Method and device for preparing single-phase nano epsilon-Fe3N or gamma'-Fe4N powder

A technology of -fe3n and -fe4n, which is applied in the field of preparation of iron nitride materials, can solve problems such as the difficulty in preparing nano-iron nitride powder, and achieve the effects of ensuring quality stability, narrow particle size distribution, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

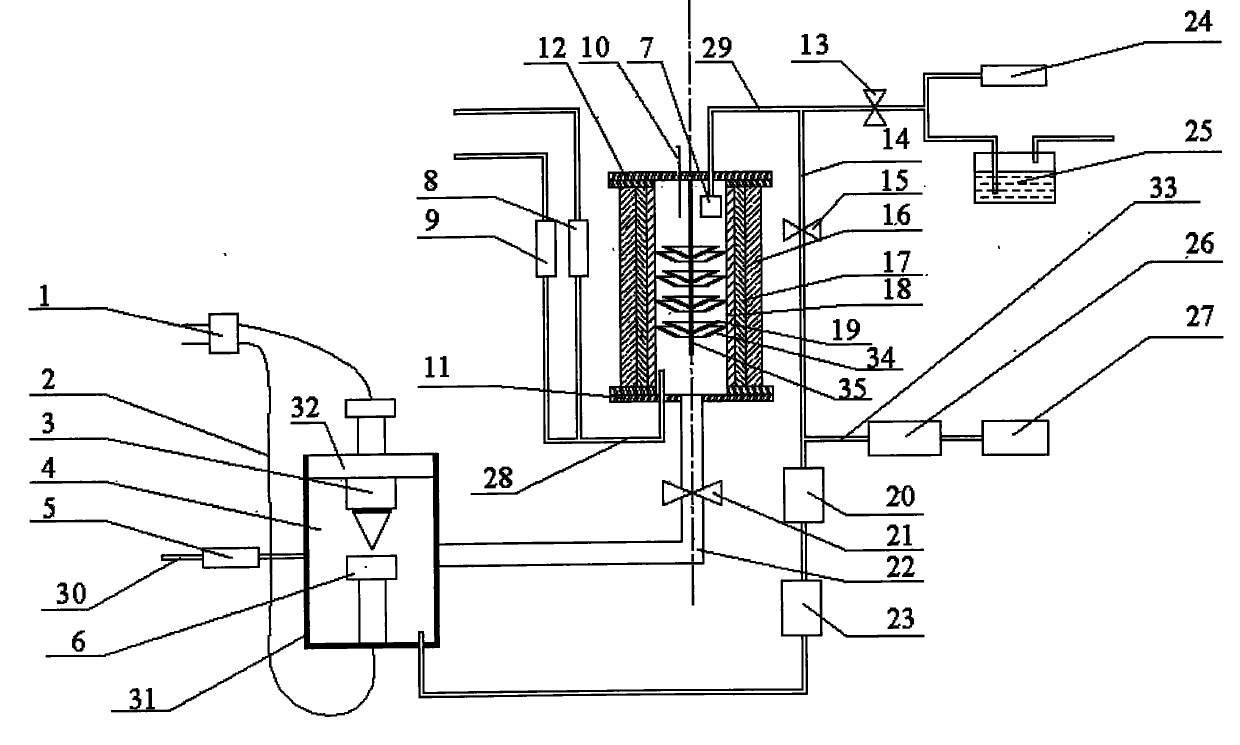

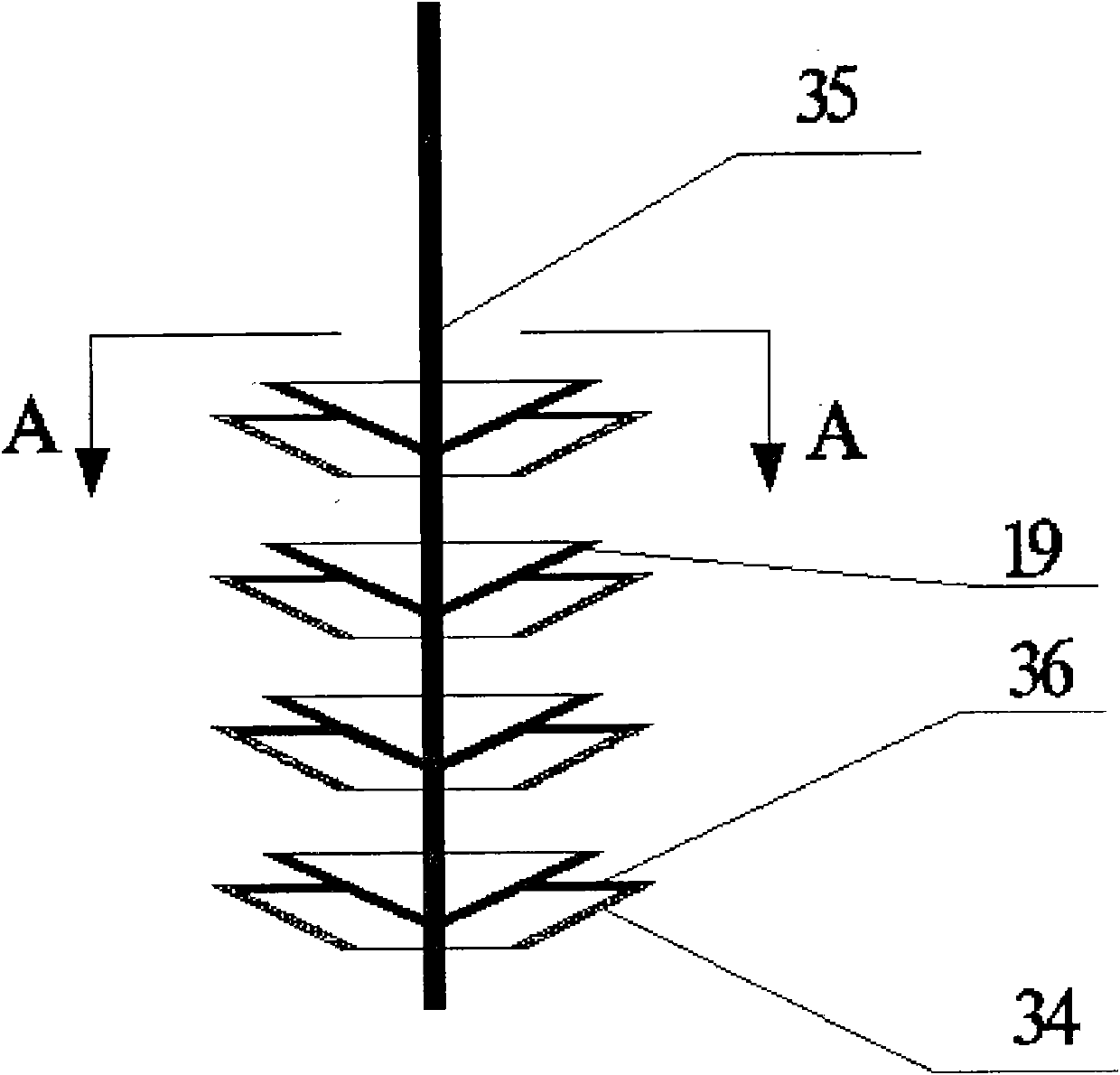

Method used

Image

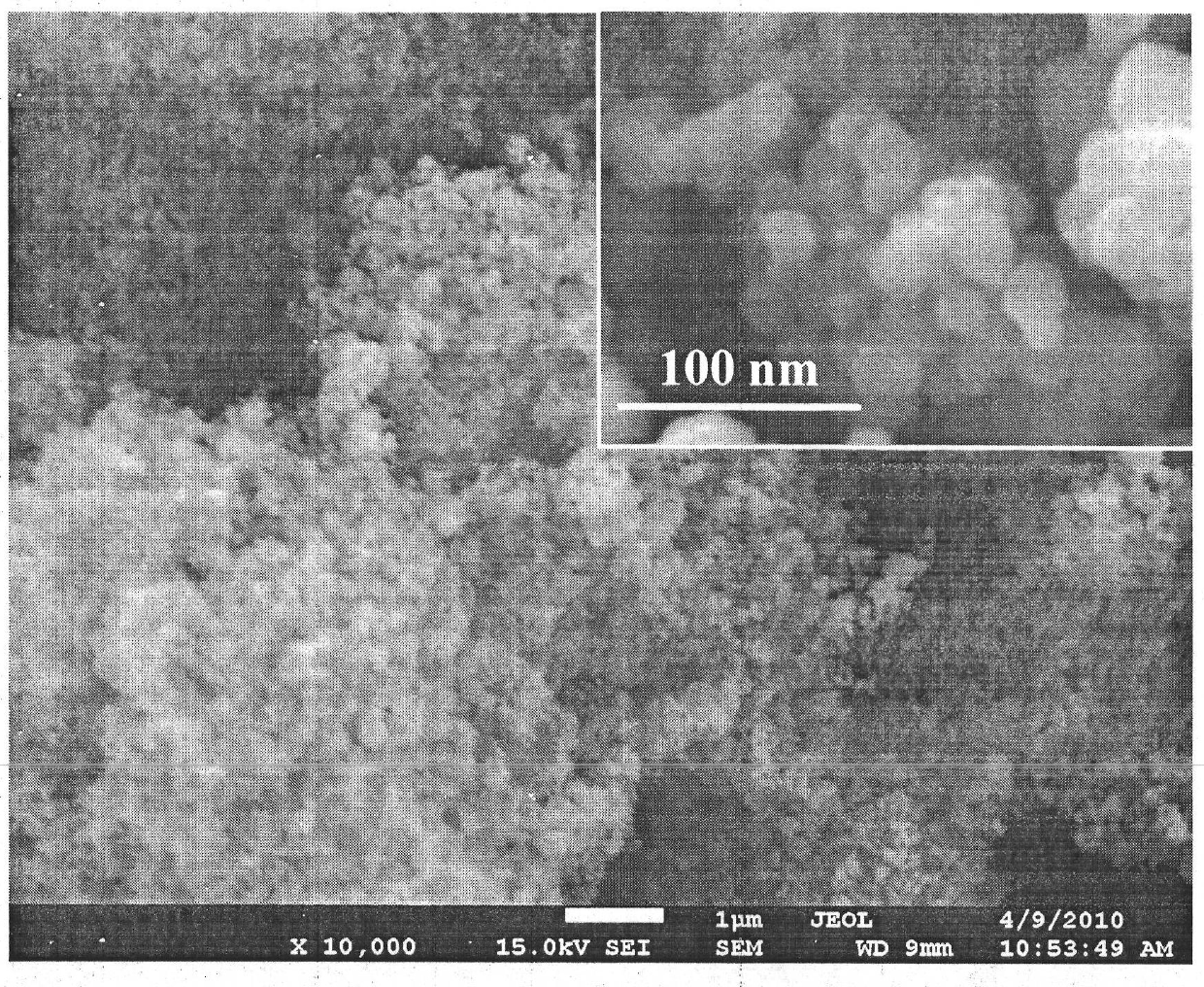

Examples

Embodiment 1

[0048] Preparation of single-phase nanometer γ'-Fe 4 The method of N powder is as follows.

[0049] (1) vacuuming, forced gas circulation

[0050] After filling the water-cooled crucible with pure iron raw materials (block shape, purity ≥ 99.99%), close the exhaust valve, open the valve of the exhaust branch pipe, open the valve of the powder outlet channel, start the vacuum pump and the turbomolecular pump in turn, and pump the reactor Vacuum to 3.0×10 -4 Pa. Then open the reactor air inlet flowmeter to charge the protective gas (Ar gas), the inflation pressure is 0.05MPa, turn off the turbomolecular pump at the same