Patents

Literature

51results about How to "Milling speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

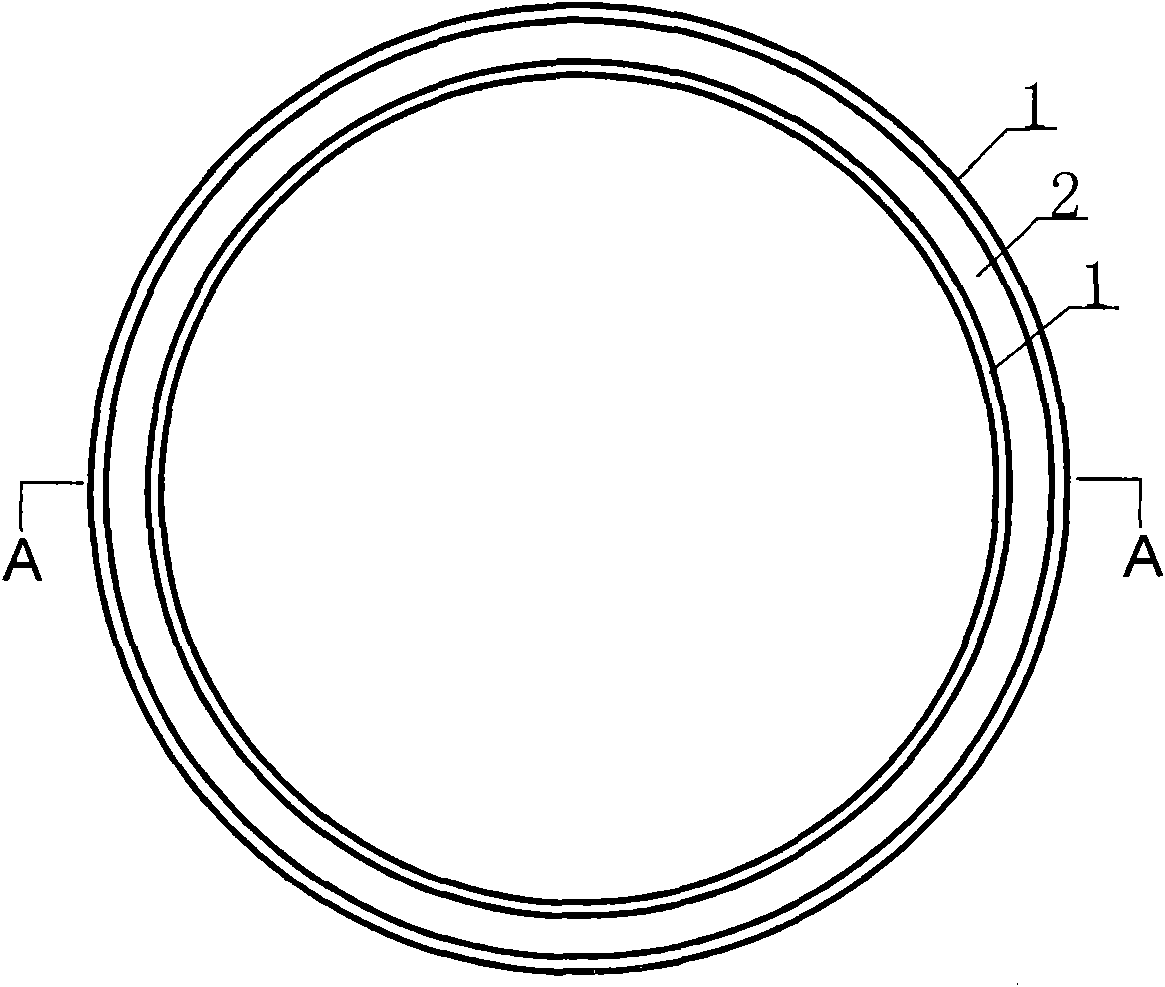

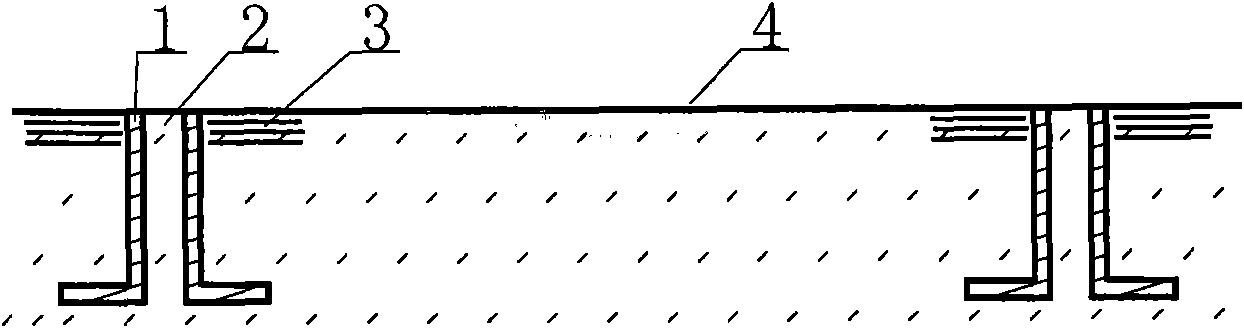

Method for connecting slotted sections in underground construction of diaphragm wall

The invention discloses a method for connecting slotted sections in underground construction of diaphragm wall of 'deep wall, large thickness and needing rock-socketed' applied to large acale bridges and construction foundation pit excavation. The method comprises the following steps: establishing a guide wall and a construction platform; constructing I phase slotted section of the diaphragm wall; constructing of a slotted eye of II phase slotted section of the diaphragm and jagged section surface of the I phase slotted section; forming an underground diaphragm wall; cleaning and brushing the wall of the II phase slotted section repeatedly up and down by a special steel brush carried by a hydraulic grab, until the steel brush does not have obvious spare, deposit on the bottom of the eye does not increase; releasing a reinforcing cage and casting concrete so as to complete the connection of I phase slotted section and II phase slotted section after the II phase slotted section is completed; forming a complete diaphragm wall after connection. After the method is adopted, the progress of the construction of the underground diaphragm wall is greatly improved; construction cost is saved; construction problems, such as concrete circumferential motion prevention, water seepage in seam and the like can be completely solved by the jagged connection section so as to improve construction quality and safety reliability.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

Method for milling and vibration-damping blisk

InactiveCN101912990AEliminate milling distortionEliminate ChatterMilling equipment detailsMaintainance and safety accessoriesEngineeringChatter mark

The invention belongs to the technical field of machining and discloses a method for milling and vibration-damping a blisk. The method comprises the following specific process steps of: (1) preparing a filling material according to the proportion; (2) melting the filling material; (3) mounting a pouring clamp; (4) pouring a filling agent; (5) condensing the filling agent at normal temperature, secondarily condensing the filling agent and checking the condensing state of the filling agent; (6) mounting a filtering clamp; and (7) carrying out the abutted milling processing and chip removal processing. By pouring the filling agent between the blisk and vanes in the milling processing of vane profile five coordinates of the blisk, the method enhances the rigidity of parts in the milling processing of the vanes, eliminates the chatter marks generated at the vent tip part of the vanes during milling and reduces the roughness of the surfaces of the vanes. Meanwhile, the rigidities of the parts and a clamping system thereof are enhanced, so that the milling feed rate is increased and the milling speed can be improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

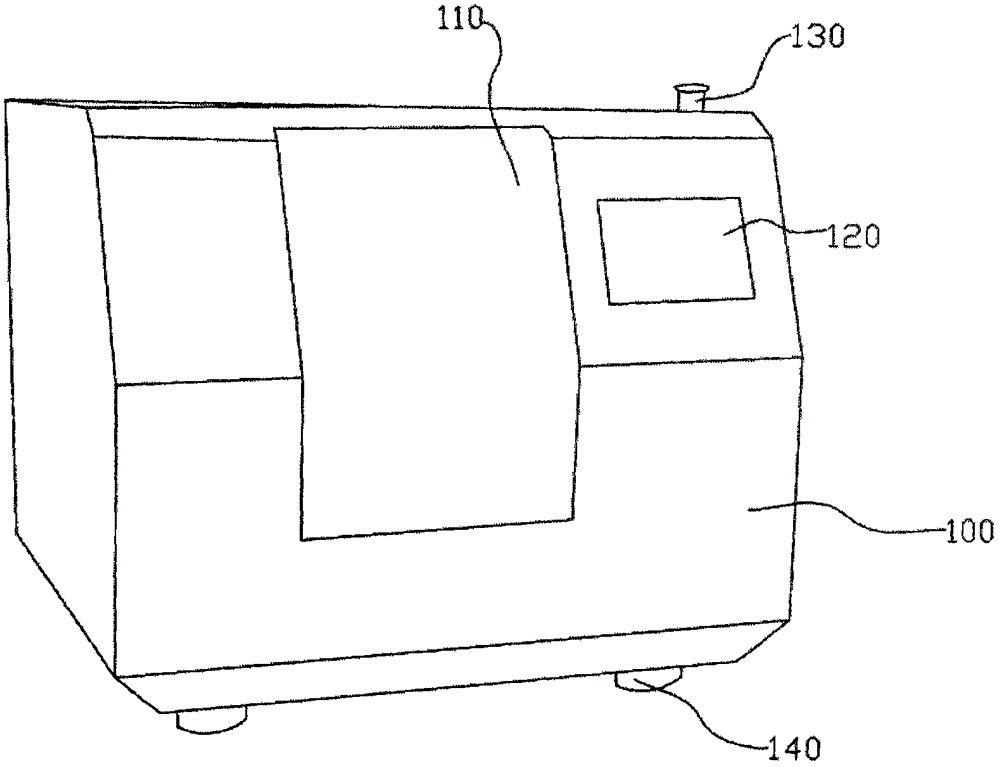

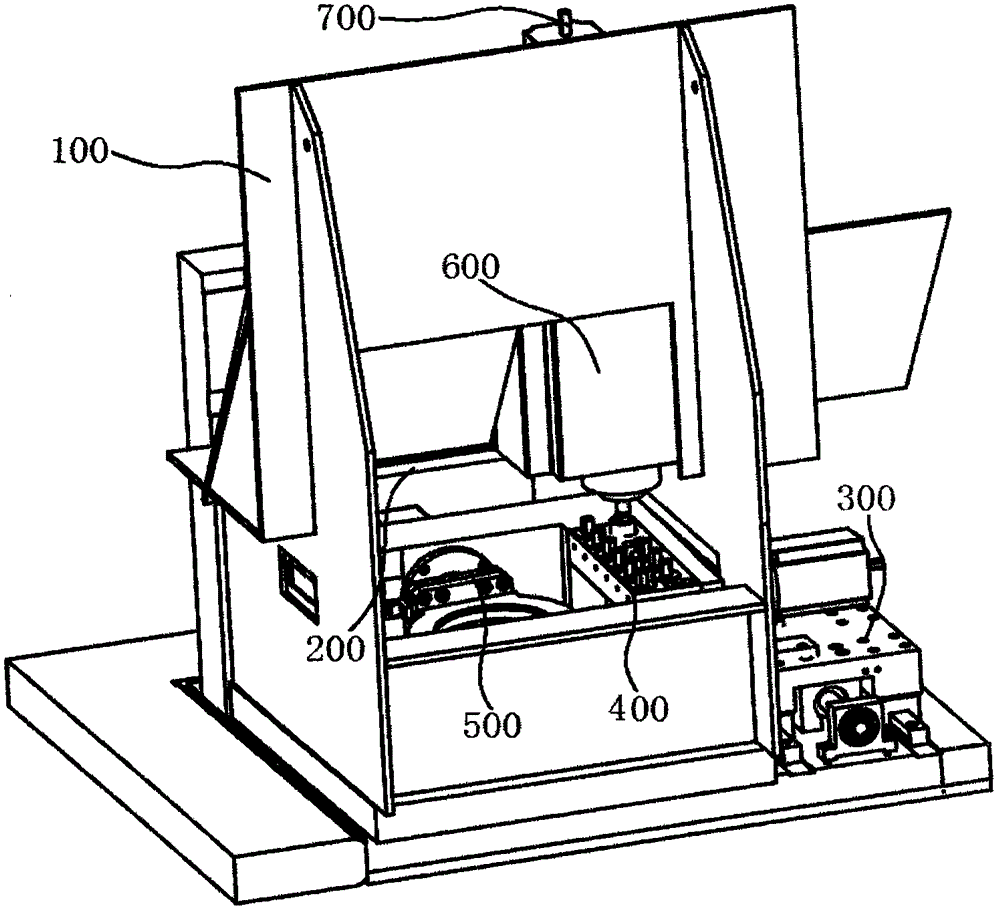

Full-automatic five-axis false tooth processing equipment

The invention discloses full-automatic five-axis false tooth processing equipment which comprises a machine cover, wherein the machine cover is internally in a hollow structure, and the machine cover internally comprises an X-axis motion platform, a Y-axis motion platform and a Z-axis motion platform which are respectively provided with a basic axis; an A-axis inclined device is arranged on a position which is overturned around the X-axis motion platform, and a B-axis overturning device is arranged on a position which is overturned around the Y-axis motion platform; and the A-axis inclined device and the B-axis overturning device are both arranged on an L-shaped support frame of the Y-axis motion platform. The full-automatic five-axis false tooth processing equipment disclosed by the invention can be used for processing pure titanium, zirconium oxide and a wax type material, and processing relatively multiple varieties of false tooth materials through one equipment, is capable of operating a complex processing path, greatly reducing the thickness of a material block needed by a long bridge, and can be used for machining special angles and inverted recesses inside a material disc, supporting the normal mode processing, achieving a individual base station and the bridge body milling, supporting the grinding of a glass ceramic tooth, a beautifying patch and an inlay and fast completing a workpiece, is good in practicability and novel in design, is a very good innovation scheme and has great market popularization prospect.

