Patents

Literature

48results about How to "Good milling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

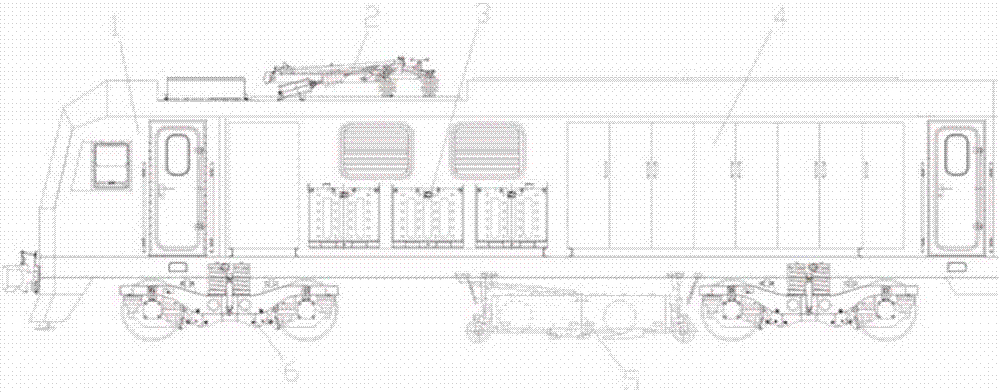

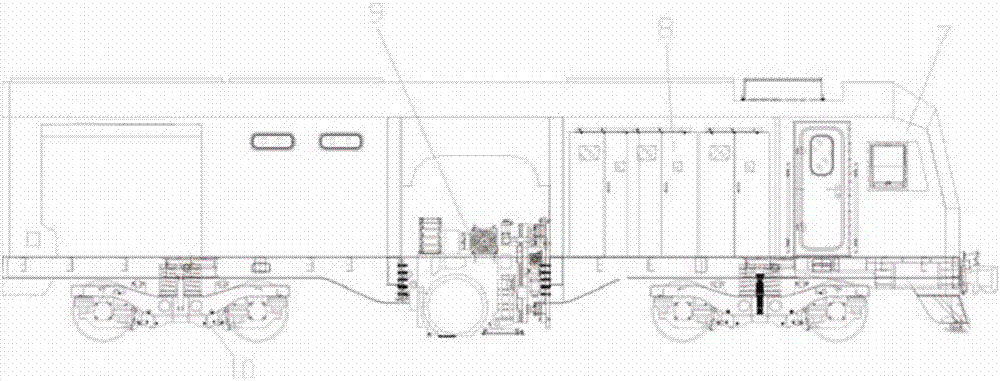

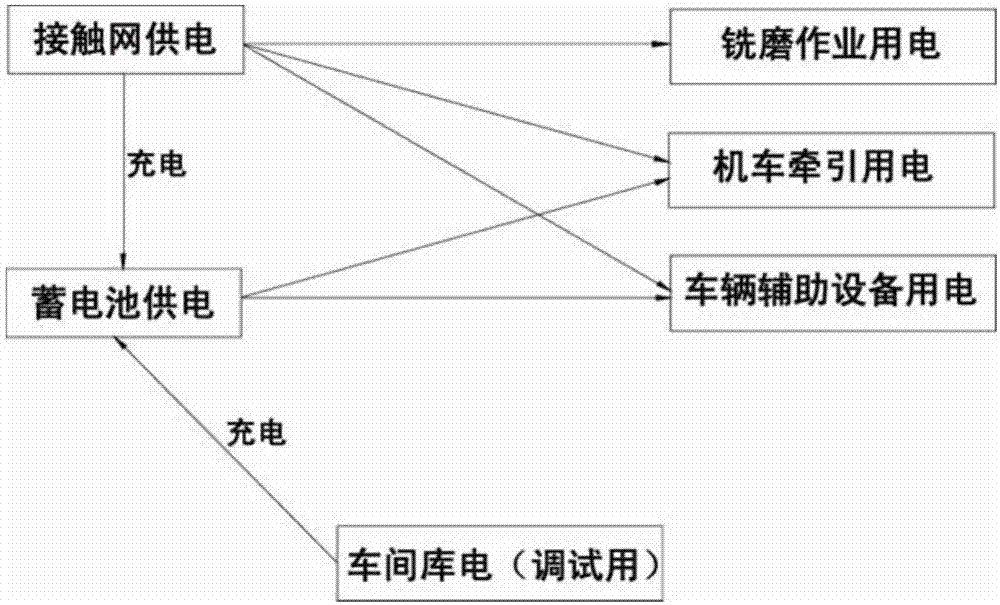

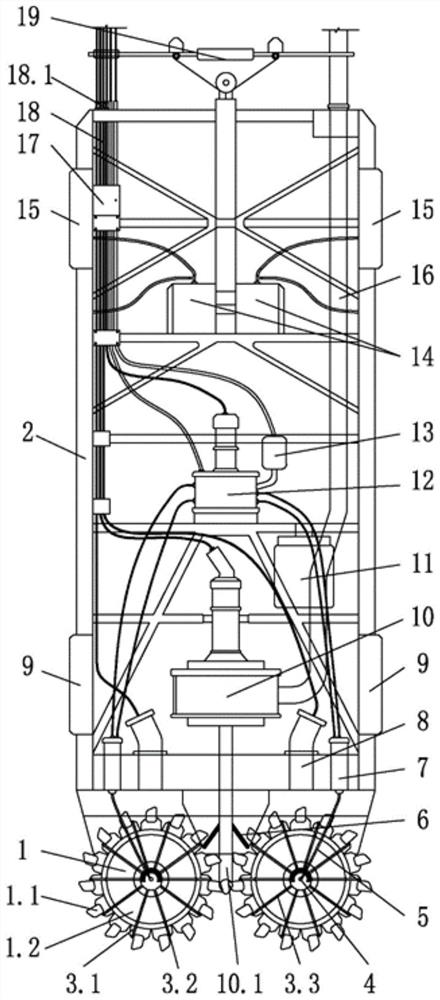

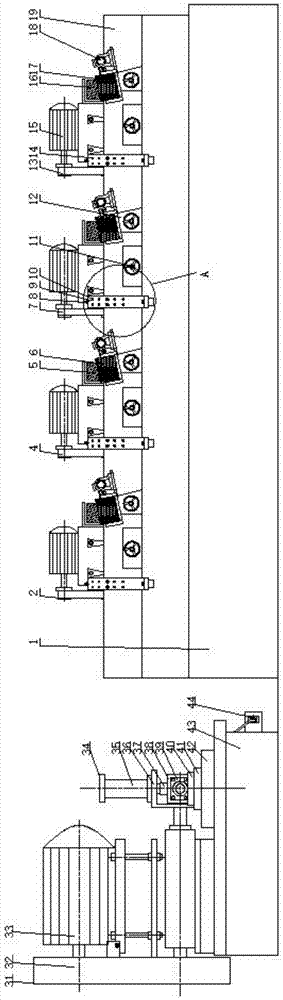

Electric contact net and storage battery set dual-power steel rail milling-grinding machine

ActiveCN107299567AEasy access to electricityImprove recognitionVehicular energy storageRailway track constructionBattery chargeBattery room

An electric contact net and storage battery pack dual-power steel rail milling-grinding machine is disclosed and comprises a power vehicle providing power needed by vehicle operation and travelling and an operation vehicle provided with a milling-grinding operation device. The power vehicle is provided with a storage battery chamber and a traction electrical cabinet chamber, the storage battery chamber is internally provided with a storage battery, and the traction electrical cabinet chamber is internally provided with an auxiliary current transforming cabinet, an auxiliary power supply cabinet and a storage battery managing cabinet; the output end of the auxiliary current transforming cabinet is connected to the input end of the auxiliary power supply cabinet, the auxiliary power supply cabinet supplies power to the milling-grinding operation device, an on-vehicle auxiliary device and a battery charger, and the battery charger supplies power to the traction storage battery; the storage battery managing cabinet comprises a breaker, a charging module and a direct current parallel-connection assembly and is used for protecting the storage battery and controlling charging and discharging of the storage battery; and the storage battery can temporarily supply power to the power vehicle and the operation vehicle. The electric contact net and storage battery pack dual-power steel rail milling-grinding machine can be suitable for operation in closed environments such as subways, safe and stable operation of the vehicles are ensured, vibration is small, and the milling-grinding cutting effect is excellent.

Owner:BEIJING TUOBOER TRACK MAINTENANCE TECH CO LTD +1

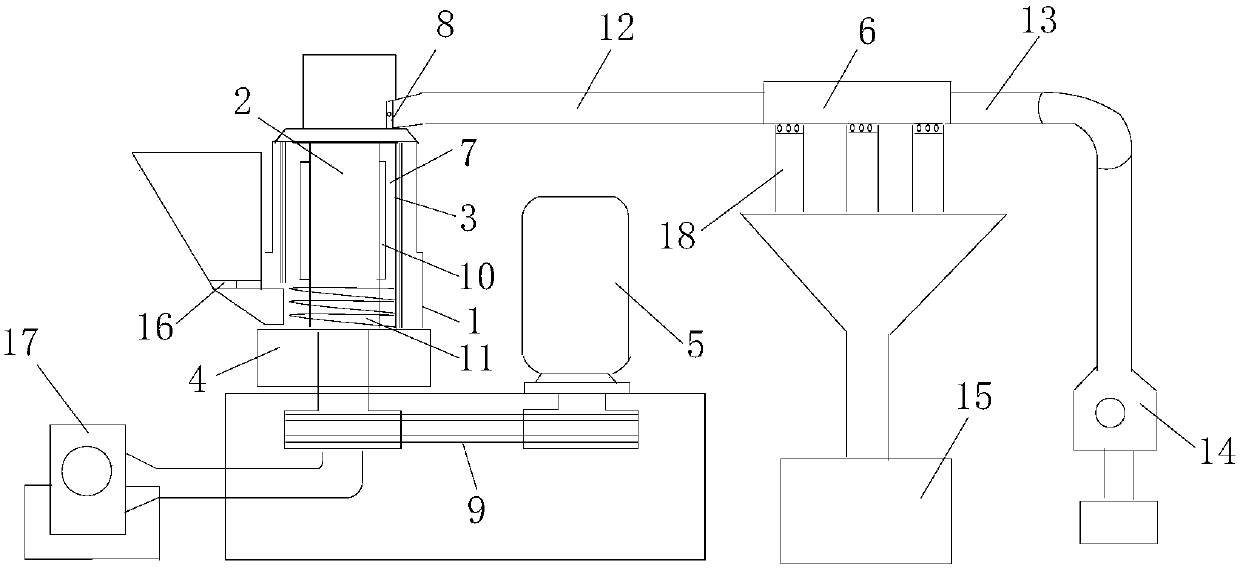

Rice and bran separation type rice milling machine

InactiveCN107694659ALow circumferential pressureLittle change in circumferential pressureGrain huskingGrain polishingHuskPropeller

The invention belongs to the technical field of rice milling equipment and relates to a separation type rice milling machine. The separation type rice milling machine comprises a case, a spindle, a bran sieving device, a bran collection chamber, a driving motor and a rice and bran separator; a whitening chamber is formed between the spindle and the bran sieving device; the bran collection chamberused for bran outlet is formed in the bottom of the whitening chamber; an output shaft of the driving motor is connected with the spindle through a belt; an emery roller for milling rice is arranged on the upper portion of the spindle; a spiral propeller is arranged in the position, on the lower portion of the whitening chamber, of the spindle; a feeding inlet for feeding of rice in husks is formed in the lower portion of the case; a discharging outlet for rice outlet is formed in the upper portion of the case and provided with a discharging pipe; the discharging pipe is connected with one endof the rice and bran separator, and the other end of the rice and bran separator is fixedly connected with a bran suction pipe; a negative pressure fan is arranged at one end of the bran suction pipe; a rice collection chamber is connected to the lower end of the rice and bran separator. The separation type rice milling machine has the uniform whitening effect, and rice grains are not piled at the bottom of the rice milling machine and can be subjected to secondary bran removing.

