Milling machine used for efficiently machining hydraulic cylinder

A hydraulic cylinder and milling machine technology, which is applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as wasting time and affecting production efficiency, and achieve the effects of reducing labor intensity, facilitating fine-tuning and correction, and accelerating milling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following is attached Figure 1-5 The application is described in further detail.

[0033] The embodiment of the present application discloses a milling machine for efficiently machining hydraulic cylinders.

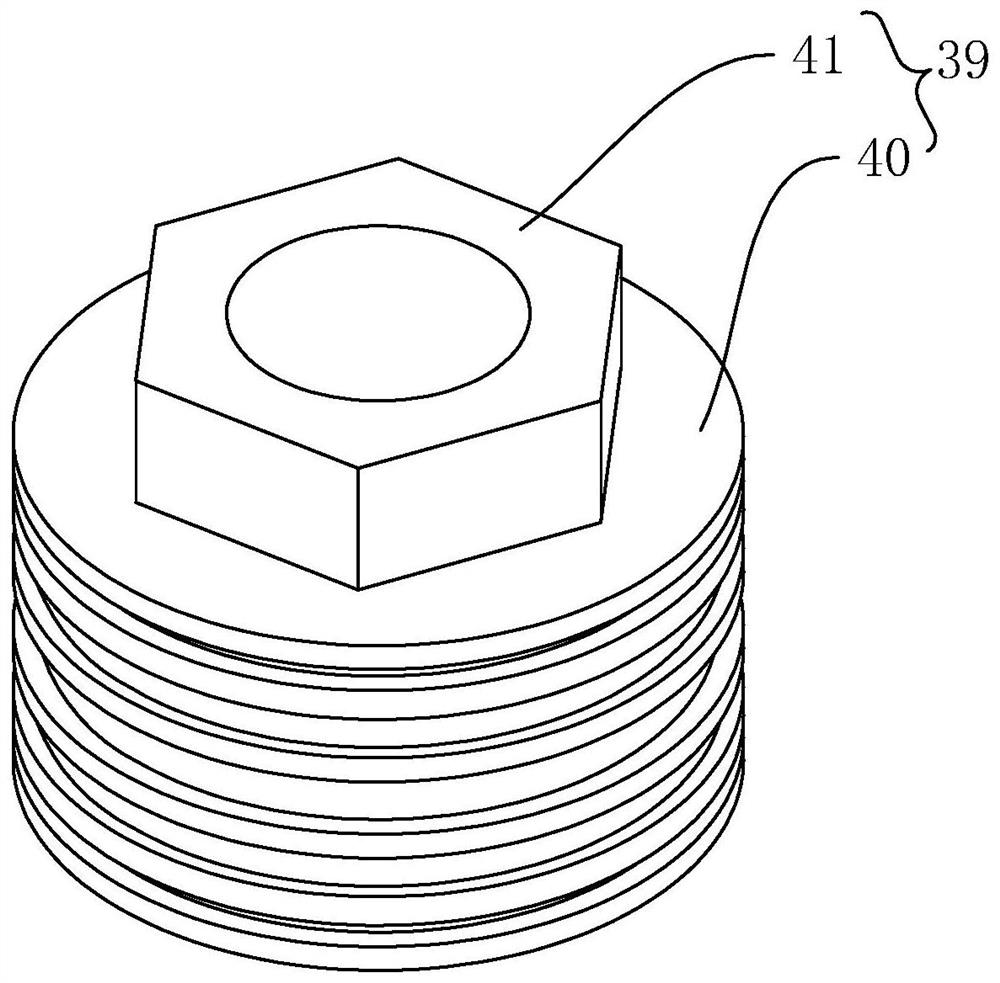

[0034] refer to figure 1 It is known that the existing piston 39 includes a seal seat 40 and a rod sleeve 41 integrally fixed on the seal seat 40. Existing manufacturers usually need to process the rod sleeve 41 into a prismatic shape. Usually, in the process of processing the rod sleeve 41, the manufacturer It is necessary to fix the piston 39 on the milling machine and mill the five facets of the milling machine. The existing method is to mill out one face, turn the piston 39 and fix the piston 39 again, and then mill out the second face, milling in turn according to the above processing method Out of five sides so far.

