Clamping fixture for milling forks

A technology of fixing devices and jaws, which is applied in the direction of positioning devices, clamping, milling machine equipment, etc., can solve the problems of low working efficiency of milling forks, and achieve the effects of simple structure, improved processing efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

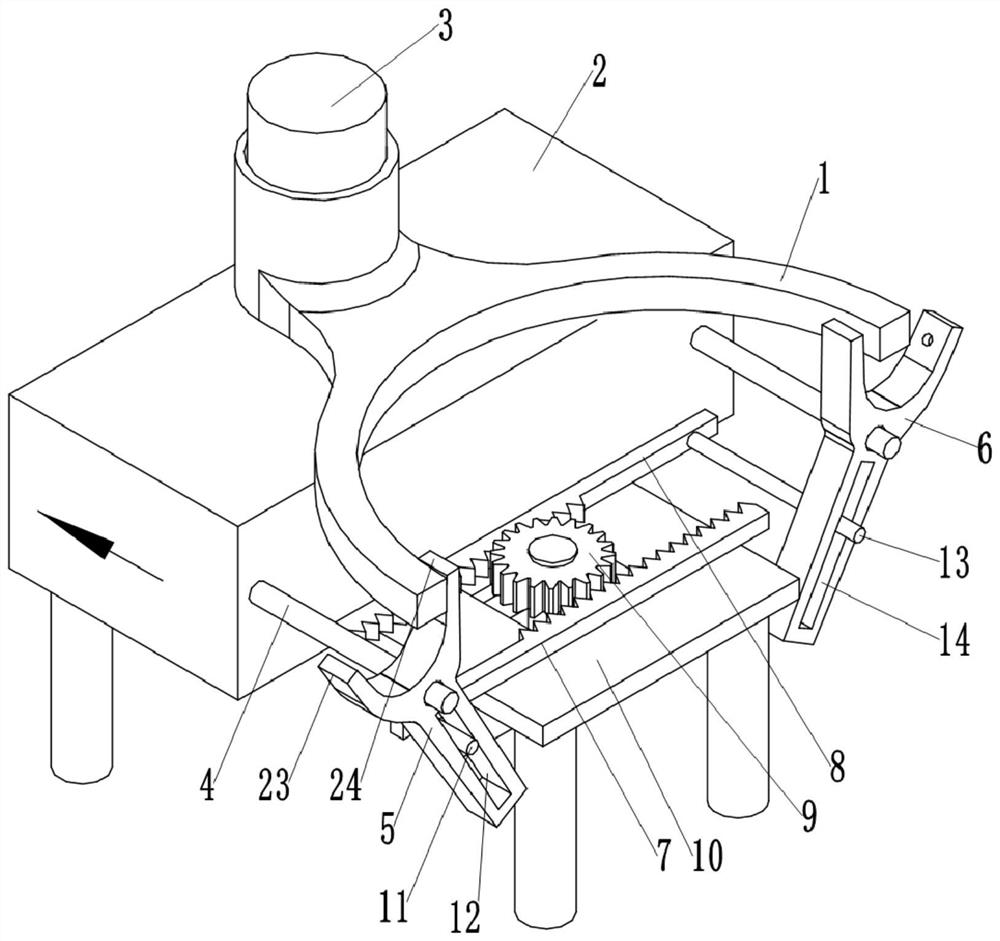

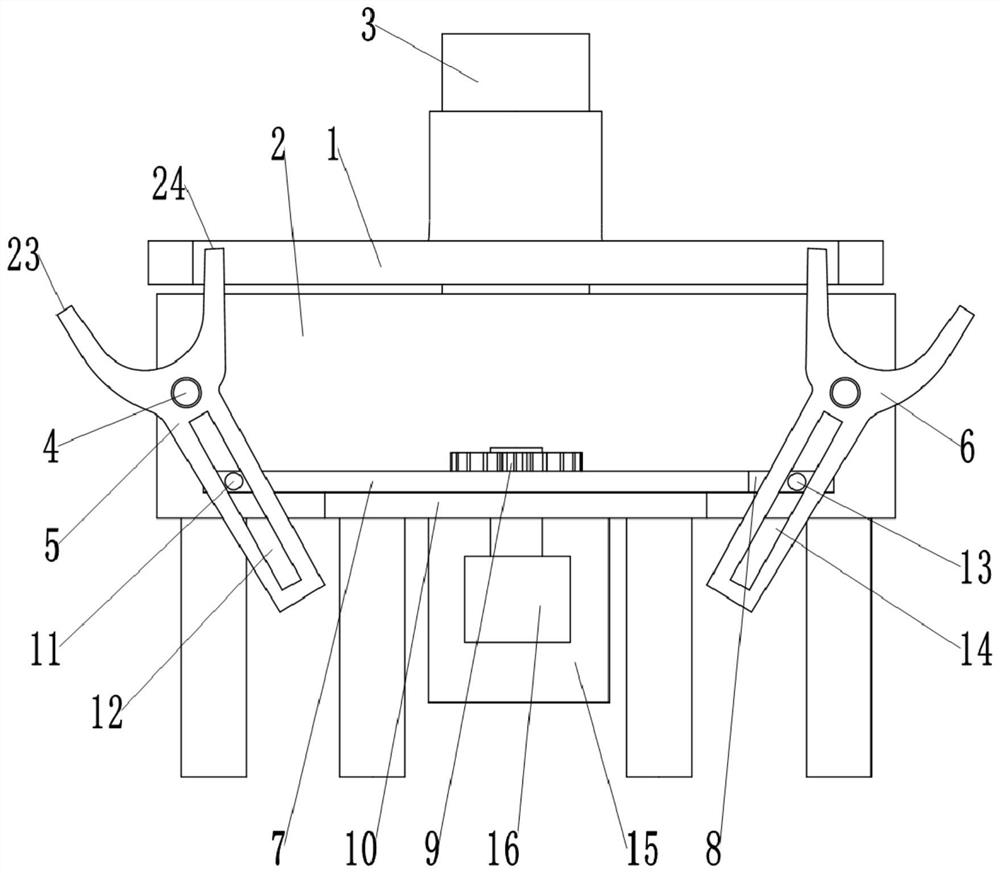

[0031] as attached figure 1 Shown: The clamping and fixing device for the milling fork, including the frame 2 and the fixing mechanism for clamping the shift fork 1, the fixing mechanism includes the positioning column 3, the first hinged swing rod 5 and the second hinged swing rod 6 , the positioning column 3 is fixed vertically on the upper surface of the frame 2, the first hinged swing link 5 and the second hinged swing link 6 are located on the same side of the positioning column 3, the first hinged swing link 5 and the second hinged swing link 6 With respect to the mirror-symmetrical setting of the positioning column 3, the setting method of the second hinged swing rod 6 is the same as that of the first hinged swing rod 5. Here, the setting method of the first hinged swing rod 5 is used as an example for illustration: the first hinged swing rod 5 The upper end is integrally formed with a left jaw 23 and a right jaw 24, the frame 2 is fixedly provided with a horizontal bar...

