Steel rail fat edge milling device

A milling device and rail technology, applied in milling machine equipment, details of milling machine equipment, metal processing, etc., can solve the problems such as the inability to adjust the milling position, the extremely high requirements for clamping guide rail components, and the large vibration of single-layer milling, so as to achieve the milling effect. Better, better clamping, better milling results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

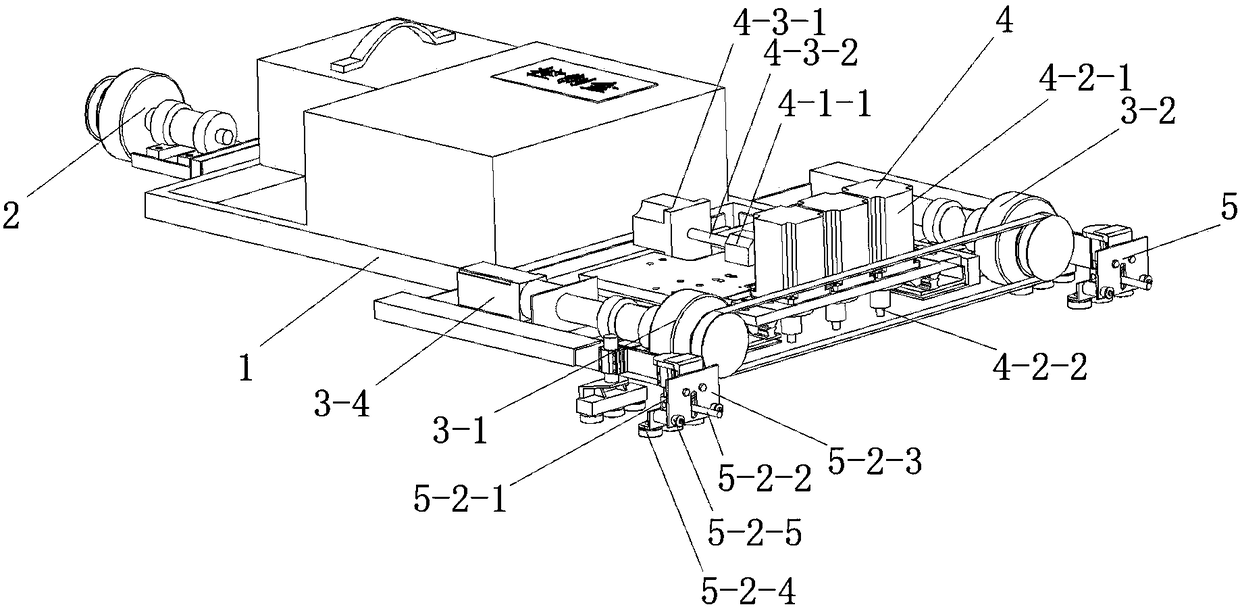

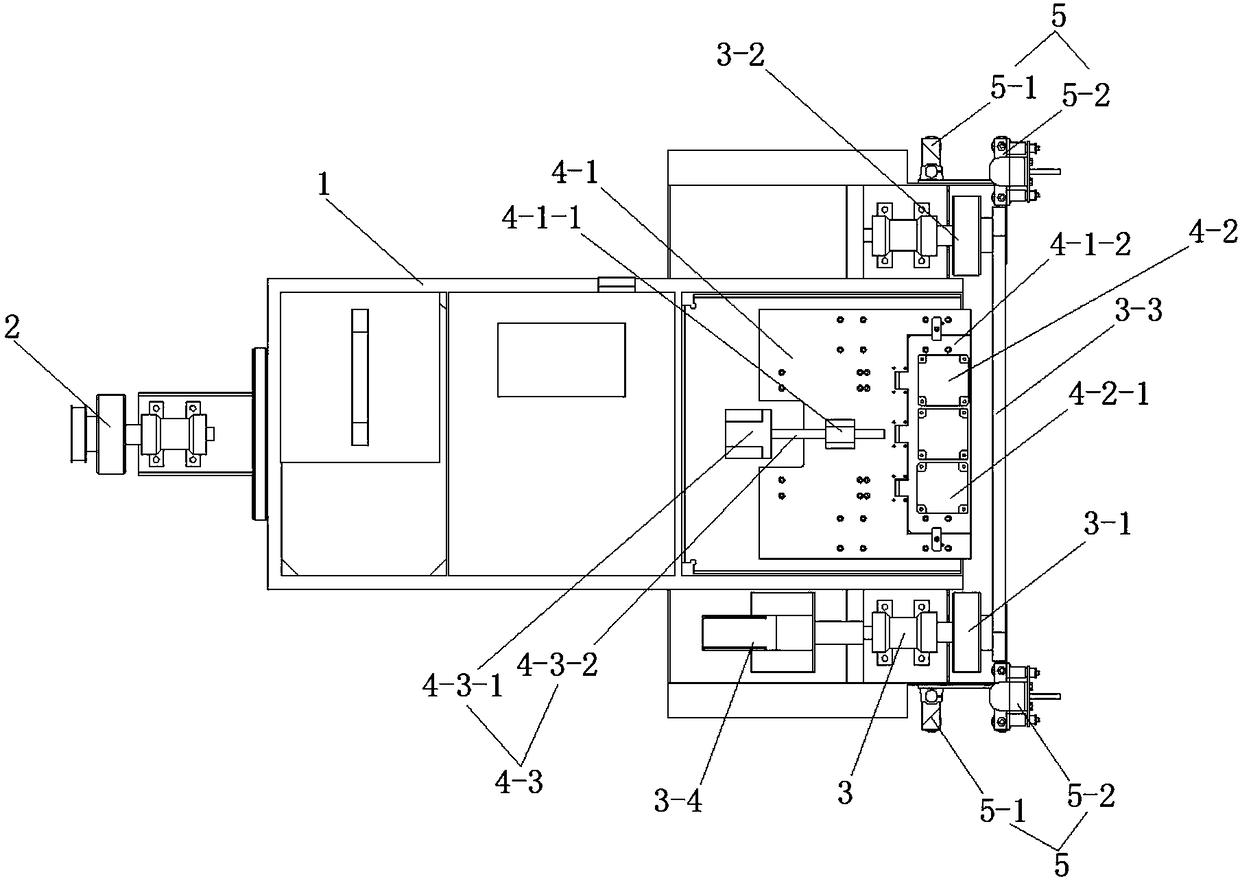

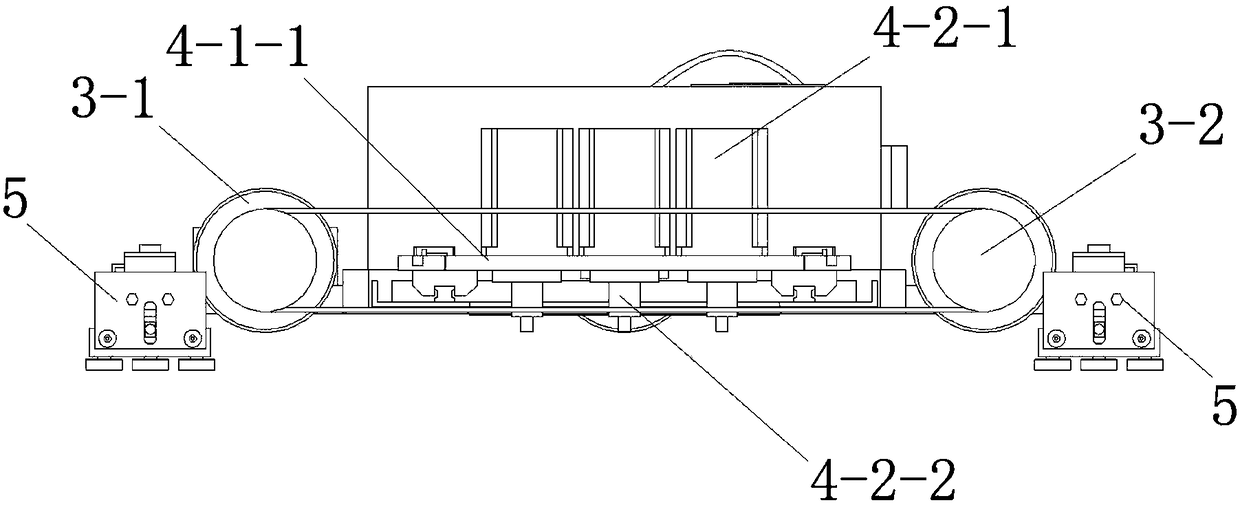

[0037] See Figure 1 to Figure 9 , The rail fat edge milling device of the present embodiment includes a vehicle frame 1, a working part and a support wheel 2.

[0038] The working part and the supporting wheels 2 are installed on both sides of the vehicle frame respectively. The working part includes a traveling mechanism 3 , a milling mechanism 4 and a multiple guide wheel clamping mechanism 5 . The running mechanism 3 and the support wheel 2 ride on two steel rails respectively. The driving frame 1 moves along the rail. The milling mechanism 4 includes a bottom plate 4-1, a milling cutter assembly 4-2 and an adjustment assembly 4-3. The multi-guide wheel clamping mechanism 5 clamps a steel rail, and moves along the steel rail following the vehicle frame 1. Base plate 4-1 is slidably connected on vehicle frame 1. The milling cutter assembly 4-2 is installed on the side edge of the steel rail that the base plate 4-1 faces toward the multi-guidance wheel clamping mechanis...

