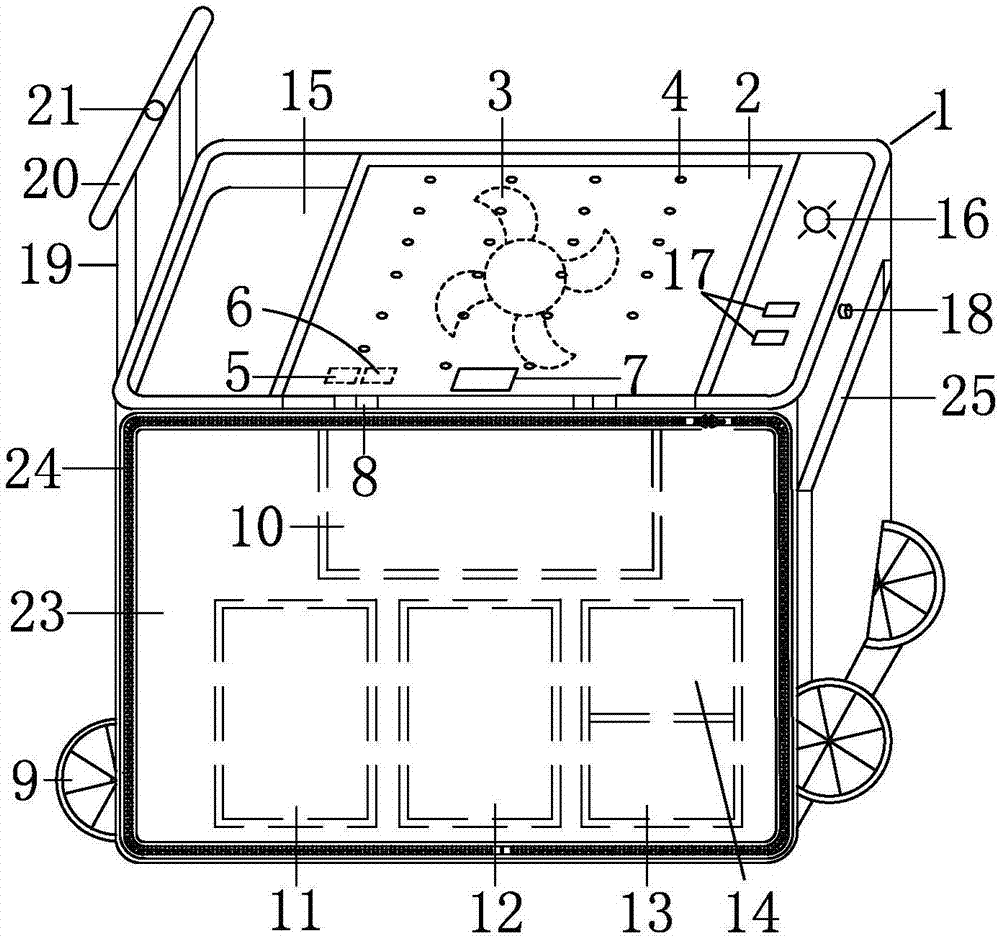

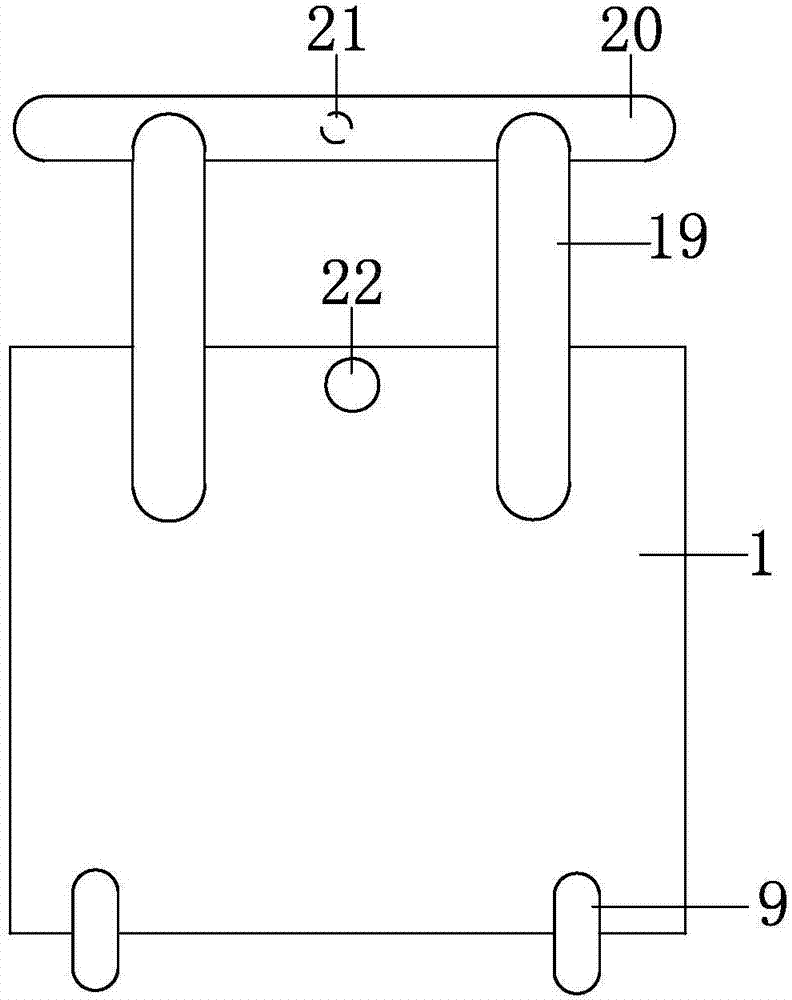

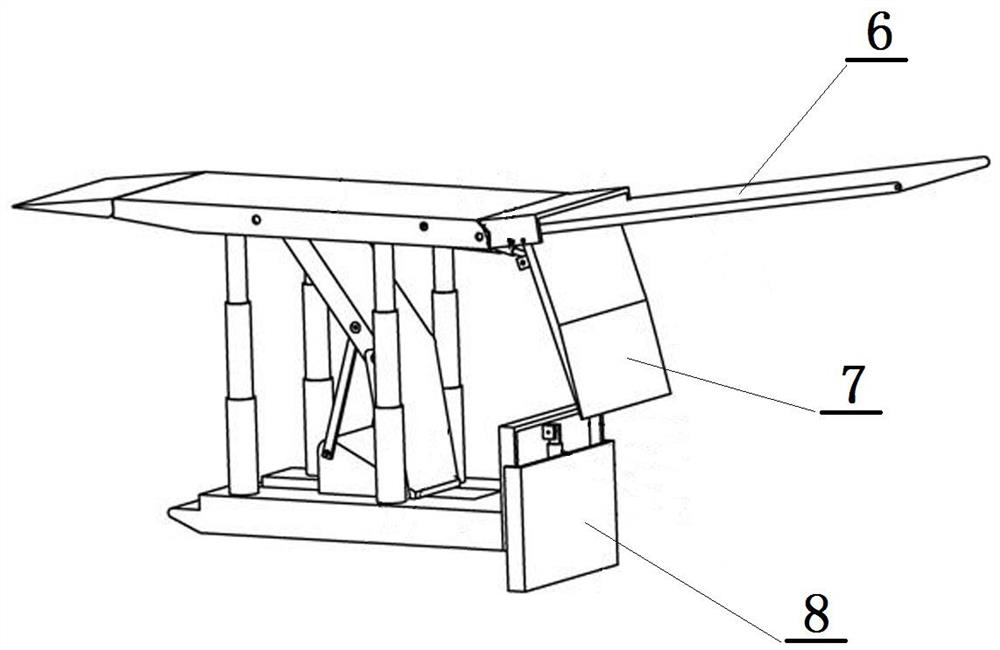

Environment-friendly workover work platform with rotatable table top and application method

ActiveCN112145098AHighly integratedReduce space consumptionDrilling rodsDerricks/mastsRotary stageBlowout preventer

The invention discloses an environment-friendly workover work platform with a rotatable table top and an application method. The environment-friendly workover work platform comprises a work platform body, adjustable supporting legs, a recyclable ladder, a dirt receiving box, a liquid level sensor, a rotating support, a hydraulic drive slewing bearing, a self-sealing blowout preventer, a mechanicalarm mounting base, an upper shackle hydraulic clamp guide rail, a control box, a pipeline and the like. The problems that an existing workover work platform is single in function and poor in weighingperformance ad cannot integrate wellhead automatic work tools, when the work position is adjusted, procedures are complex, time and labor are wasted, pollution is severe, and the safety of operatorsis harmed are solved; the environment-friendly workover work platform has the characteristics that wellhead automatic work tools can be integrated, according to the well site arrangement situation, the work positions of automatic tools can be conveniently adjusted by rotating the table top, oil stains scattered on the platform during work can be effectively treated, and safety and environmental protection are achieved; and the functions of wellhead rapid mounting, oil pipe mud scraping, sealing between oil casings, mud collection, hydraulic detection, hydraulic steering of the table top of theplatform, height adjustment and the like can be achieved.

Owner:中石化四机石油机械有限公司 +1

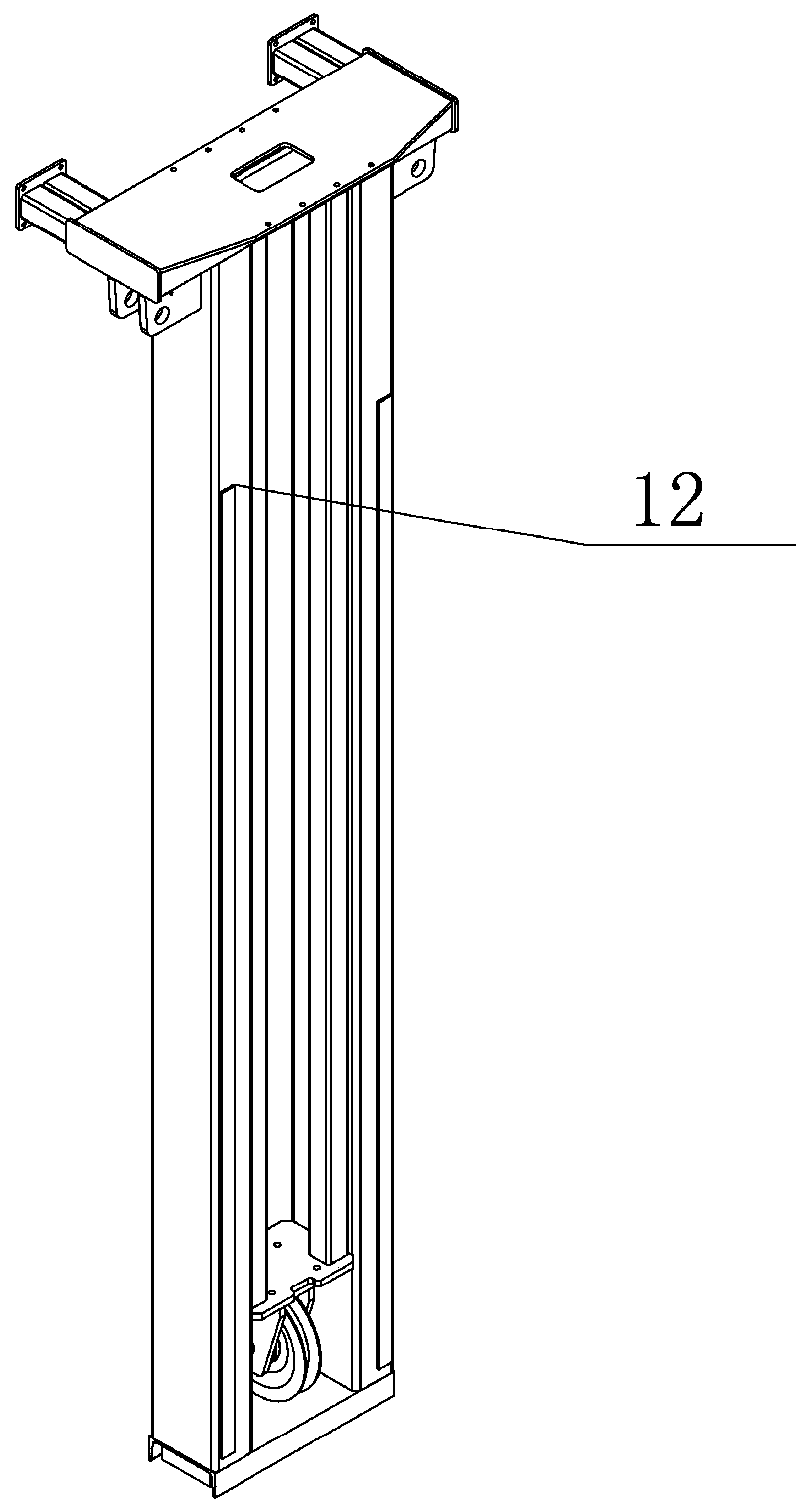

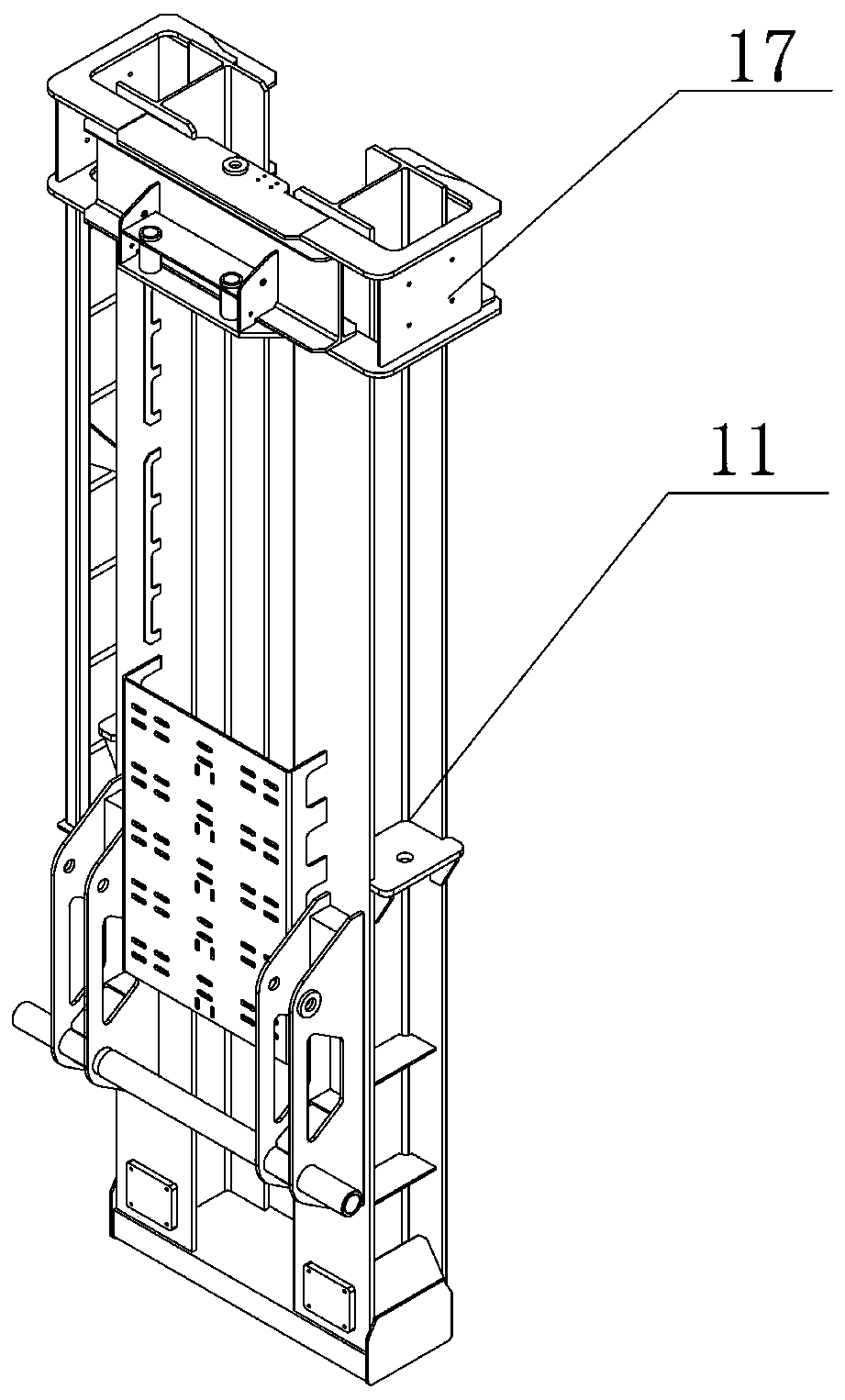

Lifting, damping and transportation-integrated device for on-board large telescope