Owner:广西贵港市恒桥米业有限公司

Chemical milling solution for aluminum-lithium alloy

The invention relates to chemical milling solution for an aluminum-lithium alloy. The solution is characterized in that: 1000ml of solution is prepared by 140 to 180g of NaOH, 13 to 22g of Na2S, 40 to 50g of triethanolamine, 19 to 60g of Al<3+> and the balance of water. The aluminum-lithium alloy which is milled by the chemical milling solution has high surface accuracy, does not have chemical milling transition region defects and completely meets technical requirements.

Owner:SHENYANG AIRCRAFT CORP

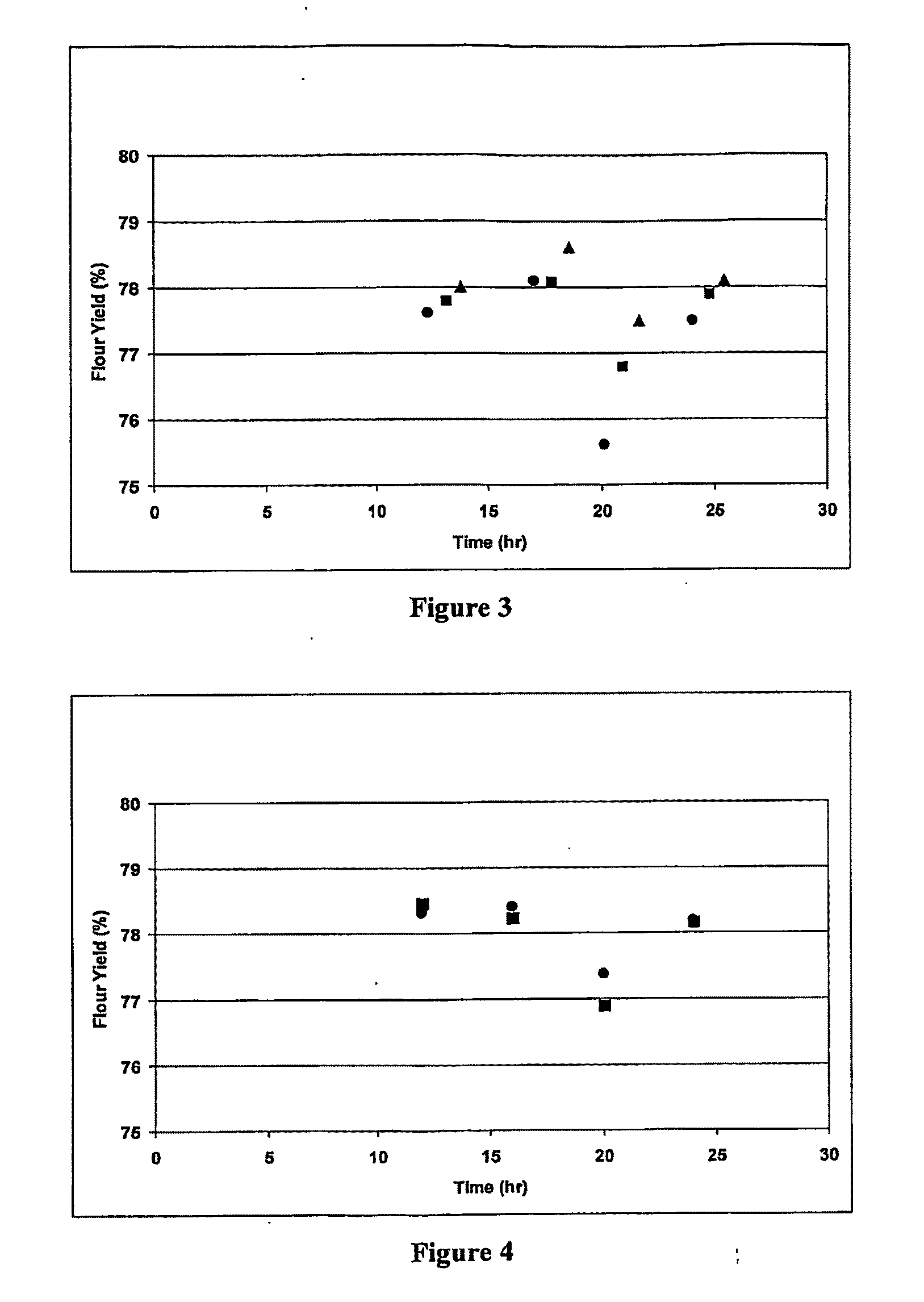

Bioprocessing of grains

InactiveUS20100323062A1Decrease in qualityDecrease in yieldDough treatmentHydrolasesBiotechnologyPlant hormone

A method of treating a crop kernel prior to milling to improve millability, which includes the step of exposing the crop kernel to one or more plant hormones is provided. Typically, the crap kernel is a cereal such as wheat. The plant hormone is selected from the group consisting of auxins, gibberellins and abscisic acid. The method further includes the step of exposing the crop kernel to an enzyme. Typically the enzyme is a plant cell-wall degrading enzyme such as xylanase, lipase and cellulase. Also provided are methods of production of flour, food products and compositions. A particular application of this method is the optimisation of milling performance for the production of high quality flour.

Owner:GRAIN FOODS INNOVATIONS

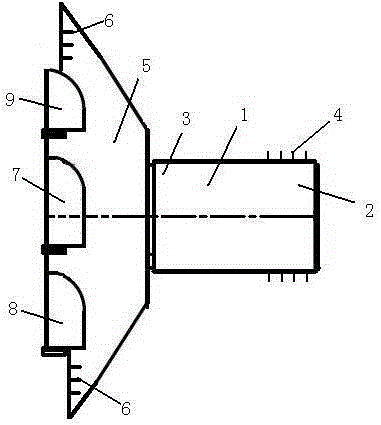

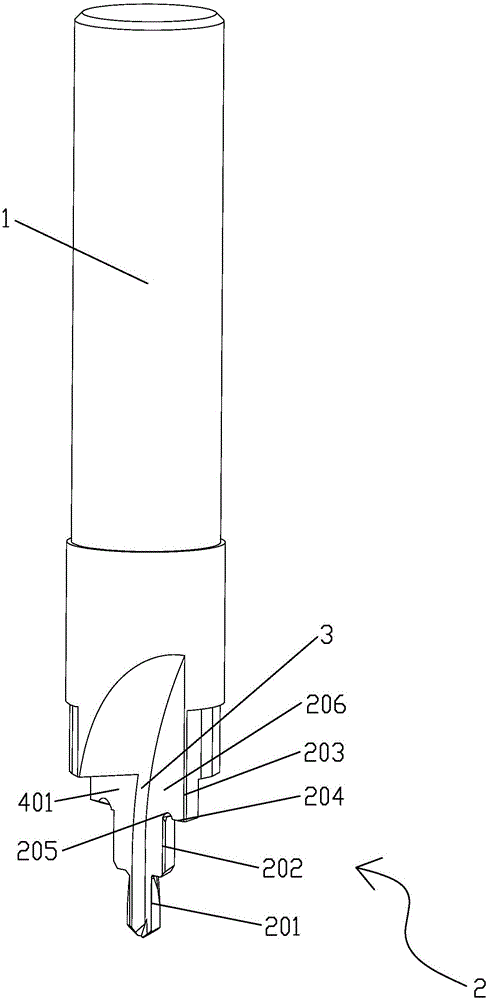

Efficient and novel PCD cutter set

The invention provides an efficient and novel PCD cutter set which comprises a connecting rod, wherein one end of the connecting rod serves as a connecting end, the other end of the connecting rod serves as a cutting end, a facing cutter is arranged at the cutting end, a plurality of chip grooves are evenly formed in the periphery of the facing cutter, a first blade, a second blade and a third blade are arranged on the facing cutter, the structure is simple, the design is reasonable, finish milling, semi-finish milling and rough milling are integrally combined on one disc milling cutter, cutter replacement frequency is lowered, the processing time is saved, a great amount of man power and material resources is saved, the cutting speed is relatively high, the workpiece removing rate is high, the integral production efficiency is improved, the milling effect is relatively good, the precision is high, errors are small, the cost is relatively low, due to the arrangement of the chip grooves, a chip accumulating layer, which is caused by chip residual during cutting and impacts the work efficiency and the service life of the cutter set, is effectively prevented, and requirements of manufacturers are be met.