Owner:SHANGHAI VULTURE NC MACHINERY

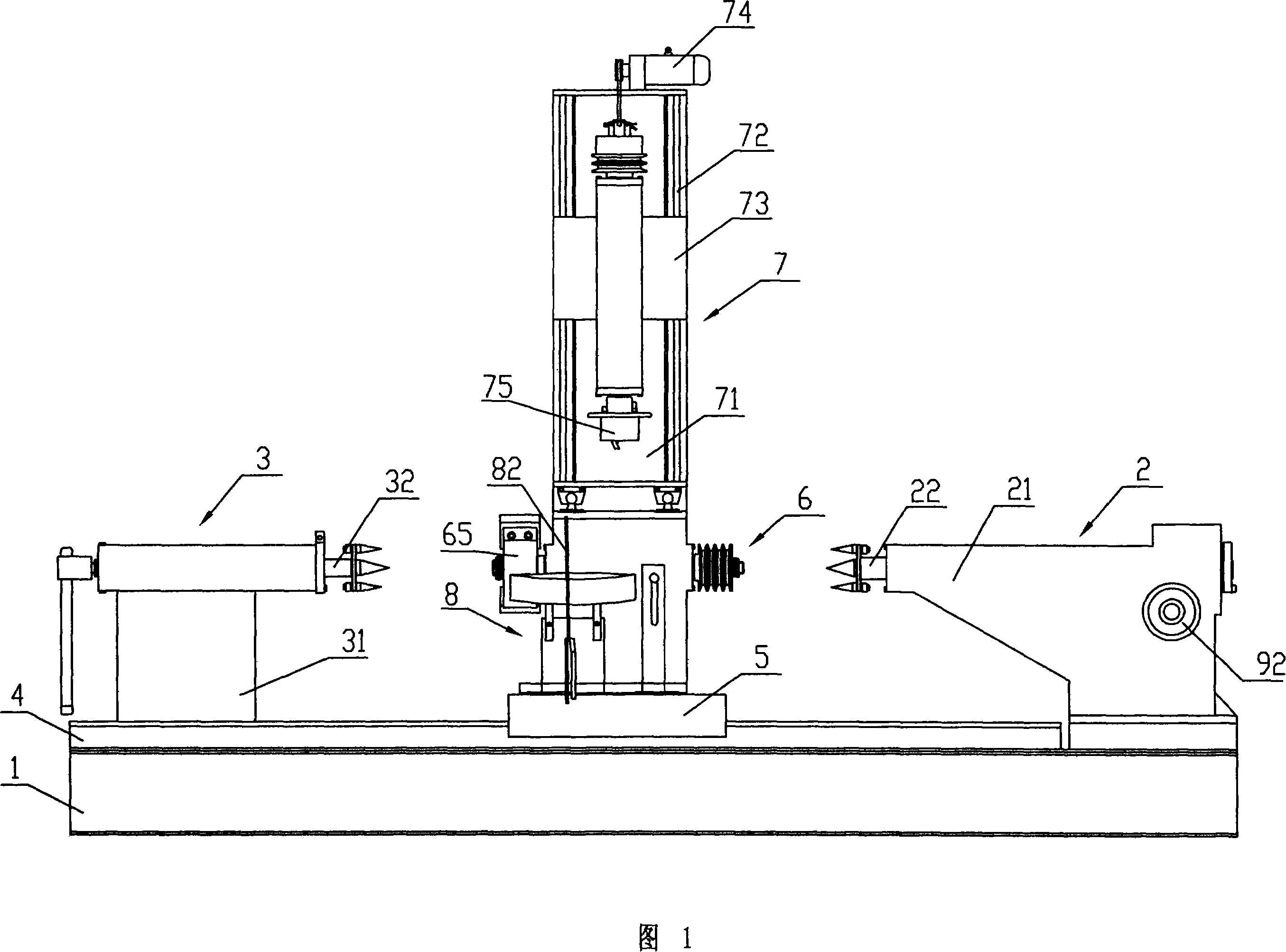

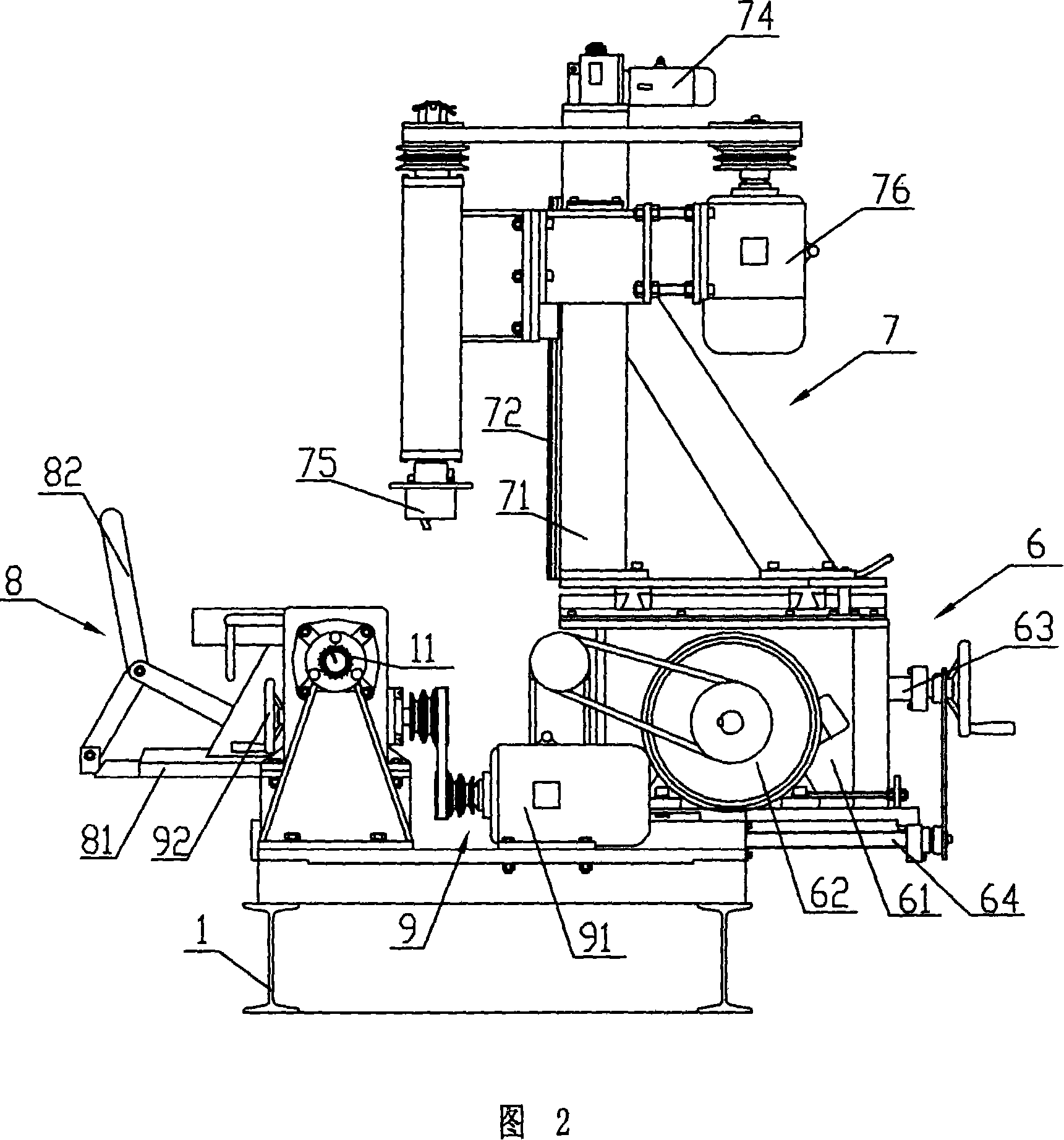

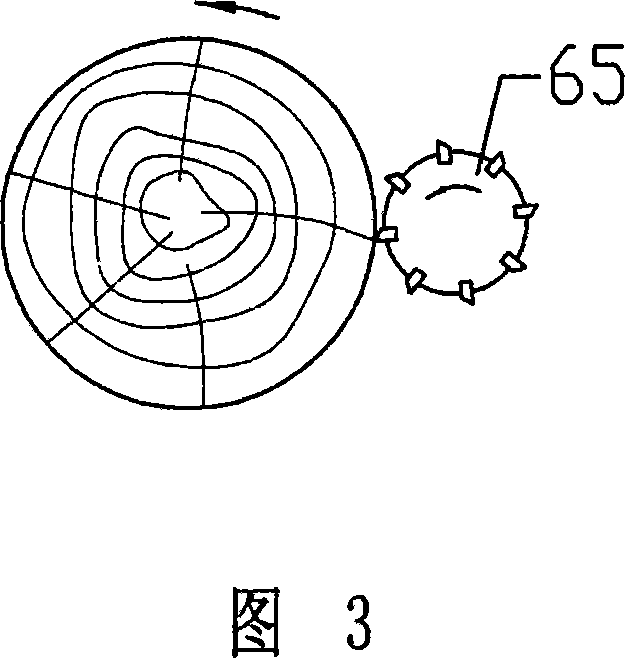

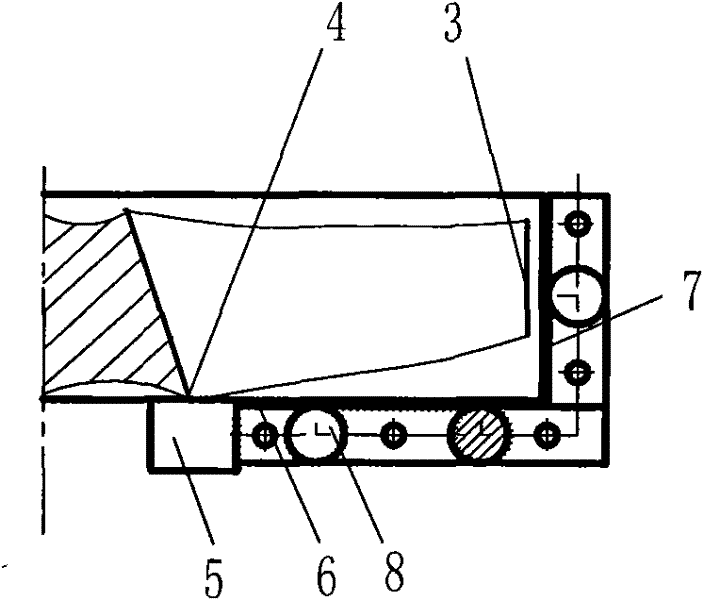

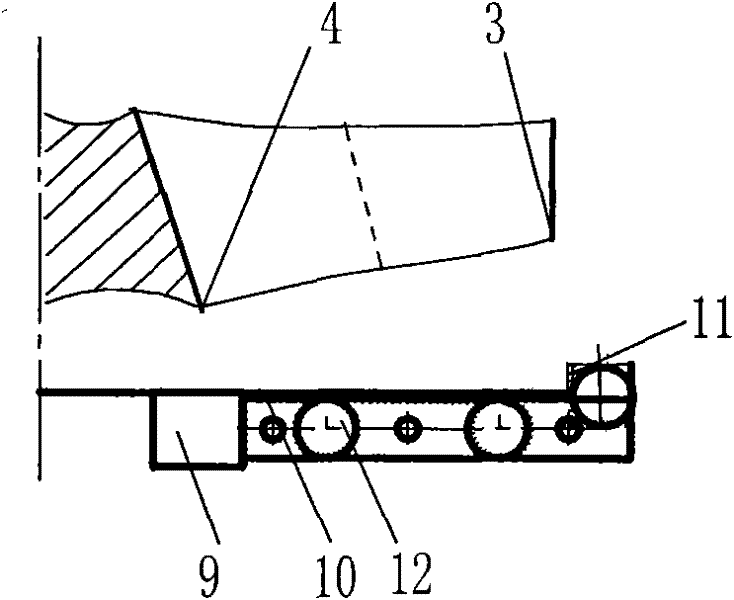

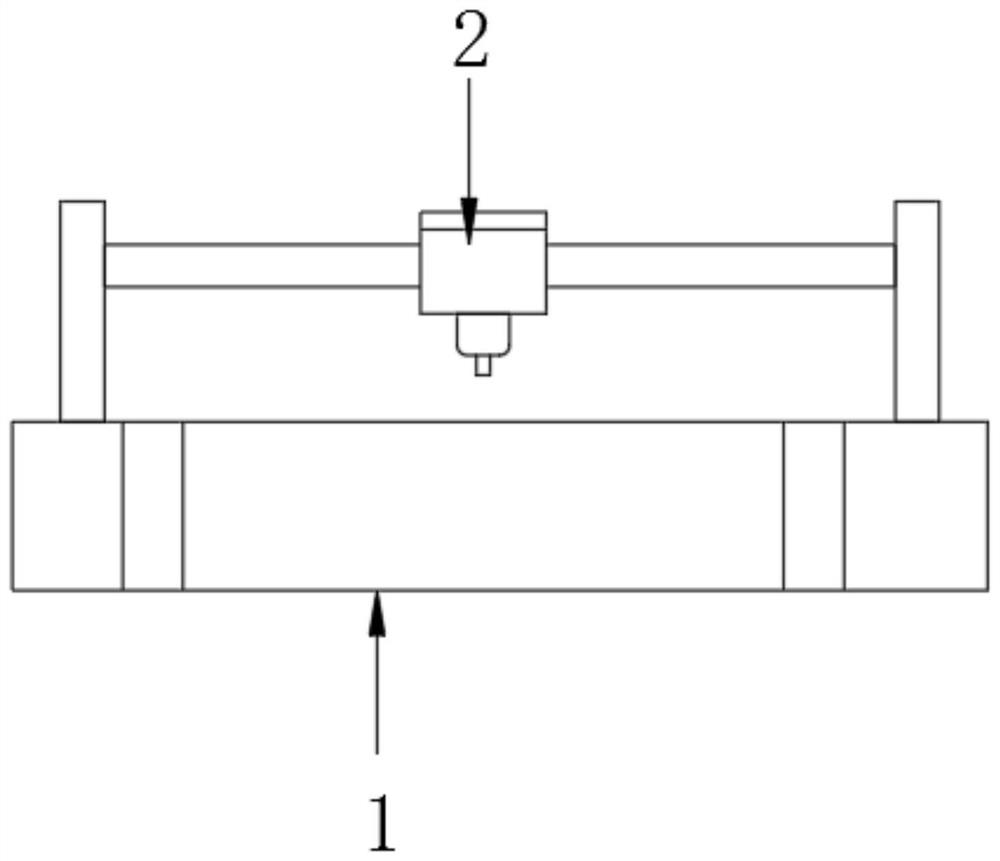

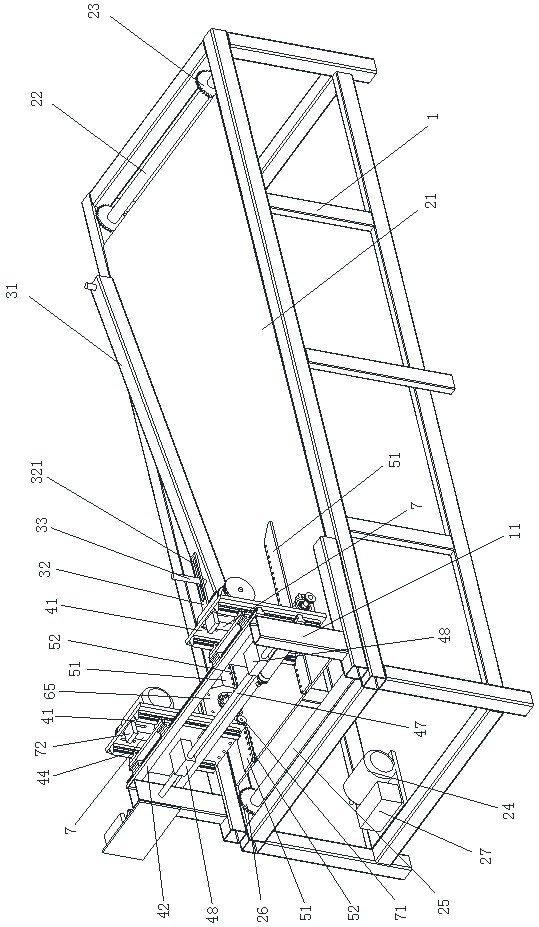

Carpentry machine tool used for log processing

InactiveCN101058196AImprove processing efficiencyEasy to stackProfiling/shaping machinesWood-turning machinesCircular discEngineering

The invention relates to a woodworking tool machine for original wood processing that comprises the vertical track base with both ends sticking the original wood and driving its motor tail base and support tail base, sliding base between them and being able to move along the vertical track, horizontal milling and cutting device for the original wood with vertical milling device installed on the horizontal milling base. The woodworking machine is not only able to process original wood with high efficiency, but also be able to vertical concave slot, horizontal concave slot and vertical sawing seam processing on the wood. It is multifunctional, with convenience for wood transportation, usage and storage.

Owner:杜明干

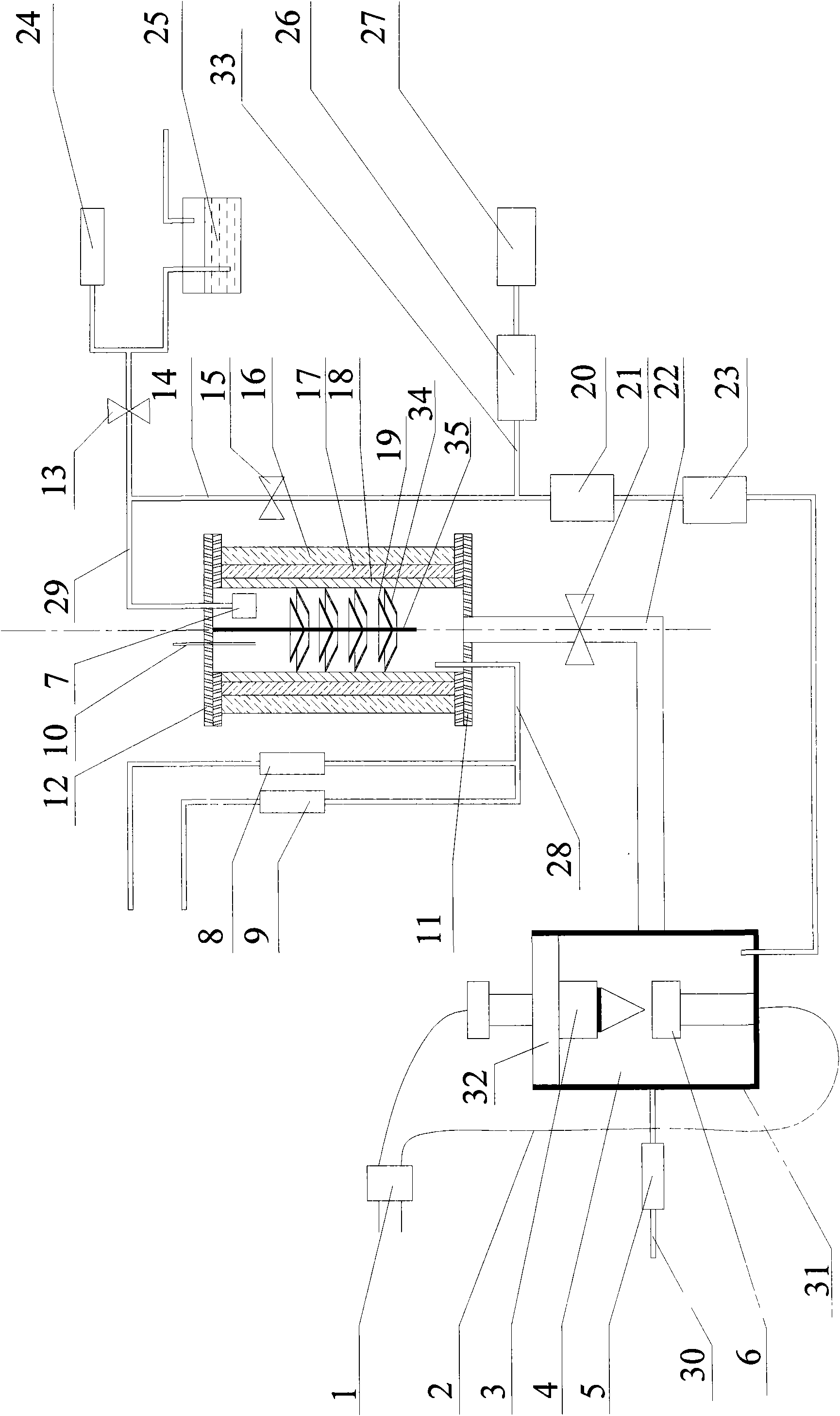

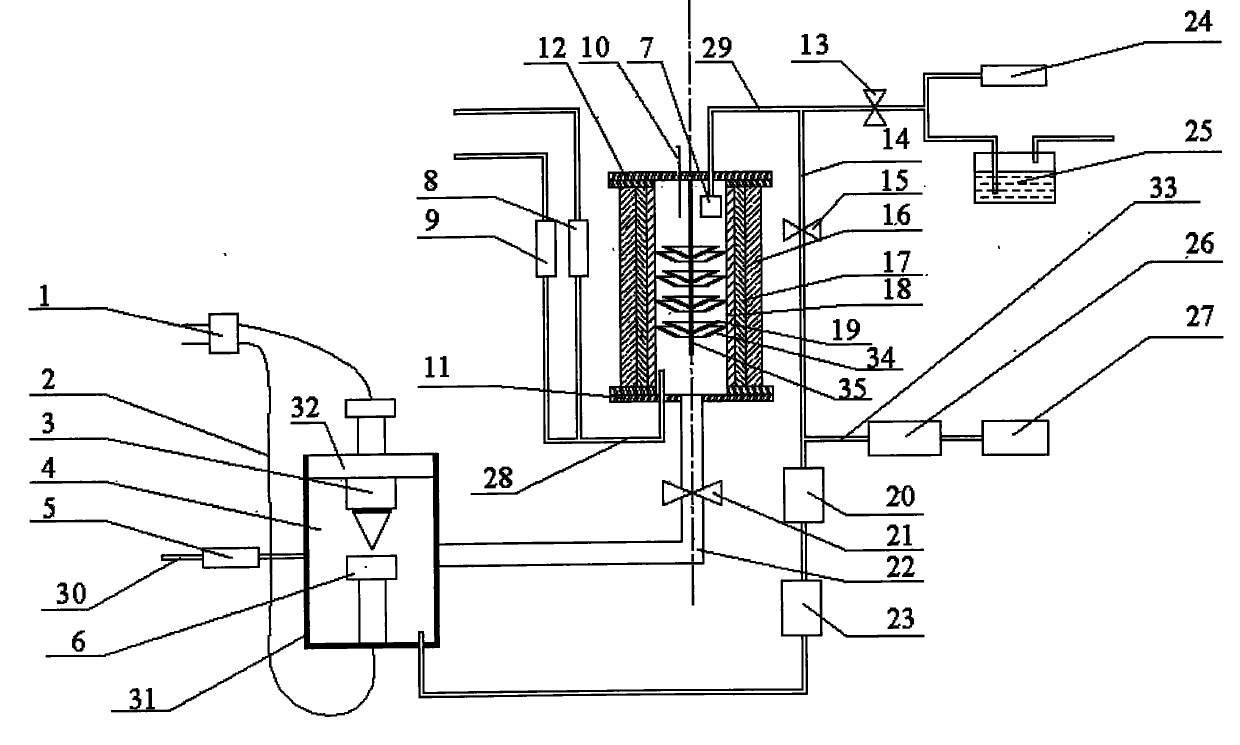

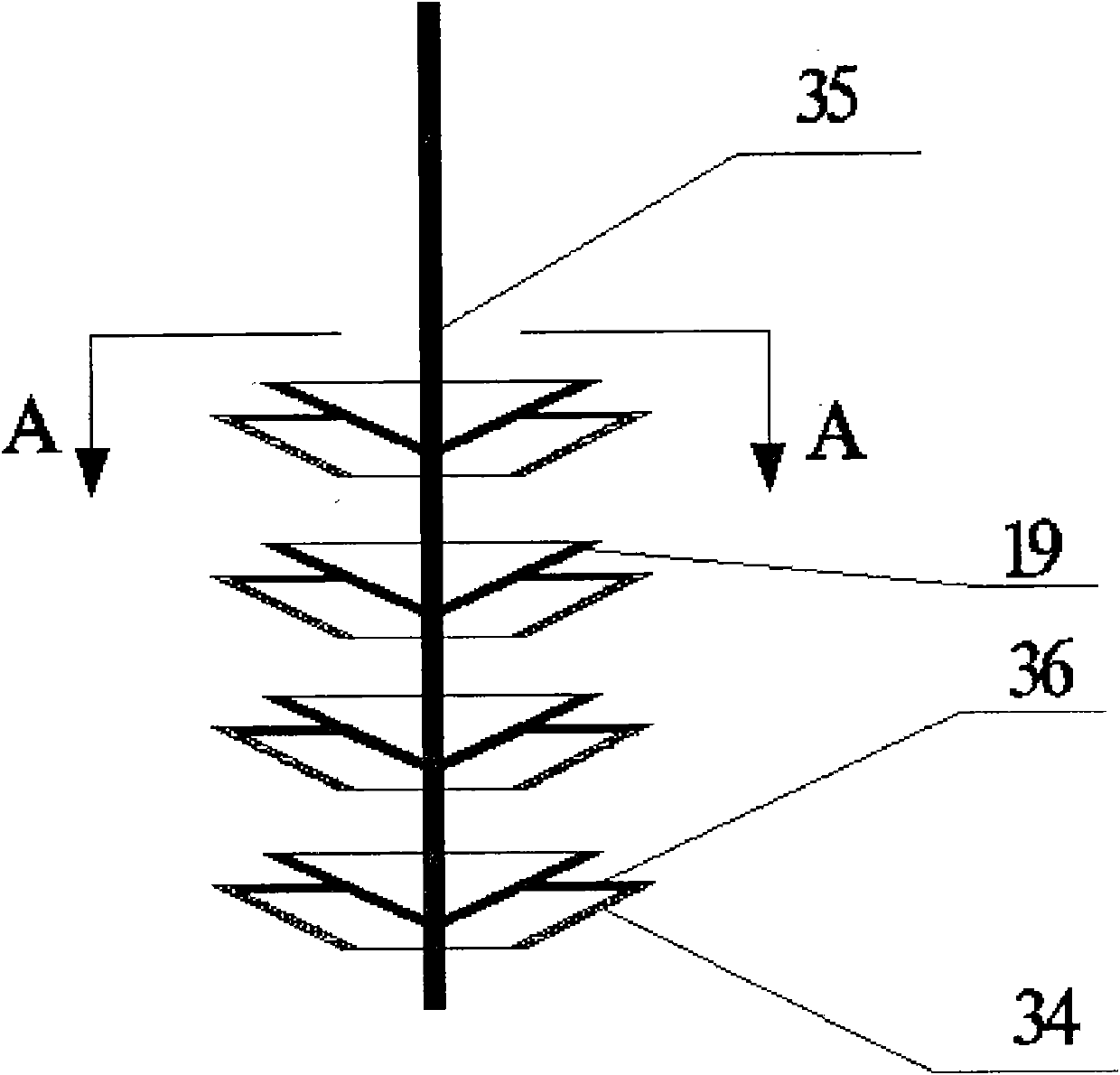

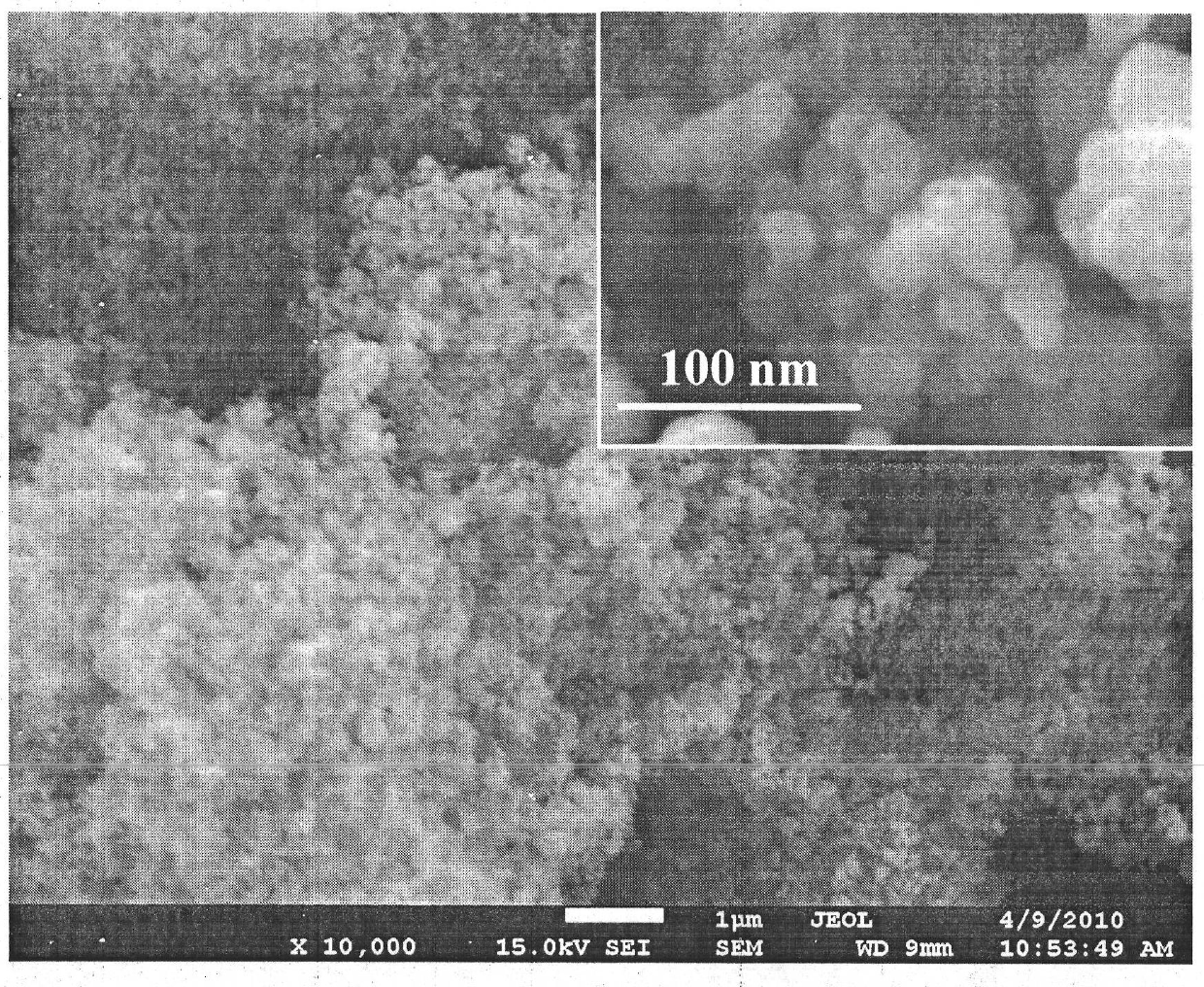

Method for preparing single phase nanometer epsilon-Fe3N or gamma'-Fe4N powder and device thereof

InactiveCN101628712ARapid coolingSmall diameterNitrogen-metal/silicon/boron binary compoundsHydrogenIron nitride

The invention relates to a method for preparing single phase nanometer epsilon-Fe3N powder or gamma'-Fe4N powder and a device thereof; the device comprises a plasma evaporation pulverizing system, a powder collection and modification system, a vacuum system and a circulating system. The process for preparing single phase nanometer epsilon-Fe3N or gamma'-Fe4N powder comprises the following steps: vacuumizing, cycling gas compulsively, then performing plasma evaporation to prepare powder, then modifying the powder while ensurng that the cubic content ratio of ammonia to hydrogen is (1.4-1.6):1, the temperature of a powder catcher room is 345-355 DEG C and the temperature is kept for 5-7h and obtaining the single phase nanometer gamma'-Fe4N powder; or modifying the powder while ensurng that the cubic content ratio of ammonia to hydrogen is (2.4-2.6):1, the temperature of a powder catcher room is 445-455 DEG C and the temperature is kept for 1-3h and obtaining the single phase nanometer epsilon-Fe3N powder. By controlling the reaction atmosphere precisely, the product is ensured to be high purity single phase nanometer iron nitride powder.