The invention discloses a lifting, damping and transportation-integrated device for an on-board large telescope. The device is mainly composed of a lifting frame upper panel, a lifting frame lower panel, a motor, a synchronous belt / wheel, screws, nuts, a damper and the like. The motor rotates to drive the synchronous belt / wheel, the synchronous belt / wheel and the screws of which the number is four rotate synchronously, after the synchronous belt / wheel passes a screw thread pair formed by the screws and the nuts of which the number is four and the rotational degree of freedom is constrained, the rotary motion is converted into the linear motion of the nuts, the telescope is directly connected with the nuts through the damper, and therefore the rotary motion of the motor is converted into the lifting motion of the telescope. The device has the lifting function, so that the problem that the on-board large telescope has to be transported in a split way due to the size limit of road boundary lines is solved, the preparation time for working is shortened, the damping function is fulfilled, so that the problem of safety and reliability of ferry transportation can also be solved, and the lifting, damping and transportation-integrated device for the on-board large telescope can be widely applied to on-board large telescopes.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Large-thrust high-speed hydraulic cylinder and work method thereof

ActiveCN106015130AInstantaneous high-speed high-thrust output of high-pressure gasHigh speed and large thrust outputFluid-pressure convertersActuator accumulatorsHydraulic cylinderEngineering

The invention relates to a large-thrust high-speed hydraulic cylinder. A hydraulic cylinder body is a sealed cavity which is transversely arranged. A high-speed cylinder barrel is fixedly arranged at the front end of the hydraulic cylinder body in an axial extending manner. A high-speed cylinder piston rod is coaxially sleeved with the high-speed cylinder barrel. The high-speed piston rod coaxially slides in a sealed manner in a high-speed cylinder rod cavity. An energy accumulator piston rod penetrating an energy accumulator gas cavity and a supercharger cavity is coaxially installed in the hydraulic cylinder body. An energy accumulator piston is fixedly arranged at the end portion, at the front end of the energy accumulator gas cavity, of the energy accumulator piston rod. The energy accumulator piston is installed in the hydraulic cylinder body in a sealed and sliding manner. An energy accumulator liquid cavity is formed between the energy accumulator piston and the high-speed cylinder piston rod. A pressure cylinder piston is coaxially manufactured on the energy accumulator piston rod in the supercharger cavity. The pressure cylinder piston is installed in the supercharger cavity in a sealed and sliding manner. By means of the high-thrust high-speed hydraulic cylinder, through the manner that a piton type energy accumulator and the high-speed hydraulic cylinder are directly connected in series, high-speed output of large thrust of the high-speed cylinder can be achieved.

Owner:TIANJIN URANUS HYDRAULIC MACHINERY

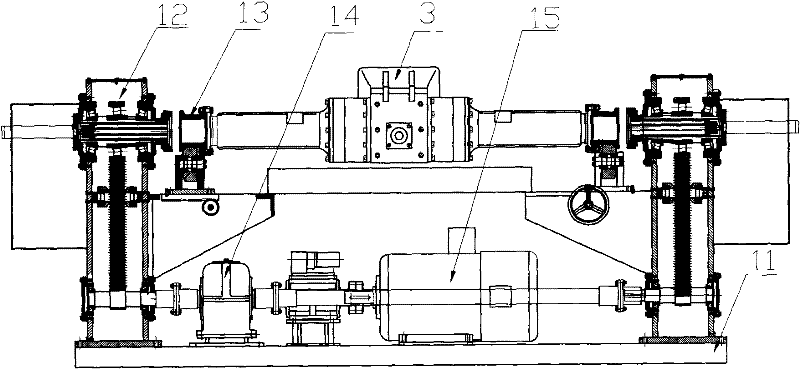

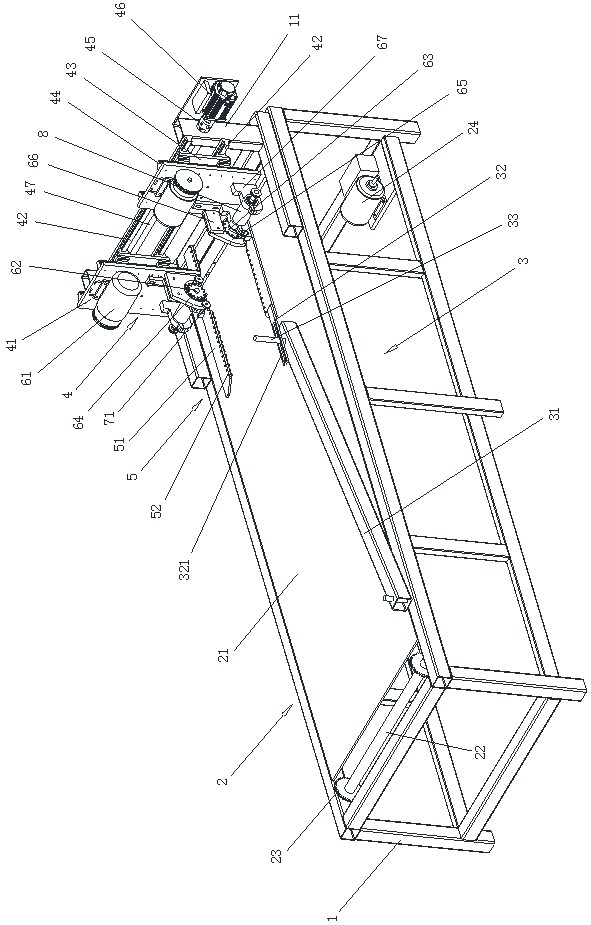

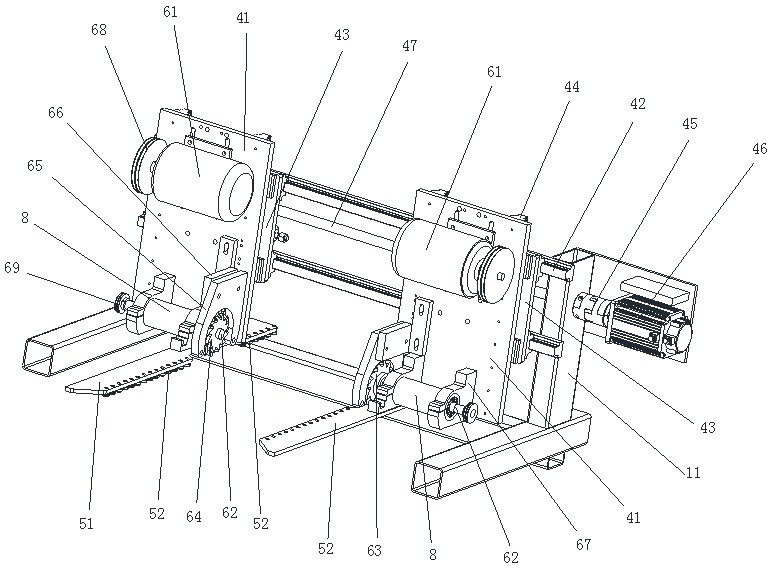

Tractor chassis self-weight load type running-in purification test stand and running-in purification process thereof

ActiveCN103454094AShorten the timeReduce job preparation timeVehicle testingAutomatic controlEngineering

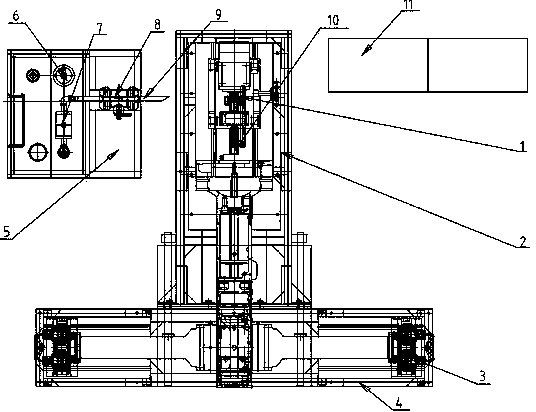

The invention discloses a tractor chassis self-weight load type running-in purification test stand and process. The tractor chassis self-weight load type running-in purification test stand comprises an input mechanism, a lifting mechanism, a rear axle installation locating mechanism, a front end installation locating mechanism, an input machine base, a rear axle machine base, a base, a hydraulic system, a hydraulic purification system and an automatic control system. The running-in purification process of the test stand is further disclosed. According to the tractor chassis self-weight load type running-in purification test stand and the running-in purification process, running-in purification can be conducted by utilizing the self-weight load of a tractor chassis transmission system under the condition that an external loading mechanism is not added, potential safety hazards inside the transmission system are removed, energy and time are saved, and production efficiency and quality of the whole vehicle are improved.

Owner:湘潭科达电工专用成套设备有限责任公司

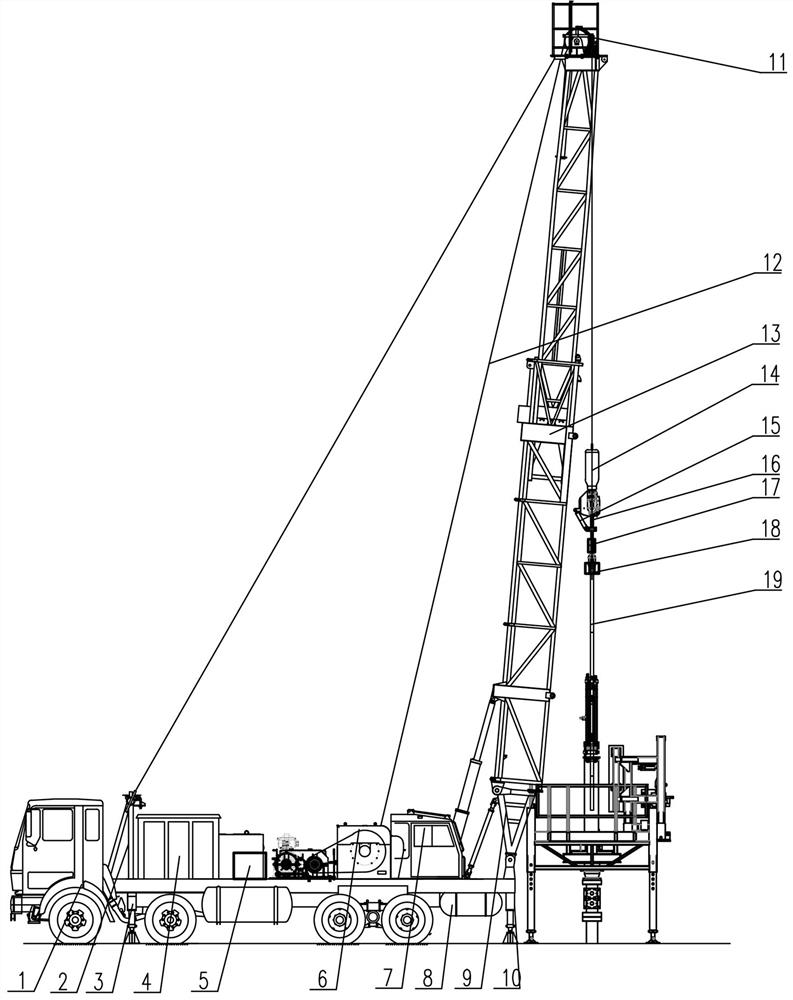

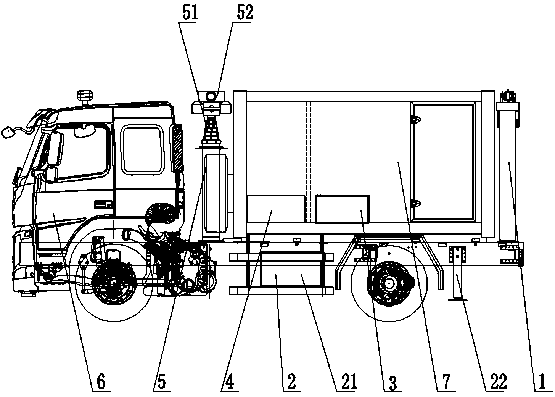

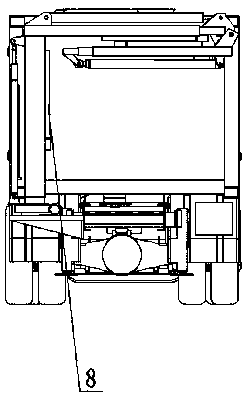

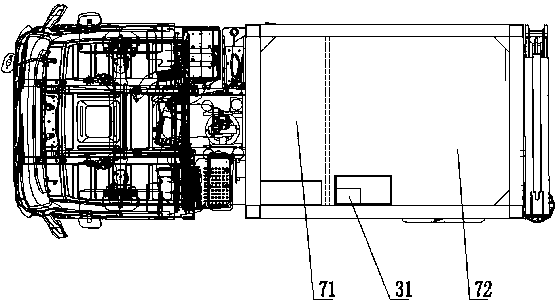

Automatic workover rig driven by power grid

ActiveCN113073948AReduce homeworkGood energy saving and environmental protection effectDrilling rodsDrilling casingsGear wheelBlock and tackle

The invention discloses an automatic workover rig driven by power grid. A derrick front support, an electric control room and a hydraulic system are arranged at the front end of a self-propelled chassis of equipment, an electric air compressor, a multi-gear variable-speed winch and a deadline anchor are arranged in the middle of the self-propelled chassis, an operation room, an air storage tank and a derrick rear support are arranged at the tail of the self-propelled chassis, a working platform is arranged on a wellhead at the tail part of the self-propelled chassis, a tubular column storage device is connected with a tubular column conveying device and is vertically arranged on one side of the upper end surface of the working platform, one end of a steel wire rope is connected with the multi-gear variable-speed winch and the deadline anchor, the other end of the steel wire rope is connected with a grabbing system after bypassing a crown block pulley block, and the grabbing system is used for grabbing a tubular column. According to the automatic workover rig driven by the power grid, various matched devices and systems are connected with respective control systems, workers only need to conduct whole-process monitoring in a driller control room in the whole workover operation, and full-automatic operation of wellhead tubular column connection, buckling, screwing-on and screwing-off and tubular column feeding and discharging operation platforms is achieved.