Owner:江苏中晟钻石工具有限公司

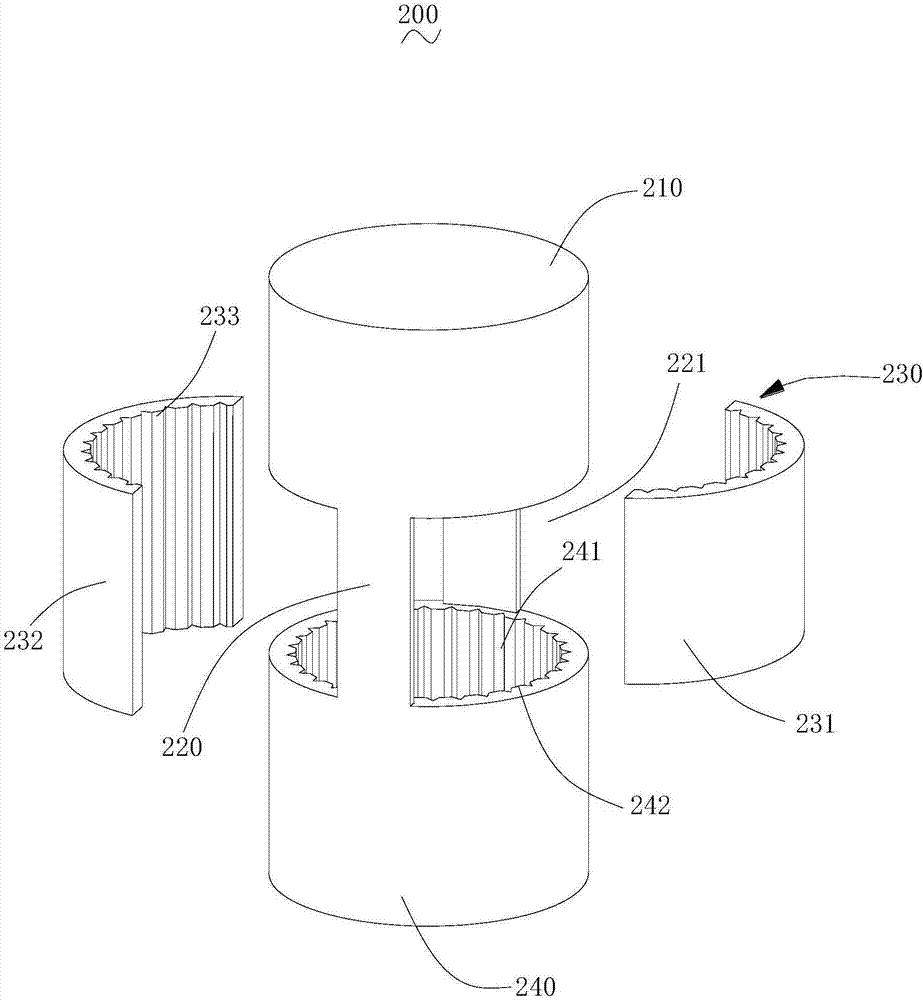

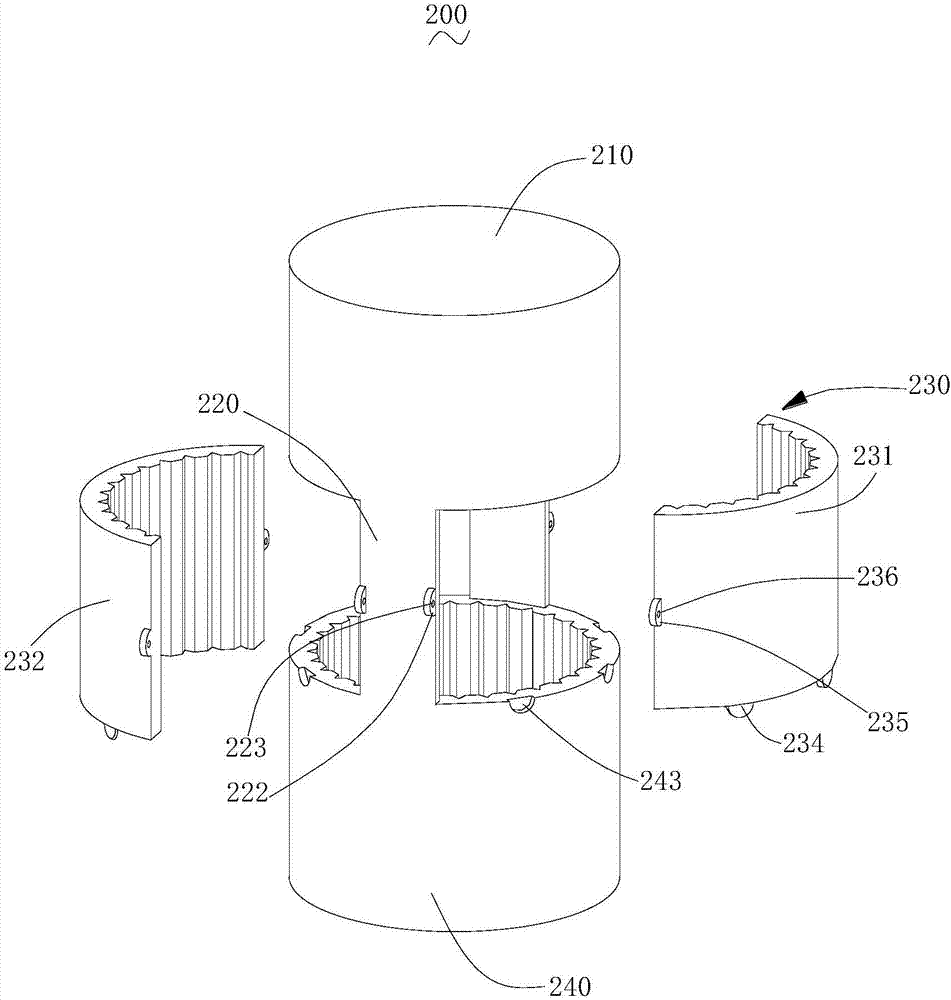

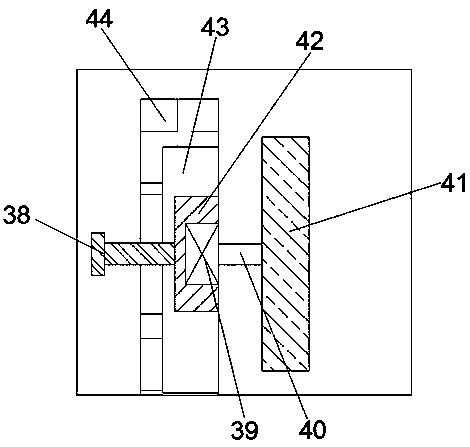

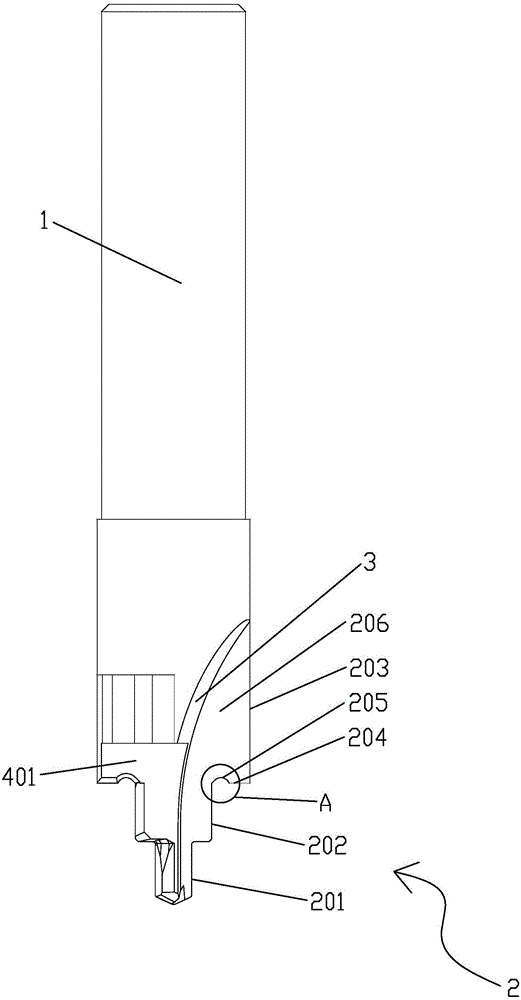

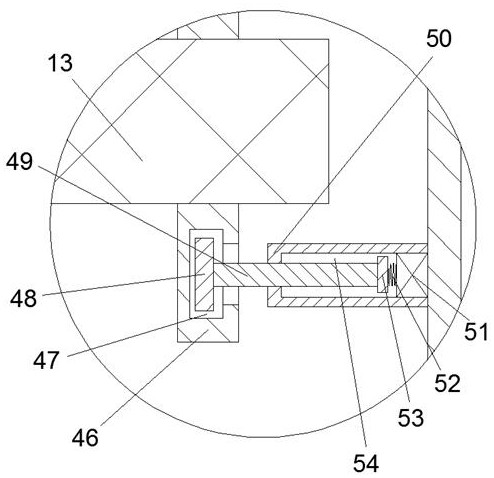

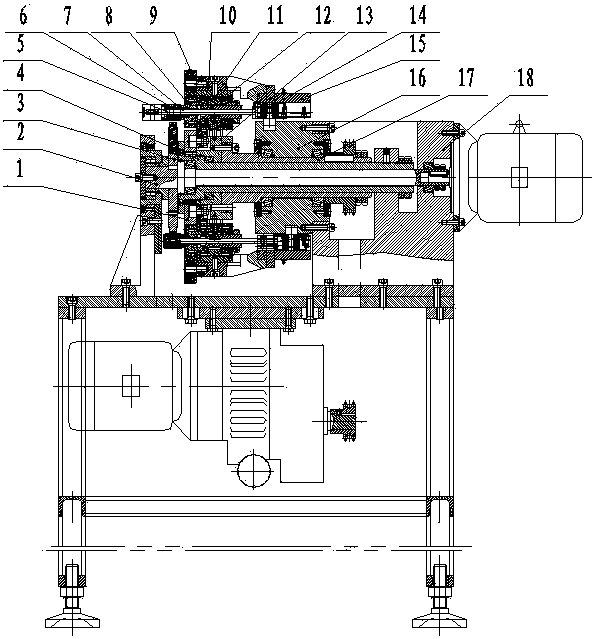

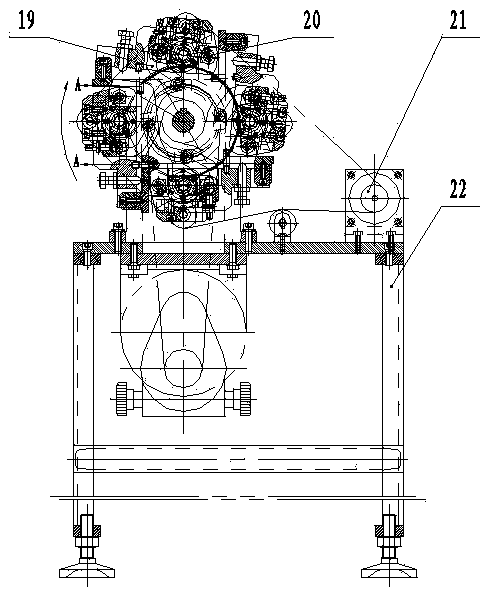

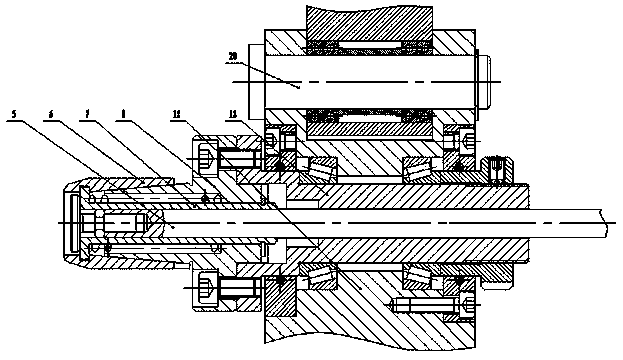

Milling device and drive connecting assembly thereof

InactiveCN107127383ALong-term job stabilityIncrease contact areaMilling cuttersOther manufacturing equipments/toolsMilling cutterDrive shaft

