Automatic edge milling machine for aluminum alloy formwork

A technology of aluminum alloy formwork and edge milling machine, which is applied in the direction of milling machines, milling machine equipment, milling machine equipment details, etc., can solve the problems of difficulty in meeting large-scale, industrial production requirements, unsightly cutting surfaces, and high labor costs, and achieve the elimination of tolerances Accumulation phenomenon, improvement of processing quality, effect of high milling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

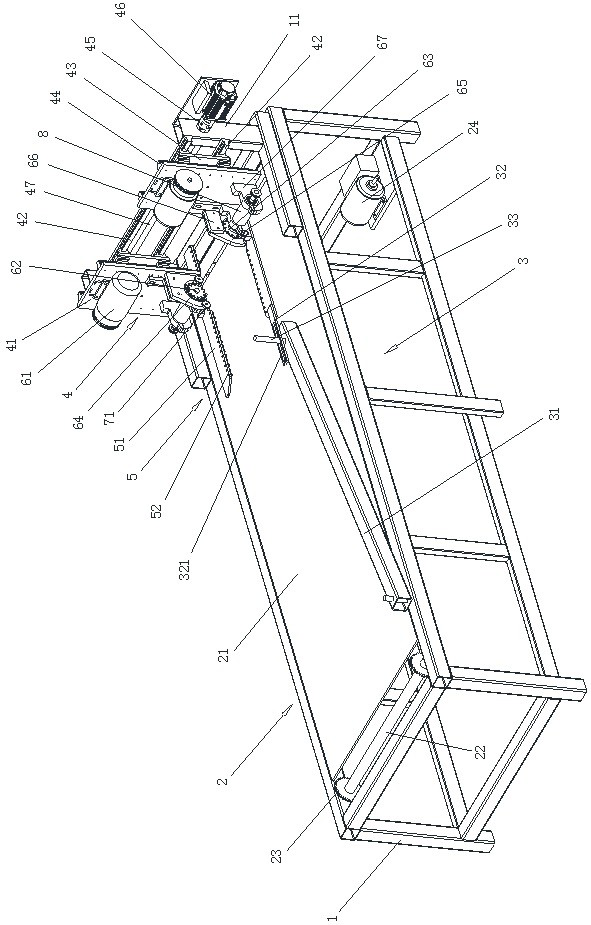

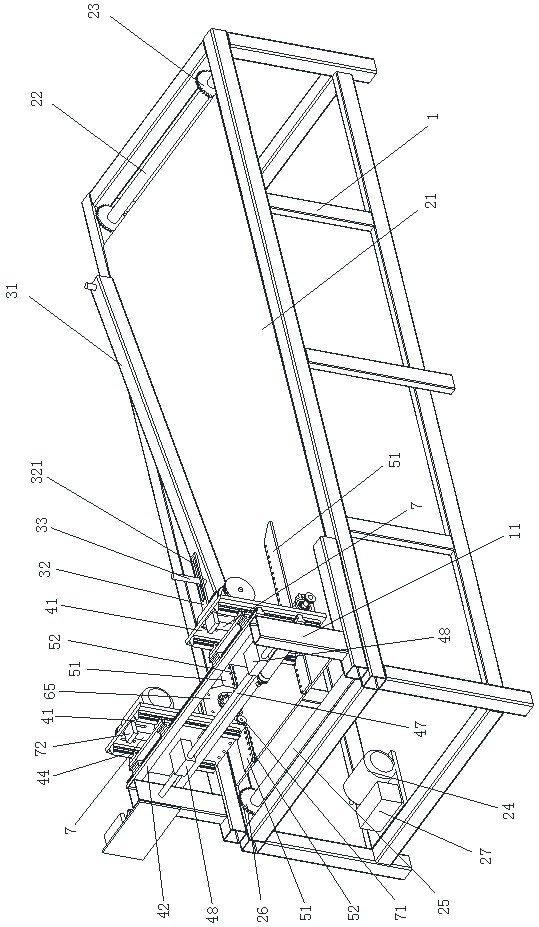

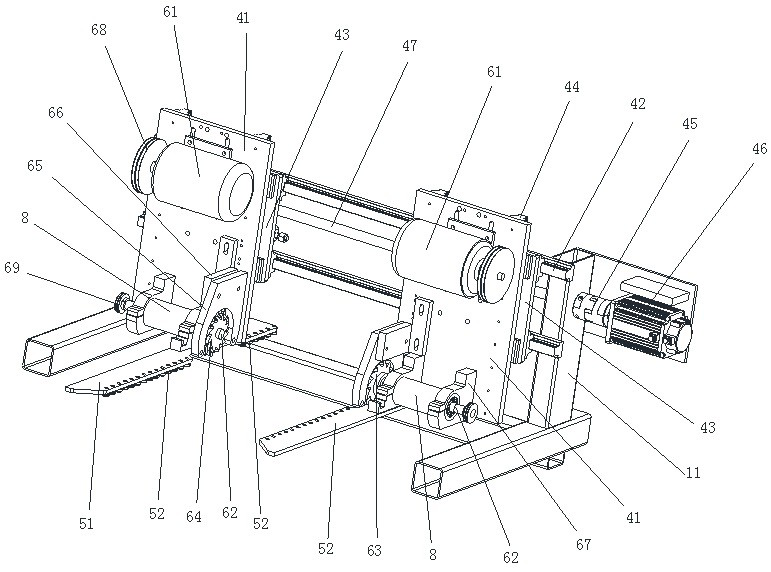

[0033] combine Figure 1 to Figure 4 , an aluminum alloy formwork automatic edge milling machine, including a frame 1, a feeding device 2, an introduction mechanism 3, a length-adjusting mechanism 4, a guide positioning mechanism 5, a pre-tightening mechanism, an edge milling mechanism and an electric control system, the frame 1 is a steel frame structure, and the feeding device 2 is installed on the top of the frame 1. The feeding device 2 comprises a supporting plate 21, a feeding belt, a driving shaft 25, a driven shaft 22 and a driving mechanism, the driving shaft 25 and the driven shaft 22 are relatively arranged on the frame 1, and are connected by a feeding belt, and the supporting plate 21 It is horizontally arranged on the frame 1 and is positioned at the inner side of the feeding belt. The function of the support plate 21 is to support the upper part of the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com