Owner:中石化四机石油机械有限公司 +1

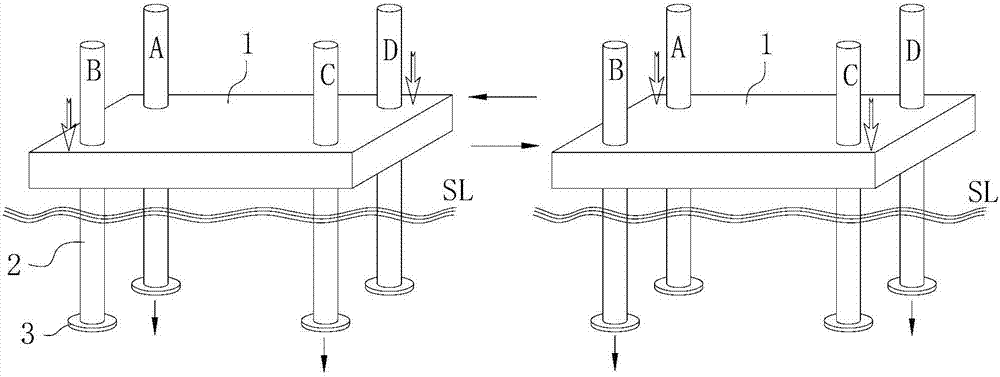

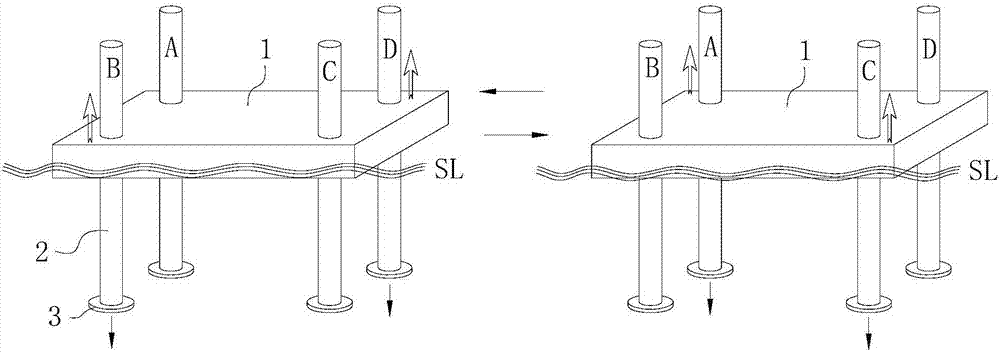

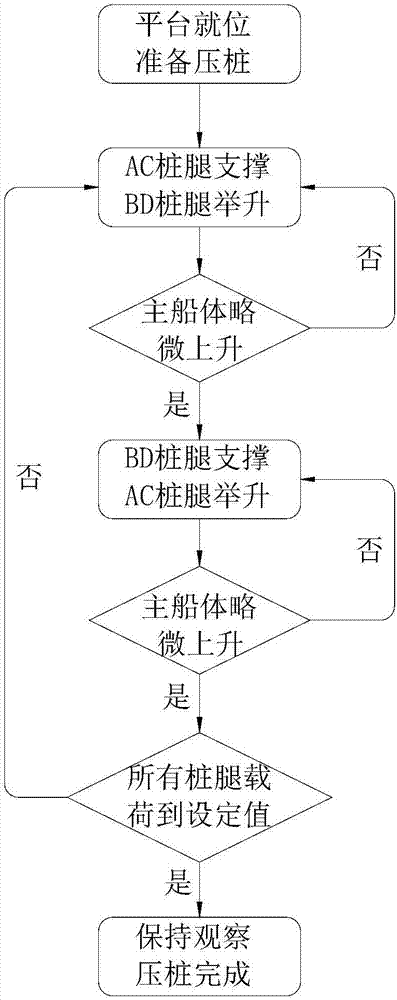

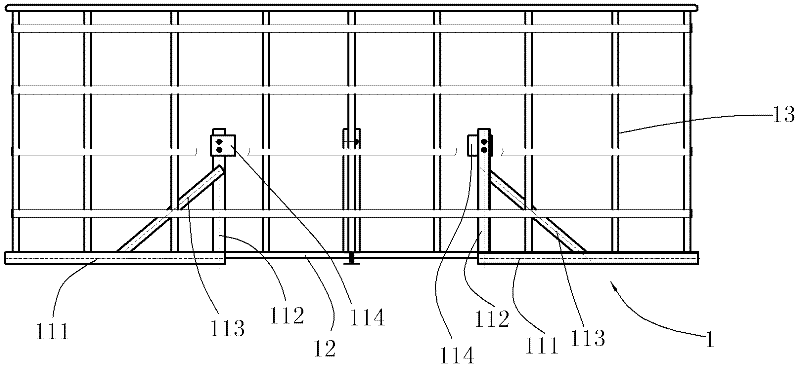

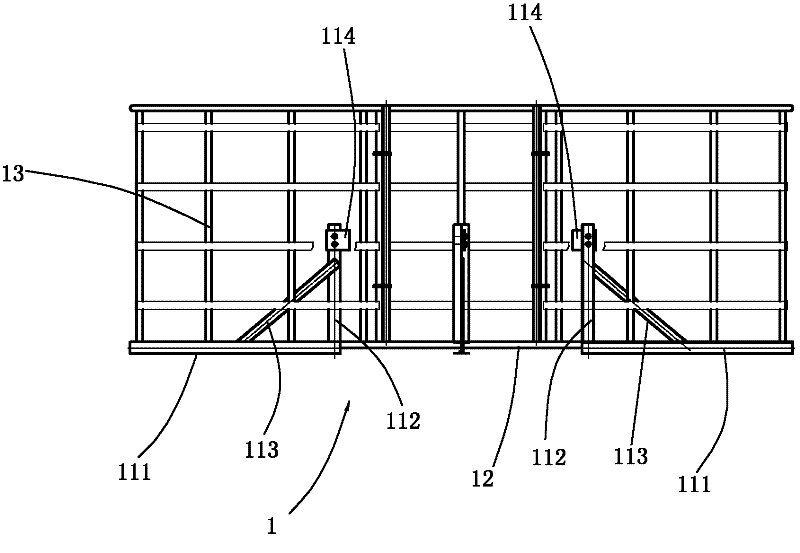

Pile prepressing method of four-pile-leg self-elevating platform

ActiveCN107268558AReduce job preparation timeShorten working timeArtificial islandsUnderwater structuresWork safetySeabed

The invention provides a pile prepressing method of a four-pile-leg self-elevating platform. The pile prepressing method comprises the steps that S10, platform pile inserting locating is carried out; S20, a platform main ship body is kept in a state of floating in seawater, two pile legs on one diagonal line of the platform are in a supporting state so as to keep relatively fixed with the main ship body, and meanwhile two pile legs on the other diagonal line are in a lifting state so as to descend relative to the main ship body so that the two pile legs can be pressed down towards the seabed; and S30, the ascending and descending state of the main ship body is monitored, when the main ship body slightly ascends, the two pile legs originally in the lifting state are converted to the supporting state, the two pile legs originally in the supporting state are converted to the lifting state, and the step is repeated till the load of each pile leg is not smaller than a load set value. According to the method, the work time of pile prepressing can be shortened, and the work safety of pile prepressing can be improved.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +2

Removing method of lifting cover for hoisting

ActiveCN102583149AShorten demolition preparation timeReduce job preparation timeLoad-engaging elementsMarine engineeringFlange

The invention relates to a removing method of a lifting cover for hoisting. The removing method is characterized by comprising the following steps of: installing the lifting cover and an operating platform on equipment to be hoisted; connecting hoisting ropes, starting a main hoist to hoist the equipment to be hoisted to an equipment installing foundation in position; hoisting operators to the operating platform by using an auxiliary hoist, loosening double-head studs and nuts for fixing the lifting cover and equipment flanges, and then returning the operators to the ground by using the auxiliary hoist; lifting a hoisting hook of the main hoist, separating the operating platform and the lifting cover from a top flange of the equipment; rotating an arm rod of the main hoist, and falling the hoisting hook, till the operating platform and the lifting cover fall to the ground; and disassembling the operating platform and the lifting cover on the ground. The removing method has the advantages that by specially-designed matching of the operating platform and the lifting cover, the lifting cover and the operating platform can be quickly disassembled from the equipment after the hoisting is finished, and then the operating platform is separated from the lifting cover on the ground, so that the working efficiency and the hoisting safety are greatly improved, and meanwhile the hoisting construction cost is also reduced.

Owner:CHINA PETROLEUM & CHEM CORP +2

Scanning electron microscope having detachable shaft, and image acquisition method using same

PendingCN113519038AEasy maintenanceEasy to manageElectric discharge tubesEngineeringMechanical engineering

Owner:COXEM CO LTD

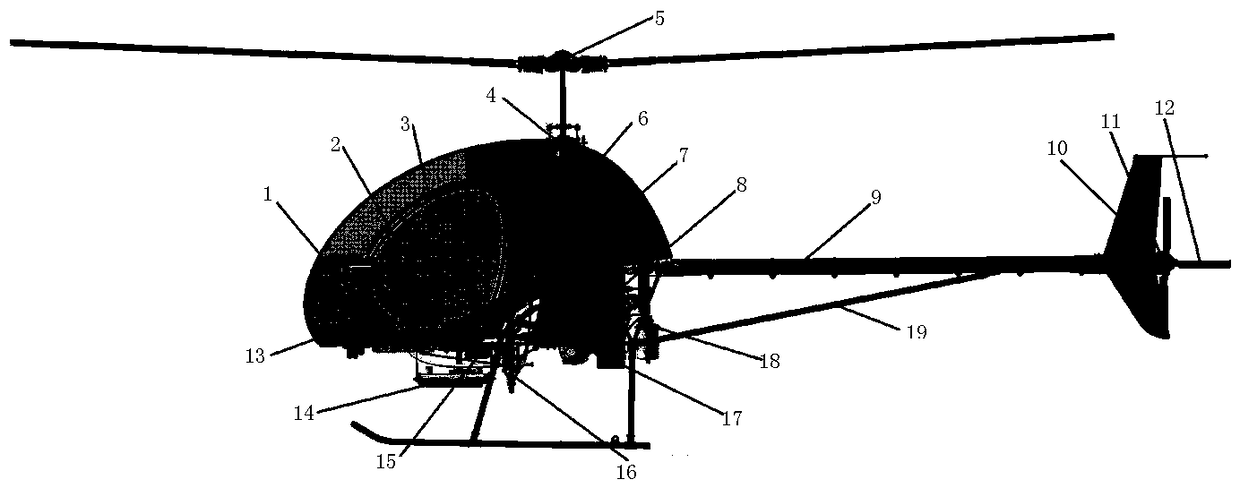

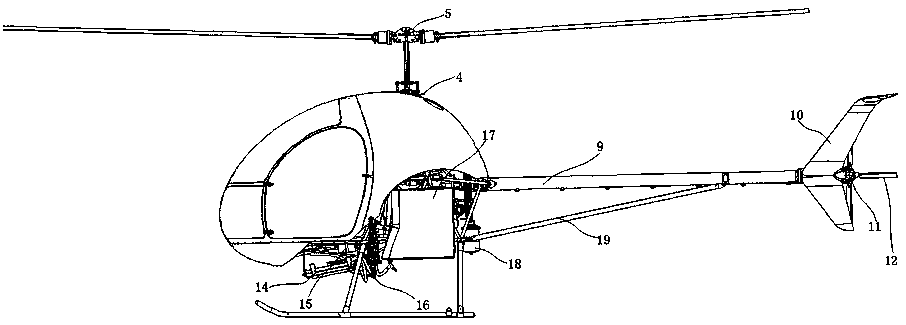

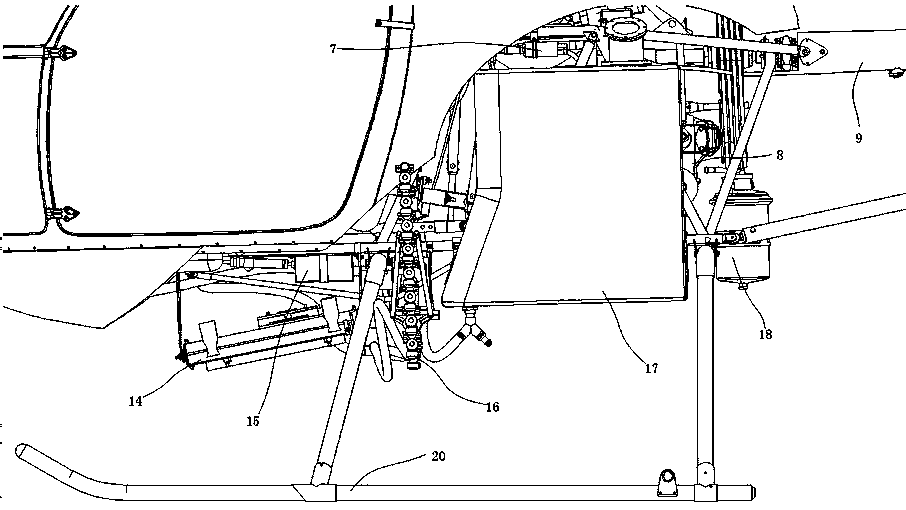

Extremely light manned agricultural and forestal plant protection helicopter

InactiveCN108791838ALarge cargo capacityImprove work efficiencyAircraft componentsRotocraftAgricultural engineeringFuselage

The invention discloses an extremely light manned agricultural and forestal plant protection helicopter. The extremely light manned agricultural and forestal plant protection helicopter comprises a powering device, an accessory system, a transmission system, a rotor wing system, a helicopter body structure, an operation system, an electric instrument system and an agricultural and forestal spraying device. The powering device comprises a piston type engine with turbocharging, and the engine is mounted on the rear portion of a cabin. The extremely light manned agricultural and forestal plant protection helicopter has the beneficial effects that the commercial capacity is large, operation efficiency is high, reliability and security are high and the operation cost is low.

Owner:江西直升机有限公司

Tractor and automobile chassis load running-in test bench and its running-in process

The invention relates to the electromechanical field, and discloses a tractor and automobile chassis load running-in test bench and a running-in process thereof, wherein the running-in test bench includes an input mechanism, a lifting mechanism, an output mechanism, a loading mechanism, a base, a hydraulic purification system and an automatic control system; The input mechanism is located at one end of the base, and a lifting mechanism is arranged between the input mechanism and the base; the output mechanism and the loading mechanism are located at the other end of the base, and the loading mechanism is located below the output mechanism and passes through the coupling and the output mechanism connection; the automatic control system is electrically connected with the input mechanism and the loading mechanism; during the running-in test, the input mechanism, the output mechanism and the hydraulic purification system are respectively connected with the tractor or the automobile chassis test piece. The running-in process mainly adopts the loading and running-in purification process. The invention has the beneficial effects of improving the quality of the whole vehicle, saving energy, time, occupying space, improving production efficiency, reducing the repair rate of products leaving the factory, and being capable of automatic control.