The invention relates to a milling device and a drive connecting assembly thereof. The drive connecting assembly comprises a drive shaft, a connecting part, a fixed sleeve part and a limiting sleeve; the drive shaft is connected with the limiting sleeve through the connecting part, a limiting hole is formed in the limiting sleeve, multiple first limiting keys are arranged on the side wall of the limiting hole, the two sides of the connecting part are each provided with a containing groove, the fixed sleeve part comprises a first sleeve part and a second sleeve part, the first sleeve part and the second sleeve part are arranged in the two containing grooves, the inner surface of the first sleeve part and the inner surface of the second sleeve part are each provided with multiple second limiting keys, and the second limiting keys are staggered from the first limiting keys. Through the drive connecting assembly, power of a driver can be transmitted to a milling cutter, through spline fit of the second limiting keys and a milling cutter, the contact area between the drive connecting assembly and the milling cutter can be effectively increased, wear can be effectively reduced, the milling cutter can be more stable after working for a long time, and the milling effect is better.

Owner:惠州市格农科技有限公司

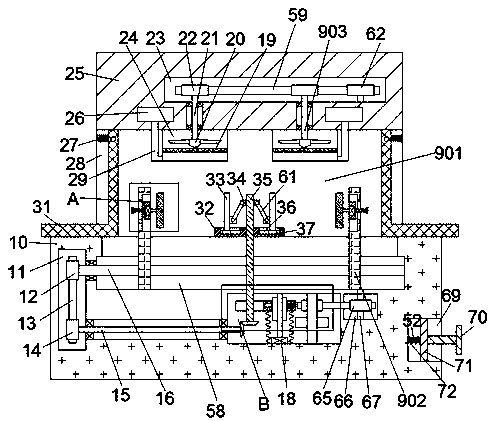

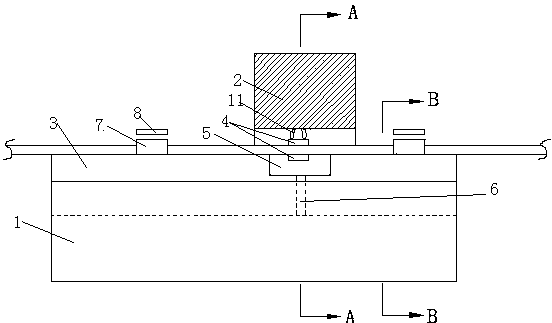

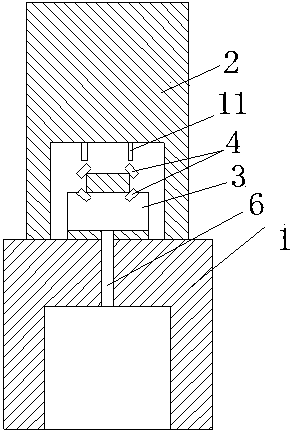

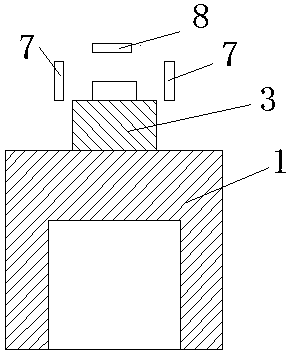

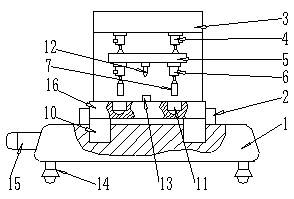

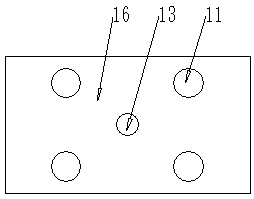

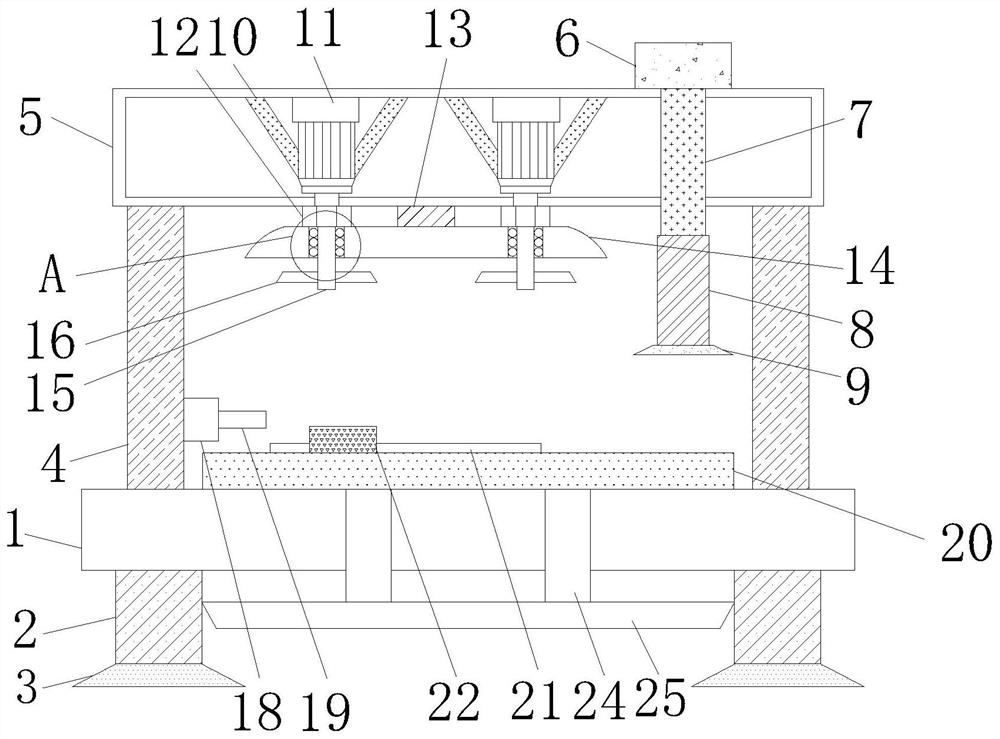

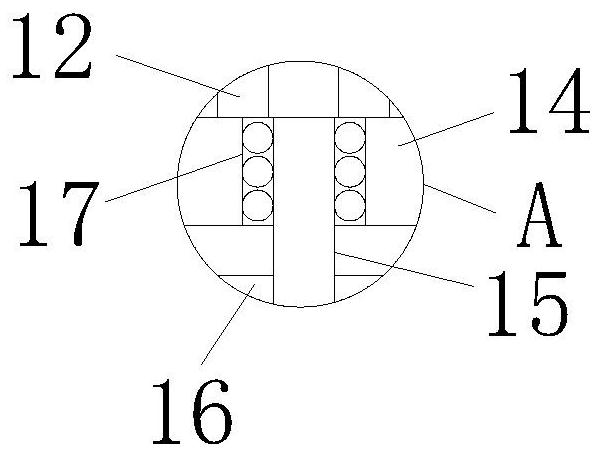

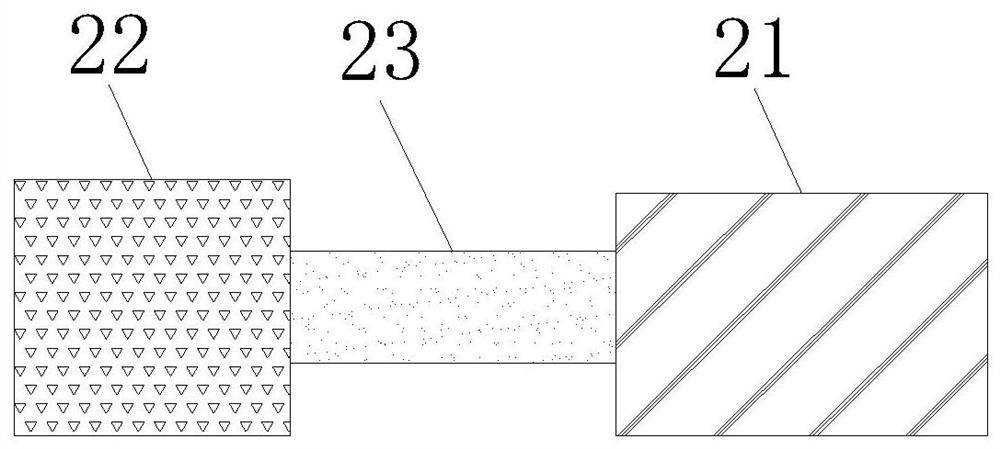

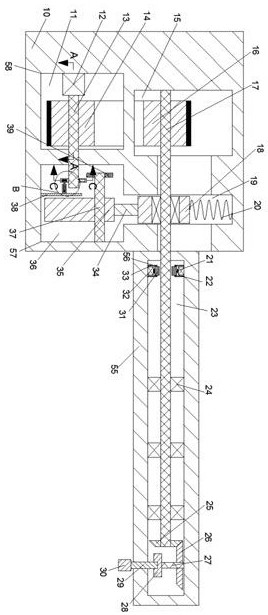

Disposal device of milling waste of hollow steel tube

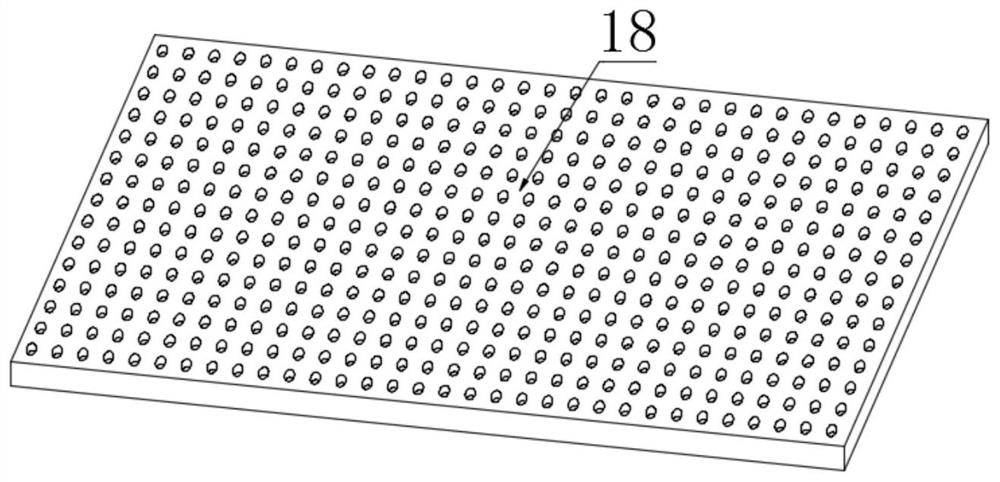

ActiveCN111360304AImprove work efficiencyGood milling effectMilling equipment detailsPositioning apparatusSteel tubeWaste material