Owner:NORTHEASTERN UNIV

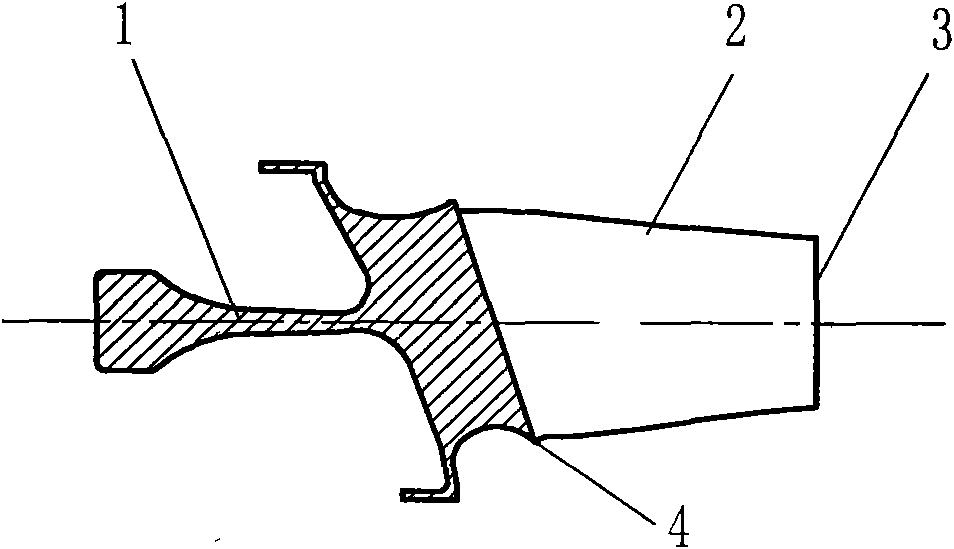

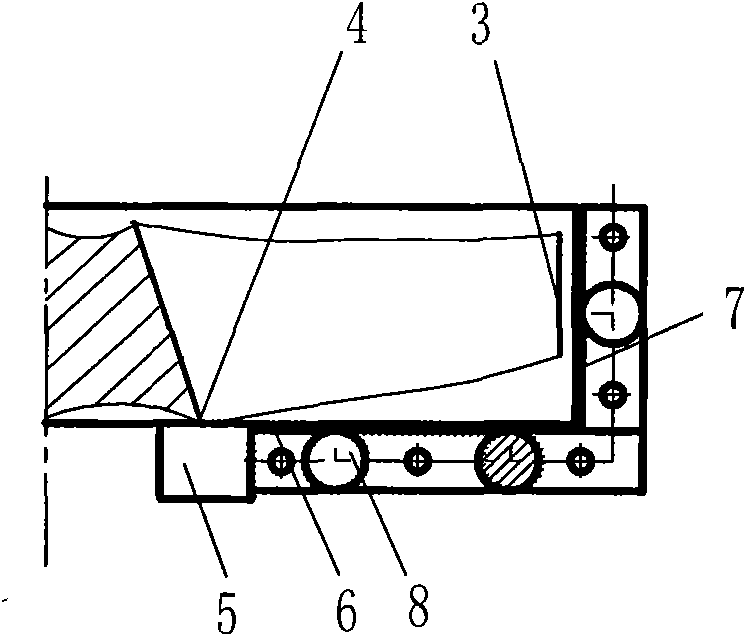

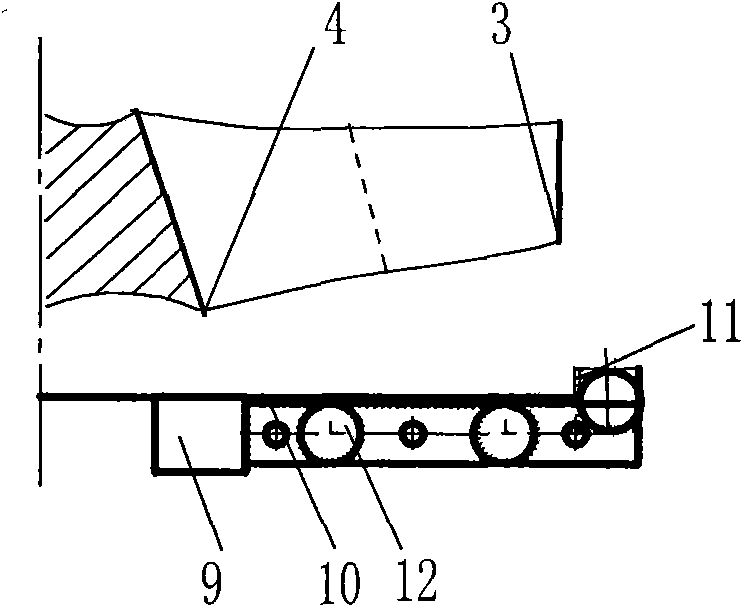

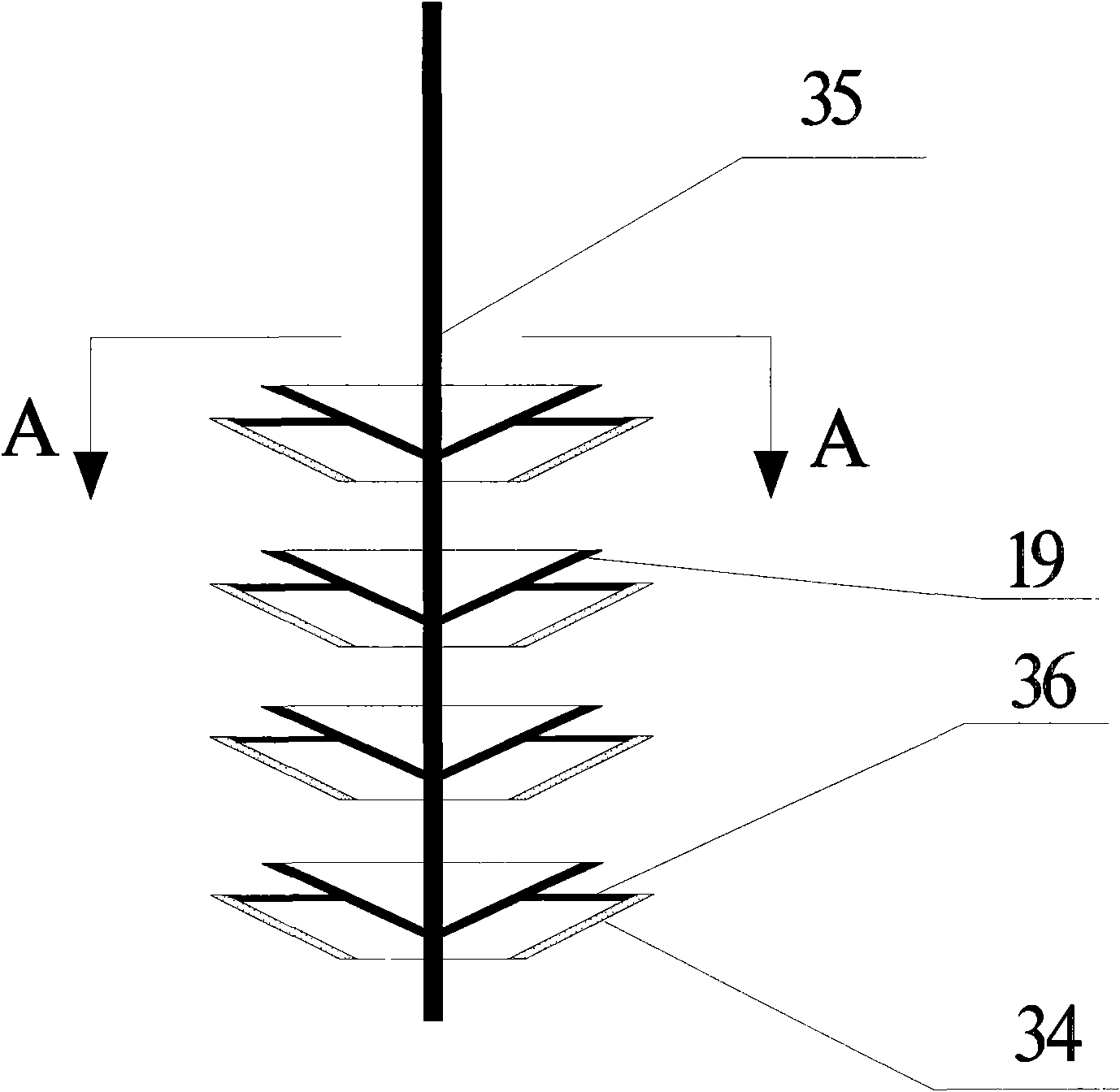

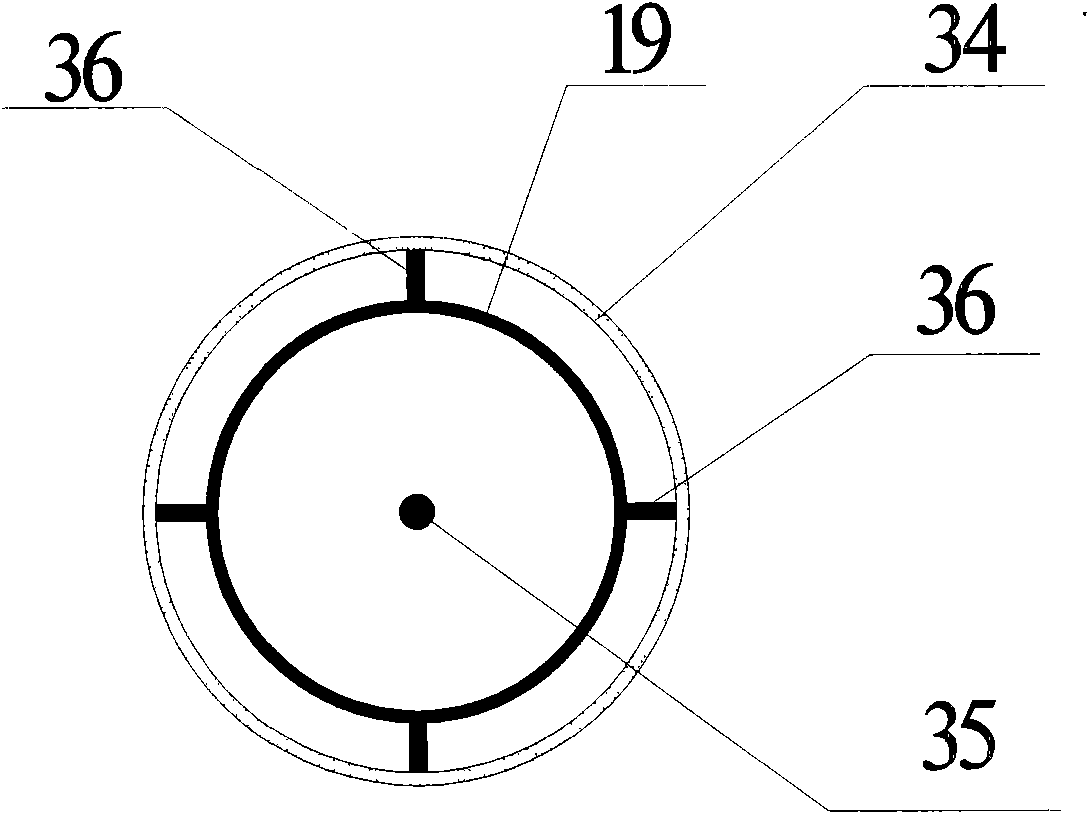

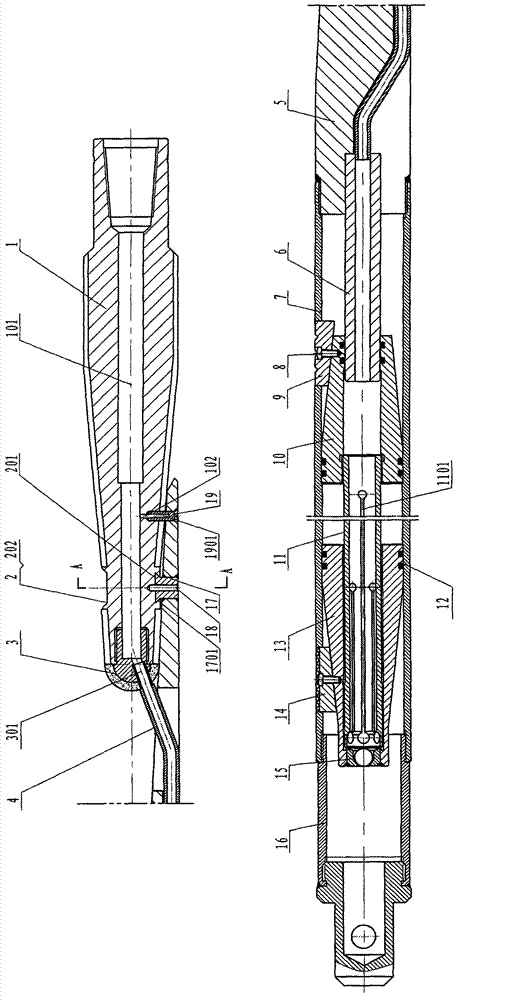

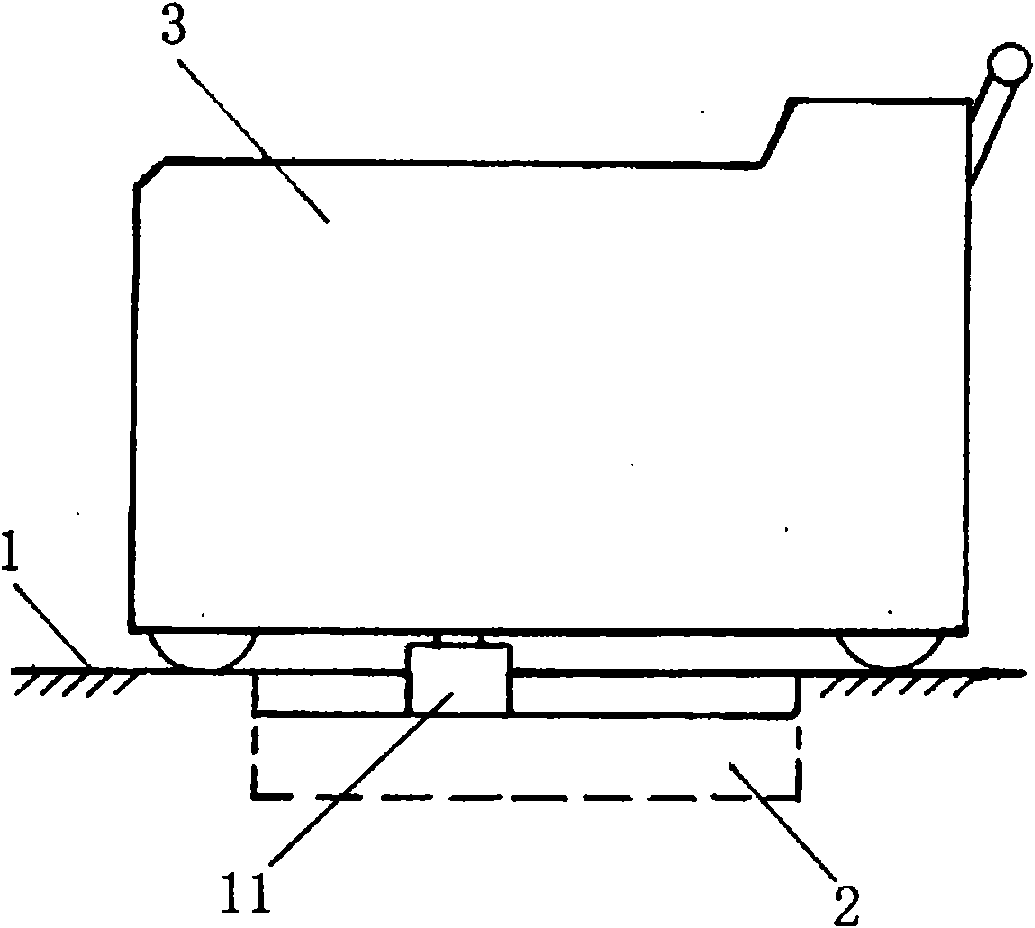

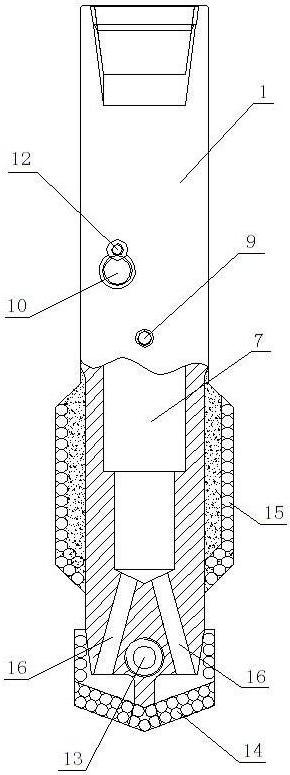

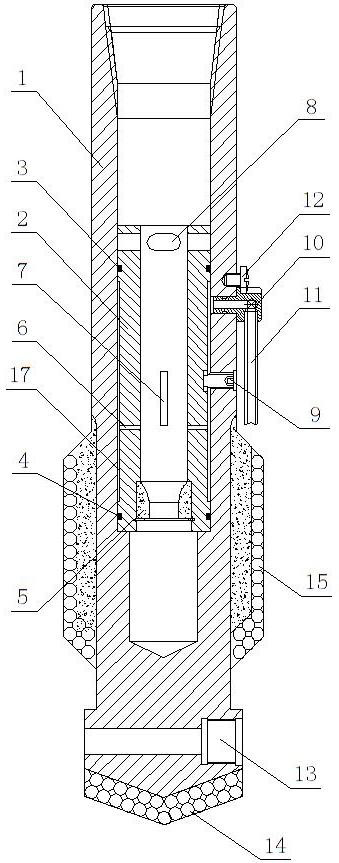

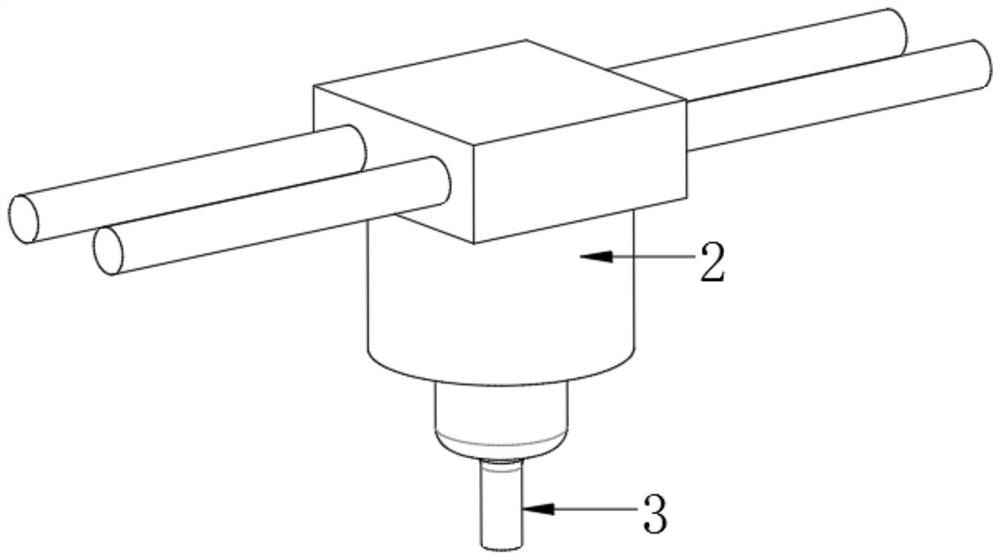

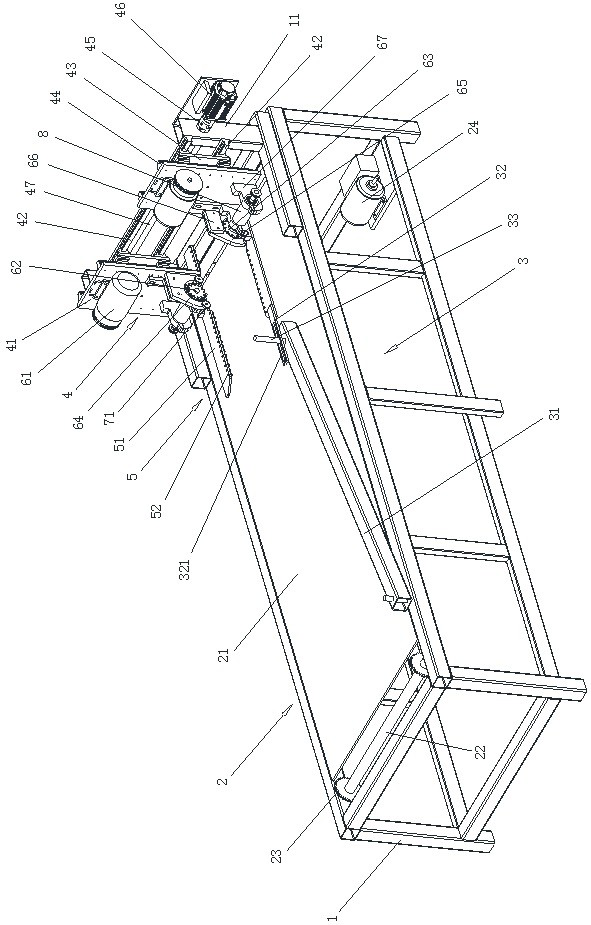

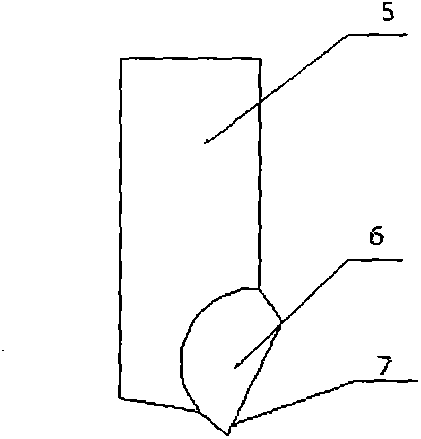

Integrated window sidetrack drilling tool

ActiveCN103195362AAvoid pumpingMilling speed is fastDrilling machines and methodsUltimate tensile strengthGuide tube

The invention discloses an integrated window sidetrack drilling tool. The integrated window sidetrack drilling tool comprises a hollow tapered mill, a wedge deflection tool deflection iron and a setting and anchoring member which are sequentially connected, the wedge deflection tool deflection iron is clamped in an arch-shaped dovetail groove on the lower portion of the tapered mill, a positioning bolt is arranged between the upper end of the wedge deflection tool deflection iron and the tapered mill, and a liquid guide tube is arranged in the wedge deflection tool deflection iron. The integrated window sidetrack drilling tool is characterized in that an auxiliary liquid hole corresponding to the positioning bolt is arranged on the tapered mill, a blind hole communicated with the auxiliary liquid hole is arranged on the positioning bolt, the auxiliary liquid hole is blocked by the positioning bolt when the wedge deflection tool deflection iron and the tapered mill are clamped, and an inner hole of the tapered mill is communicated with the outside through the auxiliary liquid hole and the blind hole of the positioning bolt when the positioning bolt is cut. The integrated window sidetrack drilling tool has the advantages of being capable of avoiding pump choking caused by the blocking of a nozzle of the tapered mill, guaranteeing drilling pressure can be fully added during windowing, and improving milling speed to enhance the efficiency of windowing; and completing the fixing of the wedge deflection tool and the windowing and window repair of the tapered mill through a trip of drilling to greatly improve work efficiency and reduce construction cost and labor intensity.