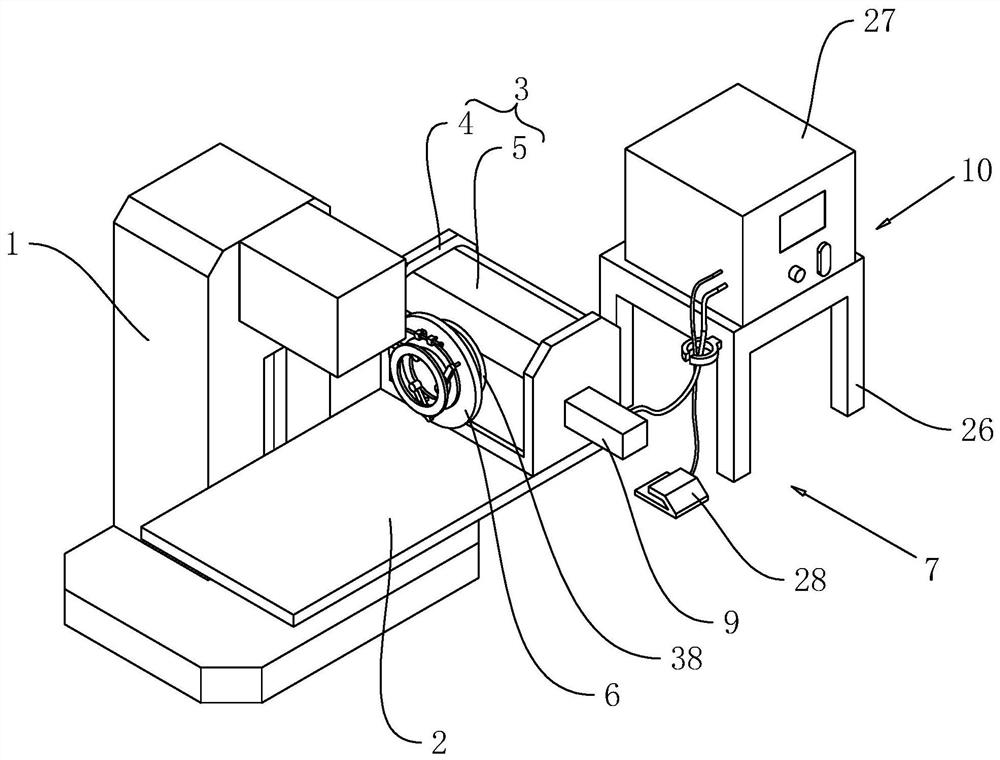

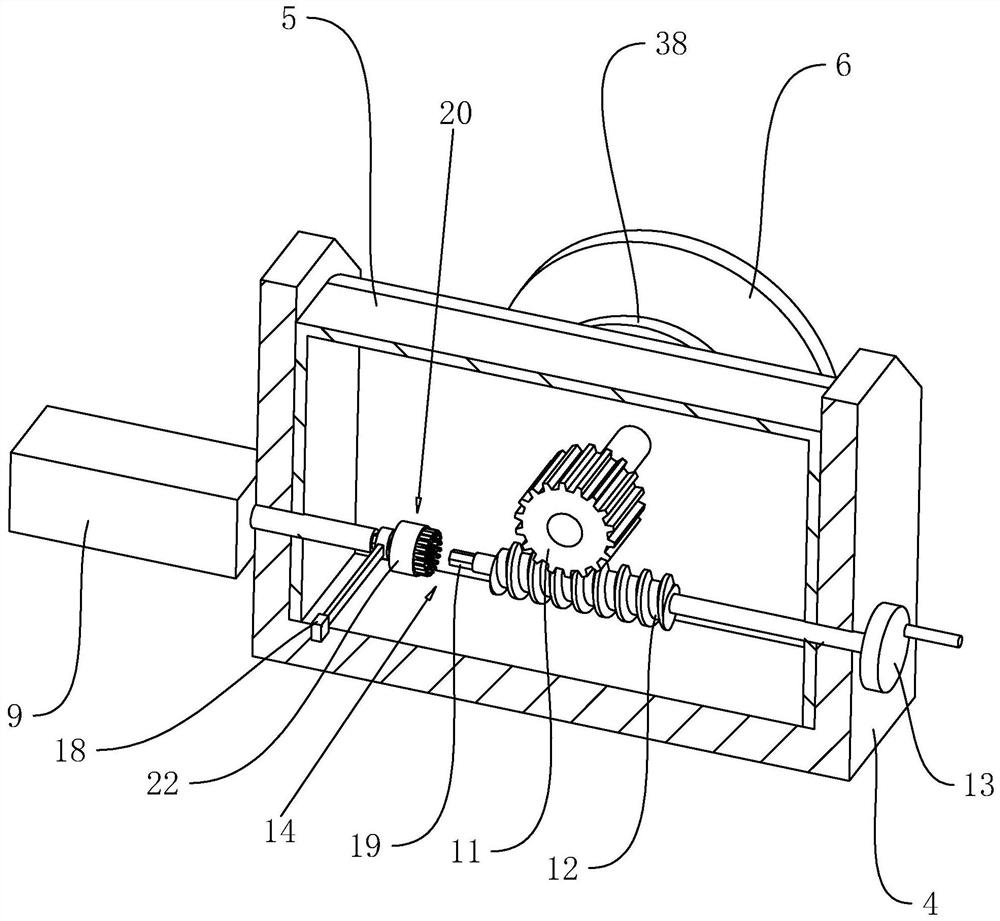

[0035] refer to figure 1 and figure 2, a milling machine for high-efficiency processing of hydraulic cylinders, including a body 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com