The invention provides a disposal device of milling waste of a hollow steel tube. The disposal device comprises a machine body, wherein a placement clamping device is disposed in the machine body; theplacement clamping device comprises a fixation block; and a milling device is also disposed on the lower side of the placement clamping device. The disposal device provided by the invention has the beneficial effects that the to-be-milled steel tube is clamped by the placement clamping device, so that installation instability of the steel tube during milling and influences on milling effects areavoided; the milling device is disposed on the lower side of the placement clamping device and can realize milling of two sides of the steel tube, working efficiency is high, and milling effects are good; and a waste collection device is also disposed on the upper side of the milling device and can collect waste generated after milling in time, so that damage caused by stacking of the milling waste on the device can be avoided.

Owner:聊城市浩鑫机械配件有限公司

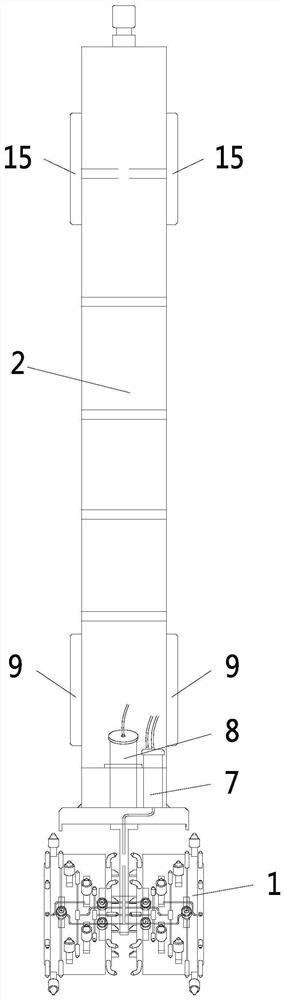

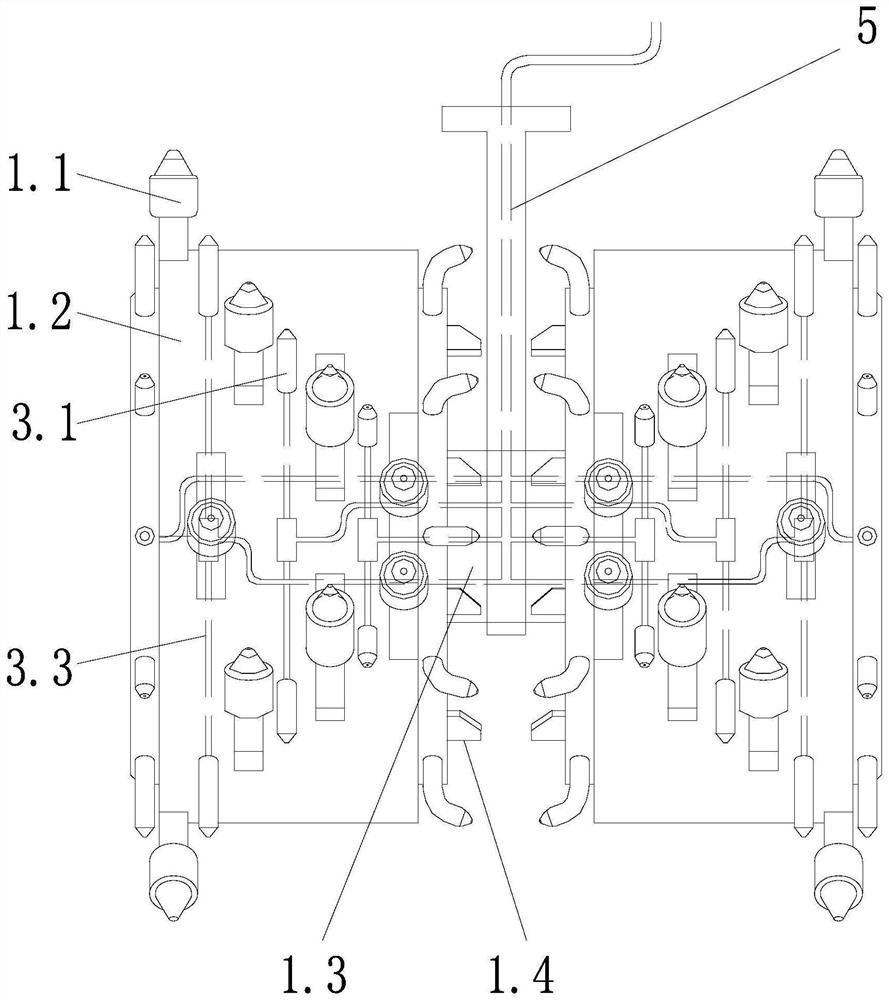

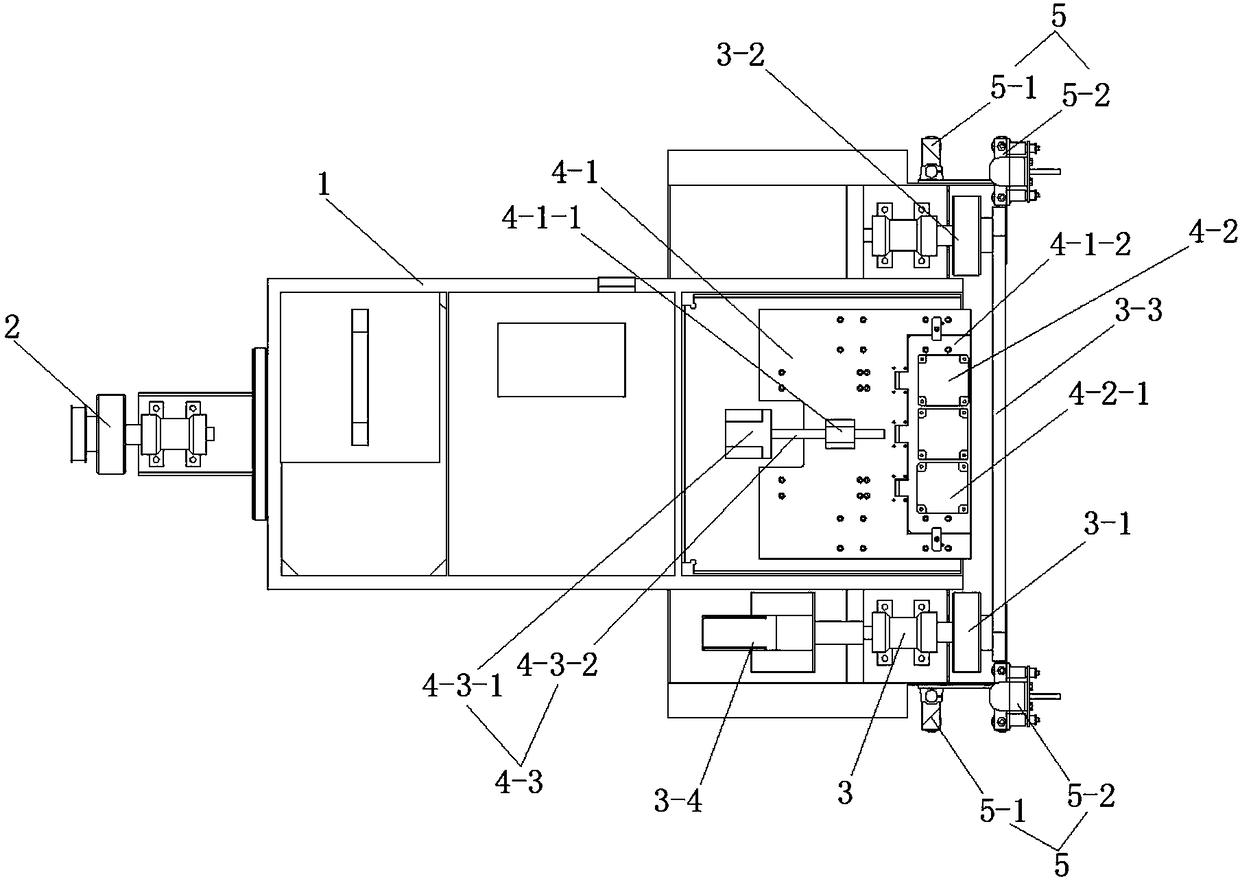

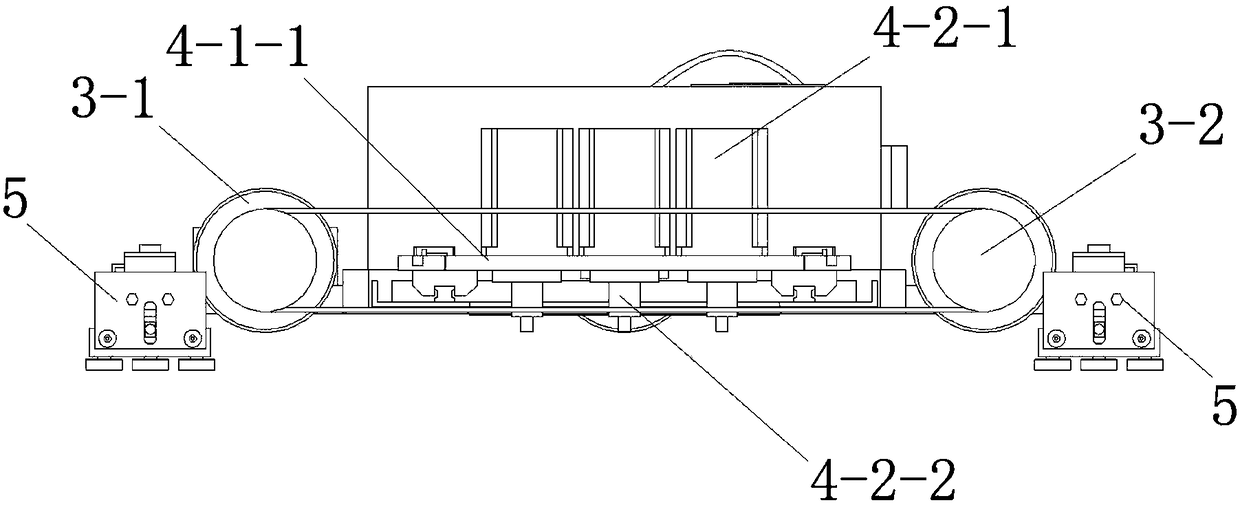

Hydraulic-mechanical combined rock-breaking milling wheel and double-wheel slot milling machine