Owner:JINZHOU QINGHUA MACHINERY

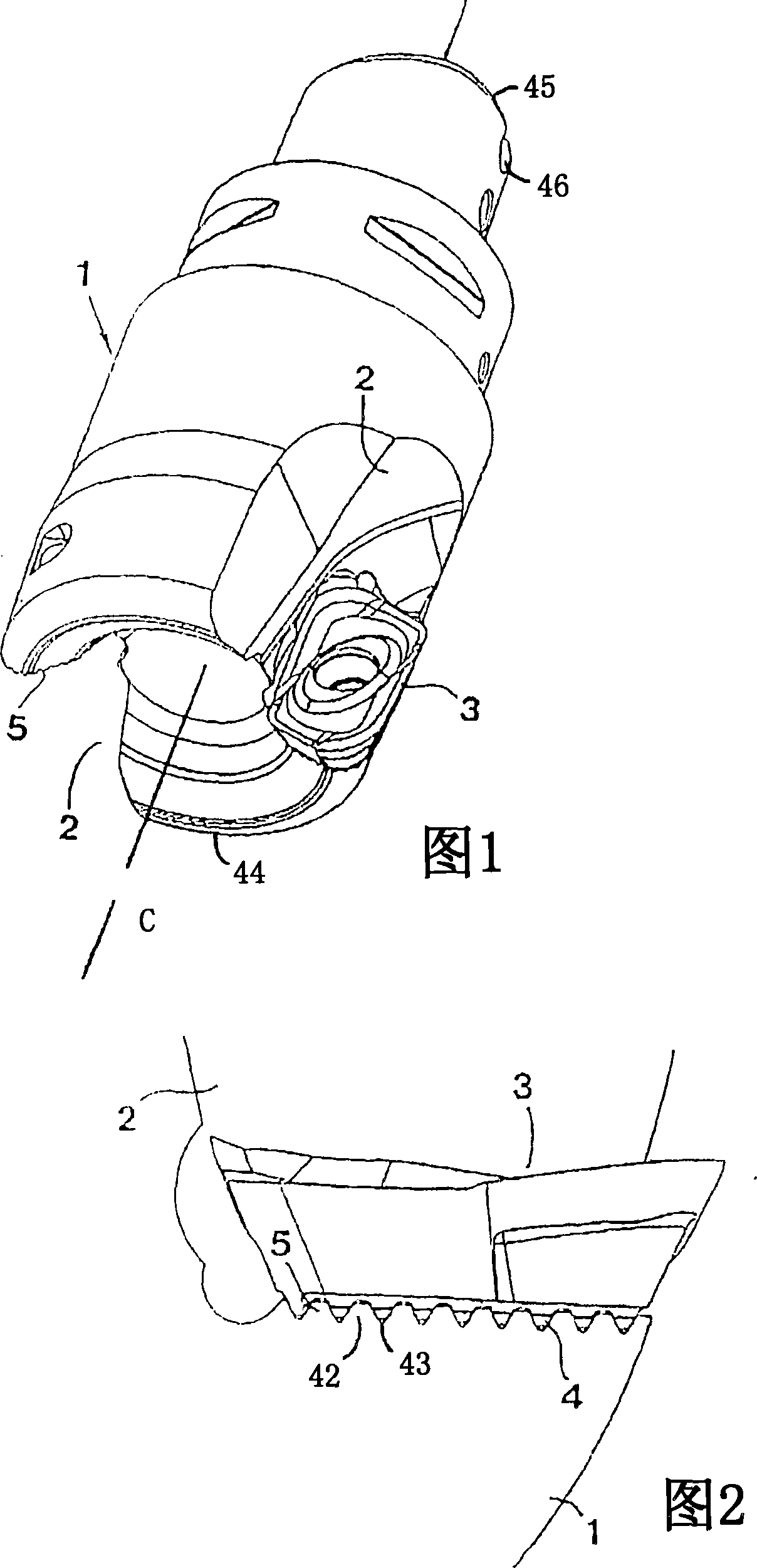

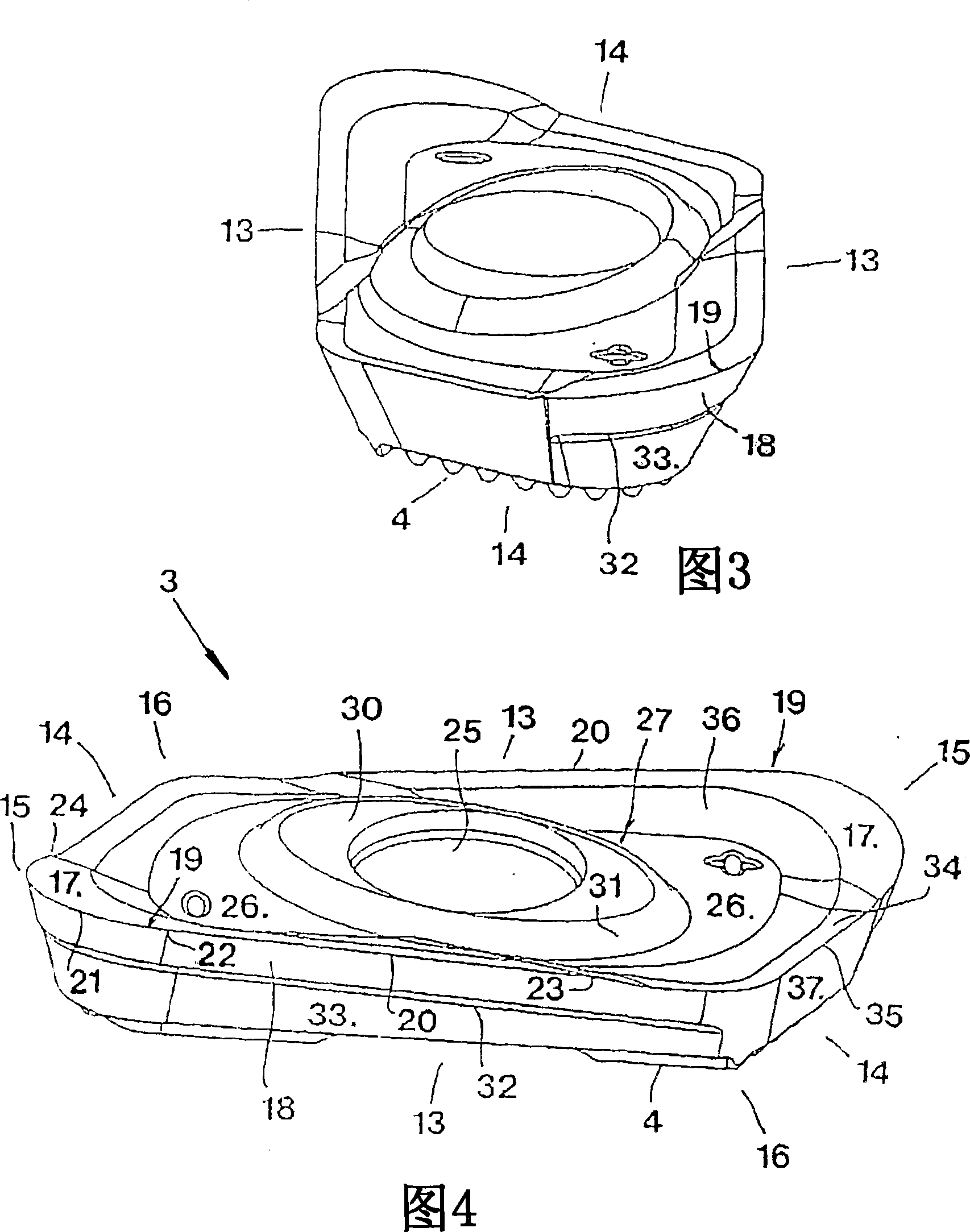

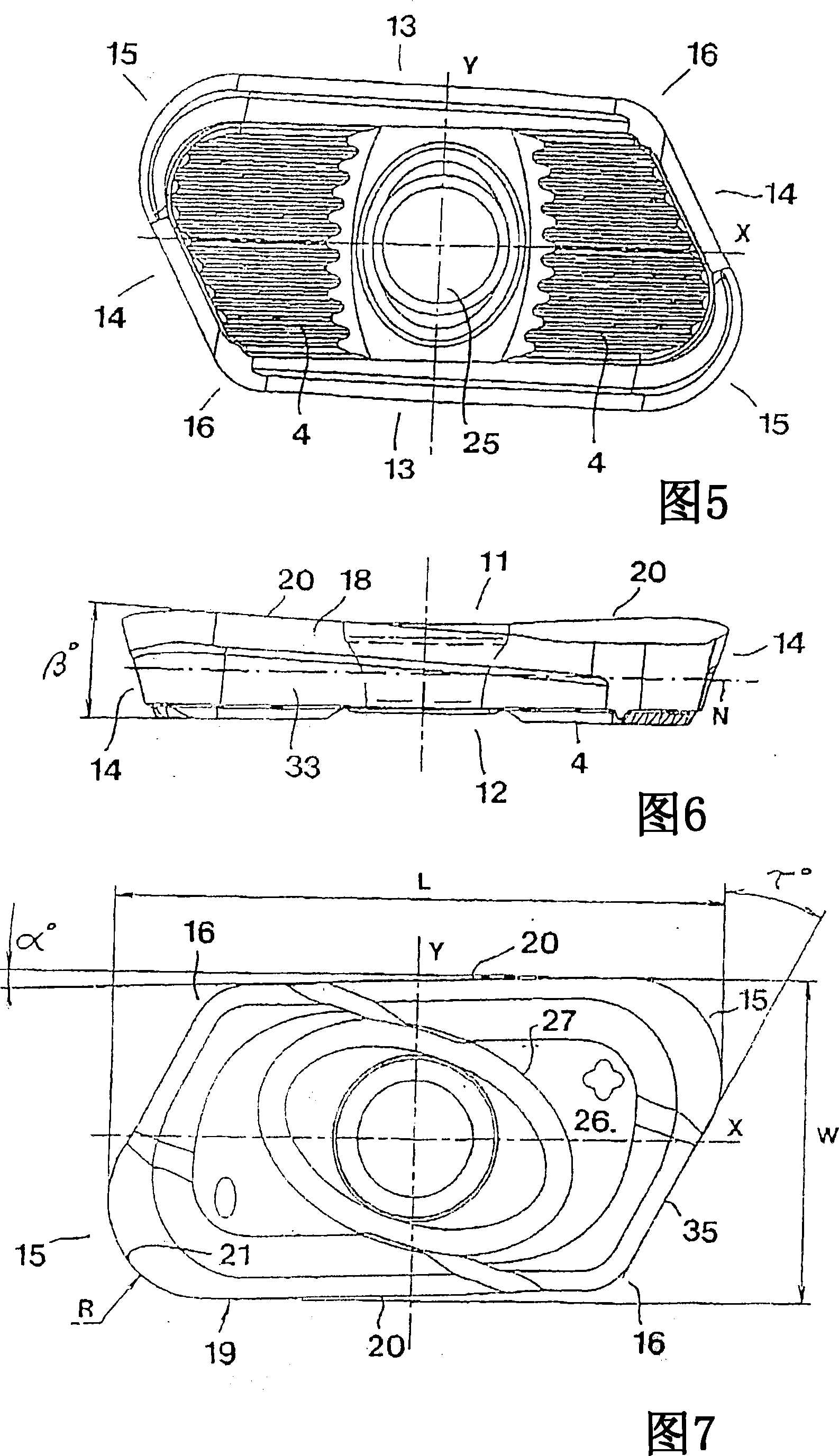

A milling tool, a cutting insert for milling tool as well as a solid milling tool

InactiveCN101014439AGuaranteed StrengthHigh strengthMilling cuttersShaping cuttersMilling cutterEngineering