Owner:湘潭科达电工专用成套设备有限责任公司

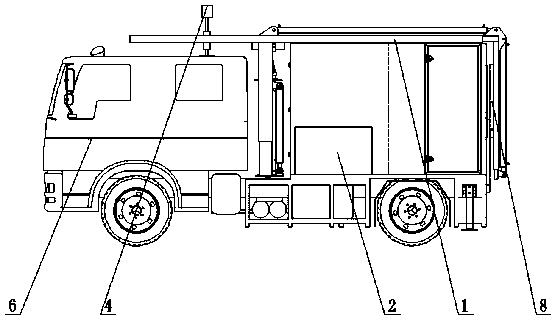

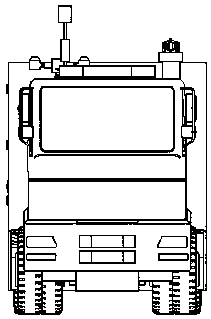

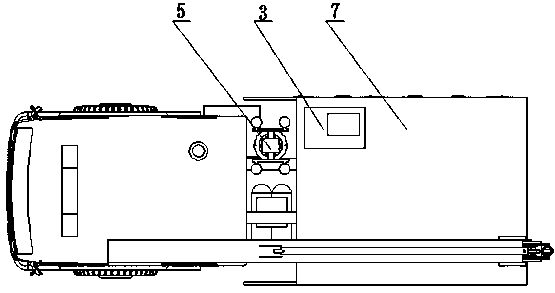

Telescopic inspection vehicle and operating method

PendingCN110861564ASolve the spaceSolve the problem of slow deploymentItem transportation vehiclesCommunications systemControl system

The invention relates to a special vehicle, in particular to a telescopic inspection vehicle and an operating method. The telescopic inspection vehicle comprises a chassis and a carriage and further comprises a gate type detection mechanical arm, a hydraulic system, a control system and a communication system, wherein the control system is used for controlling automatic leveling support legs to besupported on the ground stably and operating the gate type detection mechanical arm to be unfolded in sequence, and the gate type detection mechanical arm is provided with detection instruments. Thegate type detection mechanical arm comprises a fixed seat, a main arm, an upper arm, a cross beam, an outer side arm and a tail arm, wherein the fixed seat is connected with the carriage, and the mainarm executes vertical lifting motion along the fixed seat under driving of a main lifting oil cylinder. Compared with the prior art, the telescopic mechanism is adopted, the integration is good, andthe mechanism is convenient to unfold; by adoption of an intelligent operation system, one-key leveling of the vehicle and automatic operation of the mechanism are realized, work preparation time is shortened, and safety performance of the vehicle is improved; and by adoption of one-key operation intelligent control, rapid inspection of the vehicle is realized, and the problem about applicabilityof the detection mechanism is solved.

Owner:LONGYAN HAIDEXIN AUTOMOBILE

Automatic edge milling machine for aluminum alloy formwork

ActiveCN112091295AClose contactEliminate tolerance build-upMilling machinesMilling equipment detailsDrive shaftMachine

The invention discloses an automatic edge milling machine for an aluminum alloy formwork. The machine comprises a rack, a feeding device, a leading-in mechanism, a sizing and distance adjusting mechanism, a guide positioning mechanism, pre-tightening mechanisms, two edge milling mechanisms and an electric control system, wherein the feeding device is arranged at the upper part of the rack and comprises a support plate, a feeding belt, a driving shaft, a driven shaft and a driving mechanism. The driving shaft and the driven shaft are oppositely arranged on the rack and connected through the feeding belt. The sizing and distance adjusting mechanism comprises two adjustable workbenches, the two adjustable workbenches are adjustably and fixedly connected with the rack, and the pre-tightening mechanisms are arranged on the rear sides of the adjustable workbenches. The guide positioning mechanism comprises two guide plates which are symmetrically arranged, and two sets of side guide wheels are arranged on the opposite sides of the two guide plates respectively. The two edge milling mechanisms are arranged on the two adjustable workbenches in a bilateral symmetry mode. Automatic continuous feeding, automatic guiding alignment and one-time multi-edge cutting are achieved, the cutting speed is high, the machining precision is high, the production cost is low, and the production efficiency is high.

Owner:YANTAI ZHONGCHENG NEW BUILDING

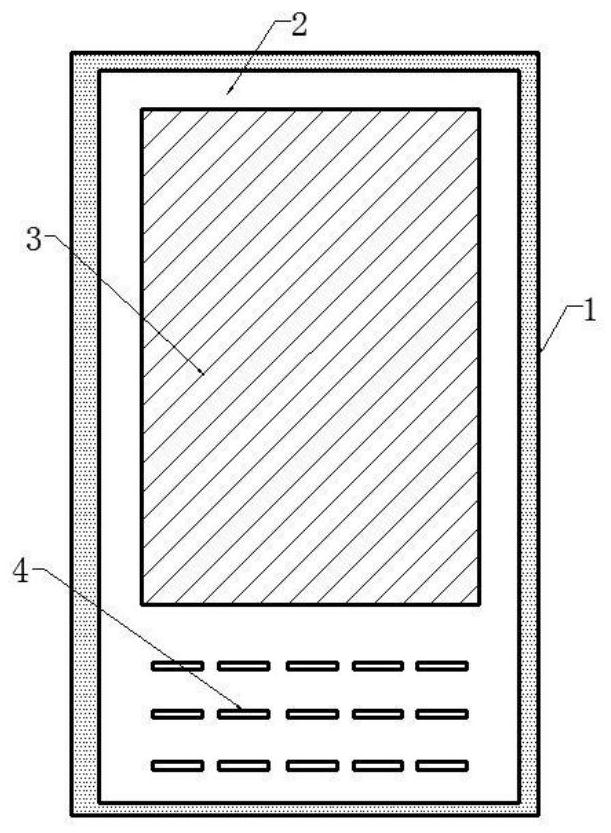

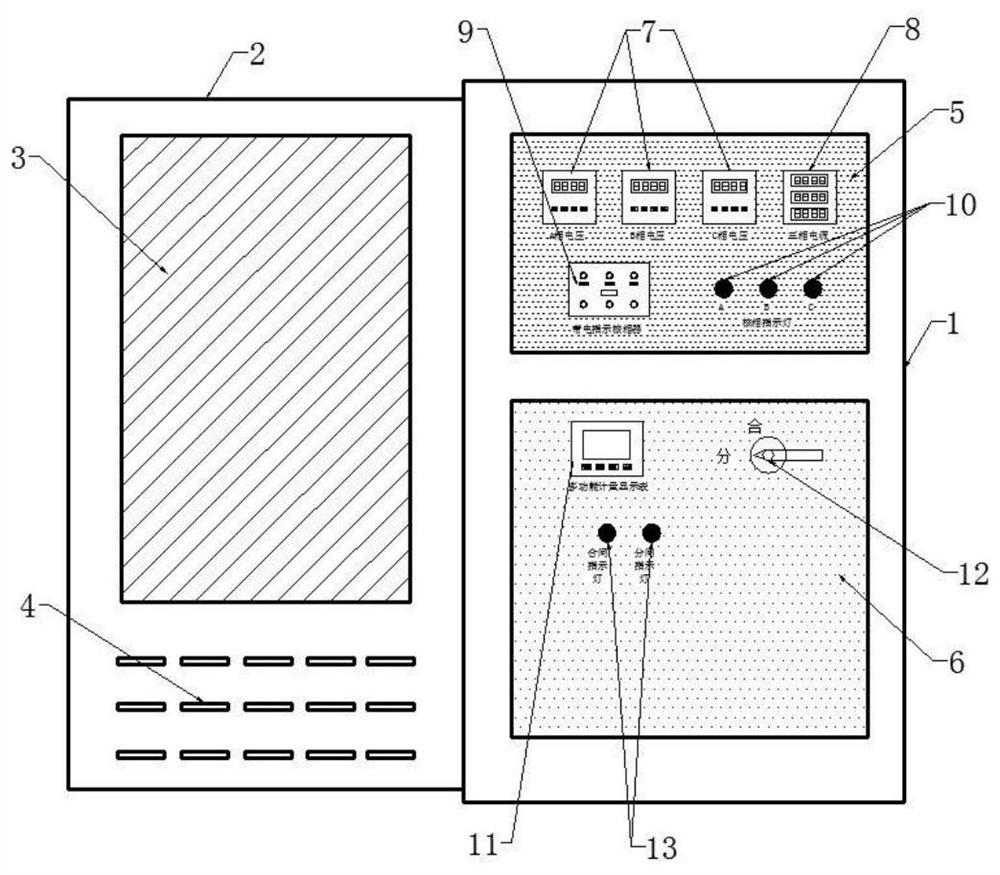

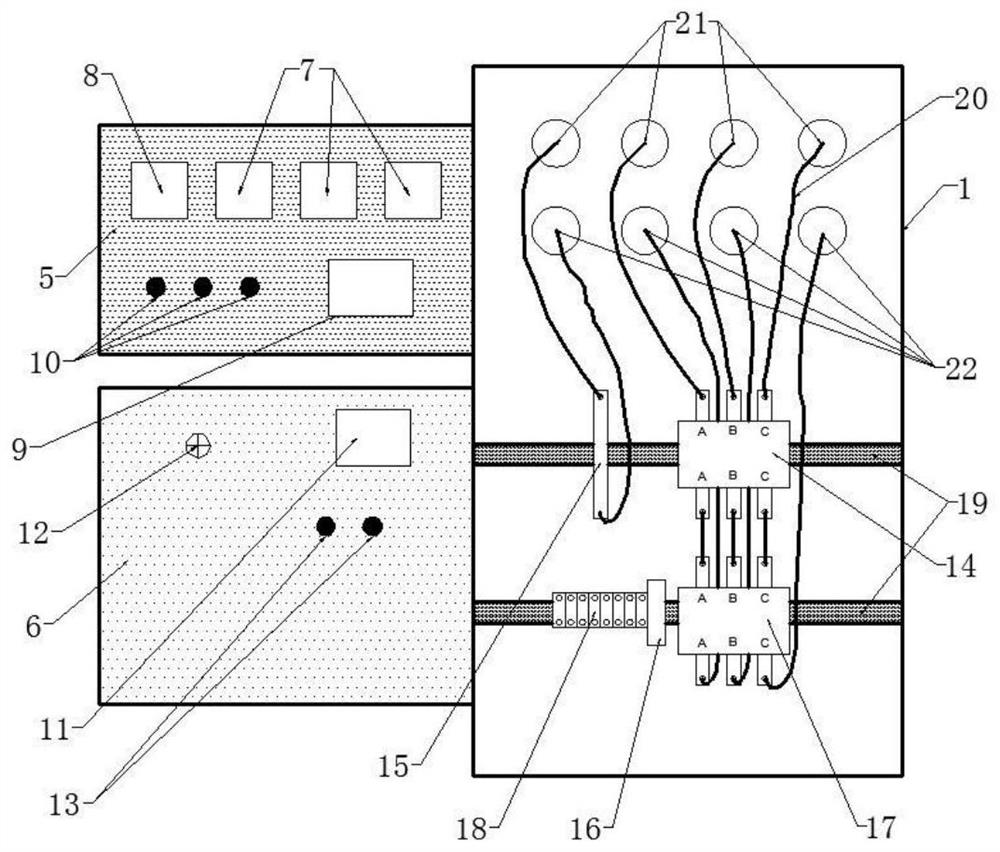

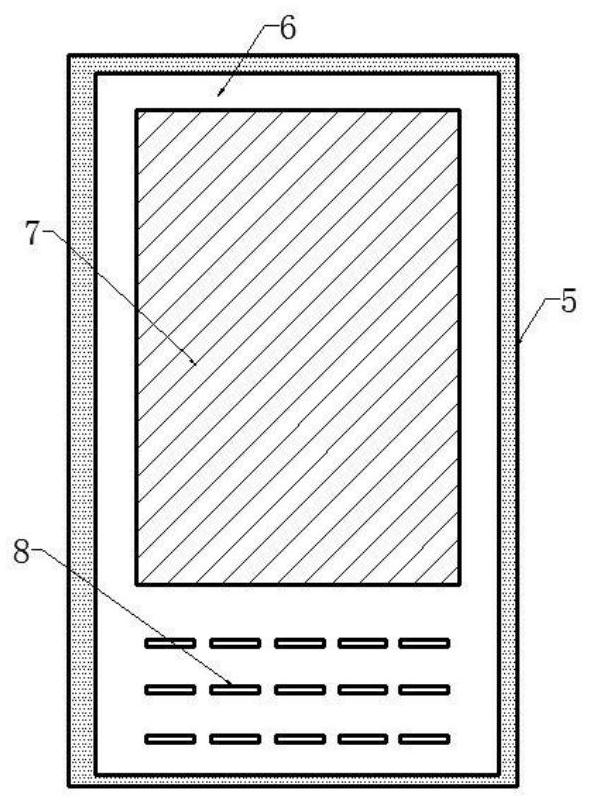

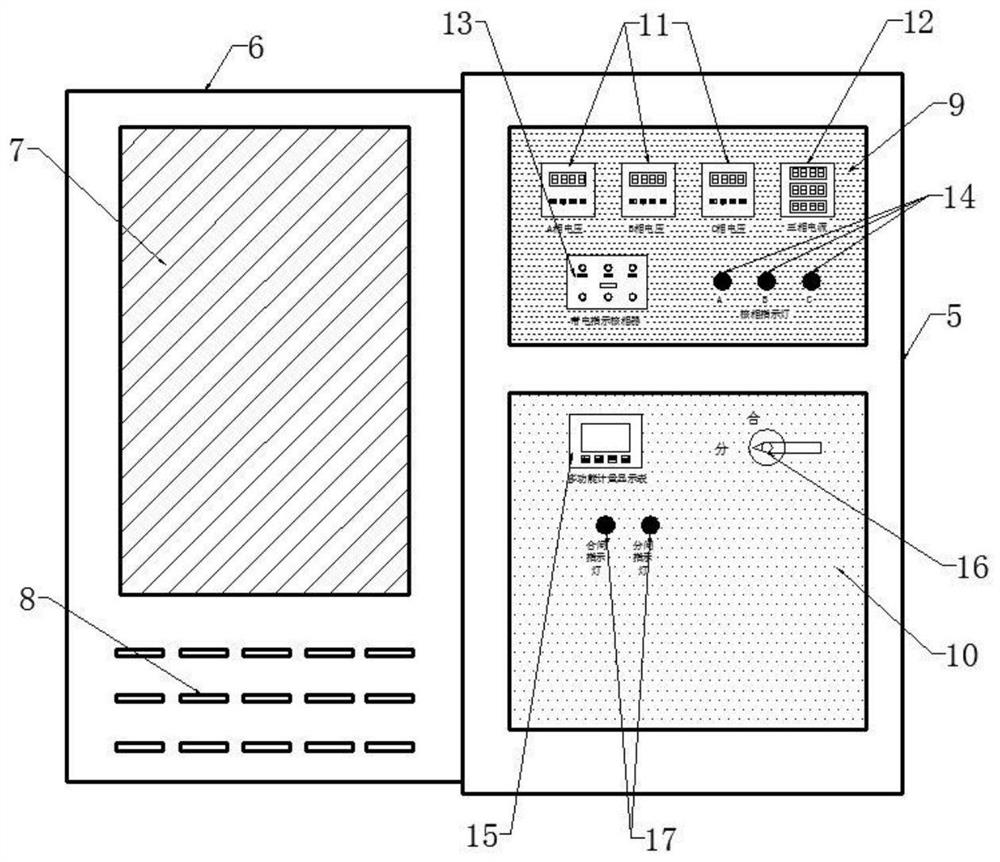

400V multifunctional bypass switch cabinet and using method thereof

PendingCN111835001AWith protectionEffective protectionBus-bar/wiring layoutsSelective ac load connection arrangementsPhase currentsVoltmeter

The invention discloses a 400V multifunctional bypass switch cabinet, which is characterized in that a voltmeter is installed on an upper panel, a voltage value can be read from the front of a mechanical instrument, a wiring terminal is arranged on the back of the mechanical instrument, and the mechanical instrument can measure the three-phase voltage conditions at the two ends of a load switch; athree-phase ampere meter is installed on the upper panel; a phasing tester is installed on the upper panel; a phasing indicator lamp is installed on the upper panel; a multifunctional metering display meter is installed on a lower panel; and real-time and historical power and electric quantity of a bypass can be checked on the front. According to the using method of the 400V multifunctional bypass switch cabinet, one end of a low-voltage flexible cable is inserted into a corresponding wire outlet end cable quick plugging interface of the device, and after the phase sequence is all correct, anoperator rotates a switch operating handle in the device from a switching-off position to a switching-on position. The 400V multifunctional bypass switch cabinet has the advantages that the operatoris isolated from an electrical loop, the personal safety is guaranteed, the bypass phase sequence is conveniently and quickly checked and adjusted, the triple phase sequence checking and protecting functions are achieved, and the operation efficiency and safety are improved.