PendingCN111622288AReduce wearImprove rock breaking efficiencyMechanical machines/dredgersEngineeringStructural engineering

The invention relates to a hydraulic-mechanical combined rock-breaking milling wheel and a double-wheel slot milling machine. The milling wheel comprises a milling wheel body, multiple milling teeth,multiple cutting teeth, a milling wheel spindle and a high-pressure water jet device, wherein the multiple milling teeth are fixed to the circumference of the milling wheel body; the multiple cuttingteeth are arranged in a ring at the inner side of the milling wheel body; the milling wheel spindle drives the milling wheel body to rotate through a milling wheel driving mechanism; the high-pressurewater jet device comprises a nozzle controller, multiple edge-trimming nozzles, multiple rock-breaking nozzles, multiple blind area milling nozzles and multiple fixing components; the nozzle controller is fixed into a through hole of the milling wheel spindle to rotate synchronously with the milling wheel spindle; and the edge-trimming nozzles, the rock-breaking nozzles and the blind area millingnozzles are fixed to the milling wheel body through the fixing components respectively. Through the double-wheel slot milling machine, the rock-breaking efficiency and the rock-breaking effect are both improved to a certain extent compared with a traditional mechanical rock-breaking mode, tool wear is small, a milling blind area has a good milling effect, and improvement to construction efficiency and reduction of construction cost are benefited.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