Owner:SANDVIK INTELLECTUAL PROPERTY AB

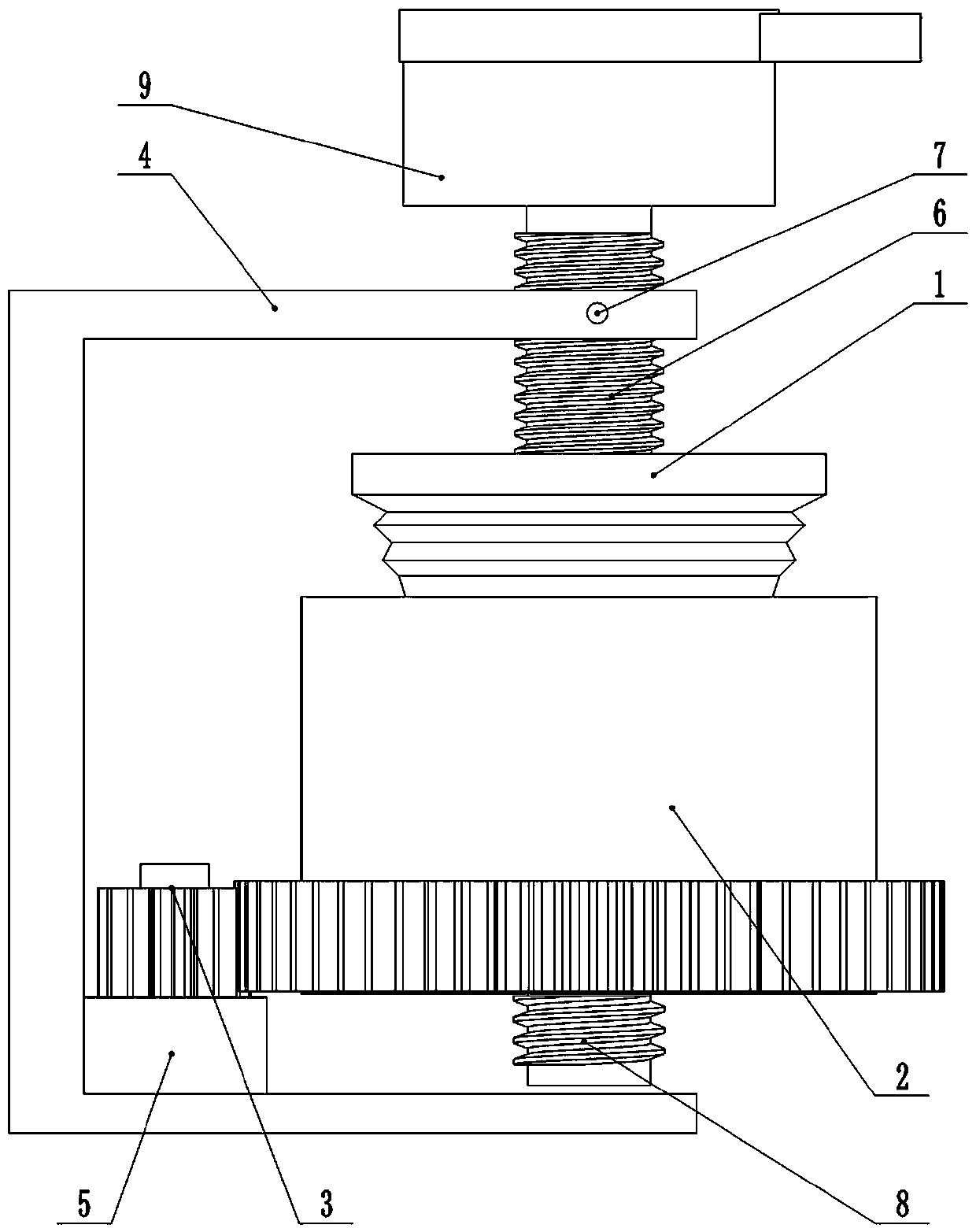

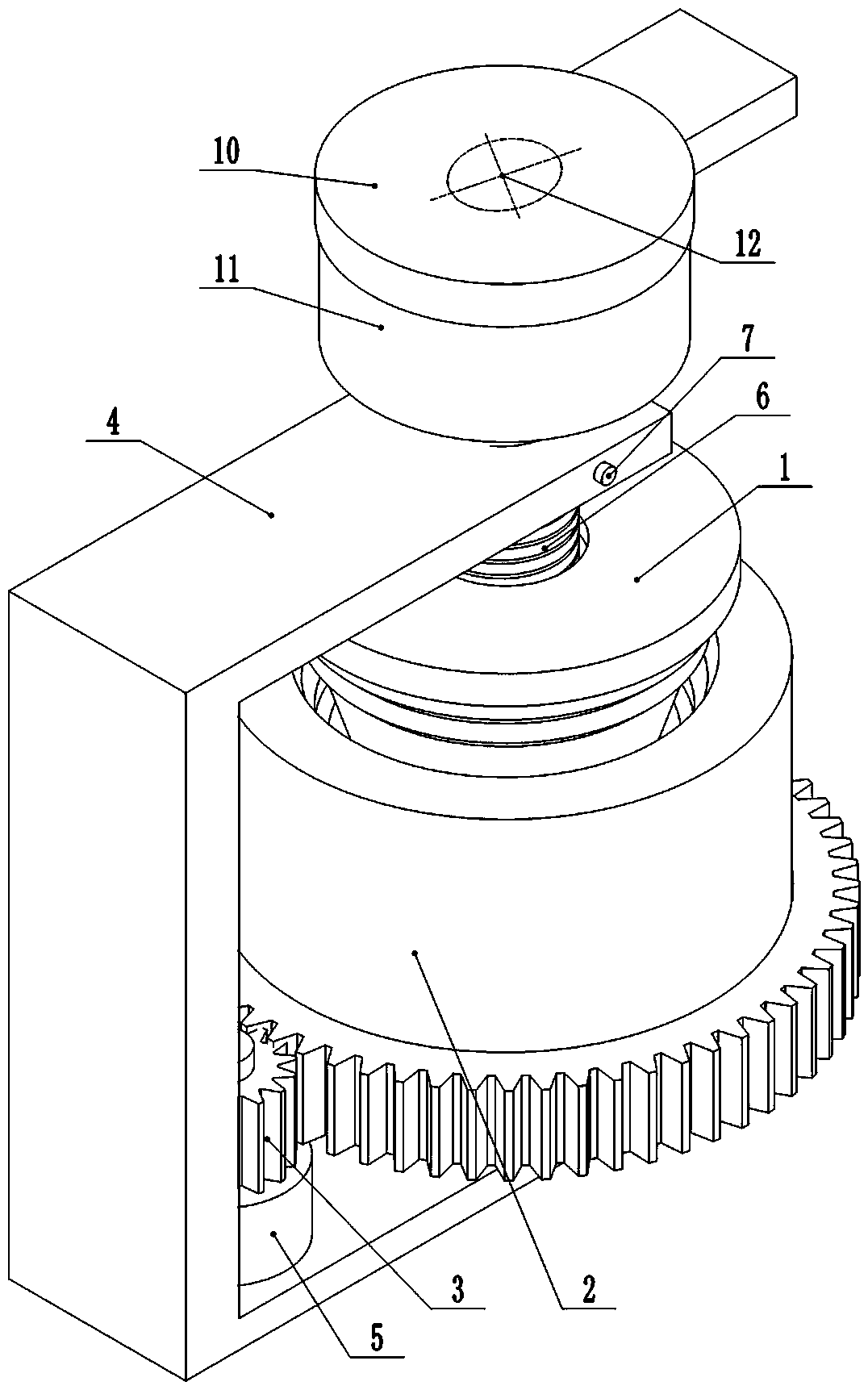

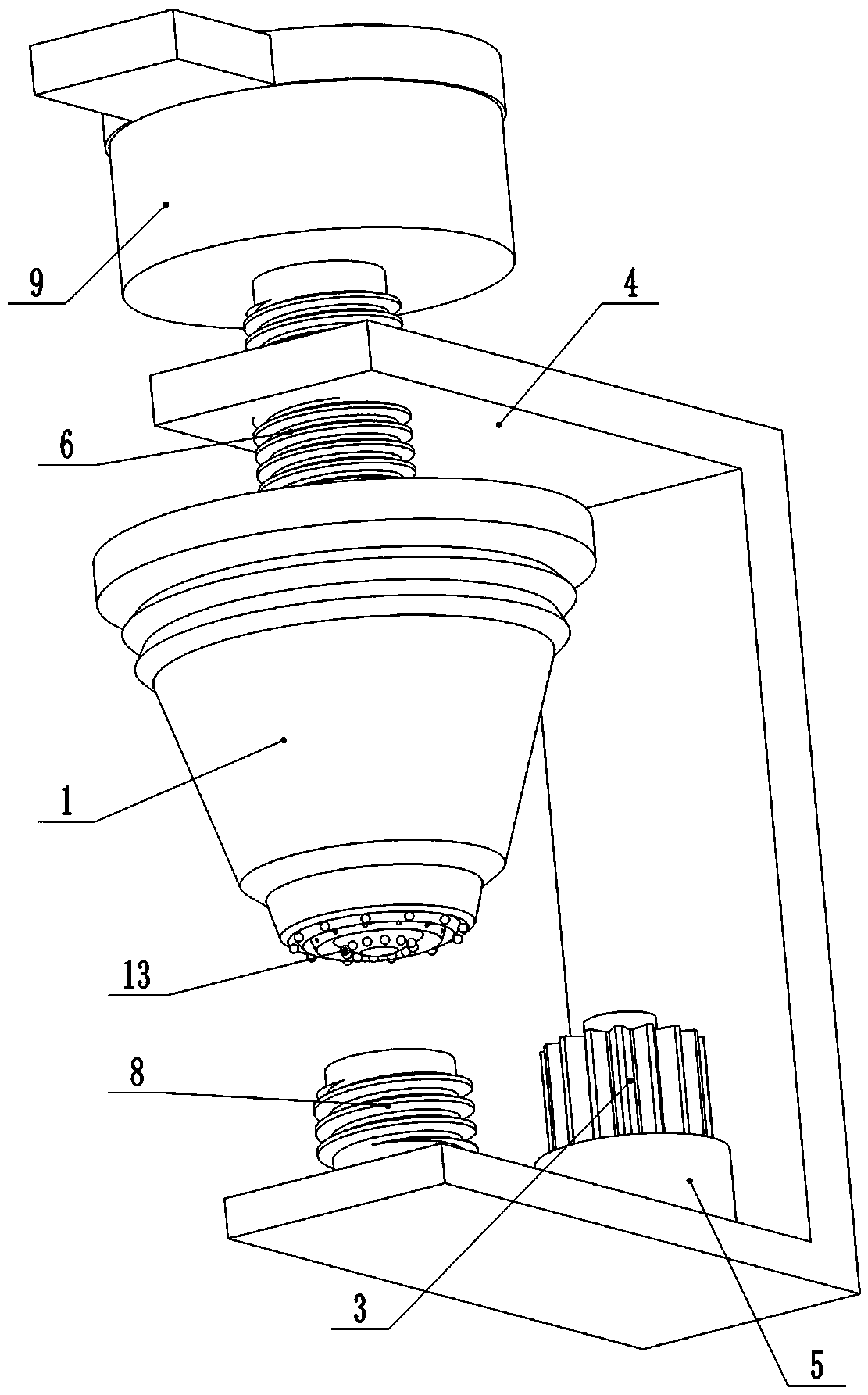

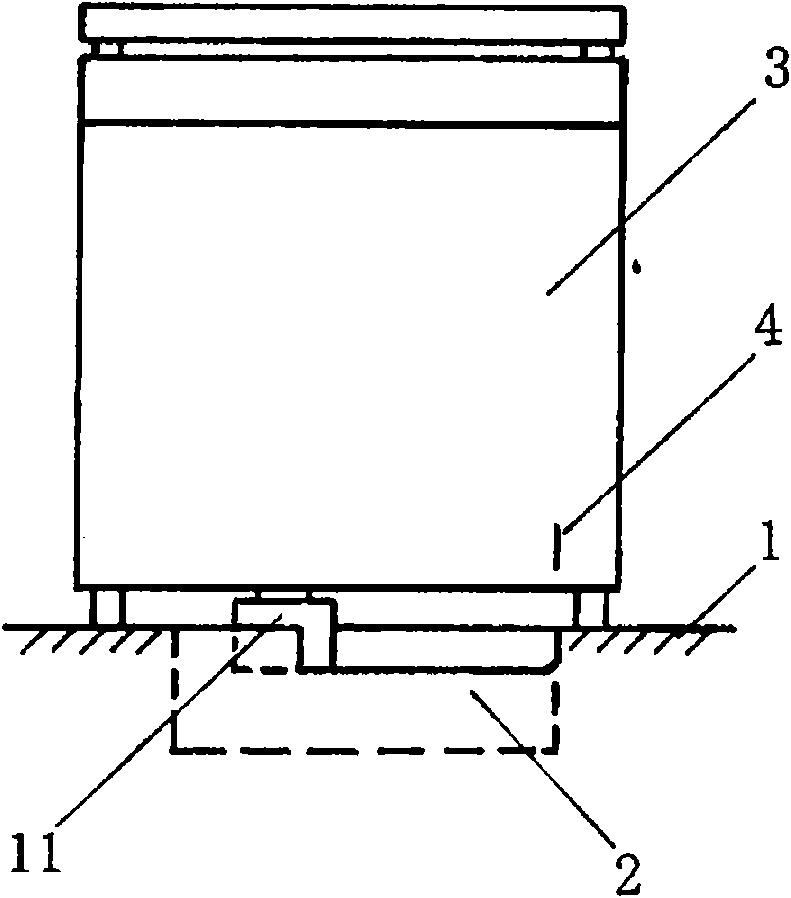

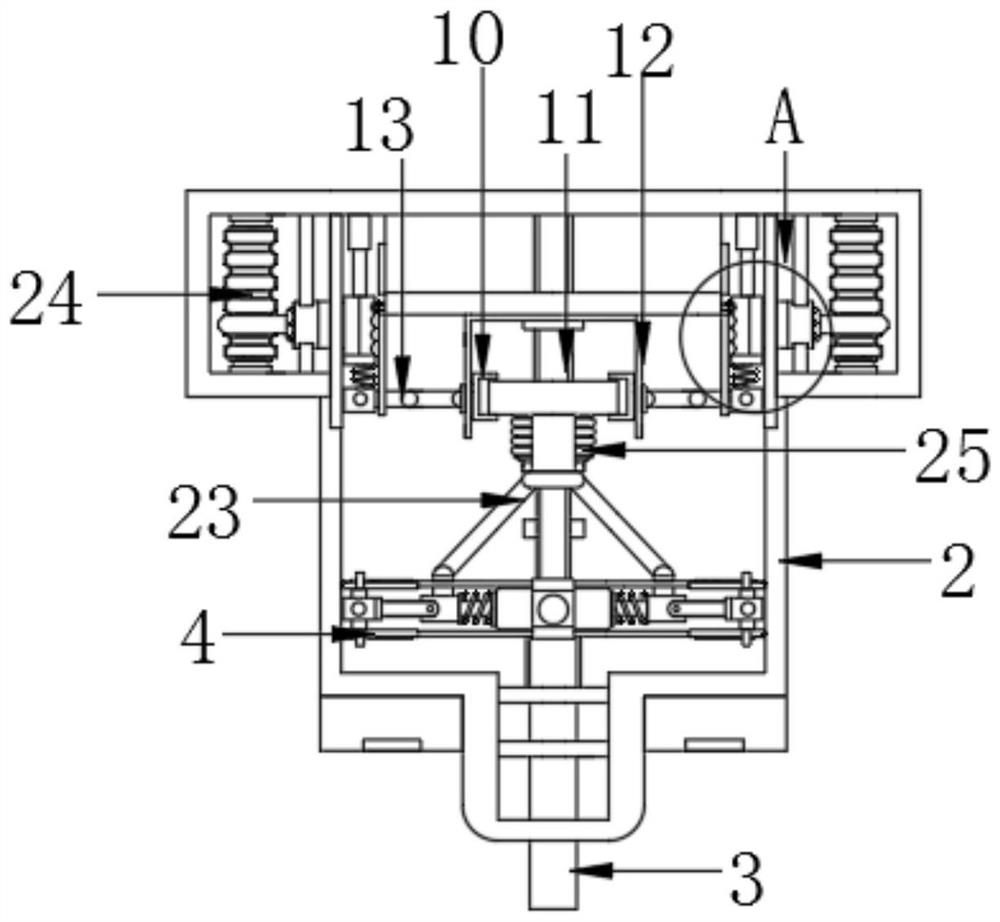

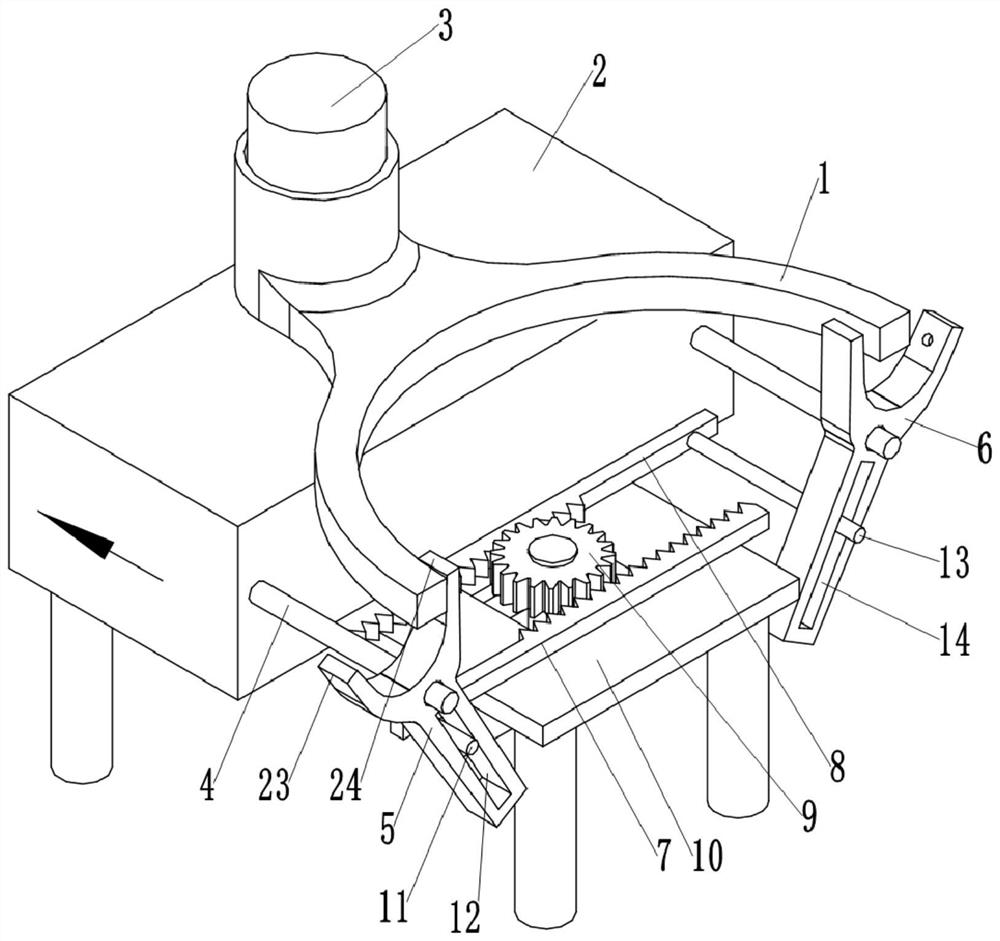

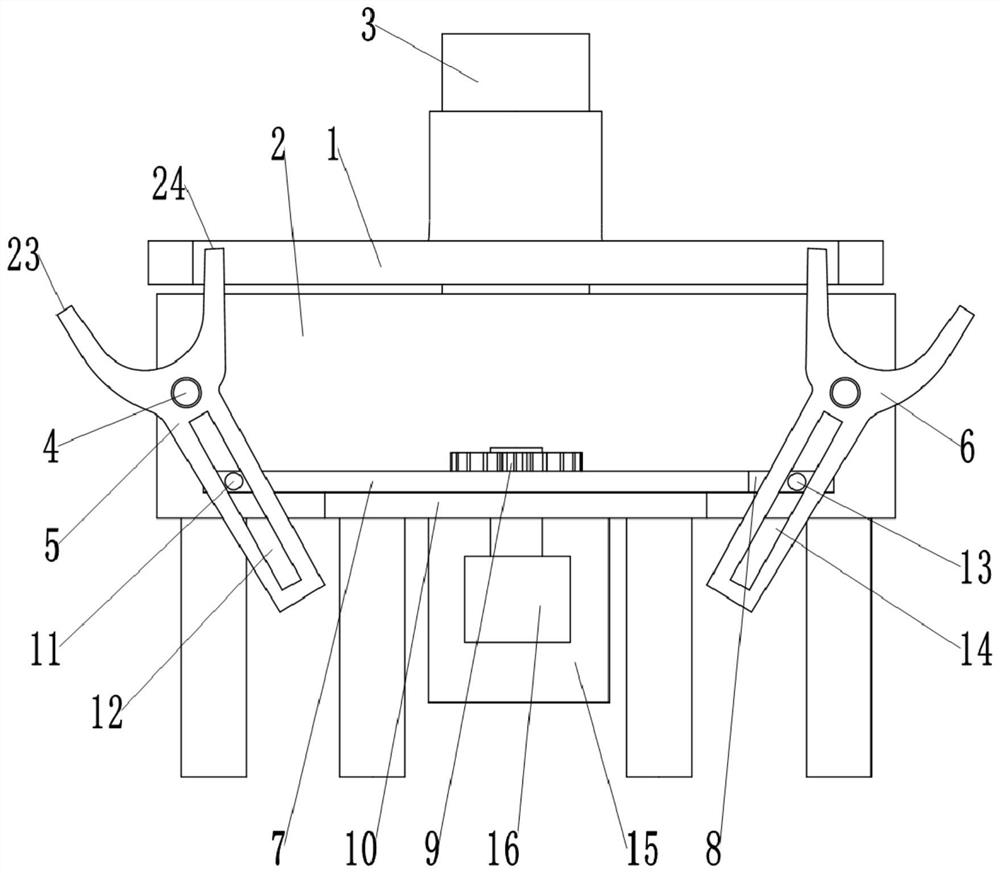

Portable automatic oral medicine grinding machine

PendingCN110124827AIncrease frictionMilling speed is fastOral administration deviceGrain treatmentsOral medicineSpherical shaped

The invention relates to a portable automatic oral medicine grinding machine comprising an upper mold, a lower mold, a transmission structure and a fixing base. The lower surface of the upper mold isin a convex spherical shape, a cone shape or a column shape, the lower surface of the upper mold is matched with the concave upper plane of the lower mold, the upper mold or the lower mold is fixed tothe output end of the transmission structure and can be rotated or moved along with the output end of the transmission structure, that is, the lower mold or the upper mold relatively fixed on the corresponding end of the fixing base is rotated or moved so that tablets located between the upper mold and the lower mold can be extruded and rubbed one time or many times to form granular powder, the transmission structure is driven by a gear motor to start or stop a power supply to control operation of the grinding machine, and the fixing base can limit the positions of the upper mold, the lower mold and the transmission structure. By means of the design, the portable automatic oral medicine grinding machine has the beneficial effect that the upper mold can be moved or rotated relative to thelower mold to grind the tablets between the upper mold and the lower mold, manpower is not needed for grinding the tablets into the powder, the motor is directly used for driving for grinding the tablets, and time and labor are saved; and the motor can repeatedly rotate positively and negatively to achieve repeated grinding, the grinding effect is better, and the tablets can be ground to be finerand more even.

Owner:THE FIRST AFFILIATED HOSPITAL OF WENZHOU MEDICAL UNIV

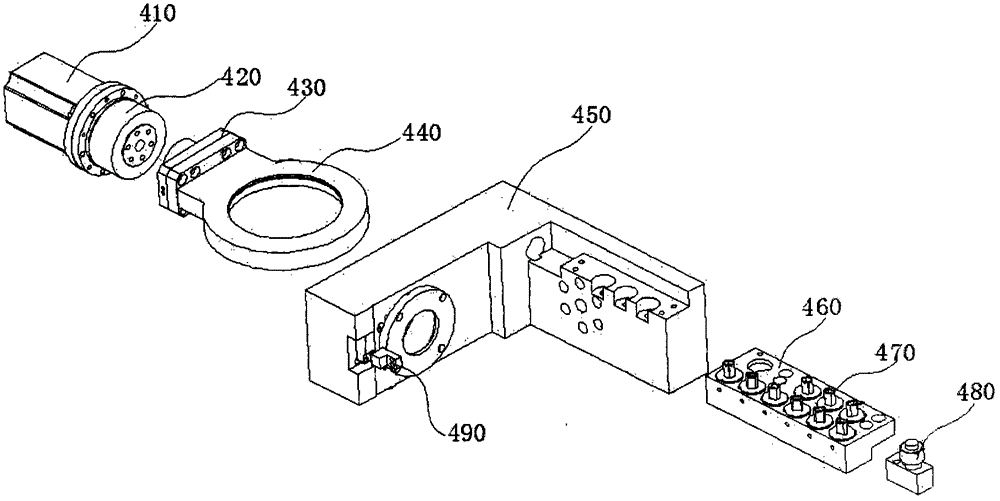

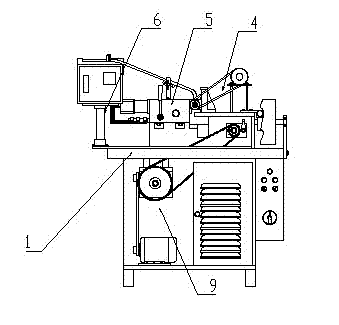

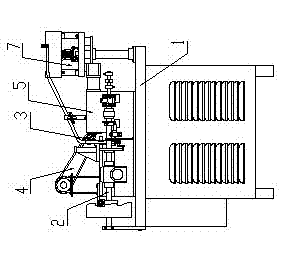

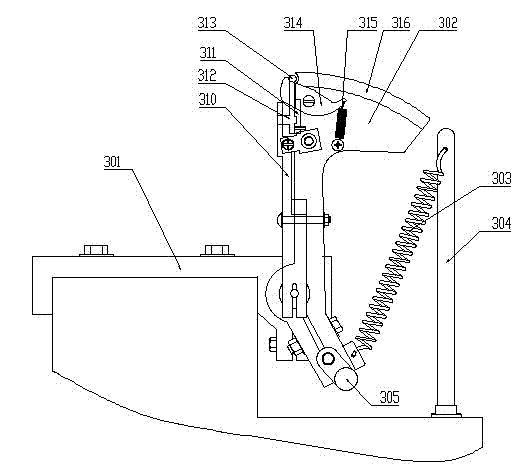

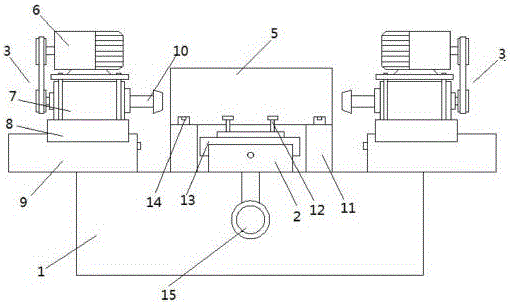

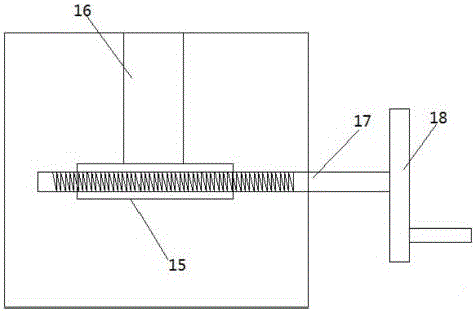

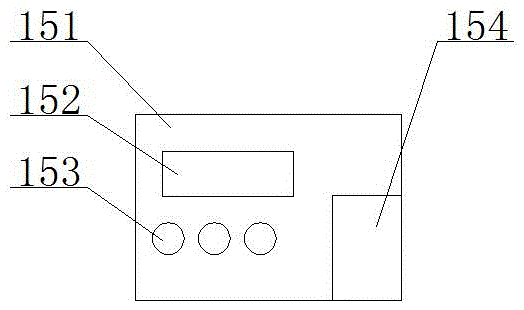

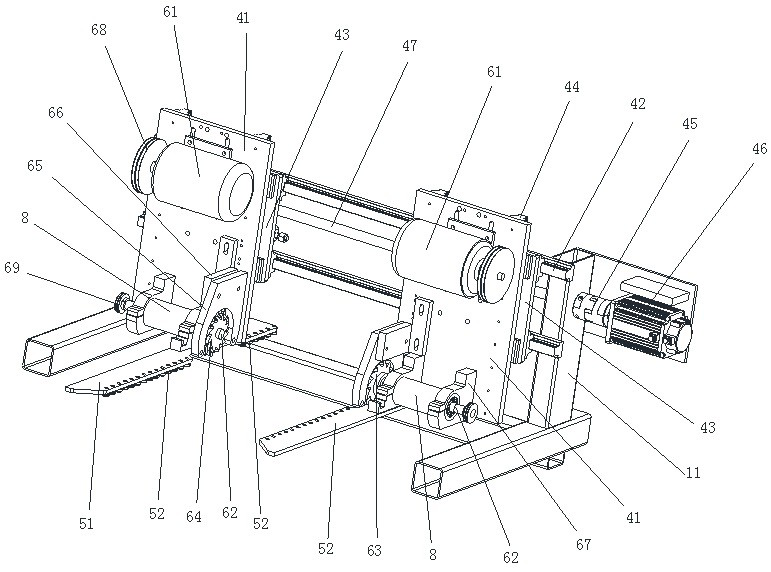

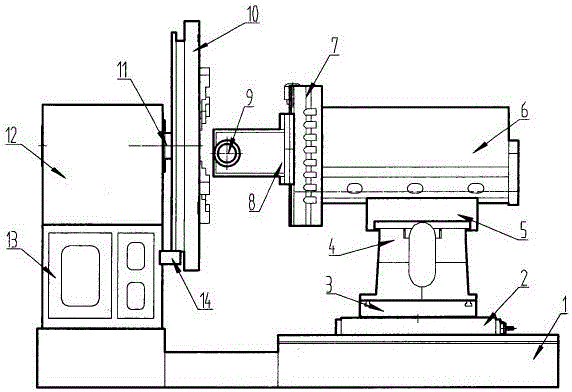

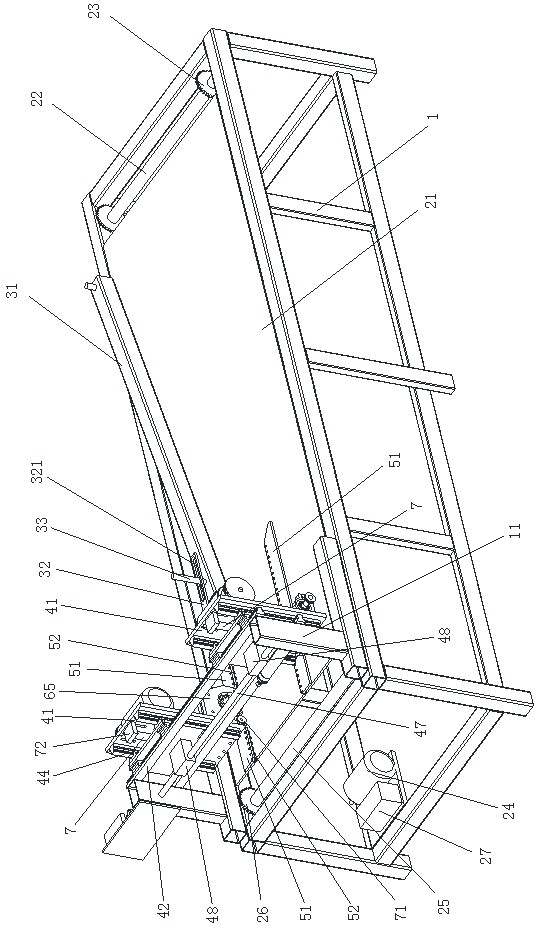

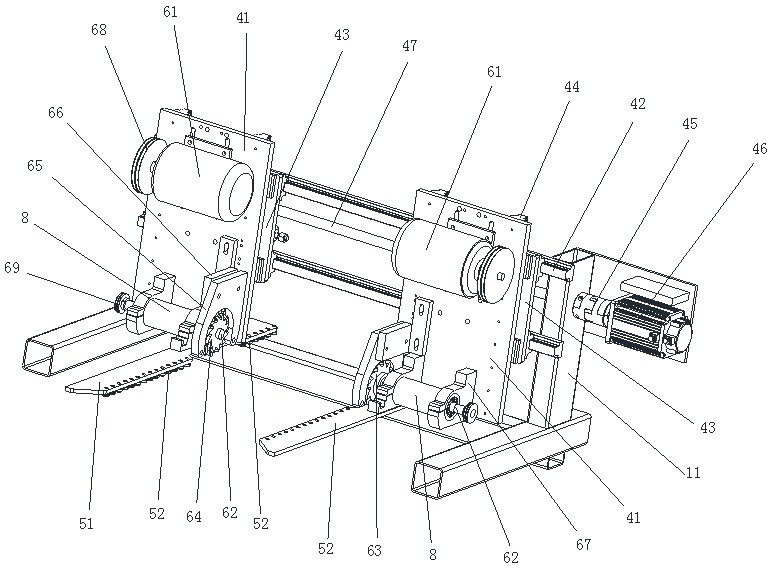

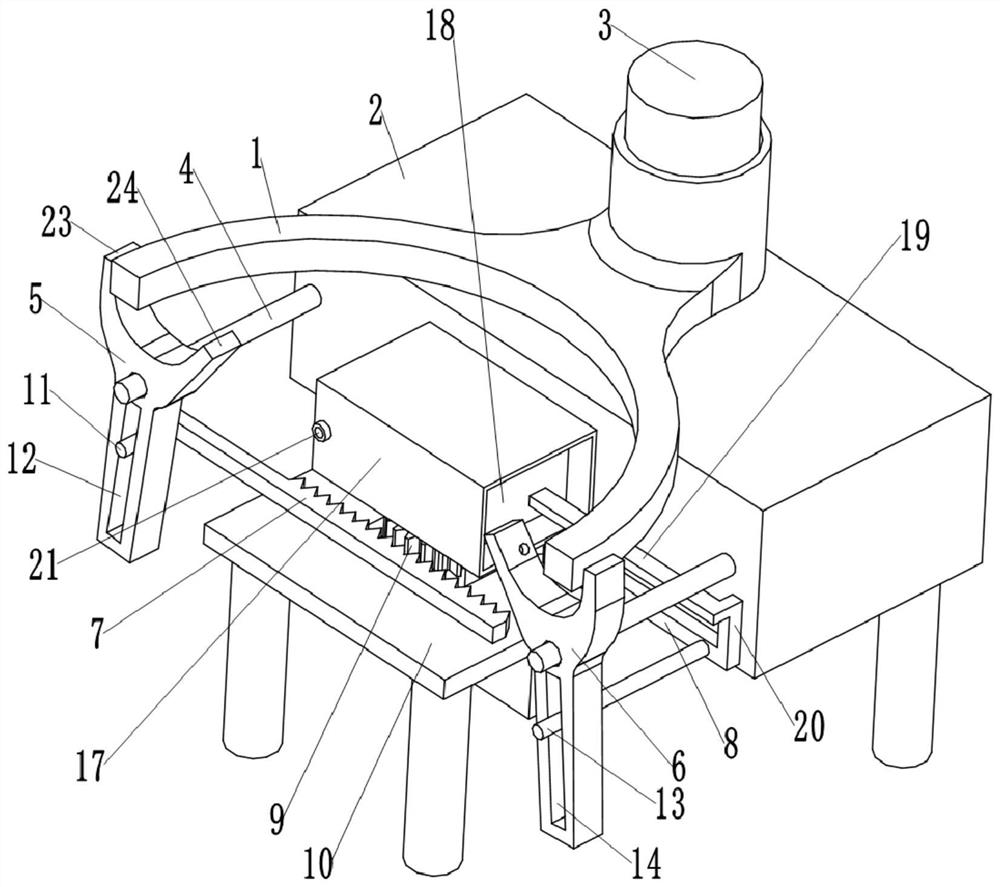

Numerical control slot milling machine for processing copper tailstock of optical fiber connector

InactiveCN102632286AReduce vibrationImprove efficiencyLarge fixed membersMilling equipment detailsNumerical controlEngineering

The invention relates to a numerical control slot milling machine for processing a copper tailstock. The slot milling machine comprises a rack, a main shaft, a feed mechanism, a mechanical arm mechanism, a clamp mechanism, a cutter mechanism, a power mechanism, a transmission mechanism and a numerical control sense mechanism, wherein the feed mechanism, the mechanical arm mechanism, the clamp mechanism, the cutter mechanism, the power mechanism, the transmission mechanism and the numerical control sense mechanism are installed on the rack; the power mechanism is connected with the transmission mechanism; the numerical control sense mechanism is connected with main shaft; and the cutter mechanism is connected with the main shaft. The numerical control slot milling machine for processing the copper tailstock is characterized in that the mechanical arm mechanism comprises a mechanical arm base, an oscillating bar, a chuck, a chuck spring, a bend board, a connecting rod, a shaft base, a push rod device, a cam device, a cullis, a scraping wing, a fixed rod, an oscillating bar spring, a connecting sliding column and an oscillating bar. The numerical control slot milling machine for processing the copper tailstock is high in automation degree, high in work efficiency, high in slot milling precision and high in slot milling speed.