Owner:YINGKOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

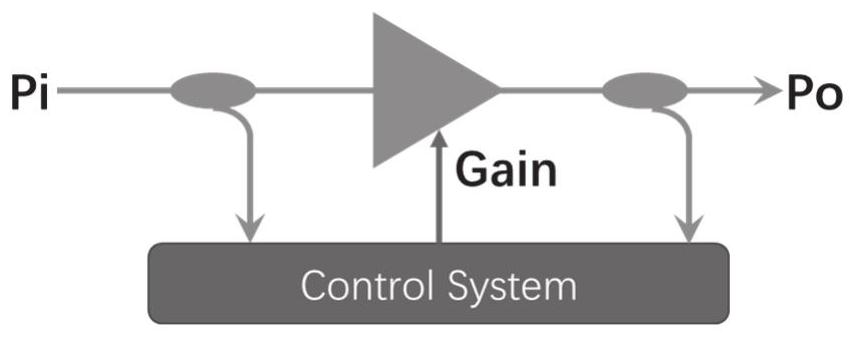

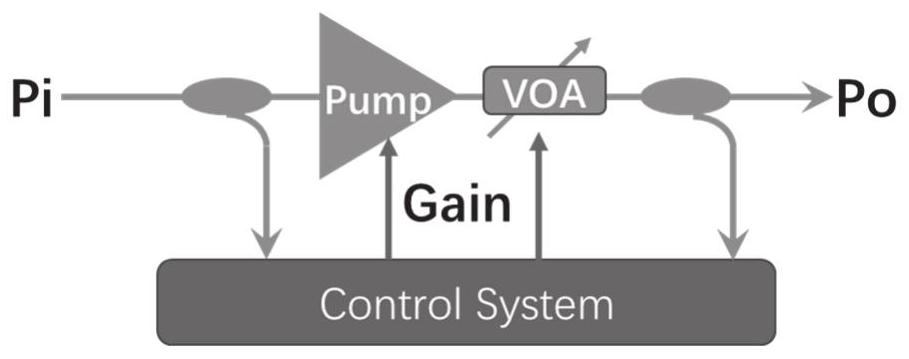

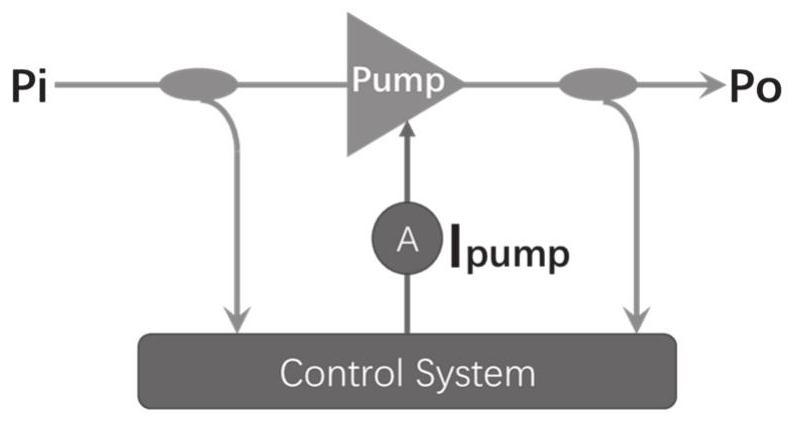

System, method and device for performing pulse energy control on optical fiber amplifier, processor and computer readable storage medium thereof

InactiveCN113794095AReduce job preparation timeImproved pulse stabilityElectromagnetic transmissionActive medium shape and constructionOptical couplerGain

The invention relates to a pulse energy control system for an optical fiber amplifier, and the system comprises an input optical coupler which is used for inputting an input optical pulse signal into the system for energy detection; an optical fiber amplification module which is used for performing signal amplification processing on the input optical pulse signal; an output optical coupler which is used for carrying out shunt processing on the amplified input optical pulse signal; an energy detection module which is used for detecting output pulse energy of the output optical pulse signal; and a control detection subsystem which is used for carrying out real-time adjustment of gain control according to the input detection and energy detection results of the optical fiber signals. The invention further relates to a corresponding method and device, a processor and a storage medium thereof. By adopting the system, the method, the device, the processor and the storage medium of the invention, the pulse output stabilization time is shortened to minutes, the process is not influenced by environmental changes, the work preparation time of the system is shortened by hundreds of times, and the pulse stability of the system is improved by dozens of times.

Owner:上海拜安实业有限公司

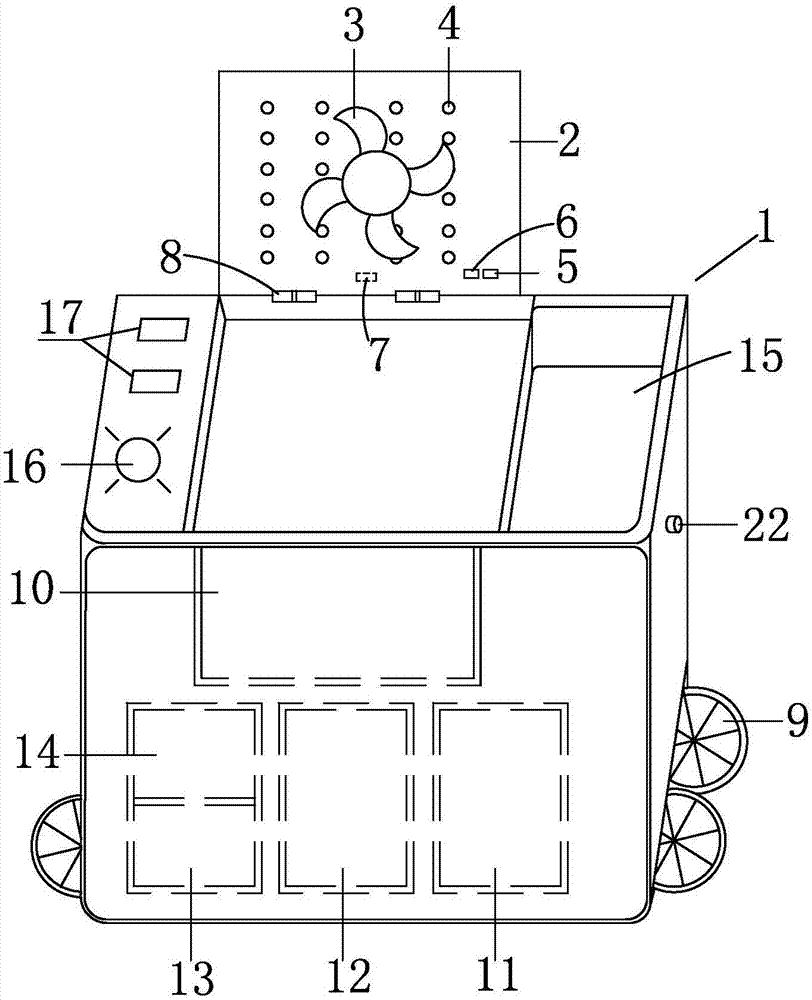

Multifunctional following optical cable welding workbench

PendingCN107255849AEasy to weldReduce the temperatureCoupling light guidesDisplay deviceElectric machinery

A multifunctional following optical cable welding workbench disclosed by the present invention comprises a box body, a workbench surface is arranged at the middle position of the upper top surface of the box body and is connected with an edge at the front side of the upper top surface of the box body via a damping hinge structure, and a fan is arranged on one surface of the workbench surface facing the inner side of the box body. The fan and the workbench surface are arranged parallelly, a temperature sensor and a temperature induction controller are also arranged at the positions close to the left front side of the fan of one surface of the workbench surface facing the inner side of the box body, and a temperature display is arranged on the workbench surface and is connected with the temperature sensor via a conducting wire. The temperature sensor is connected with the temperature induction controller via a conducting wire, the temperature induction controller is connected with a speed regulation joint of a fan motor via a conducting wire and is connected with a storage battery via a conducting wire, and a plurality of radiating holes are also arranged on the workbench surface. The multifunctional following optical cable welding workbench of the present invention enables the temperature of an optical fiber welding machine to be reduced, and the working efficiency of the optical cable welding to be improved.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

Vehicle-mounted door type detection operation system and method

PendingCN111006875ASolution volumeAddress usability issuesVehicle testingCommunications systemIn vehicle

The invention relates to a special automobile, in particular to a vehicle-mounted door type detection operation system and method. The system comprises a chassis vehicle, a carriage, a gate-type detection mechanical arm, a hydraulic system, a control system and a communication system, the control system is used for controlling automatic leveling supporting legs to be stably supported on the groundand operating the gate-type detection mechanical arm to be unfolded in sequence, and the gate-type detection mechanical arm is provided with a detection instrument. Compared with the prior art, a folding arm type telescopic mechanism is adopted, integration is sound, and mechanism unfolding is convenient; the intelligent control system is adopted, one-key leveling of the vehicle and automatic operation of the mechanism are achieved, operation preparation time is shortened, and the vehicle safety performance is improved; and one-key operation intelligent control is adopted, rapid detection ofdifferent vehicle types is achieved, and the applicability problem of the detection mechanism is solved.