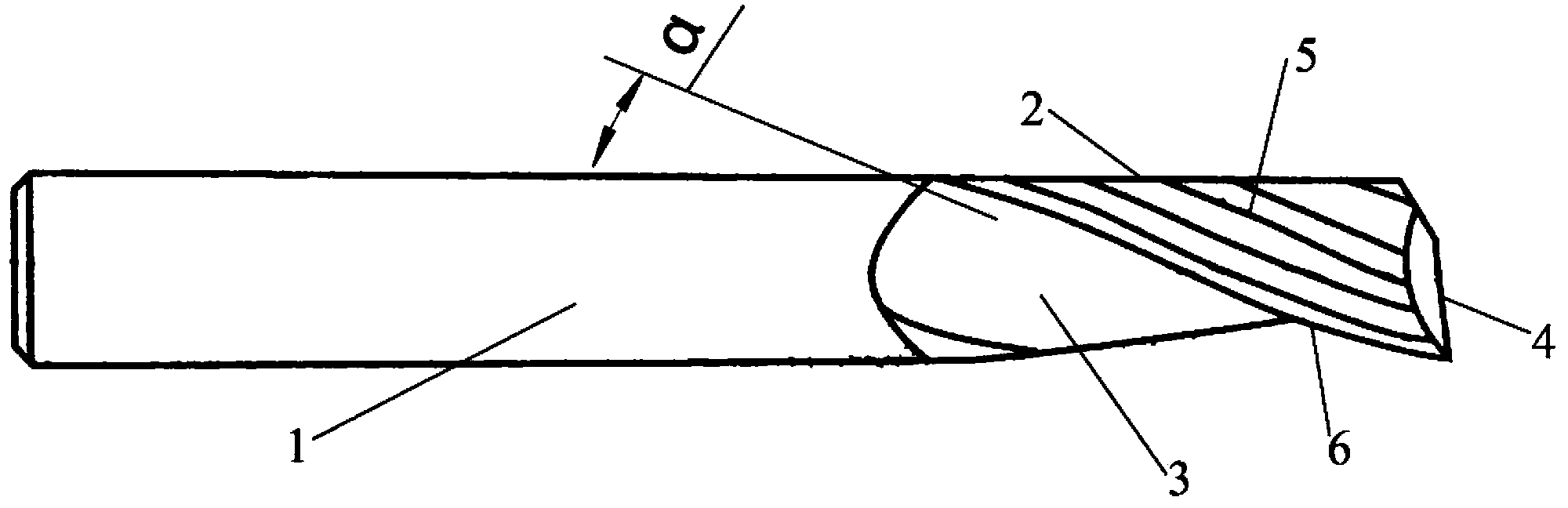

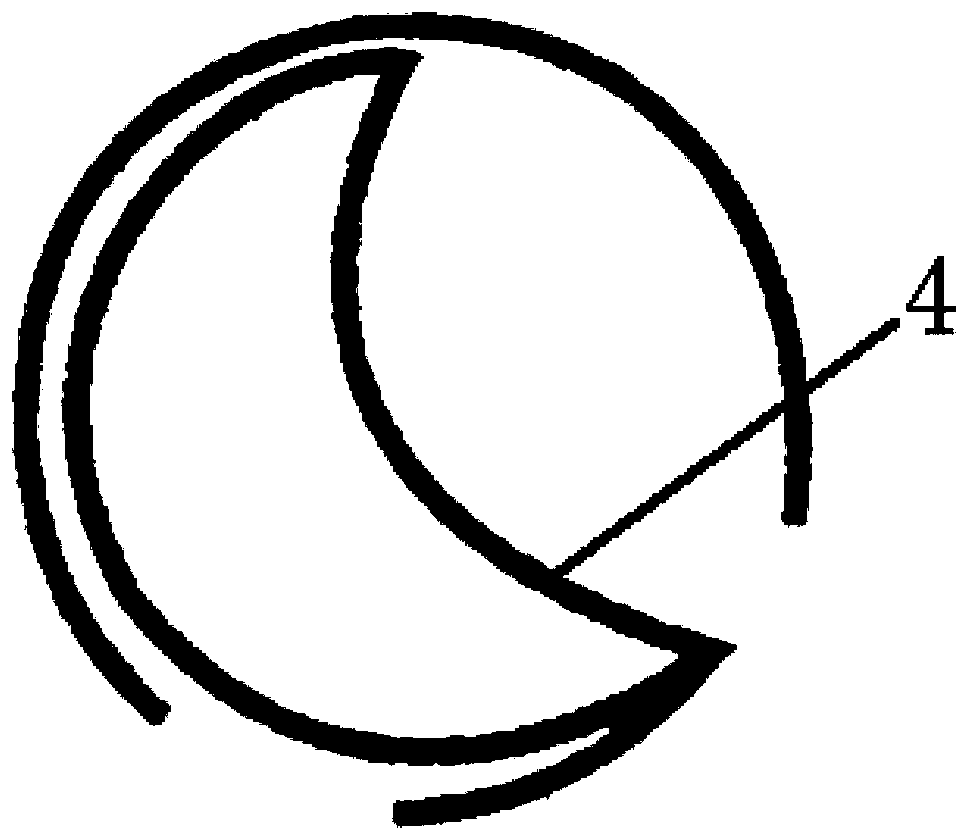

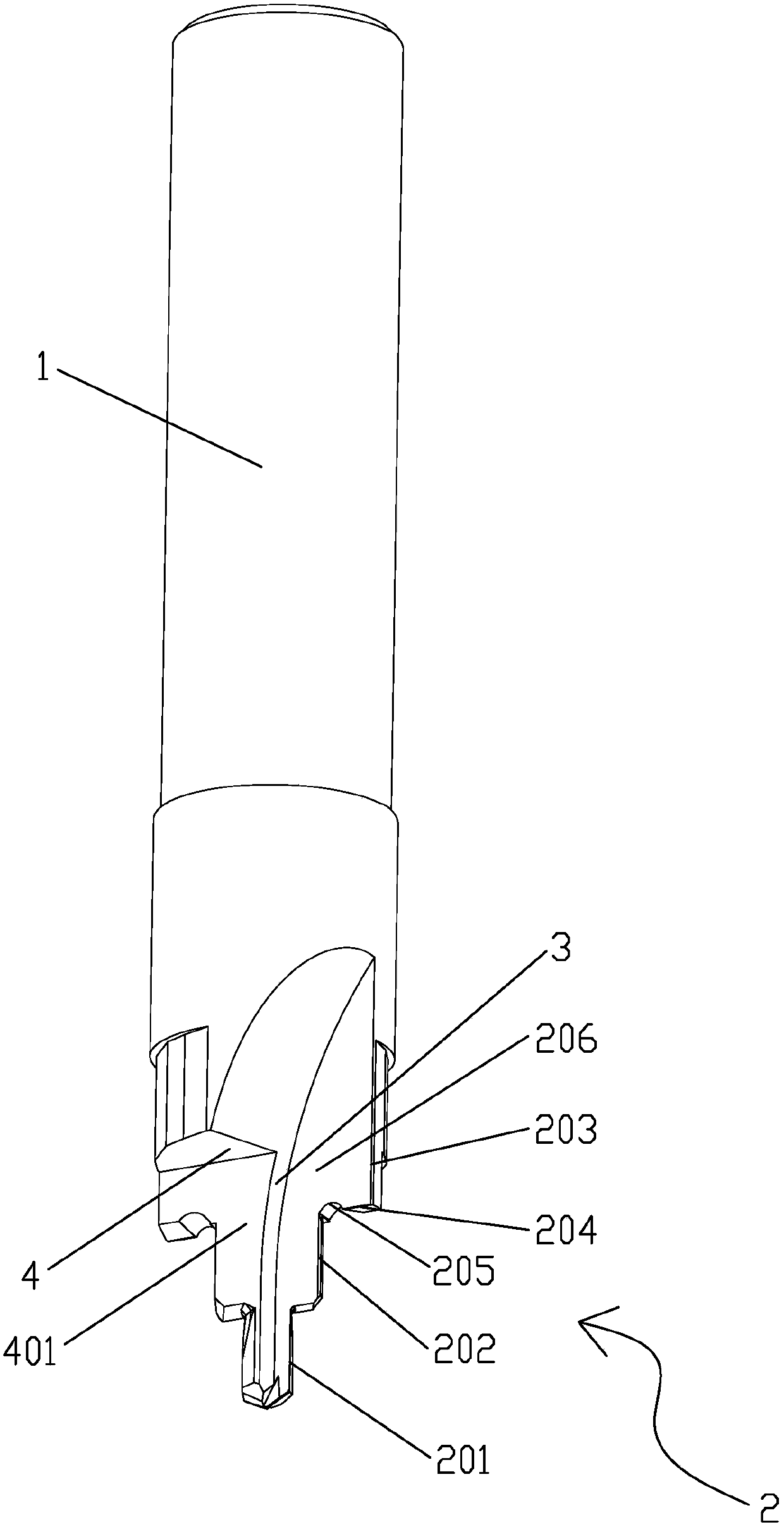

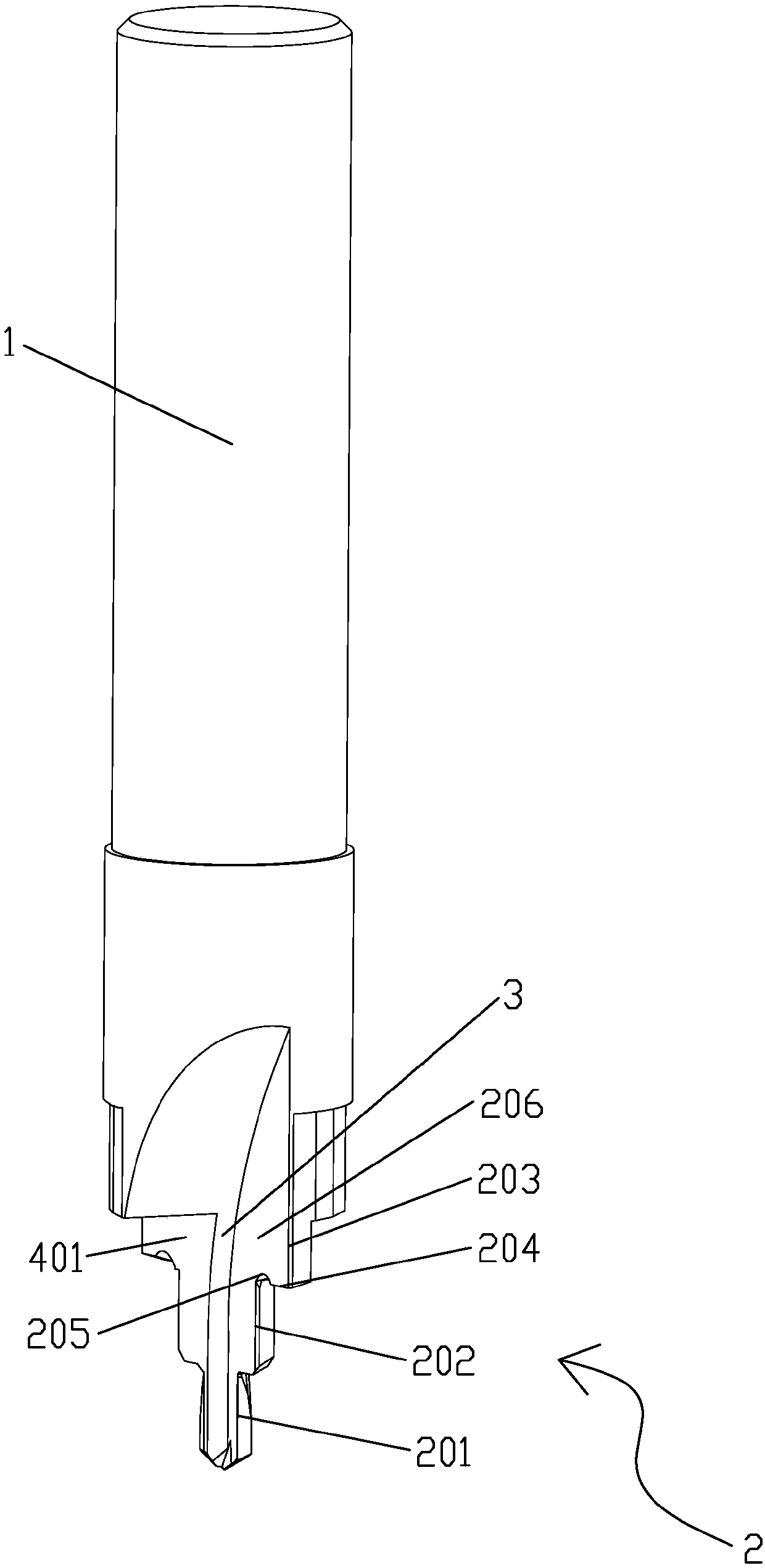

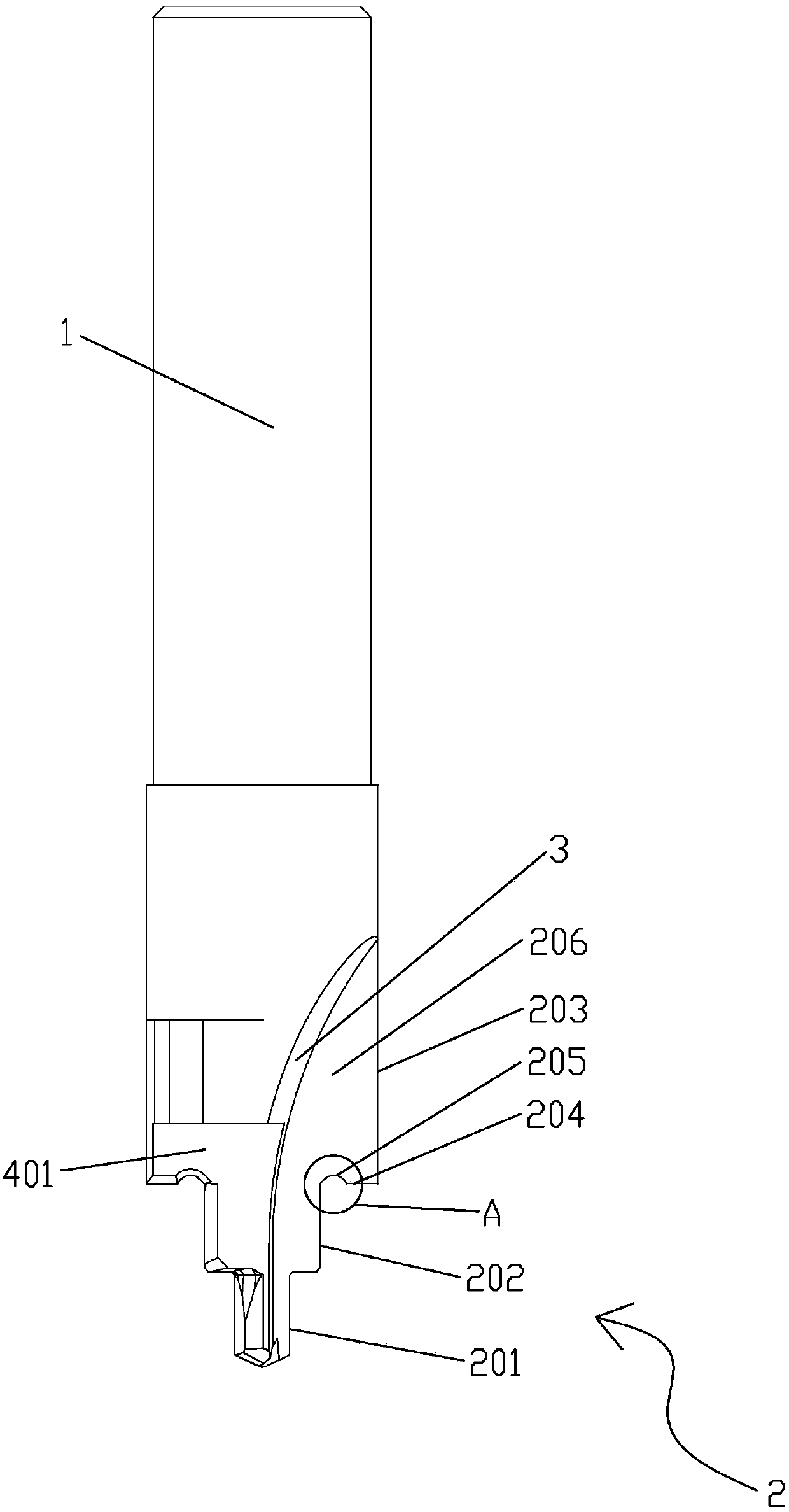

Single-edged milling cutter for aluminum

InactiveCN104339007APrecise processingGood milling effectMilling cuttersWorkpiecesMilling cutterEngineering

The invention relates to a single-edged milling cutter for aluminum. The milling cutter comprise a cutter rod and a cutter head, the cutter head is provided with a helical chip discharging slot, the helical angle alpha of the chip discharging slot is 25DEG or 35DEG, the chip discharging slot extends to the cutter edge at the tip of the cutter head, the cutter edge is crescent in shape, the outer wall surface of the cutter head is provided with a carving back, and the side surface of the cutter head is provided with a side edge. The surface of the cutter head is provided with a titanium aluminum nitride coating. The end portion of the cutter rod is provided with a 45DEG chamfer angle. The single-edged milling cutter adopting the above structure has the advantages of accurate processing and good milling effect.

