Cyclone milling device high in precision

A whirlwind milling, high-precision technology, applied in the direction of tangent devices, metal processing equipment, manufacturing tools, etc., can solve the problems of low precision, inconvenient installation, non-adjustable helix angle, etc., to achieve high precision, easy operation, and processing high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

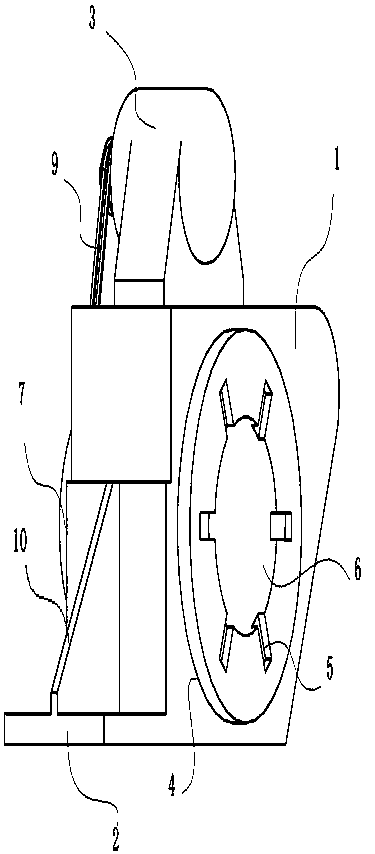

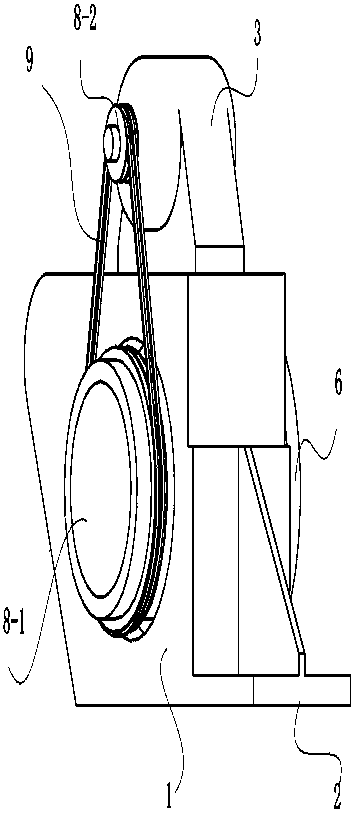

[0012] Such as figure 1 and figure 2 As shown, a whirlwind milling device with high precision is composed of a milling body 1, a base 2 and a motor 3. The milling body 1 is provided with a high-speed rotary cutterhead 4, and the high-speed rotary cutterhead 4 consists of at least six Forming knife 5 is formed. The milling body 1 is provided with a main shaft 6, and the main shaft 6 is provided with a chuck 7. One end of the milling body 1 is provided with a rotating shaft 8-1, and the periphery of the rotating shaft 8-1 is covered with a belt 9. , one end of the motor 3 is provided with a rotating shaft 8-2, and the high-speed rotary cutter head 4 drives the rotating shaft 8-1 and the rotating shaft 8-2 through a belt 9 on the motor 3 to move at a high speed, and the rotation axis of the high-speed rotary cutter head 4 is relatively The axis of the workpiece is inclined by a helix angle, the upper end of the base 2 is fixed with a supporting steel sheet 10, and the helix ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com