time, turn off the vacuum pump after the inflation is completed, and turn on the variable frequency Roots pump to realize the protection gas passing through the reactor, Forced circulation and cooling of powder outlet channel, powder collection chamber, exhaust pipe, exhaust branch pipe, variable frequency Roots pump and condenser. The circulation velocity is...

Embodiment 2

[0058] Preparation of single-phase nanometer γ'-Fe 4 The method of N powder is as follows.

[0059] (1) vacuuming, forced gas circulation

[0060] After filling the water-cooled crucible with pure iron raw materials (block shape, purity ≥ 99.99%), close the exhaust valve, open the valve of the exhaust branch pipe, open the valve of the powder outlet channel, start the vacuum pump and the turbomolecular pump in turn, and pump the reactor Vacuum to 5.0×10 -4 Pa. Then open the reactor inlet flow meter to charge the reaction gas (N 2 ), the inflation pressure is 0.1MPa, and the turbomolecular pump is turned off at the same time. Forced circulation and cooling of gas branch pipe, variable frequency Roots pump and condenser, the circulation flow rate range is 5m / s. The circulating gas passes through the condenser, which is a shell and tube condenser, and the ice-water mixture with a temperature of 0°C is used as the cooling medium, and the gas can be cooled to 10°C.

[0061] (...

Embodiment 3

[0068] Preparation of single-phase nanometer γ'-Fe 4 The method of N powder is as follows.

[0069] (1) vacuuming, forced gas circulation

[0070] After filling the water-cooled crucible with pure iron raw materials (block shape, purity ≥ 99.99%), close the exhaust valve, open the valve of the exhaust branch pipe, open the valve of the powder outlet channel, start the vacuum pump and the turbomolecular pump in turn, and pump the reactor Vacuum to 1.0×10 -4 Pa. Then open the reactor inlet flow meter to charge the reaction gas (NH 3 ), the inflation pressure is 0.01MPa, and the turbomolecular pump is turned off at the same time. Forced circulation and cooling of gas branch pipe, variable frequency Roots pump and condenser, the circulation flow rate range is 1m / s. The circulating gas passes through the condenser, which is a shell and tube condenser, and the ice-water mixture with a temperature of 0°C is used as the cooling medium, and the gas can be cooled to 1°C.

[0071] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com