Owner:LONGYAN HAIDEXIN AUTOMOBILE

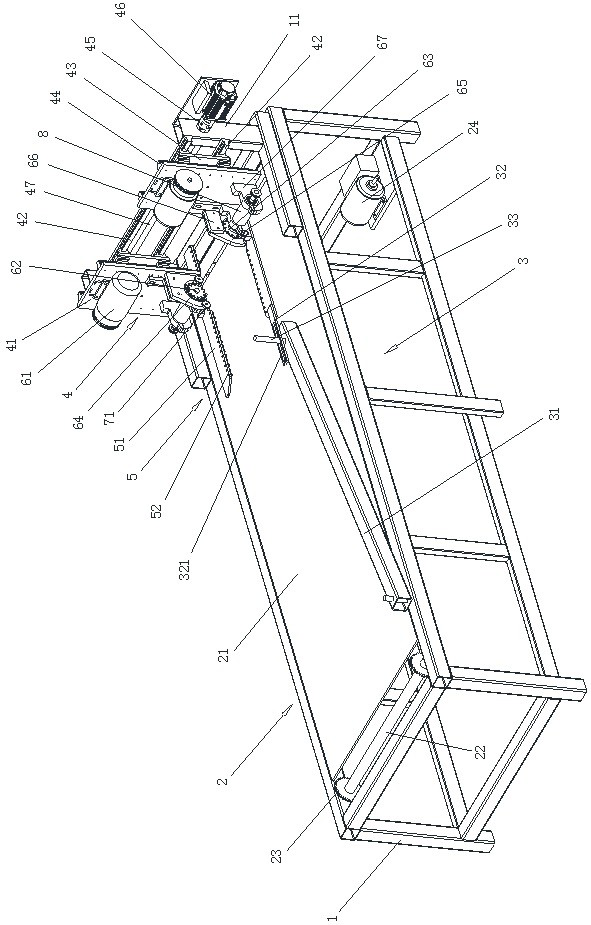

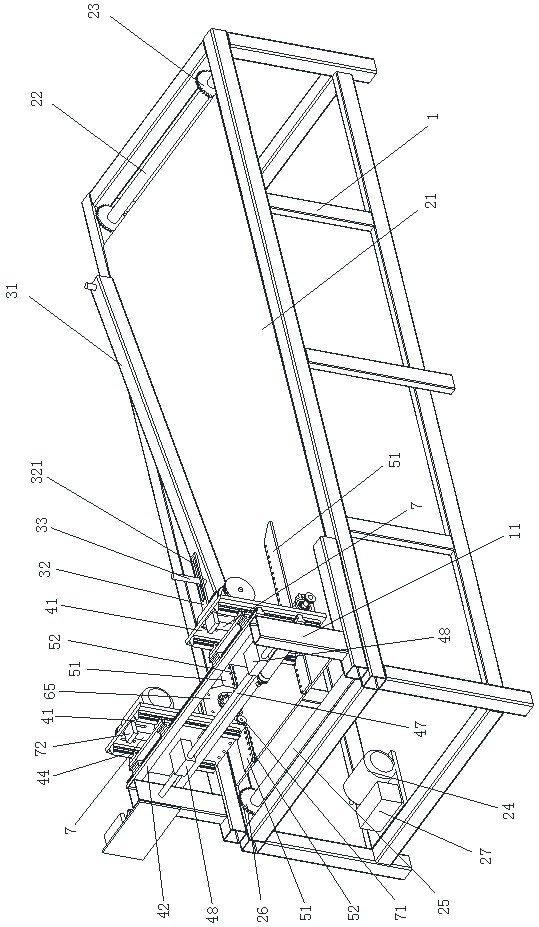

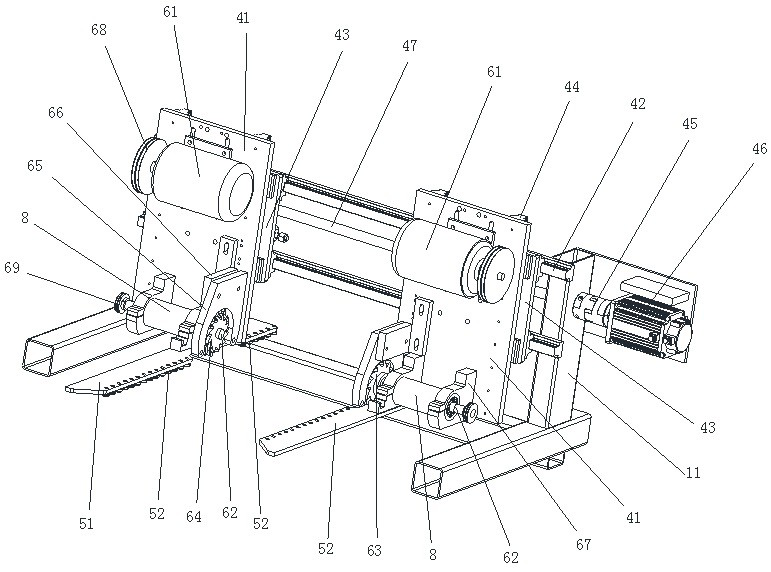

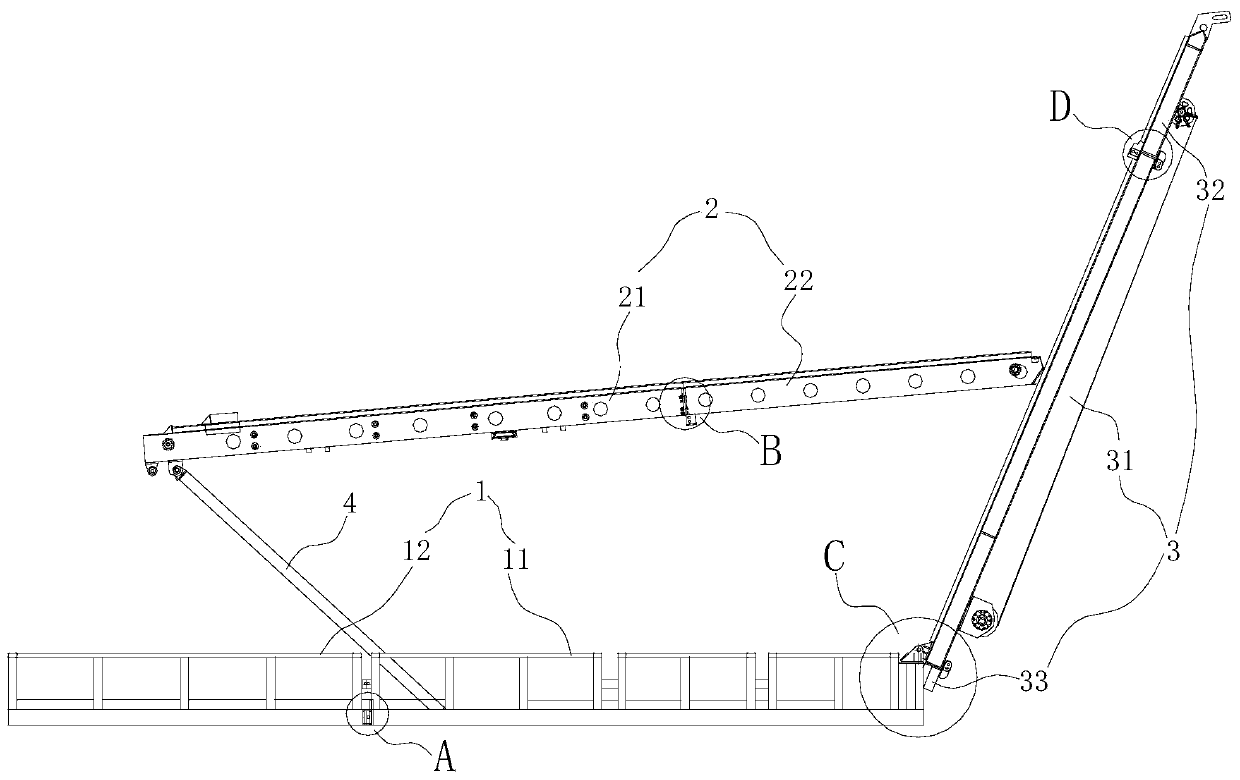

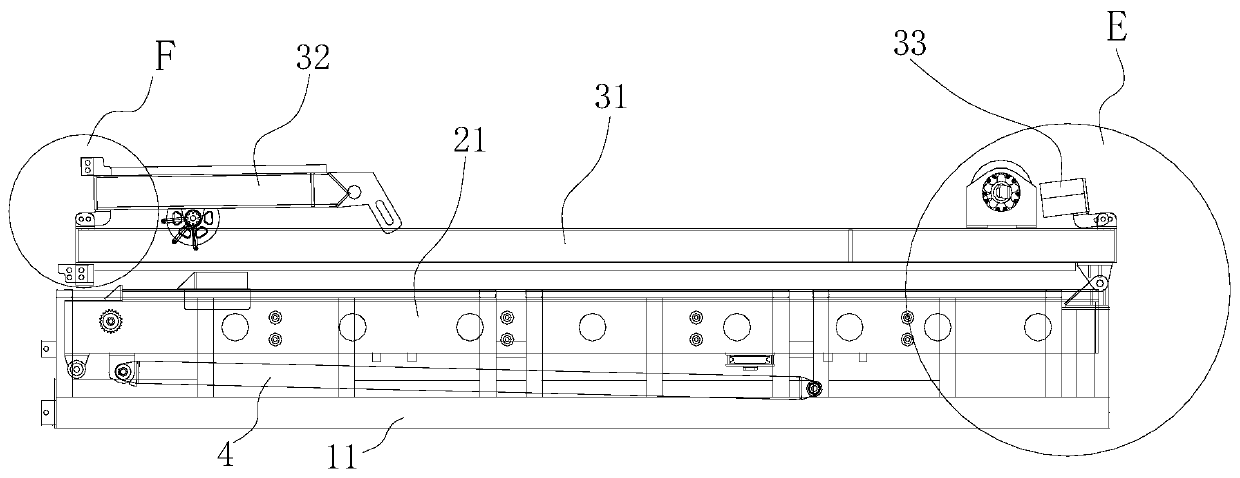

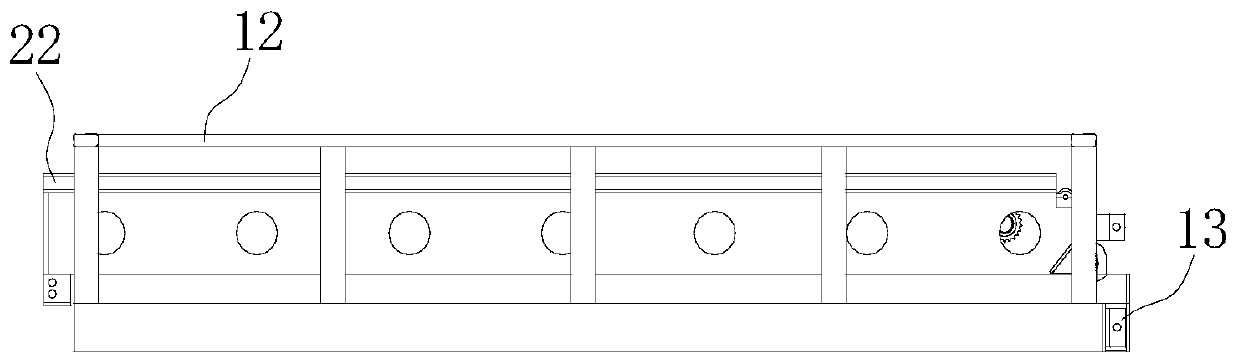

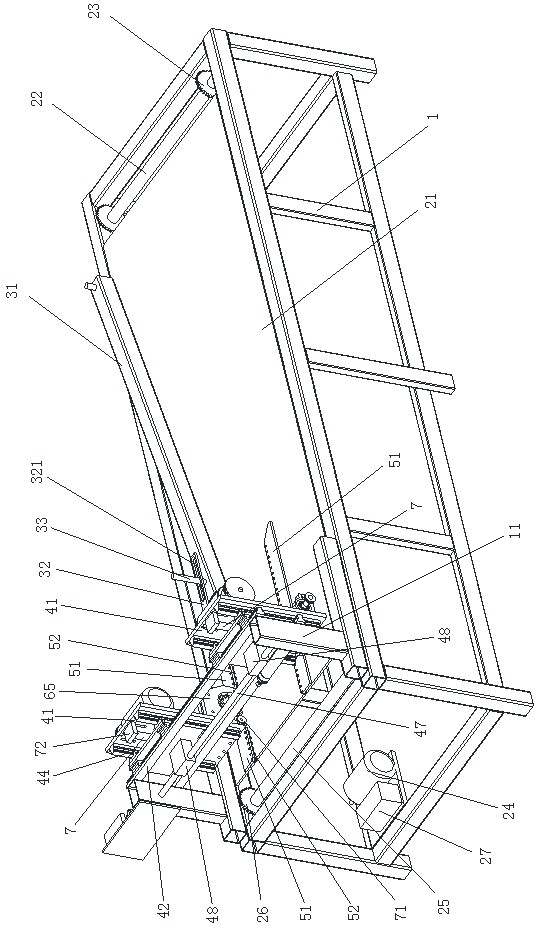

Catwalk machine

PendingCN110306942ARealize the breakAchieve/or foldDrilling rodsDrilling casingsWorkloadMechanical engineering

The invention provides a catwalk machine and relates to the technical field of tubular column lifting and / or conveying equipment. Mainly the technical problems that a catwalk machine in the prior artis too long in self length and inconvenient to transport are solved. The catwalk machine comprises a foundation base, a bearing platform and a rampway; and the foundation base, the bearing platform and the rampway each comprise at least two segments of split structures; the split structures in the foundation base, the bearing platform and / or the rampway are detachably connected and / or movably connected, so that the foundation base, the bearing platform or the rampway can be broken and / or overturned and folded. According to the catwalk machine, the foundation base, the bearing platform and therampway large in length value in the catwalk machine are broken and / or overturned and folded, so that the catwalk machine is diverse in transporting manner, and then transporting on a narrower road and / or field domain is achieved. Only parts large in length are dismantled, other parts are not needed to be disassembled, and therefore the assembling workload can be greatly relieved, and the operation preparing time is shortened.

Owner:山东泽元石油机械有限公司

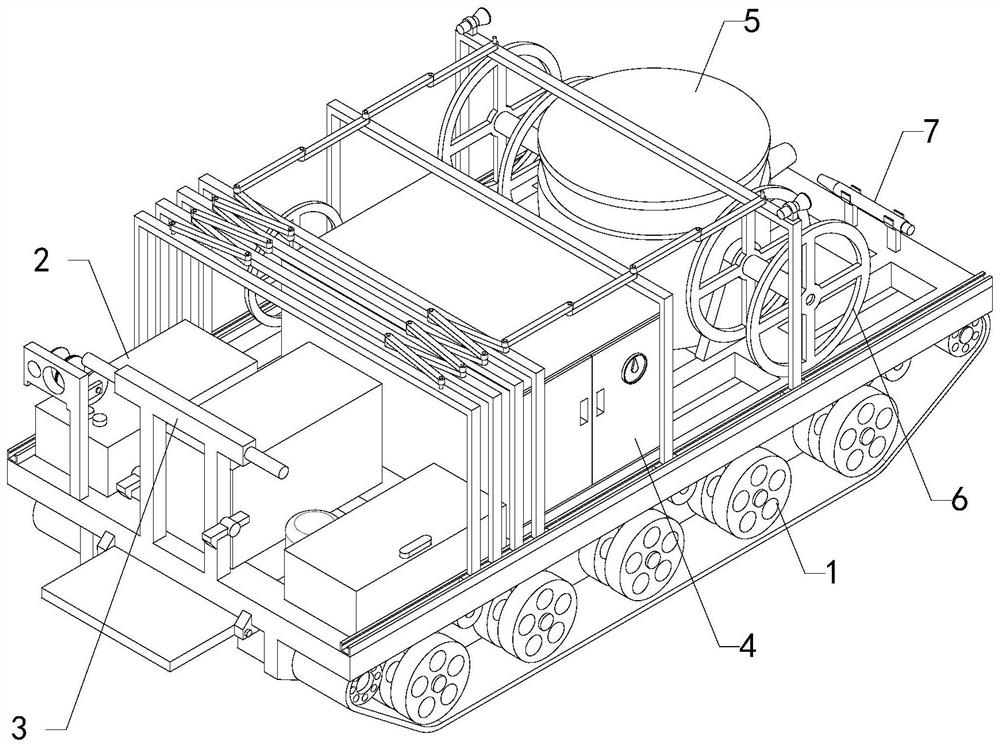

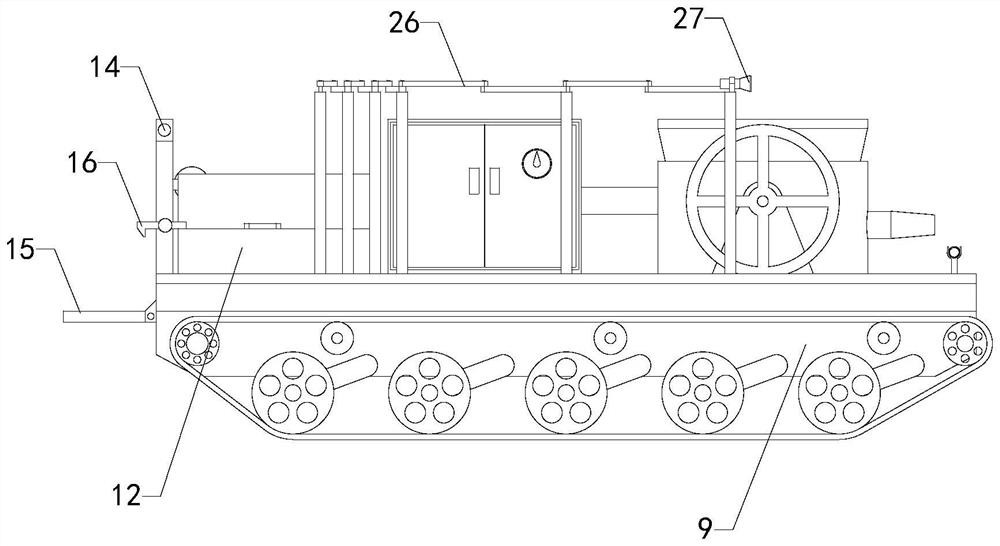

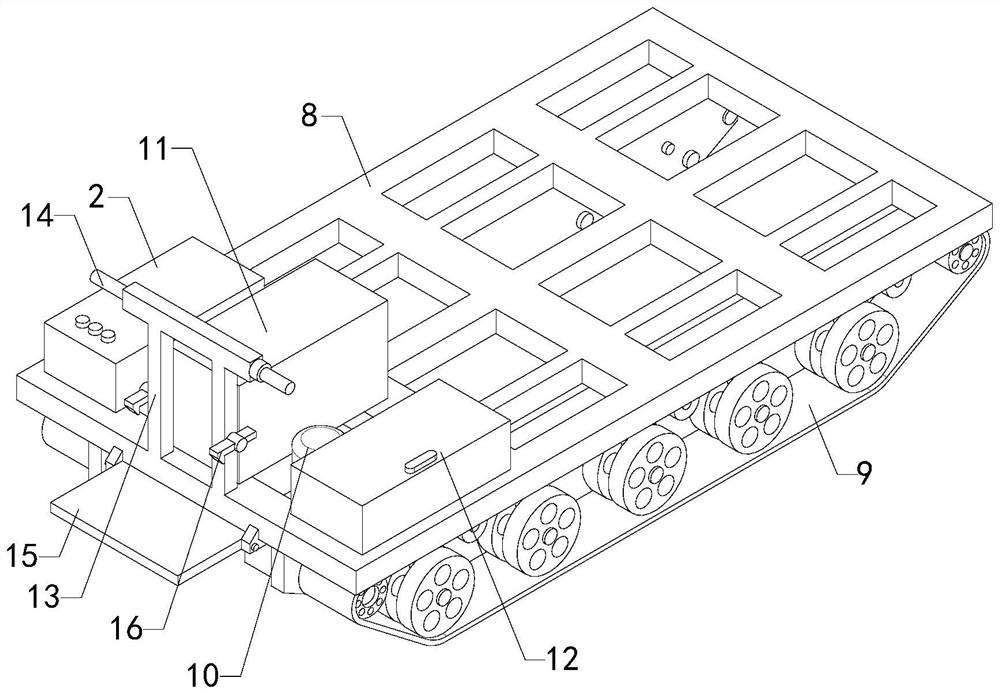

Mining concrete spraying vehicle

PendingCN114382511AReduce sizeSmall size, passing capacityUnderground chambersTunnel liningAir compressorElectric cables

The invention relates to the technical field of concrete spraying, in particular to a mining concrete spraying vehicle which can flexibly operate in a new mine tunnel, and the working efficiency is improved. Comprising a crawler chassis, a control box, a console, an air compressor, an injection machine, a plurality of retractors and a spray gun, the control box and the console are mounted at the rear end of the crawler chassis, the air compressor is mounted on the right of the middle of the crawler chassis, the injection machine is mounted in the middle of the front of the crawler chassis, and the retractors are mounted on the crawler chassis respectively. The multiple winding devices are located on the left side of the air compressor and the left side and the right side of the injection machine correspondingly, a cable is wound on the winding device located on the left side of the air compressor, a concrete input pipe is wound on the winding device located on the left side of the injection machine, a concrete injection pipe is wound on the winding device located on the right side of the injection machine, and the air compressor is connected with the injection machine through a high-pressure air pipe. The concrete spraying pipe is connected with an output port of the spraying machine and the input end of the spraying gun.

