Laser welding device of solar flat plate collector

A solar panel and laser welding technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unstable welding quality, poor heat transfer of solar panel collectors, and difficult welding, so as to reduce work Preparation time, improved heat transfer effect, effect of improved welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

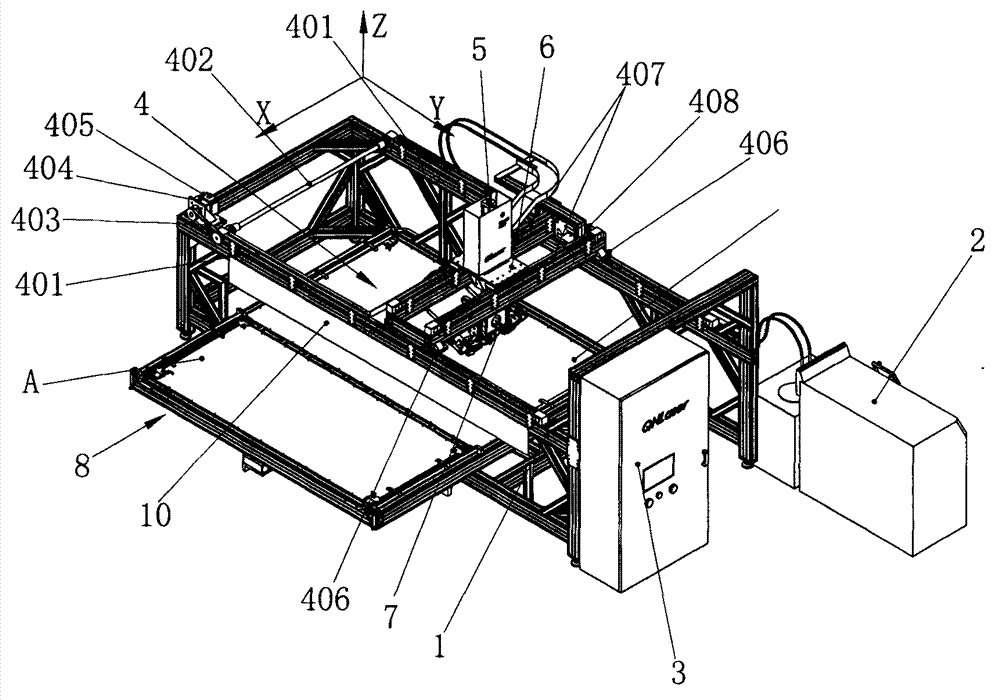

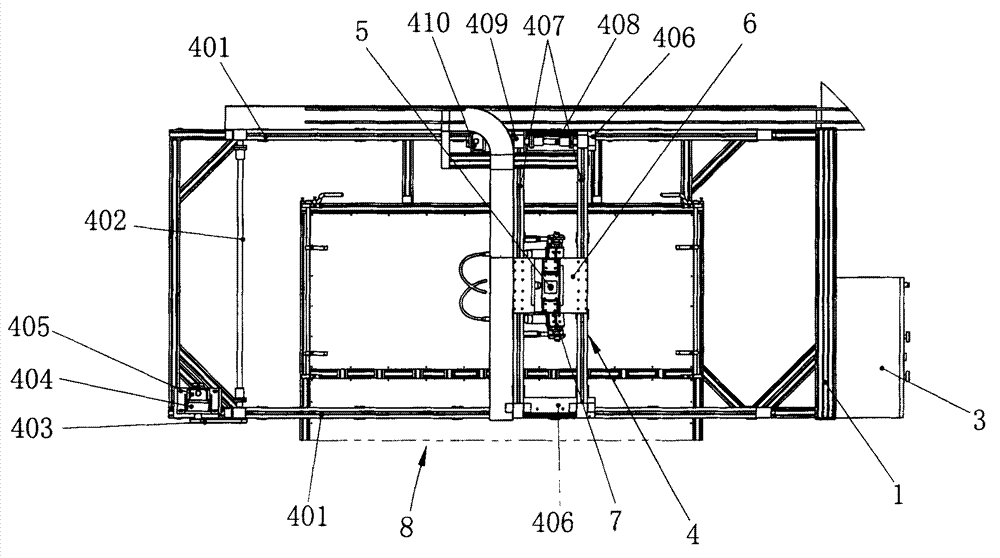

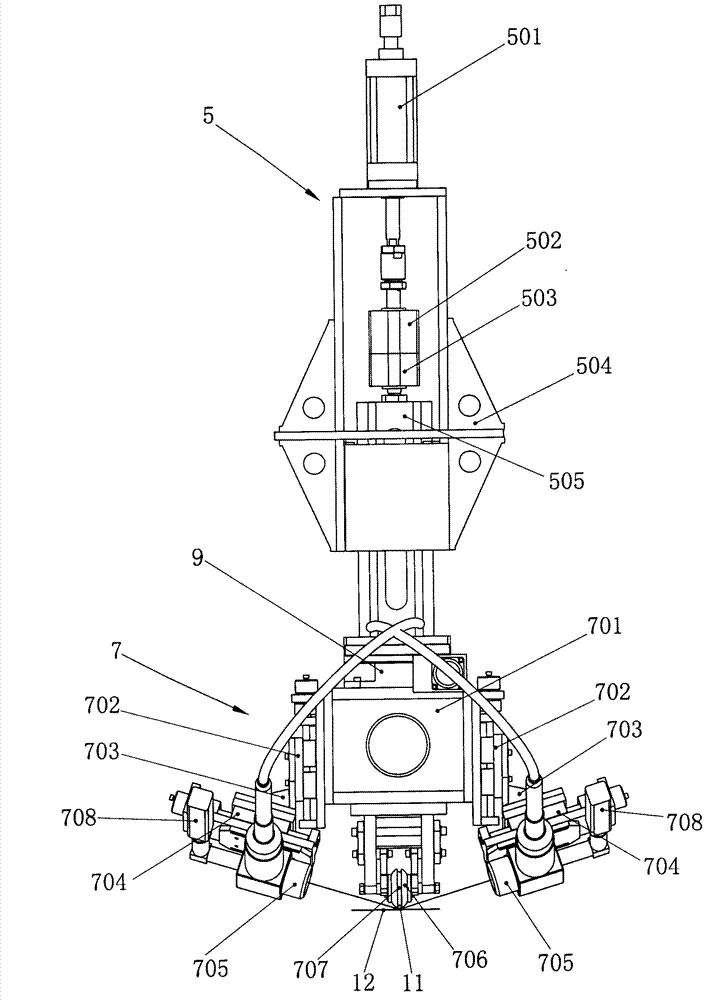

[0030] like figure 1 , 2 As shown, the present invention includes a frame 1, a solid-state pulse laser system 2 and a control system 3, the XY axis servo drive mechanism 4 is installed on the frame 1, and the main body of the frame 1 is made of standard aluminum alloy profiles, corner reinforcing members, etc. , High-strength bolts and washers are used to connect and fasten, and the plane on the upper part of the frame 1 is the reference plane for installing the XY-axis servo drive mechanism 4 . The Z-axis lifting mechanism 5 and the laser welding head 7 are mounted on the XY-axis servo drive mechanism 4 through the carriage 6 , a rotary table 8 is arranged under the laser welding head 7 , and a radiation isolation wall 10 is arranged on the frame 1 . The partition wall 10 is used to shield the laser radiation during welding and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com