Owner:HANGZHOU GUANHE MACHINERY MFG

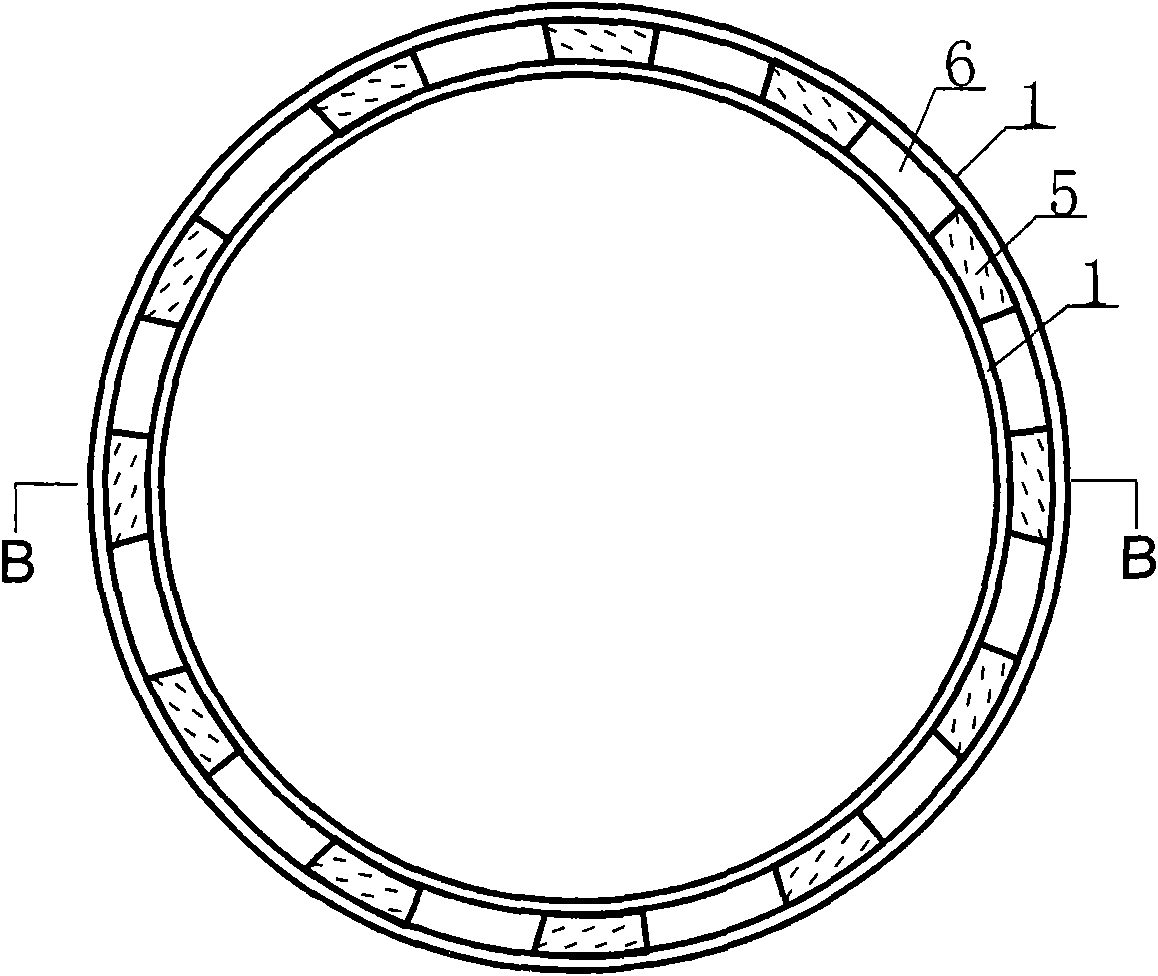

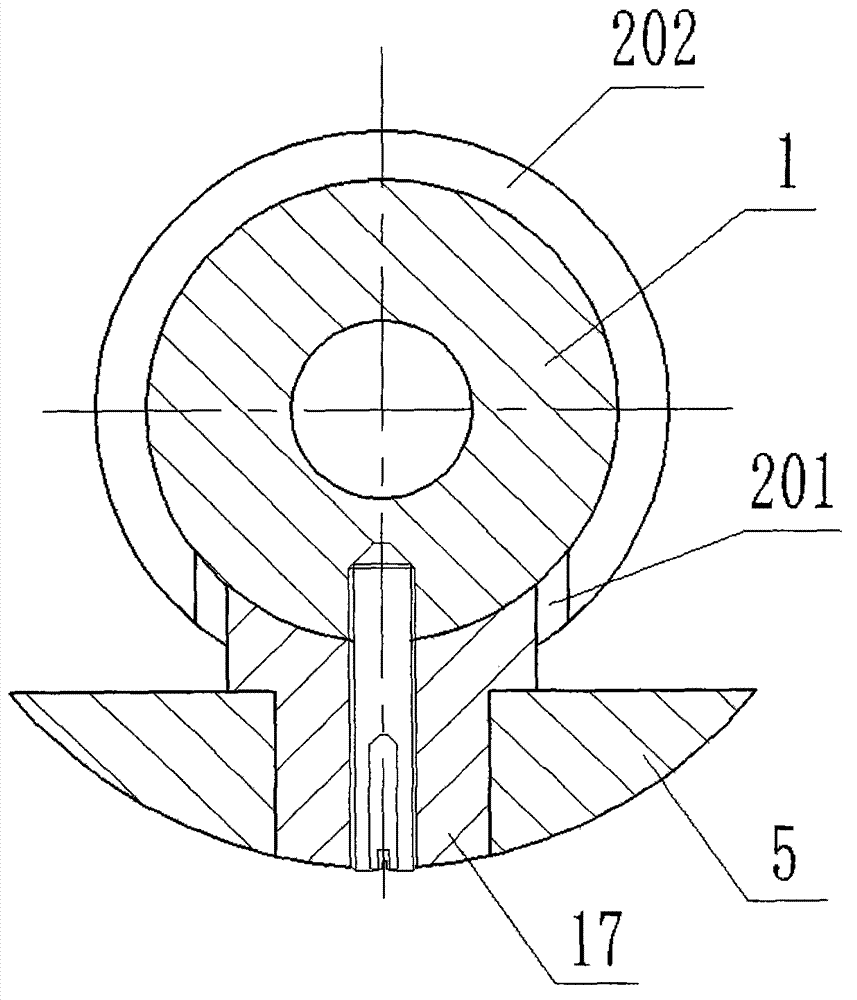

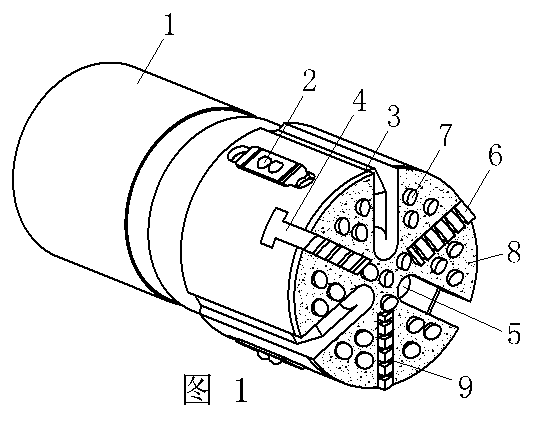

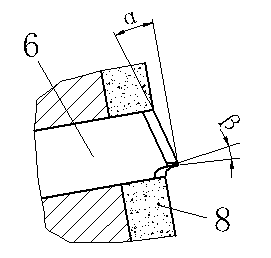

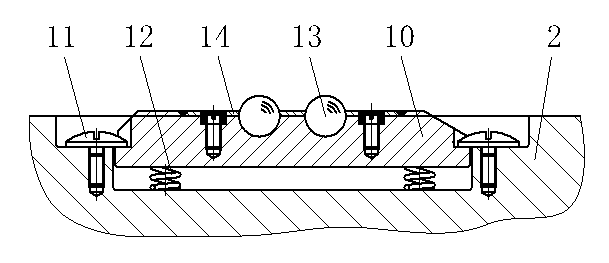

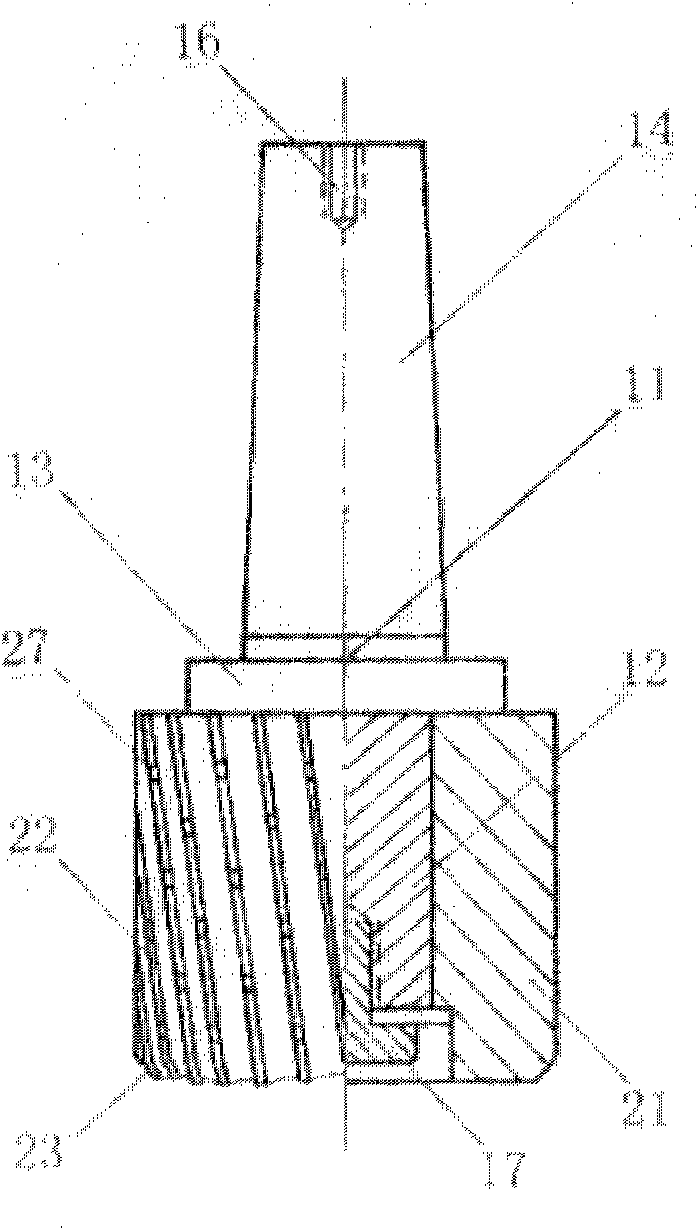

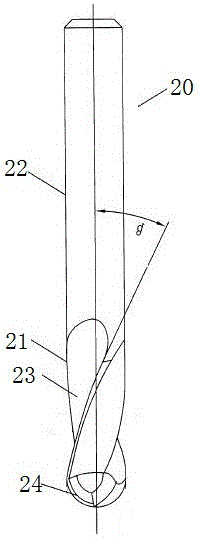

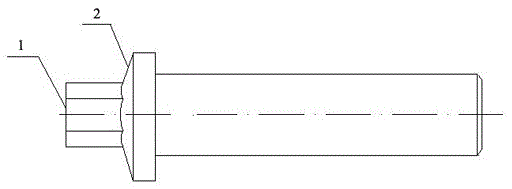

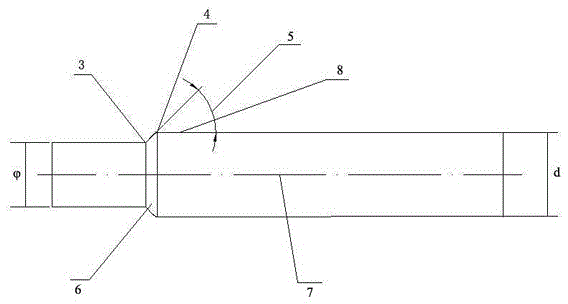

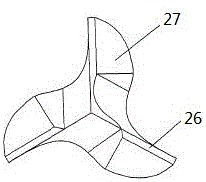

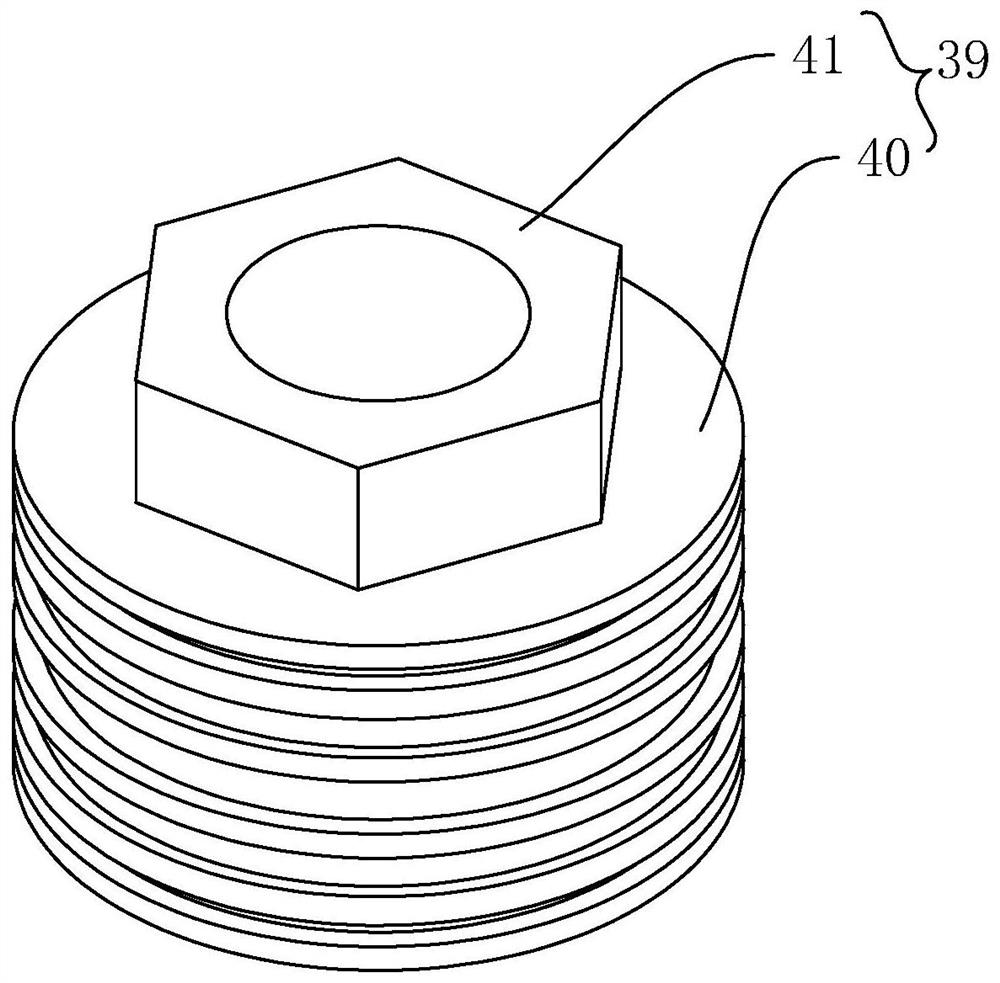

Grinding shoe used for grinding and milling under the shaft of oil field and manufacturing method thereof

The invention discloses a grinding shoe used for grinding and milling under the shaft of an oil field and a manufacturing method of the grinding shoe. The grinding shoe comprises a grinding shoe body, a hard alloy column is fixed to the bottom of the grinding shoe body, the grinding shoe body is manufactured in a cylinder shape, a set of centralizers with roll balls is evenly distributed on the cylinder surface of the grinding shoe body in the circumferential direction, and the roll balls of the centralizers with the roll balls can roll; meanwhile, a set of T-shaped grooves is evenly distributed on the cylinder surface of the grinding shoe body in the circumferential direction, and a T-shaped cutting blade is installed in each T-shaped groove. The grinding shoe is free of eccentric abrasion at work, and the frictional resistance between the grinding shoe and a casing wall is small. The T-shaped cutting blades are matched with the T-shaped grooves in the grinding shoe body, so that the blades do not fall off; the angle alpha is formed on the rear blade face of each T-shaped cutting blade, and the angle beta is formed on the front blade face of each T-shaped cutting blade, so that rapid chip breaking is achieved in the grinding and milling process, and scrap iron can be rapidly washed away by mud; because a groove is formed in each T-shaped cutting blade, when the cutting edge of one blade is broken, the blade will not fracture wholly.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

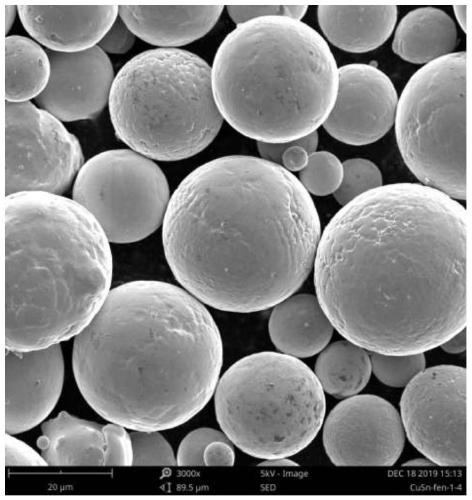

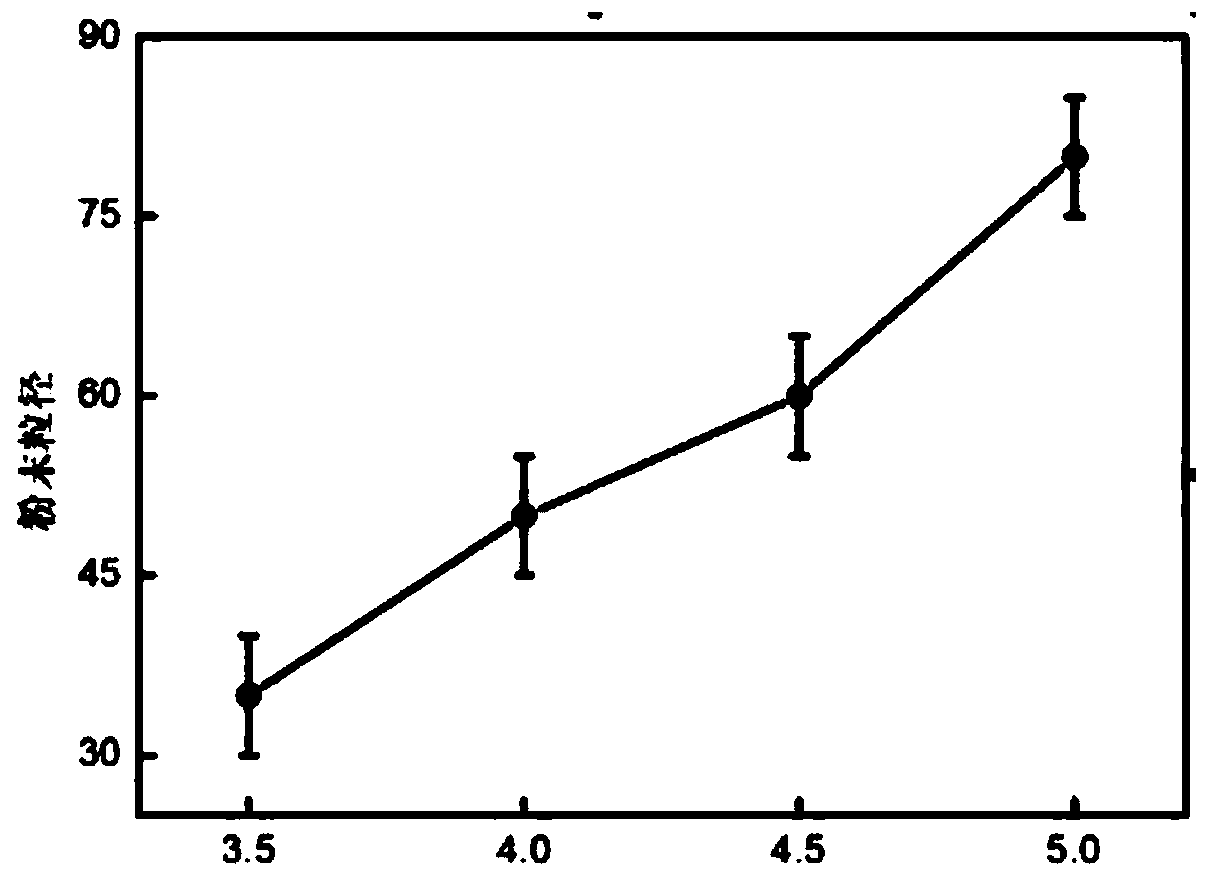

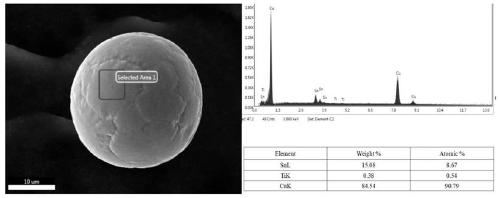

Preparation method of particle size controllable type copper-tin prealloy powder with ultrahigh tin content

The invention discloses a preparation method of particle size controllable type copper-tin prealloy powder with an ultrahigh tin content. The preparation method comprises the following specific stepsthat 1, according to the mass percentage, 77.5%-83.0% of cupper powder, 16.6%-22.1% of Sn powder and 0.4% of Ti powder are fetched in a weighed manner, and all the ingredients are mixed and made intoa cold pressing blank; 2, a crucible is pretreated, the diameter of a nozzle is controlled to be 3.5-5.0 microns, and the cold pressing blank is placed in the crucible; 3, atomizing deposition is conducted, and alloy powder is obtained; and 4, the alloy powder is screened with multiple screen nets, and then the particle size controllable type copper-tin prealloy powder with the ultrahigh tin content is obtained. The particle size of the copper-tin prealloy powder is controllable, the powder is dense, and hollow powder is avoided; by utilizing the copper-tin prealloy powder to prepare copper-tin alloy for superconduction, the problem of insufficient tin content is solved, and the tin is evenly distributed in the alloy.