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, the difference is:

[0048] The milling cutter assembly 4-2 of working part is provided with multiple along the moving direction of vehicle frame 1 on the motor mounting plate 4-1-2 of base plate 4-1. The installation positions of multiple milling cutter assemblies 4-2 are gradually approaching or away from the edge of the motor mounting plate 4-1-2 according to one end of the motor mounting plate 4-1-2 toward the other end.

Embodiment 3

[0050] This embodiment is basically the same as Embodiment 1, the difference is:

[0051] The rail fat edge milling device of this embodiment includes a vehicle frame 1 and a working part.

[0052] The supporting wheel 2 is replaced by another working part.

[0053] During use, the vehicle frame 1 is placed on the track, so that the driving wheel 3-1 and the driven wheel 3-2 of a traveling mechanism 3 ride on a steel rail of the track, and the driving wheel 3-1 and the driven wheel 3-2 of the other traveling mechanism 3 and the The moving wheel 3-2 rides on another rail of the track, adjusts the multi-guide wheel clamping mechanism 5, and squeezes the hinged plate 5-2-3 by rotating the screw on the hinged rod 5-2-2 to make the roller mounting plate 5 -The rollers on the 2-4 and the rollers on the fixed wheel frame 5-1 clamp the rail, the driving drive motor 3-4 drives the driving wheel 3-1 to rotate, and the driving wheel 3-1 drives the driven wheel 3 through the synchronous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com