Owner:HUBEI TITN HEAVY MACHINERY CO LTD

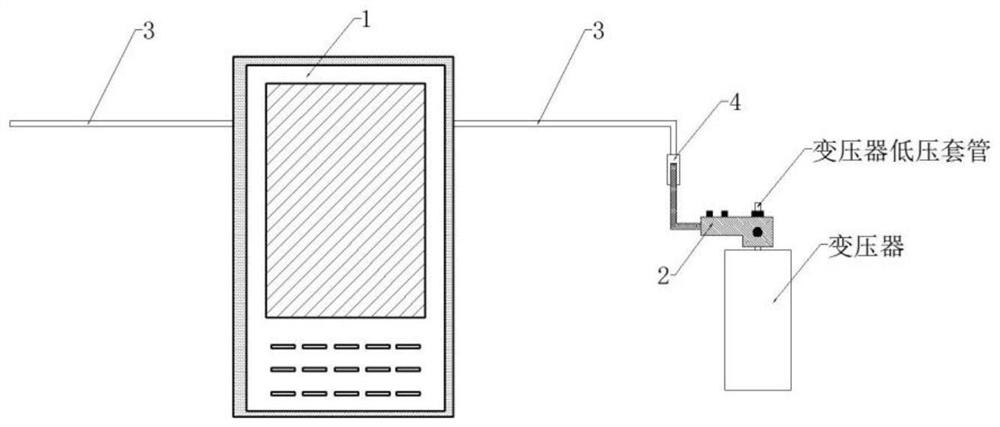

400-volt bypass switch, nuclear phase current and voltage monitoring device and using method

PendingCN111864559AWith automatic phase verification functionInhibit sheddingBus-bar/wiring layoutsBoards/switchyards circuit arrangementsPhase currentsVoltmeter

The invention discloses a 400-volt bypass switch and a nuclear phase current and voltage monitoring device. The device comprises a multifunctional bypass switch cabinet which is composed of a cabinetbody structure of an iron plate piece, connectors of a low-voltage flexible cable which are installed and fixed at the two ends of the low-voltage flexible cable and can be quickly connected to cylinders such as screws in a pluggable mode, and a voltmeter, a three-phase ammeter and a phasing tester which are arranged on an upper panel. The invention discloses the 400-volt bypass switch and a usingmethod of the nuclear phase current and voltage monitoring device, the other ends of four low-voltage flexible cables on an incoming line side are inserted into corresponding incoming line end cablequick plugging interfaces on the multifunctional bypass switch cabinet in the complete device; after the bypass normally operates, whether the bypass can depend on shunting of the line to be overhauled or not is judged through the reading of the three-phase ammeter in the multifunctional bypass switch cabinet in the complete device. The method has the advantages that the personal safety is guaranteed, the bypass phase sequence can be conveniently and quickly checked and adjusted, and the operation efficiency and safety are improved.

Owner:YINGKOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

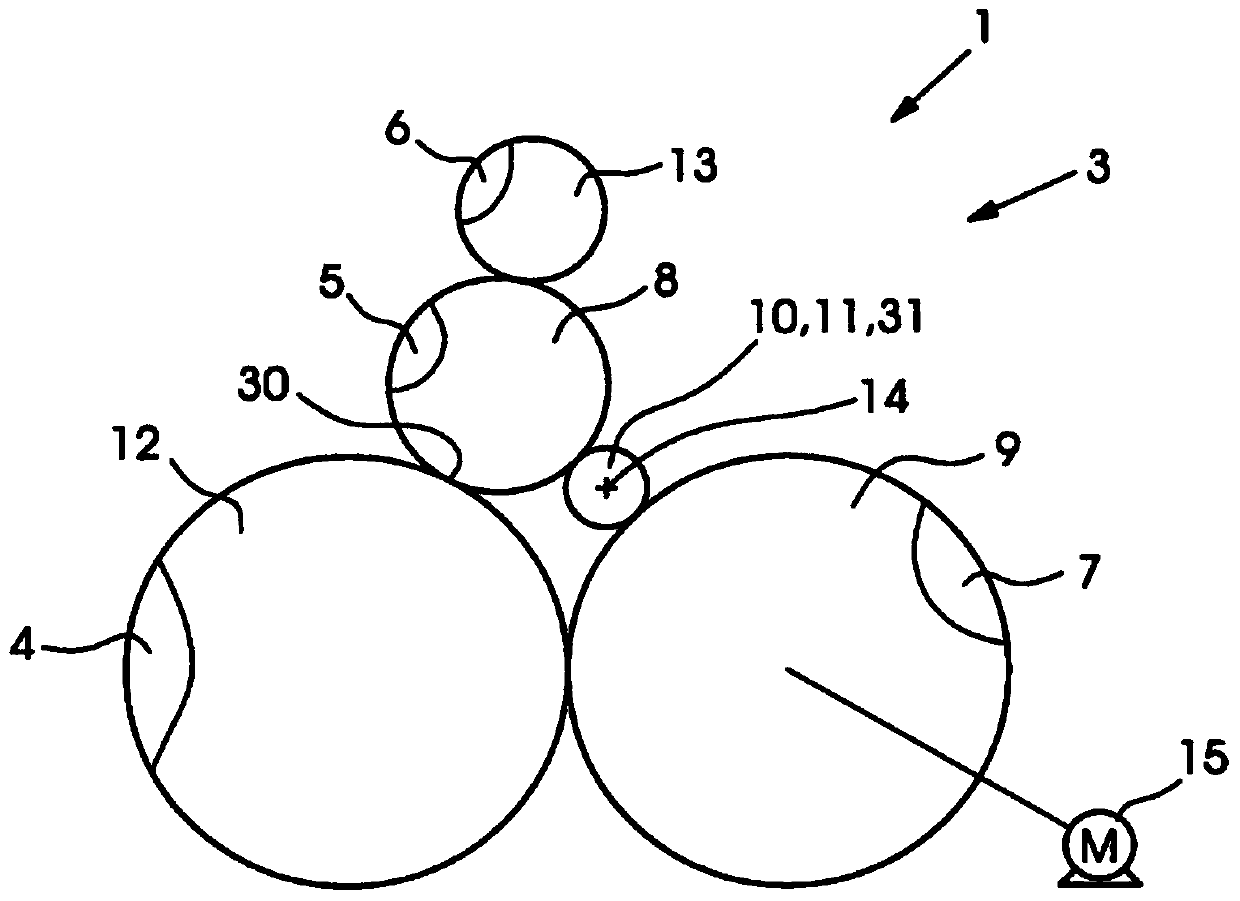

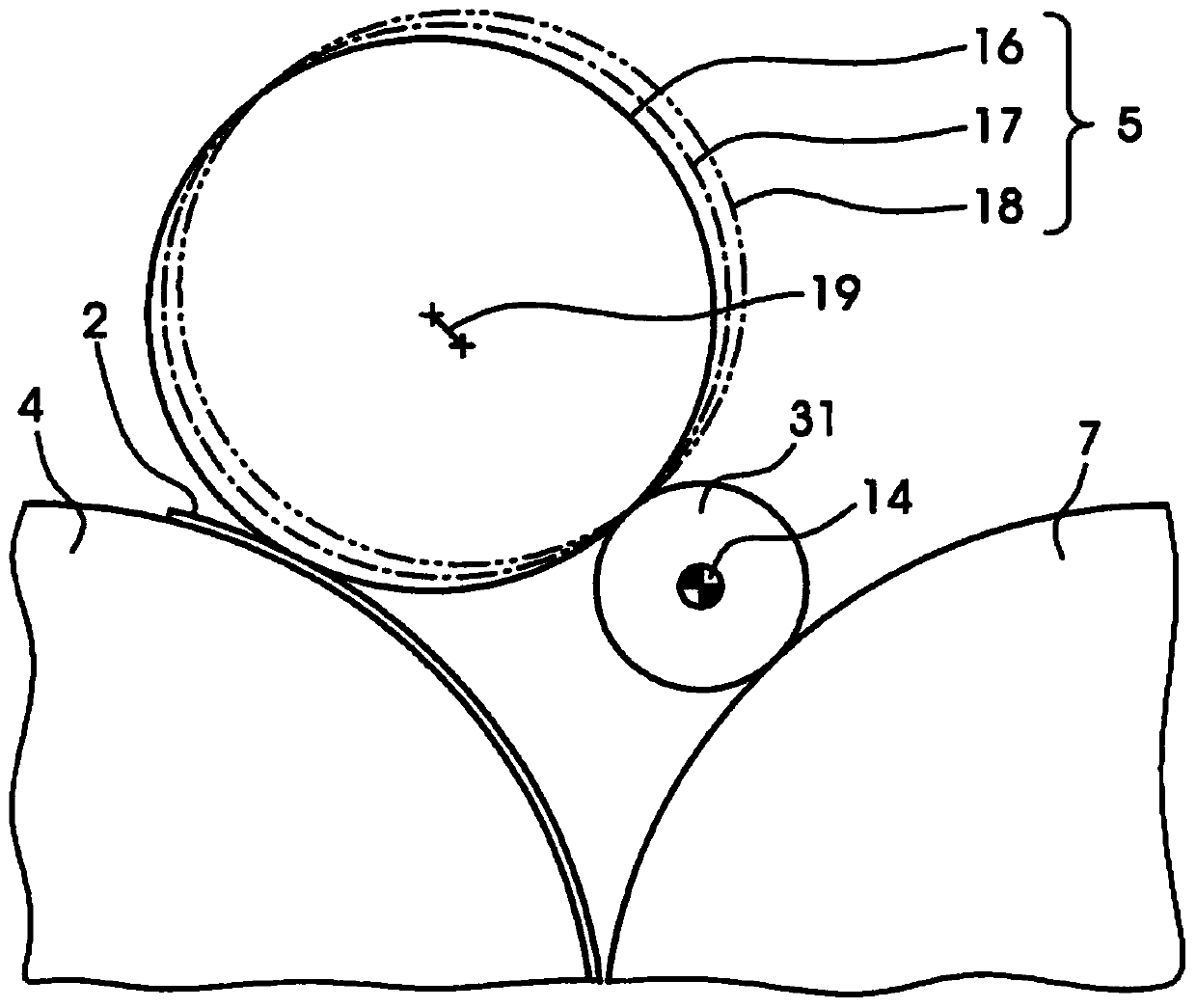

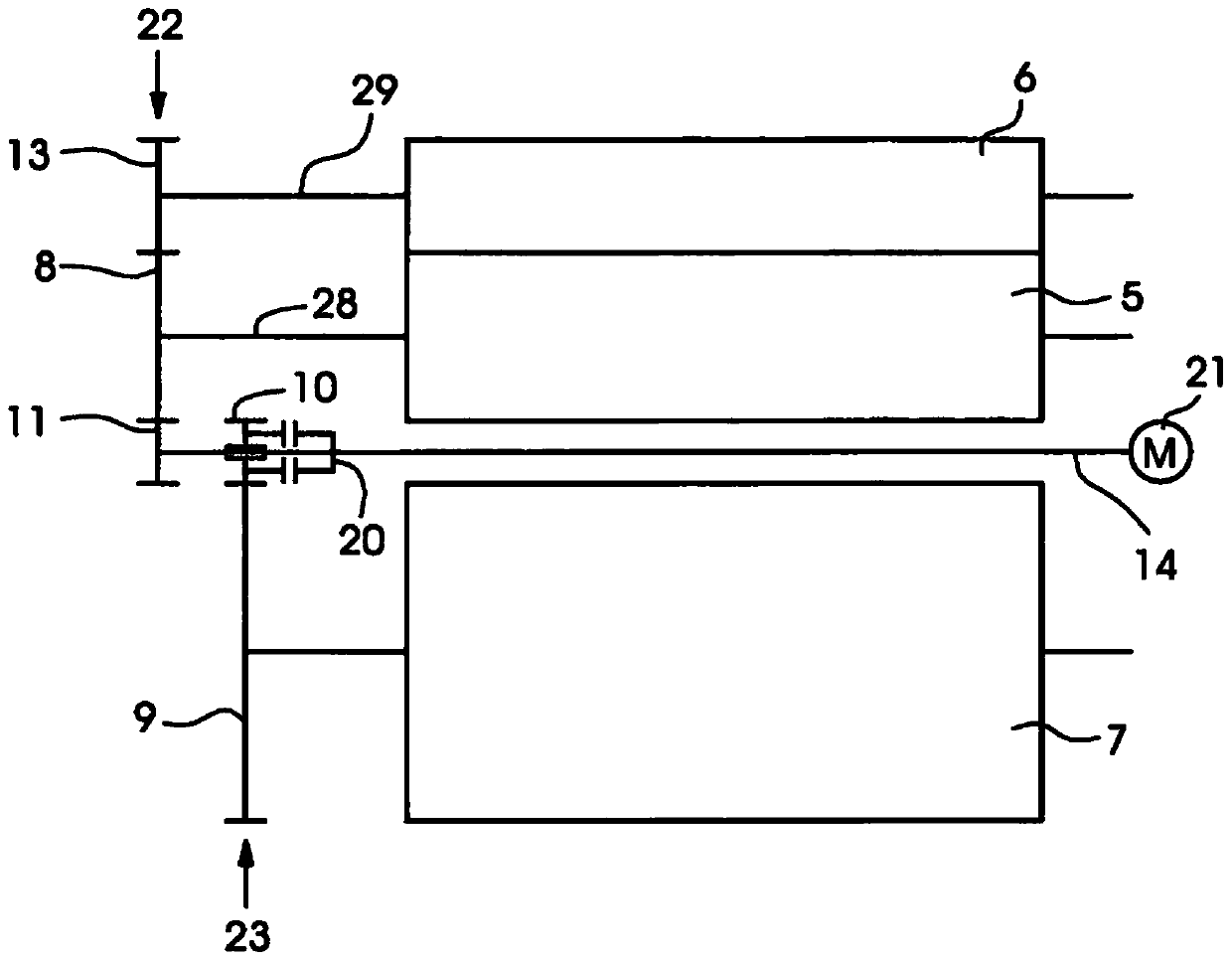

printing press

The invention relates to a printing machine comprising a first cylinder (5) with a first gear (8), a second cylinder (7) with a second gear (9) and a third cylinder (4), the third The cylinder together with the first cylinder (5) forms the impression nip and receives the sheet (2) from the second cylinder (7), wherein there is an intermediate shaft (14) with a gear arrangement (31), the first gear (8) and the second gear (9) are permanently connected to each other by a gear structure (31). Preferably, the first cylinder (5) is an application cylinder (5), the second cylinder (7) is a sheet transfer drum (7) and the third cylinder (4) is an impression cylinder (4).