Owner:XIAN UNIV OF TECH

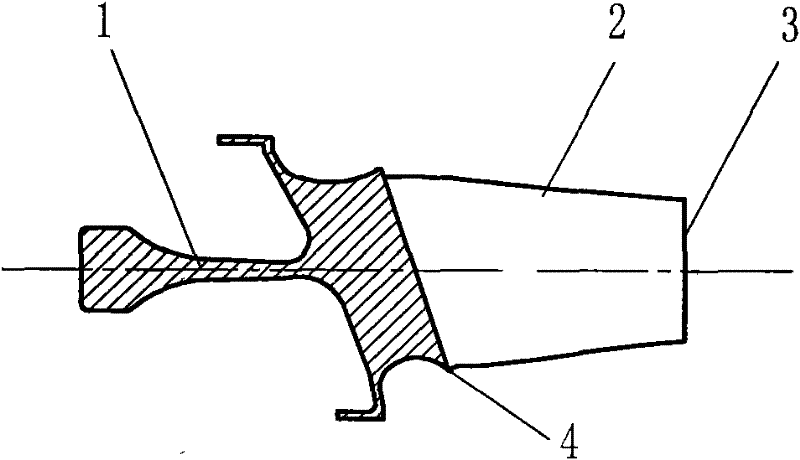

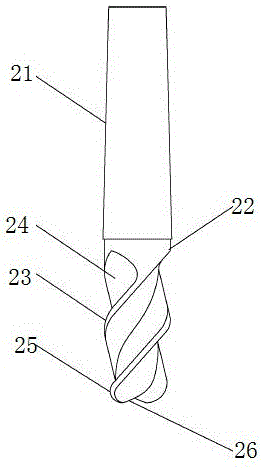

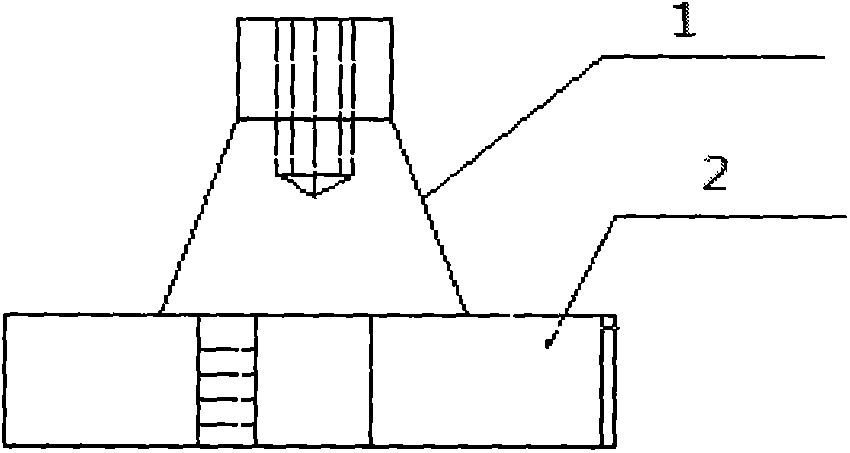

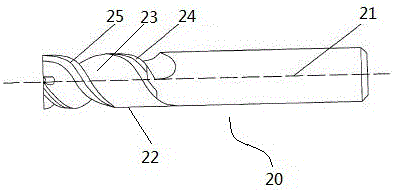

Method and milling cutter for repairing surface defect of cement concrete construction member

InactiveCN101876208AGuaranteed cutting forceGuaranteed StrengthBuilding repairsCeramic shaping apparatusMilling cutterArchitectural engineering

The invention discloses a method and a milling cutter for repairing surface defect of a cement concrete construction member, which is used for repairing the surface defects of the building construction members, such as cement concrete wall, piers, girders, plates and the like. For defects of cracks, local damage, voids and pits and the like on the surface of the building construction member, the method and the special milling cutter of the invention firstly remove defects, form a repairing groove and pour concrete again to repair. The method and the milling cutter of the invention can process the surface of the construction member into geometry, such as a plane, a cambered surface, a groove and the like, and especially processes the boundary surface of the repairing groove into regular, smooth, rough and circular-arc corner, which is favourable for construction stress and combination of new and old concrete, improves appearance quality and solves the difficulty problem that the surface of the cement concrete construction member is difficult to repair.

Owner:HEFEI UNIV OF TECH

Method for milling and vibration-damping blisk

InactiveCN101912990BImprove processing rigidityHigh milling feed rateMilling equipment detailsMaintainance and safety accessoriesFilling materialsEngineering

The invention belongs to the technical field of machining and discloses a method for milling and vibration-damping a blisk. The method comprises the following specific process steps of: (1) preparing a filling material according to the proportion; (2) melting the filling material; (3) mounting a pouring clamp; (4) pouring a filling agent; (5) condensing the filling agent at normal temperature, secondarily condensing the filling agent and checking the condensing state of the filling agent; (6) mounting a filtering clamp; and (7) carrying out the abutted milling processing and chip removal processing. By pouring the filling agent between the blisk and vanes in the milling processing of vane profile five coordinates of the blisk, the method enhances the rigidity of parts in the milling processing of the vanes, eliminates the chatter marks generated at the vent tip part of the vanes during milling and reduces the roughness of the surfaces of the vanes. Meanwhile, the rigidities of the parts and a clamping system thereof are enhanced, so that the milling feed rate is increased and the milling speed can be improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method and device for preparing single-phase nano epsilon-Fe3N or gamma'-Fe4N powder

InactiveCN101920943AImprove evaporation efficiencyMilling speed is fastNitrogen-metal/silicon/boron binary compoundsVacuum pumpingHydrogen

The invention relates to a method and a device for preparing single-phase nano epsilon-Fe3N or gamma'-Fe4N powder, and the device consists of a plasma evaporation powder making system, a powder collecting and modifying system, a vacuum system and a circulating system. The process steps for preparing the single-phase nano epsilon-Fe3N or gamma'-Fe4N powder are as follows: carrying out vacuum pumping and forced gas circulation, then carrying out plasma evaporation powder making, further carrying out powder modification, controlling the volume flow ratio of ammonia to hydrogen to be (1.4-1.6): 1, controlling the temperature in a powder trapping room at 345-355 DEG C, keeping the temperature for 5-7h, and obtaining the nano single-phase gamma'-Fe4N powder; and controlling the volume flow ratio of the ammonia to the hydrogen to be (2.4-2.6): 1, controlling the temperature in the powder trapping room at 445-455 DEG C, keeping the temperature for 1-3h and obtaining the nano single-phase epsilon-Fe3N powder. The method and the device can ensure that the product is the high-purity single-phase nano iron nitride powder through the precise control of reaction atmosphere.

Owner:NORTHEASTERN UNIV LIAONING

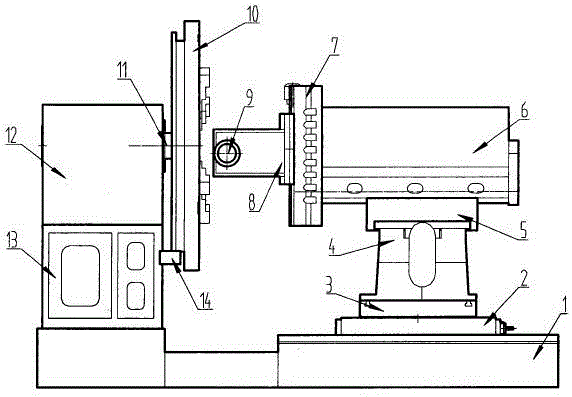

Improved milling machine for machining automobile moulds

InactiveCN106001712AMilling speed is fastWide range of applicationsMilling cuttersMilling machinesElectric machineryDrive motor

The invention discloses an improved milling machine for machining automobile moulds. The improved milling machine for machining the automobile moulds comprises a milling machine base, wherein a workpiece fixing seat and milling cutter mechanisms are arranged on the milling machine base; a transmission mechanism is arranged in the milling machine base; the workpiece fixing seat is provided with a workpiece plate; positioning blocks are arranged on the workpiece plate; each milling cutter mechanism comprises a milling cutter base, a power component and a milling cutter seat; a movable sliding table is mounted on each milling cutter base; each power component is fixedly arranged on the corresponding movable sliding table; the power components are connected with each other in a driving manner through a driving motor; each milling cutter seat is arranged on an output shaft of the corresponding power component; and a milling cutter is mounted on the corresponding milling cutter seat. The milling machine replaces manual work, and is high in milling speed and wide in application range; labor intensity is reduced; work efficiency is improved; and machining quality is good.

Owner:SUZHOU ZHENYE MOLD

Chemical milling method for titanium alloy precisely-forged blades

The invention relates to a chemical milling method for titanium alloy precisely-forged blades. The chemical milling method comprises the steps that firstly, through measurement and grouping, the placewith the minimum blade thickness difference is protected through an acid-alkali-resistant protective adhesive; and then, each group of the blades are subjected to chemical milling correspondingly, the purpose of uniform margin removal of the blades is effectively achieved, and the profile tolerance and the degree of finish of the blades can meet the technological requirements. Consistency in margin removal is realized, the complex uniform margin removal work after finish forging is ended is avoided, the whole chemical milling protection process and method are simple and easy to control, and the profile tolerance and the degree of finish of the titanium alloy blades are guaranteed.

Owner:HARBIN DONGAN ENGINE GRP

Multi-layered sleeve windowing milling shoe

PendingCN111749636AEnsure safetyConnected pressure balanceBorehole/well accessoriesPilot holeWell control

The invention provides a multi-layered sleeve windowing milling shoe. The milling shoe is constituted by a milling shoe blank, a pressure transmission sleeve, a pressure transmission plug, a bronze tube, and a pilot hole milling shoe; and the upper part of the milling shoe blank is in a shape of a drill rod fastener and is connected with an upper part drilling tool. The milling shoe is characterized in that, the milling shoe blank is of a hollow structure; a ledge is arranged at the upper end of the inner wall of the milling shoe blank; an annular groove is formed in the middle part of the outer wall of the milling shoe blank and forms an annular gap with the inner wall of the milling shoe blank; a pressure plug hole is formed in the upper end of the milling shoe blank and penetrates through the blank to communicate with the annular groove; and a flexible milling shoe is fixed on the circumference of the lower end outer surface of the milling shoe blank, and the pilot hole milling shoeis fixed at the bottom of the blank. According to a unique production design of the multi-layered sleeve windowing milling shoe, in the drilling process, liquid inside and liquid outside a drilling pillar communicate with each other, and well control safety is ensured because the inside communicates with the outside of a drilling tool; and even in case of well control risks, circulating equipressure well treatment is convenient to conduct. The unique design of the pilot hole milling shoe and the flexible milling shoe improves the milling speed and enhances the milling stability.

Owner:合力(天津)能源科技股份有限公司

Precision control mechanism for milling aluminum alloy thin-wall part

ActiveCN113798915AAvoid errorsLower resistanceAutomatic control devicesFeeding apparatusMilling cutterEngineering

The invention relates to the technical field of aluminum alloy milling, and provides a precision control mechanism for an aluminum alloy thin-wall part milling. The precision control mechanism comprises a base. The top of the base is movably connected with a milling mechanism, the inner wall of the milling mechanism is rotationally connected with a milling cutter, the top of the milling cutter is fixedly connected with a milling rotating mechanism, and the outer wall of the milling rotating mechanism is movably connected with a ring sleeve clamp. According to the precision control mechanism for milling the aluminum alloy thin-wall part, at the beginning, the milling cutter normally rotates, a sliding block stretches a centrifugal spring under the action of centrifugal force, when the milling speed of the milling cutter is reduced, the sliding block gets close to the position of a rotating shaft under the action of the elastic force of the centrifugal spring, the sliding block jacks up a ring sleeve layer through a linkage rod, the ring sleeve layer jacks up a ring sleeve clamp, the ring sleeve clamp slides along a vertical rail and changes the height of a pull block through a lever, the pull block pushes a pull plate through a top spring, the pull plate moves to reduce the resistance value of a rheostat, and the rotating speed of the milling cutter is increased.

Owner:扬州市吉奥米金属制品有限公司

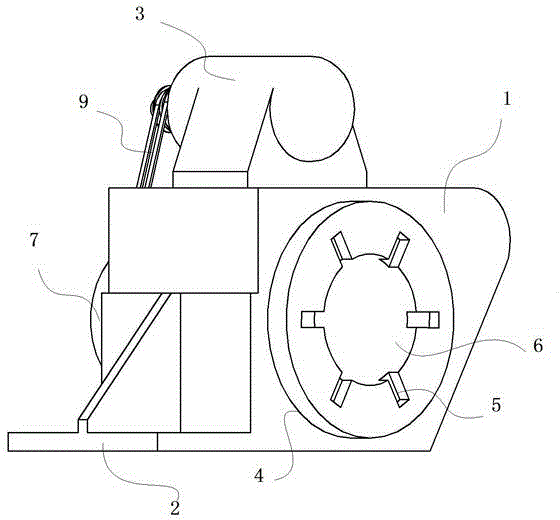

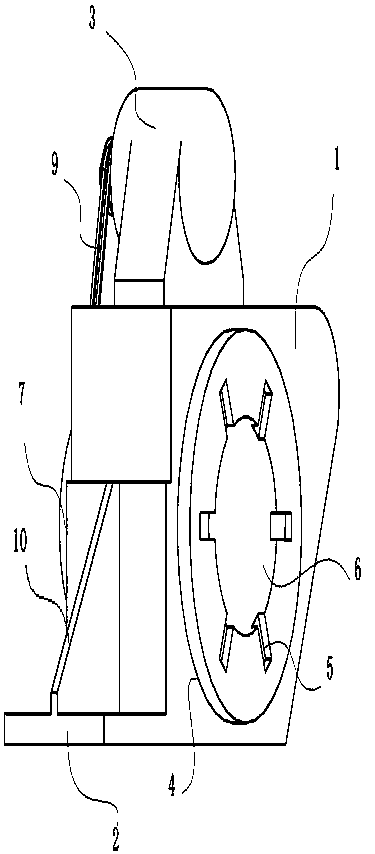

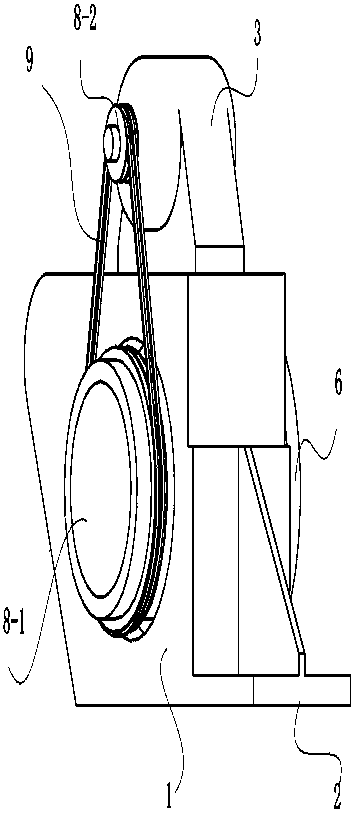

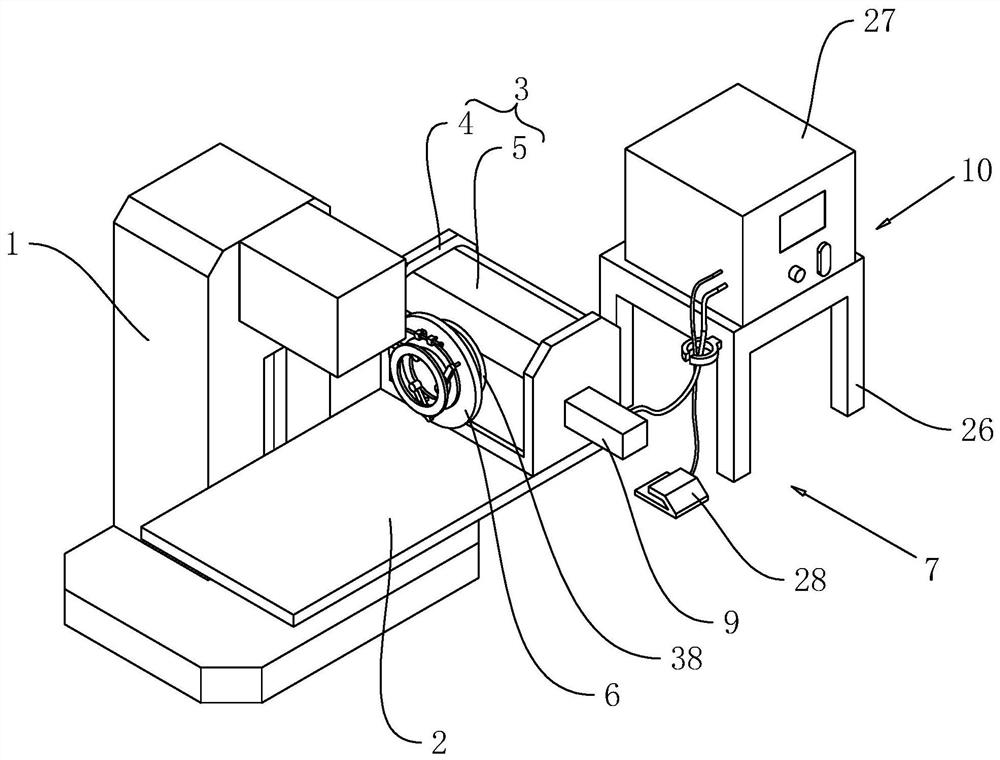

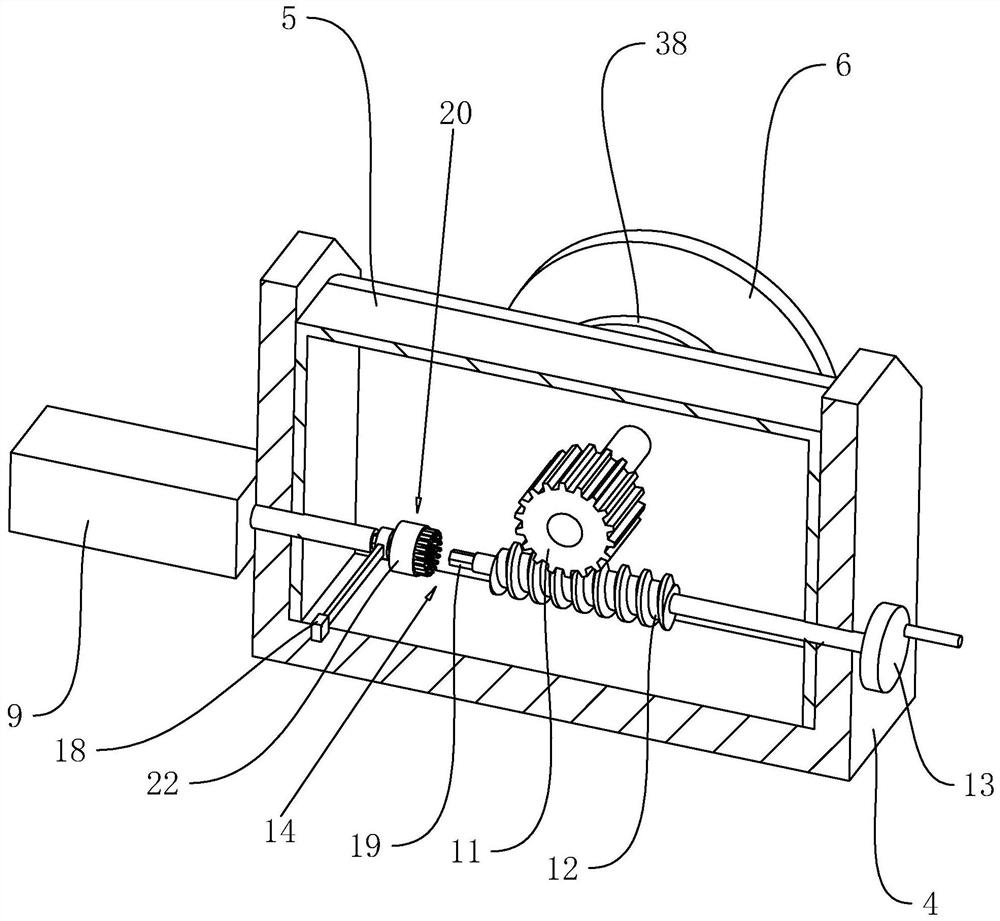

Whirlwind milling device

InactiveCN105598535ALow costReduce expertiseThread cutting auxillary apparatusSurface roughnessEngineering

The invention relates to a whirlwind milling device. The whirlwind milling device consists of a milling body, a base and a motor, wherein a high-speed rotating cutter is arranged in the milling body and consists of at least six forming tools; a main shaft is arranged in the milling body; a chuck is arranged on the main shaft; a first rotary shaft is arranged at one end of the milling body; the periphery of the first rotary shaft is wrapped in a belt; a second rotary shaft is arranged at one end of the motor; the high-speed rotating cutter drives the rotary shafts to move at high speed through a belt on the motor; the rotating axis of the high-speed rotating cutter is inclined at a helix lead angle relative to the axis of a workpiece. By the adoption of the structure, the machining efficiency is high, and compared with the conventional processing efficiency, the processing efficiency can be improved by over 10 times; a product is formed by one-time tool operation, and eccentric cutting without tool retraction is achieved, so that the accuracy is high; a whirlwind mill made through modification of a lathe does not change the structure of the lathe, the helix lead angle is adjustable, and the device is convenient to mount; the investment cost for special equipment is reduced; the surface roughness can reach Ra0.8 micron, and the processing accuracy is improved by 2 levels; the axial feed speed of the lathe is low, so that the lathe is easy to operate, and the requirement on the professional skill of a worker can be reduced.