Embodiment 2

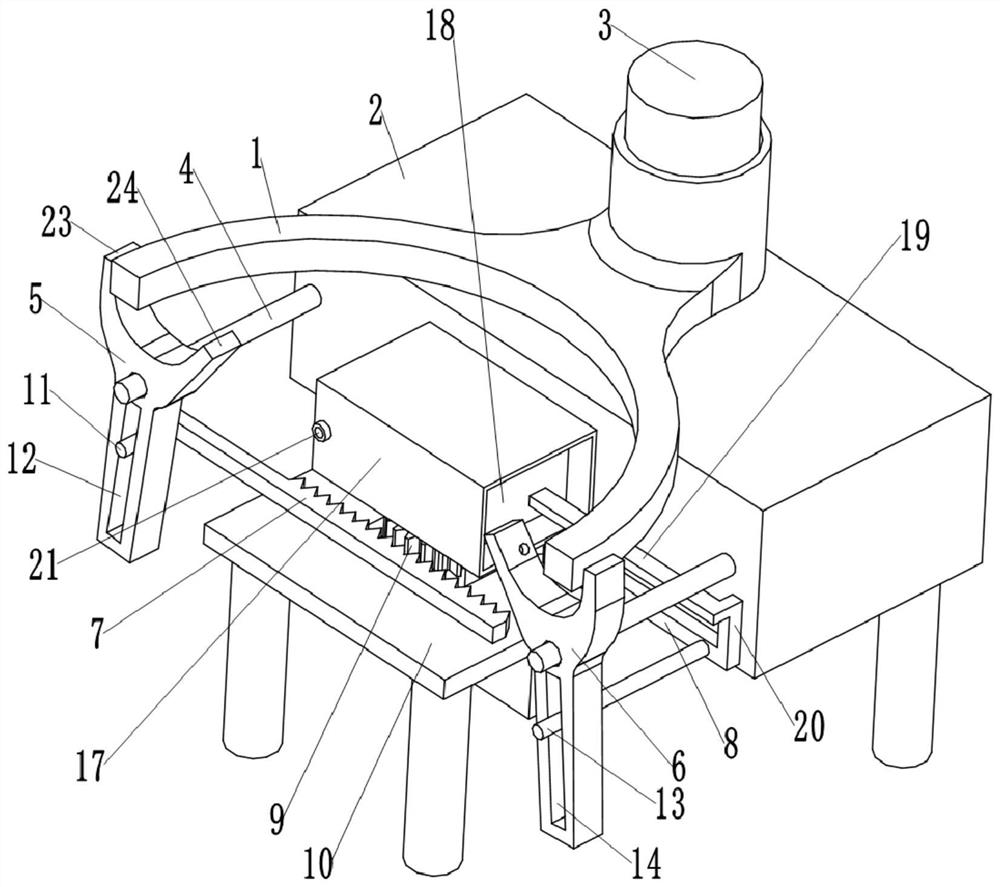

[0035] Such as image 3 As shown, the difference between the present embodiment and the first embodiment is that a sealing cylinder 17 is fixedly connected to the frame 2 by bolts, a piston 18 is slidably connected in the sealing cylinder 17, and a piston rod 19 is clamped and fixed on the right side of the piston 18. The piston 18 is provided with an air inlet, and the air inlet is provided with a one-way valve for allowing gas to flow into the sealed cylinder 17 only from the outside; the right end of the piston rod 19 is welded to the second rack 8 through an L-shaped connecting rod 20 Fixed; the sealing cylinder 17 is provided with an air outlet, and the air outlet is integrally formed with a connection port 21, and the connection port 21 is communicated with a first flexible pipe and a second flexible pipe (not shown in the figure) through a three-way pipe. Both the hinged swing rod 5 and the second hinged swing rod 6 are provided with an air flow passage 22, the first fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com