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Multifunctional optical fiber converter

PendingCN114827759AReduce job preparation timeImprove reliabilityMultiplex system selection arrangementsFibre transmissionPhysicsConverters

The invention relates to a multifunctional optical fiber converter which comprises a shell. The coupler is arranged in the shell; the conversion joint is arranged on the shell; the adapter is electrically connected with the coupler; the conversion joint comprises six ST interface jacks arranged on the side surface of the shell; the six ST interface jacks are respectively a first ST interface jack, a second ST interface jack, a third ST interface jack, a fourth ST interface jack, a fifth ST interface jack and a sixth ST interface jack; the adapter further comprises six jacks arranged on the front surface of the shell, wherein two jacks are round FC jacks with threads, two clamping type square SC jacks and two clamping type small square LC jacks; the multi-purpose optical fiber converter has the beneficial effects that the multi-purpose optical fiber converter is suitable for searching GOOSESV (Generic Object Oriented SESV) broken link defects in an intelligent substation, verifying a protection device, verifying and checking an intelligent terminal and a merging unit and applying to other intelligent equipment.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

An aluminum alloy formwork automatic edge milling machine

ActiveCN112091295BClose contactEliminate tolerance build-upMilling machinesMilling equipment detailsDrive shaftStructural engineering

The invention discloses an automatic edge milling machine for an aluminum alloy template, which includes a frame, a feeding device, an introduction mechanism, a length-adjusting mechanism, a guiding and positioning mechanism, a pre-tightening mechanism, an edge milling mechanism and an electric control system. The feeding device is arranged on the machine. The upper part of the frame includes a support plate, a feeding belt, a driving shaft, a driven shaft and a driving mechanism. The driving shaft and the driven shaft are relatively arranged on the frame and connected by a feeding belt. The length-adjusting and distance-adjusting mechanism includes two adjustable workbenches, which are adjustable and fixedly connected with the frame, and the rear sides of the adjustable workbenches are equipped with pre-tightening mechanisms. The guide positioning mechanism includes two guide plates symmetrically arranged, and two sets of side guide wheels are respectively arranged on opposite sides of the two guide plates. There are two edge milling mechanisms, which are symmetrically arranged on two adjustable workbenches. The invention realizes automatic continuous feeding, automatic guiding and alignment, one-time multi-edge cutting, high cutting speed, high processing precision, low production cost and high production efficiency.

Owner:YANTAI ZHONGCHENG NEW BUILDING

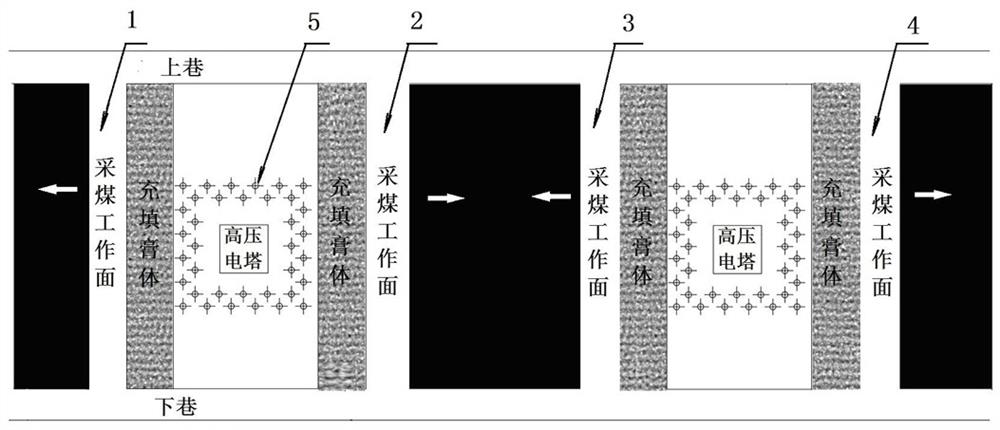

Coal mining method under high-voltage transmission line

ActiveCN112664193ASmall amount of permanent coal pressureReduce coal pressureMining devicesSolid waste managementMining engineeringCement paste

The invention discloses a coal mining method under a high-voltage power transmission line. According to the coal mining method, two or more line spans are taken as a working section, alternate operation is conducted in a mode that one working section is mined and one working section is filled, and the coal mining method comprises the specific steps that 1, primary grouting holes are drilled around a high-voltage electric tower, and cement paste is poured; 2, coal mining upper and lower roadways and forward and reverse driving working faces are excavated in a coal seam under the line; 3, mining and filling operation is carried out on the forward and reverse tunneling working faces in turn, paste filling is carried out once every 2.5-3 m of tunneling, and protection coal pillars of 5 m or above are reserved between the forward and reverse working faces located within the same line span; 4, paste is used for sealing and filling upper and lower roadways and the tunneling working face in a mining completed section; 5, secondary grouting holes are drilled, clay or mortar is poured, and a gap between the coal seam roof and the filling paste is filled; and 6, the step 1-5 is repeated, and the work of the next section is carried out. According to the coal mining method under the high-voltage power transmission line, safe coal mining under the high-voltage power transmission line is realized, and more precious resources can be replaced.

Owner:BEIJING TIANDI HUATAI MINING MANAGEMENT CO LTD +1

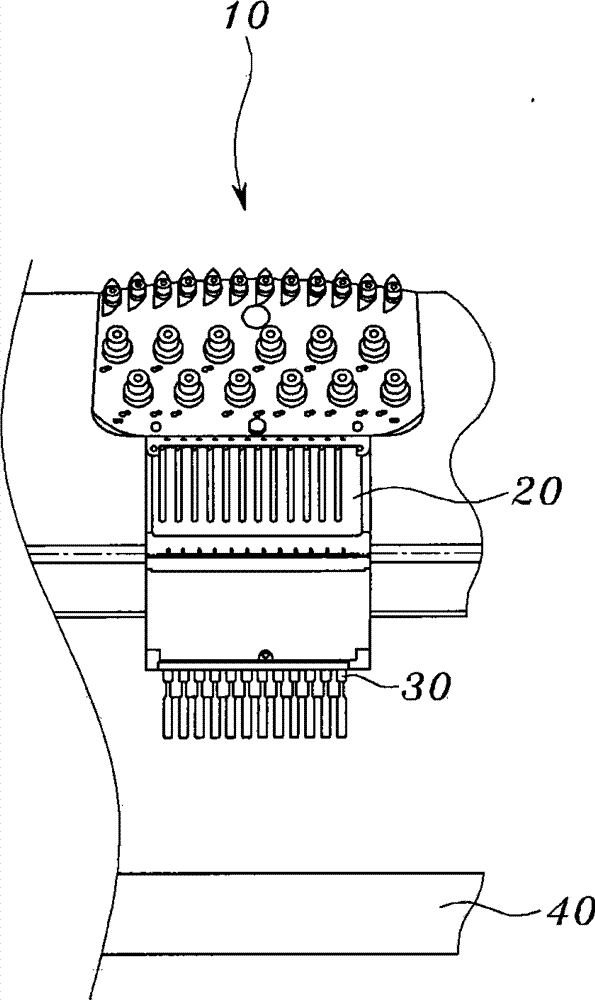

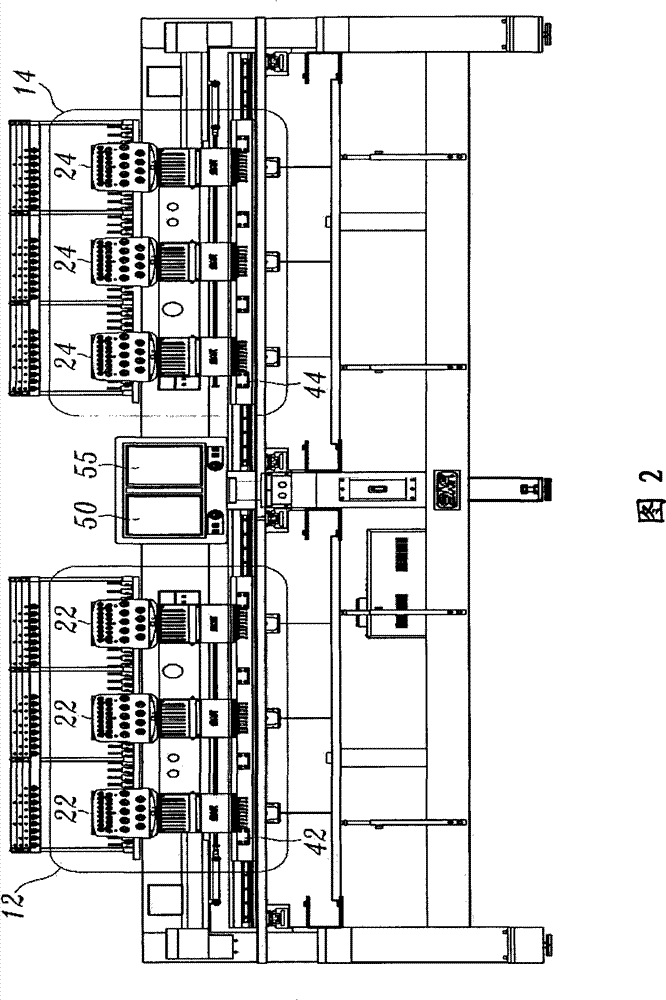

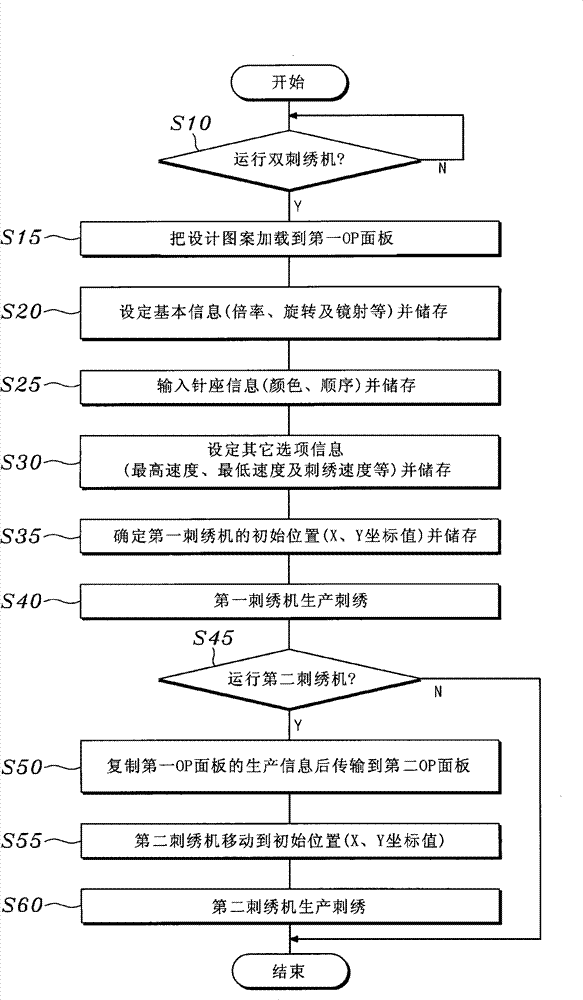

Double embroidery machine same operation device and method thereof

InactiveCN101289788BImprove work convenienceReduce job preparation timeProgramme-controlled sewing machinesData switching by path configurationSynchronous controlControl signal

The invention relates to a same operation running device of a two-embroidery machine and a method thereof suitable for the two-embroidery machine comprising a first embroidery machine, a second embroidery machine and a control unit; the device comprises a control unit for connecting the first embroidery machine and the second embroidery machine and controlling in real-time synchronous state as the input of the same operation key control signal; a first embroidery machine for joining into the control unit and embroidering according to the design pattern after deciding the initial position according to the real-time synchronous control signal; and a second embroidery machine for joining into the control unit and embroidering according to the design pattern after deciding the initial position according to the real-time synchronous control signal. Using the two-embroidery machine to produce the embroidery with the same design pattern is able to check whether each embroidery machine normally runs at initial stage, thereby shortening the operation preparing time and improving productbility.

Owner:SUSR PRECISION CO LTD

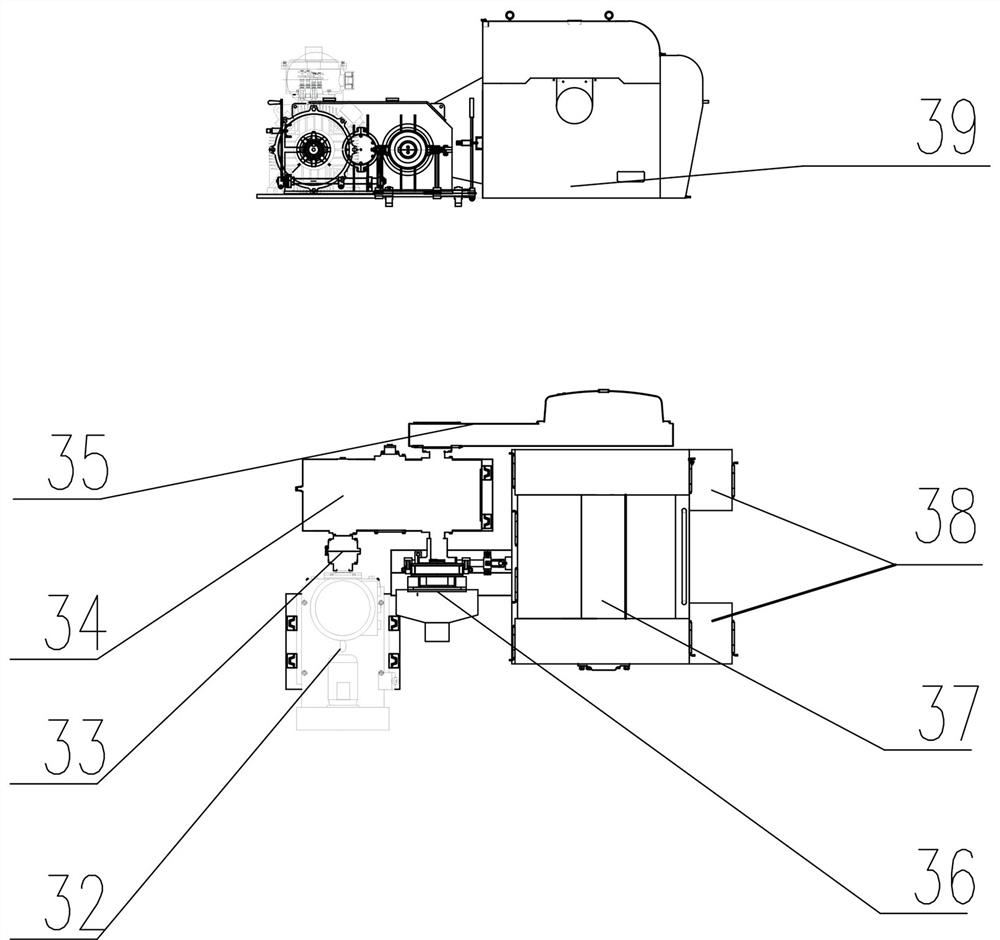

Hydraulic swabbing machine

PendingCN110578499AImprove safety and reliability performanceControl up and down travelDrilling rodsDerricks/mastsTechnology developmentControl engineering

The invention relates to a hydraulic swabbing machine. The hydraulic swabbing machine comprises a swabbing module, a power module for providing power to the swabbing module, a control module for controlling the swabbing module and the power module to act, a support leg module for supporting the swabbing module, the power module and the control module, and an unit structure module. The hydraulic swabbing machine has the following beneficial effects: through up-down lifting movement of a hydraulic oil cylinder, the automatic swabbing operation is realized, and a traditional working mode of swabbing equipment separated from a derrick is replaced. The swabbing machine has no need to be additionally provided with the derrick, can automatically perform continuous swabbing operation, can precisely control up-down travel and speed of a sucker rod, accurately simulates actual oil extraction operation, greatly saves human resources, material resources, financial resources and time, and meanwhile, can be cooperated with a traditional oil field workover rig; the swabbing machine adopts electric and hydraulic transmission and control; and the transmission and control modes comply with the present mainstream equipment and technology development tendency, and meet increasingly strict environmental protection requirements.

Owner:青岛北海俊惠电子仪表有限公司

A Method for Establishing Layout Design Rule Detection File Verification Graphics Library

ActiveCN103310037BReduce job preparation timeImprove work efficiencySpecial data processing applicationsGraphicsComputer architecture

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com