Owner:泰州三羊重型机械有限公司

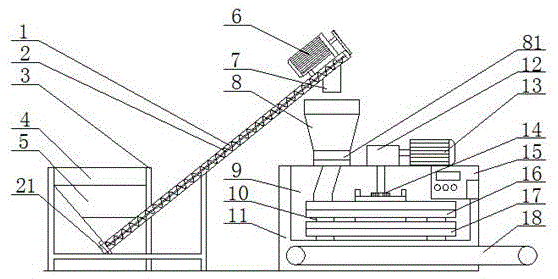

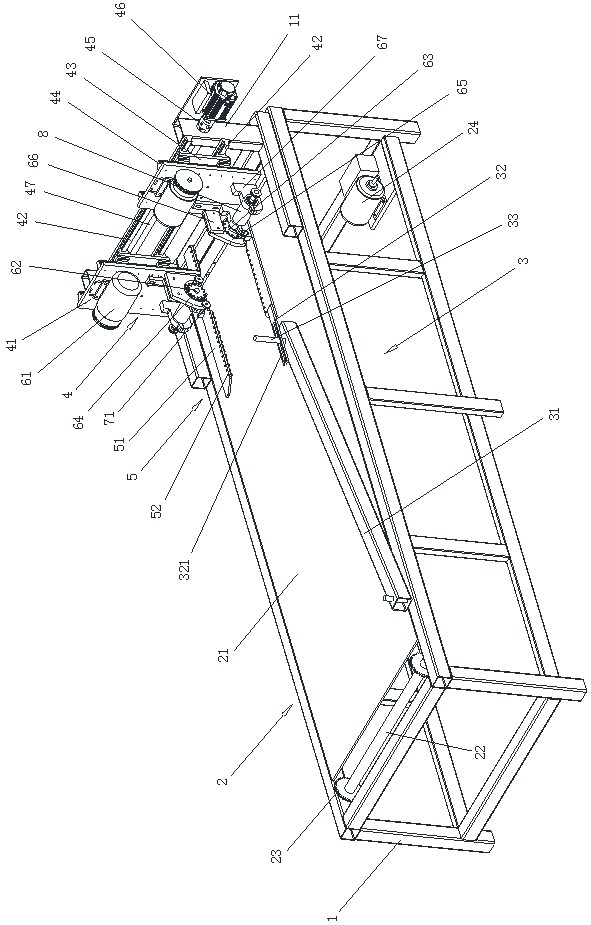

Efficient tea oil seed milling device

InactiveCN105567414AAvoid cloggingSave human effortFatty-oils/fats productionCharge controlMaterial resources

The invention discloses an efficient tea oil seed milling device which comprises a feeding pipe. The feeding pipe is mounted above a feeding support. A feeding spiral rod is arranged inside the feeding pipe. A feeding mechanism is arranged below the feeding pipe. A feeding hopper is arranged on the feeding mechanism. A feeding motor is arranged above the top of the feeding pipe. A discharge outlet is arranged below the top of the feeding pipe. A batch charging hopper is arranged below the discharge outlet and fixed above a machine box through bolts. A batch charging control valve is arranged at the bottom of the batch charging hopper. A milling motor is arranged above the right side of the machine box. A reduction box is arranged on the left side of the milling motor. A control box is arranged on the right side of the machine box. A milling box is arranged in the machine box. The efficient tea oil seed milling device has the advantages that automatic processing is achieved through the feeding mechanism, the milling box and a discharge conveying belt, processing efficiency is increased, production speed is increased, and a large amount of manpower and material resources is saved.

Owner:HENGYANG ZHIYUAN AGRI TECH

Method for thermally upsetting and forming flange plate bolt head

The invention discloses a method for thermally upsetting and forming a flange plate bolt head. The method comprises the following steps: turning raw materials into shapes of steps; reducing the diameters of material for forming a hexagonal head to phi=S-sigma-alpha by turning, wherein S is the dimensions of opposite sides of a hexagon, sigma is thermal expansion and shrinkage amount of the material, alpha is a dislocation value of upper and lower die holders used in a thermal upsetting process, and hexagonal small-diameter parts, connected transition inclined surfaces and un-reduced large-diameter parts on raw materials are formed by reducing through turning; and finally, regulating a heating temperature of hexagonal small-diameter parts in the thermal upsetting process to be a heating temperature required for thermally upsetting to form a flange plate part on the raw materials, thereby thermally upsetting and forming the flange plate bolt head. The method has the characteristics of being high in milling speed, good in surface quality, short in period, high in benefit and low in cost, and has the characteristic that folding is not generated at junctions of a hexagonal part and a flange plate, and a product can be upset fully.

Owner:AVIC STANDARD PARTS MFG

Automatic edge milling machine for aluminum alloy formwork

ActiveCN112091295AClose contactEliminate tolerance build-upMilling machinesMilling equipment detailsDrive shaftMachine

The invention discloses an automatic edge milling machine for an aluminum alloy formwork. The machine comprises a rack, a feeding device, a leading-in mechanism, a sizing and distance adjusting mechanism, a guide positioning mechanism, pre-tightening mechanisms, two edge milling mechanisms and an electric control system, wherein the feeding device is arranged at the upper part of the rack and comprises a support plate, a feeding belt, a driving shaft, a driven shaft and a driving mechanism. The driving shaft and the driven shaft are oppositely arranged on the rack and connected through the feeding belt. The sizing and distance adjusting mechanism comprises two adjustable workbenches, the two adjustable workbenches are adjustably and fixedly connected with the rack, and the pre-tightening mechanisms are arranged on the rear sides of the adjustable workbenches. The guide positioning mechanism comprises two guide plates which are symmetrically arranged, and two sets of side guide wheels are arranged on the opposite sides of the two guide plates respectively. The two edge milling mechanisms are arranged on the two adjustable workbenches in a bilateral symmetry mode. Automatic continuous feeding, automatic guiding alignment and one-time multi-edge cutting are achieved, the cutting speed is high, the machining precision is high, the production cost is low, and the production efficiency is high.

Owner:YANTAI ZHONGCHENG NEW BUILDING

Milling machine for automobile die machining

InactiveCN106392151AMilling speed is fastWide range of applicationsMilling cuttersMilling machinesEngineeringMilling cutter

The invention discloses a milling machine for automobile die machining. The milling machine comprises a milling machine base. A stroke slide carriage is arranged on the milling machine base and provided with a rotary disc. A milling cutter three-dimensional device is arranged on the rotary disc and comprises a first guide rail, a second guide rail, a third guide rail and a milling cutter spindle, and the first guide rail is fixedly mounted on the rotary disc. The second guide rail is fixedly mounted on the first guide rail, and the third guide rail is fixedly mounted on the second guide rail. The milling cutter spindle is fixedly mounted on the third guide rail and provided with a milling cutter. A workbench is further arranged on the milling machine base and corresponds to the milling cutter three-dimensional device. According to the milling machine, a machine is used for replacing manpower, the milling speed is high, the application range is wide, the labor intensity is reduced, the work efficiency is improved, and the machining quality is good.

Owner:SUZHOU ZHENYE MOLD

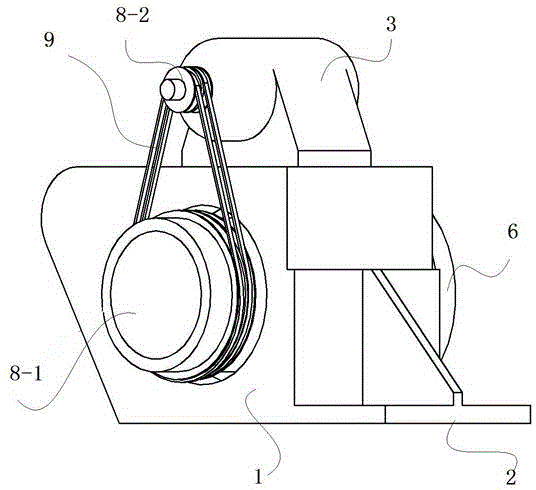

Cyclone milling device high in precision

InactiveCN107755831ALow costProfessional skills can reduceThread cutting machinesCycloneMilling cutter

The invention relates to a whirlwind milling device with high precision, which is composed of a milling body, a base and a motor. The milling body is equipped with a high-speed rotating cutterhead, which is composed of at least six forming knives. The milling body is equipped with The main shaft is equipped with a chuck, one end of the milling body is equipped with a rotating shaft, and the periphery of the rotating shaft is covered with a belt, and one end of the motor is equipped with a rotating shaft. The high-speed rotating cutterhead drives the rotating shaft to move at high speed through the belt on the motor. A helix angle is inclined relative to the workpiece axis, and the upper end of the base is fixed with a supporting steel sheet. After adopting the above structure, the processing efficiency is high, which can be increased by more than 10 times compared with the traditional processing efficiency; the product is formed by one knife, and the precision is high; Milling does not change the structure of the lathe, the helix angle is adjustable, and it is easy to install; it saves the cost of investing in special equipment; the surface roughness can reach Ra0. Expertise can be reduced.

Owner:徐秀阳

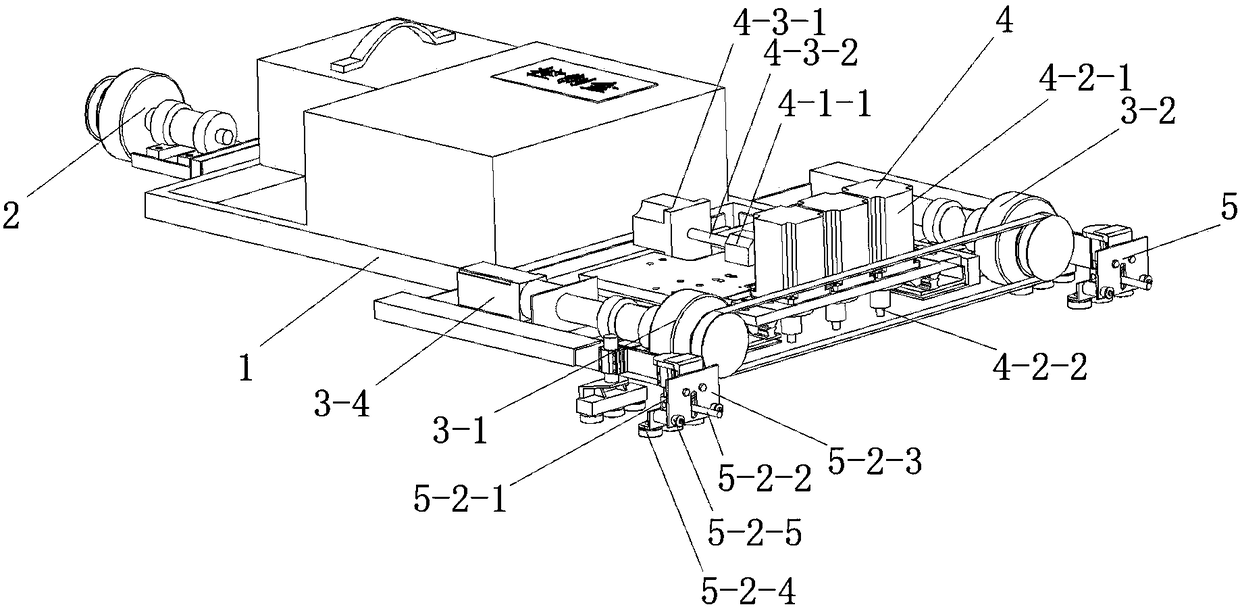

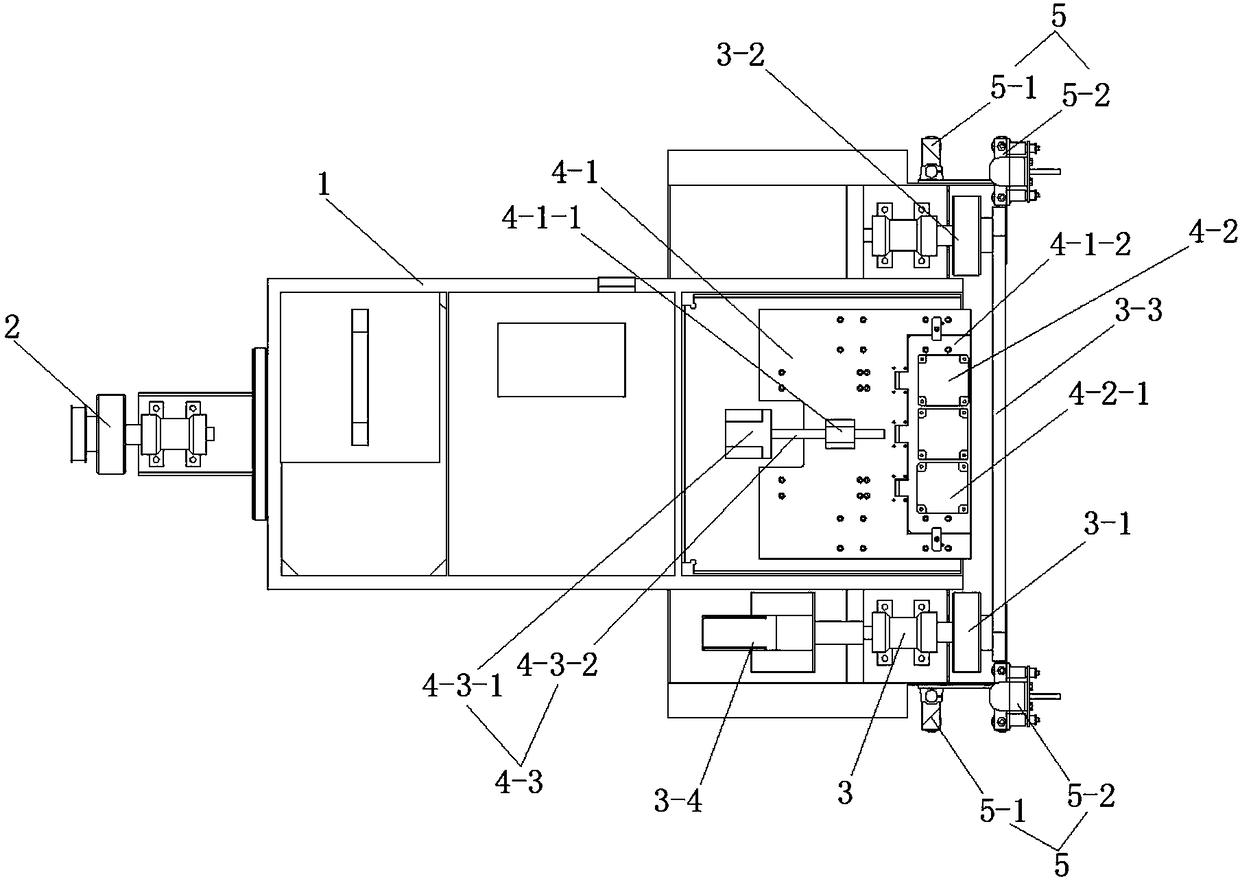

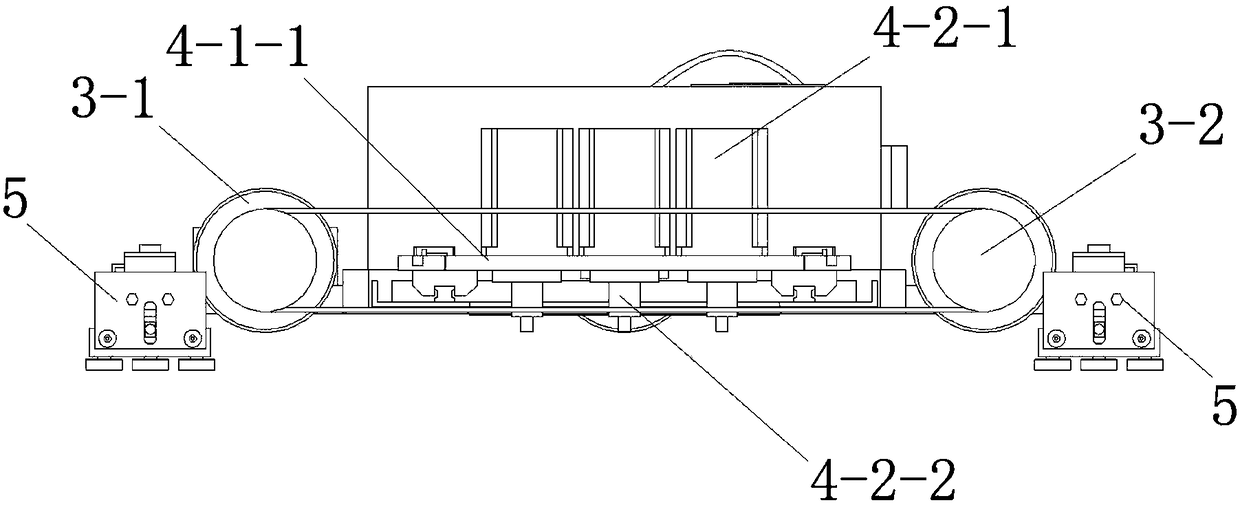

Steel rail fat edge milling device

PendingCN108515220AExtended service lifeIngenious structureWorkpiecesMilling equipment detailsVehicle frameMilling cutter

The invention discloses a steel rail fat edge milling device which comprises a frame, a working part and a supporting wheel, wherein the working part and the supporting wheel are separately mounted ontwo sides of the frame; the working part comprises a walking mechanism, a milling mechanism and a multi-guide wheel clamping mechanism; the walking mechanism and the supporting wheel are separately overlaid on two steel rails; the driving frame moves along the steel rails; the milling mechanism comprises a bottom plate, a milling cutter assembly and an adjusting assembly; the multi-guide wheel clamping mechanism clamps one steel rail and moves along the steel rails along with the frame; the bottom plate is slidably connected to the frame; the milling cutter assembly is mounted at the edge ofone side, facing the steel rails clamped by the multi-guide wheel clamping mechanism, of the bottom plate; and the adjusting assembly is used for adjusting the distance between the bottom plate and the steel rails clamped by the multi-guide wheel clamping mechanism and can fix the position of the bottom plate. The steel rail fat edge milling device disclosed by the invention is skillful in structure, high in degree of automation, more excellent in milling effect, high in milling speed, high in efficiency and longer in service life of a milling cutter. Compared with single-layered milling, reverse quake is smaller, and the structure is more stable.

Owner:CHANGZHOU HUAMING AUTOMATION TECH CO LTD +1

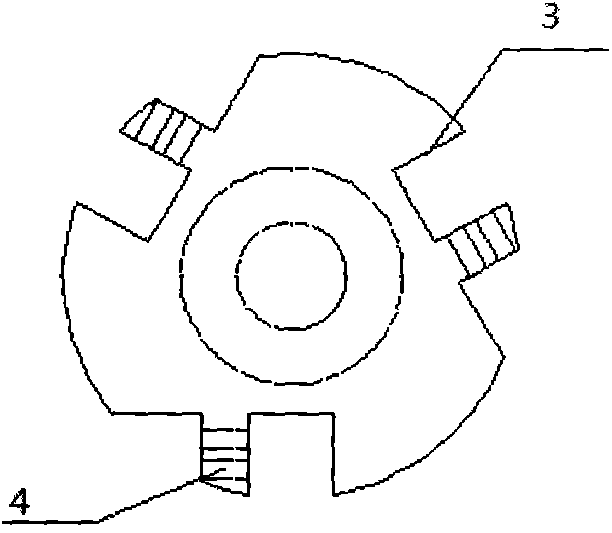

Step milling cutter

InactiveCN104741676AImprove processing efficiencyMilling speed is fastMilling cuttersTool bitMilling cutter

The invention discloses a step milling cutter, which comprises a knife handle, a base plate and 2-6 cutter bars, wherein the base plate and the cutter bars are connected with the knife handle 1 into a whole; 2-6 mounting grooves for mounting the cutter bars and a top thread hole for fixing the knife handle are formed in the base plate; a tool bit with cutter teeth is arranged at the other end, opposite to the knife handle, of each cutter bar along the axial direction of each mounting groove; the axial positions of the cutter bars in a cutter groove can be respectively adjusted; and cutting edges of the cuter bars can be located on a same plane, and can also be adjusted on different planes according to the cutting allowance. Through use of the step milling cutter disclosed by the invention, various workpices can reach high milling speeds in the milling process; time can be shortened; the labor force can be saved; and the processing efficiency of the workpices can be greatly improved.

Owner:武文斌

Milling machine used for automobile large-plane die

InactiveCN106392154AMilling speed is fastReduce labor intensityMilling cuttersMilling machinesMilling cutterEngineering

The invention discloses a milling machine used for an automobile large-plane die. The milling machine comprises a milling machine base, a stroke slide carriage is arranged on the milling machine base, a rotation disc is arranged on the stroke slide carriage, a milling cutter three-dimensional device is arranged on the rotation disc, and comprises a first guide rail, a second guide rail, a third guide rail and a milling cutter spindle, the first guide rail is fixedly mounted on the rotation disc, the second guide rail is fixedly mounted on the first guide rail, the third guide rail is fixedly mounted on the second guide rail, the milling cutter spindle is fixedly arranged on the third guide rail, and a milling cutter is arranged on the milling cutter spindle; a work table is arranged on the milling machine base, and corresponds to the milling cutter three-dimensional device. The milling machine is used for replacing manpower, the milling speed is high, the application range is wide, labor intensity is reduced, work efficiency is improved, and the machining quality is good.

Owner:SUZHOU ZHENYE MOLD

An aluminum alloy formwork automatic edge milling machine

ActiveCN112091295BClose contactEliminate tolerance build-upMilling machinesMilling equipment detailsDrive shaftStructural engineering

The invention discloses an automatic edge milling machine for an aluminum alloy template, which includes a frame, a feeding device, an introduction mechanism, a length-adjusting mechanism, a guiding and positioning mechanism, a pre-tightening mechanism, an edge milling mechanism and an electric control system. The feeding device is arranged on the machine. The upper part of the frame includes a support plate, a feeding belt, a driving shaft, a driven shaft and a driving mechanism. The driving shaft and the driven shaft are relatively arranged on the frame and connected by a feeding belt. The length-adjusting and distance-adjusting mechanism includes two adjustable workbenches, which are adjustable and fixedly connected with the frame, and the rear sides of the adjustable workbenches are equipped with pre-tightening mechanisms. The guide positioning mechanism includes two guide plates symmetrically arranged, and two sets of side guide wheels are respectively arranged on opposite sides of the two guide plates. There are two edge milling mechanisms, which are symmetrically arranged on two adjustable workbenches. The invention realizes automatic continuous feeding, automatic guiding and alignment, one-time multi-edge cutting, high cutting speed, high processing precision, low production cost and high production efficiency.

Owner:YANTAI ZHONGCHENG NEW BUILDING

Clamping fixture for milling forks

ActiveCN111036966BAchieve a fixed purposeMilling speed is fastMilling equipment detailsPositioning apparatusClassical mechanicsStructural engineering

Owner:贵州友擘机械制造有限公司

Milling machine used for efficiently machining hydraulic cylinder

ActiveCN112264816AImprove quality and efficiencyIncrease productivityMeasurement/indication equipmentsPositioning apparatusHydraulic cylinderCircular disc

The invention relates to the technical field of milling machines, in particular to a milling machine for efficiently machining a hydraulic cylinder. The milling machine comprises a machine body and aworkbench arranged on the machine body. One end of the workbench is provided with a clamping assembly used for clamping a sealing base. The clamping assembly comprises an installation base installed on the workbench and an installation cover fixed between the inner walls of the two ends of the installation base, a disc is rotationally arranged on the installation cover, a first driving assembly used for driving the disc to rotate is arranged on the installation base, and the clamping assembly used for clamping the sealing base is arranged on the side, away from the installation cover, of the disc. The milling machine has the effects that the labor intensity of workers is relieved, the milling speed is increased, and the milling quality and the production efficiency of a rod sleeve are improved.

Owner:浙江天工液压机械股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com