Owner:CHANGZHOU NAIZHILI TOOLMAKING

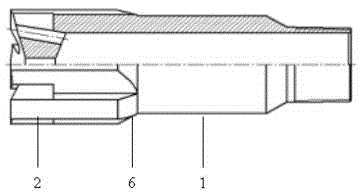

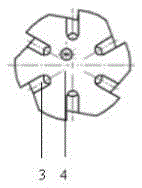

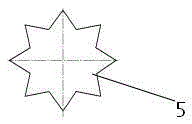

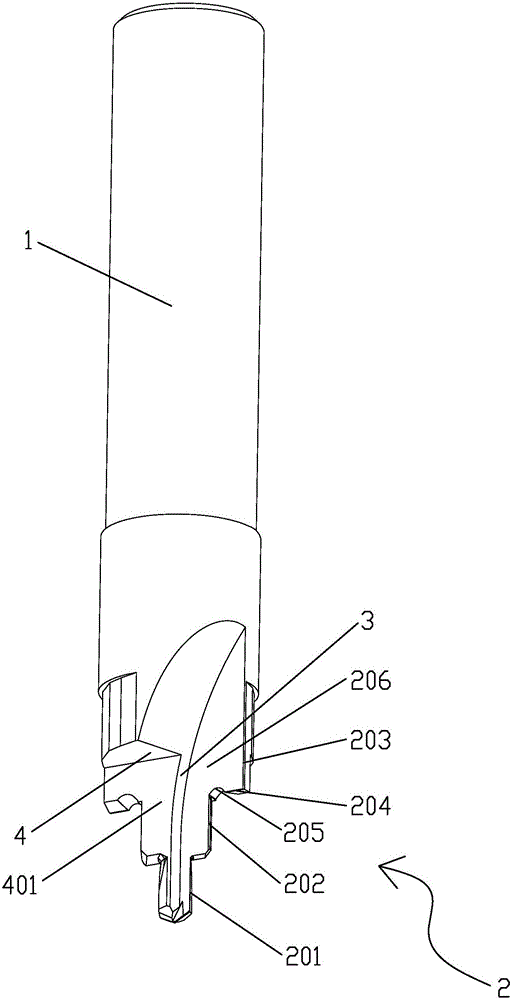

Special efficient grinding shoe for drift-diameter bridge plugs

ActiveCN105422032AImprove drilling efficiencyGuaranteed cleanlinessBorehole/well accessoriesAlloyEngineering

The invention provides a special efficient grinding shoe for drift-diameter bridge plugs. The special efficient grinding shoe comprises a body, a six-section grinding and milling inclined body, YG (tungsten-cobalt) hard alloy blocks and a reverse guide milling and grinding body, wherein one end of the body is connected to the reverse guide milling and grinding body; the reverse guide milling and grinding body is connected to the six-section grinding and milling inclined body; the bottom of the six-section grinding and milling inclined body is provided with seven channels capable of allowing a liquid to circulate; the six channels which are uniformly distributed in a ring-shaped mode are grinding and milling water holes, and the middle channel is a flushing water hole; and a plurality of layers of YG hard alloy blocks are uniformly laid between the six-section grinding and milling inclined body and the reverse guide milling and grinding body by welding. The special efficient grinding shoe can be used for quickly drilling bridge plugs with drift diameters, so that quick drilling among a plurality of bridge plugs is realized. The special efficient grinding shoe can be used for solving the technical problem that the construction efficiency is relatively low due to the fact that fragments and settlings on the lower parts of the bridge plugs cannot quickly go upwards and cannot be deposited.

Owner:PETROCHINA CO LTD

Efficient combined cutting tool

ActiveCN105750605ASimple structureReduce mistakesTransportation and packagingMilling cuttersMachining processMechanical engineering

The invention discloses an efficient combined cutting tool which comprises a main body, wherein one end of the main body can be connected with processing equipment; a cutting structure which can rotate along with the main body is arranged on the main body; the cutting structure comprises a first cutting part which is arranged at the end part of the cutting structure; a second cutting part of which the cutting range is greater than that of the first cutting part is arranged and connected with the first cutting part; a third cutting part of which the cutting range is greater than that of the second cutting part is arranged and connected with the second cutting part; a groove milling processing part is arranged on the third cutting part; a chamfering cutting part for chamfering edges of a workpiece after groove milling is arranged between the groove milling processing part and the second cutting part; the first cutting part, the second cutting part, the third cutting part and the chamfering cutting part are arranged on the same cutting plane. In the machining process, the efficient combined cutting tool does not need to change cutters or stations, so that errors can be reduced, the yield can be ensured, and meanwhile the working efficiency can be improved.

Owner:中山市光和精密科技有限公司

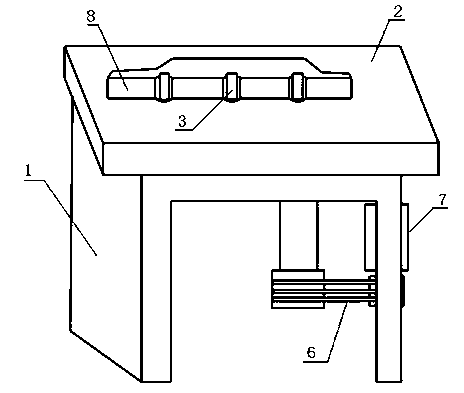

Edge-milling machine

InactiveCN103737085ASimple structureEasy to useMilling equipment detailsMetal working apparatusMilling cutterEngineering

The invention discloses an edge-milling machine which comprises a pedestal; a frame is disposed on the pedestal; a transfer channel is disposed on the pedestal; the transfer channel is located below the frame; milling cutters are mounted at positions corresponding to four corners of a workpiece on the frame; the positions of the milling cutters are adjustable; grooves are disposed at the positions corresponding to the four milling cutters in the transfer channel; a chip-discharging channel is disposed at the bottom of the grooves; guiding devices are respectively disposed at the charging side and the discharging side of the frame on the pedestal; each guiding device is located above the transfer channel. The edge-milling machine of the invention is good in milling effect, high in efficiency, fluent in process, not liable to trimming, suitable for metal bands with different widths and thicknesses, wide in application range, convenient and practical.

Owner:宋芬

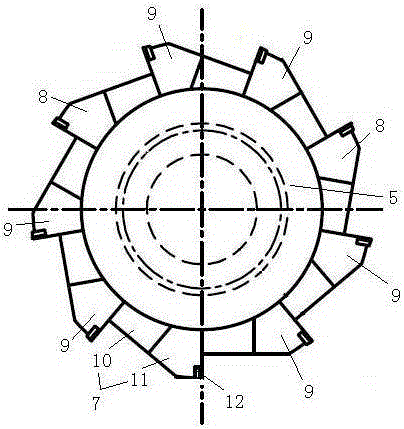

Memory card rotary disk and processing method thereof

PendingCN109063791AHigh precisionQuality improvementConveying record carriersMilling equipment detailsSmart cardEngineering

A memory card rotary disk and its processing method are disclosed, wherein the memory card turntable comprises a turntable main body, the turntable main body is provided with a plurality of receivinggrooves for receiving smart cards along the circumferential direction, one end of each receiving groove is an opening for allowing in and out of the card, the opening is located on the outer cylindrical surface of the turntable, the other end of each receiving groove extends toward the inside of the turntable, one or more guide partitions for guiding and separating the card as it enters and exitsthe receiving groove are provided on the inner side of each receiving groove, The guide partition partitions the opening of the receiving slot into at least two card inlets and outlets, each card inlet and outlet and a space in which the card inlet and outlet extend in the receiving slot form a card storage slot for a smart card. The structure of the memory card rotary disk is ingenious, which cangreatly reduce the processing difficulty of the memory card rotary disk and improve the processing efficiency, so the memory card rotary disk has the advantages of convenient processing and good useeffect.

Owner:GUANGZHOU MINGSEN TECH CO LTD

Cutting Combination Tool

ActiveCN105750605BSimple structureReduce mistakesTransportation and packagingMilling cuttersEngineeringMachining process

The invention discloses an efficient combined cutting tool which comprises a main body, wherein one end of the main body can be connected with processing equipment; a cutting structure which can rotate along with the main body is arranged on the main body; the cutting structure comprises a first cutting part which is arranged at the end part of the cutting structure; a second cutting part of which the cutting range is greater than that of the first cutting part is arranged and connected with the first cutting part; a third cutting part of which the cutting range is greater than that of the second cutting part is arranged and connected with the second cutting part; a groove milling processing part is arranged on the third cutting part; a chamfering cutting part for chamfering edges of a workpiece after groove milling is arranged between the groove milling processing part and the second cutting part; the first cutting part, the second cutting part, the third cutting part and the chamfering cutting part are arranged on the same cutting plane. In the machining process, the efficient combined cutting tool does not need to change cutters or stations, so that errors can be reduced, the yield can be ensured, and meanwhile the working efficiency can be improved.

Owner:中山市光和精密科技有限公司

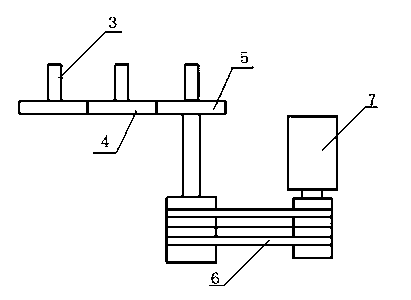

Wood milling machine

InactiveCN103009215AImprove milling efficiencyGood milling effectGrinding machinesGear driveWoodworking

A wood milling machine comprises a stander, wherein the stander is provided with a worktable, the worktable is provided with at least one milling and grinding rotating shaft, the lower part of the milling and grinding rotating shaft is connected with a driven gear, the driven gear is engaged with a driving gear, the driving gear is connected with a motor through a belt, abrasive cloth is wound on the milling and grinding rotating shaft, one side of the material, needing to be milled and ground, is contacted with the milling and grinding rotating shaft on the upper part of the worktable, a motor is started to drive the driving gear, and the driving gear drives the driven gear to rotate, so that the milling and grinding rotating shaft is driven to rotate to mill and grind the material. The wood milling machine has the characteristics of simplicity in structure, good milling and grinding effect and high efficiency.

Owner:刘秀芹

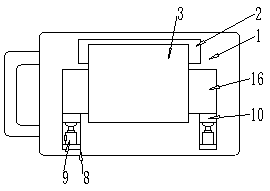

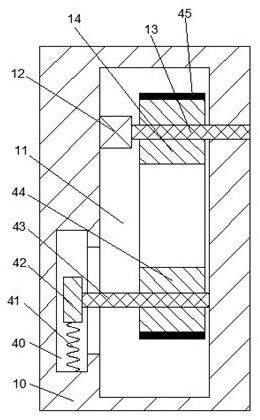

Valve pressing cap quick groove milling device

PendingCN109047868AEasy to operateGood milling effectMeasurement/indication equipmentsMilling machinesSurface mountingMilling cutter

Owner:苏州谊佳润机电制造有限公司

Woodworking milling machine

InactiveCN112388747AImprove dust removal effectImprove cleanlinessProfiling/shaping machinesBark-zones/chip/dust/waste removalHydraulic cylinderDust control

The invention relates to the technical field of woodworking machines, and discloses a woodworking milling machine which comprises a pedestal. Supporting columns are fixedly connected to the bottom ofthe pedestal, a fixing base is fixedly connected to one end of each supporting column, connecting columns are fixedly connected to the top of the pedestal, and a top base is fixedly connected to one end of each connecting column. A first hydraulic cylinder is fixedly connected to the top of the top base, a first hydraulic rod is fixedly connected to an output shaft of the first hydraulic cylinder,a fixing rod is fixedly connected to one end of the first hydraulic rod, a pressing disc is fixedly connected to one end of the fixing rod, supporting rods are fixedly connected to the inner top wallof the top base, and one end of each supporting rod is fixedly connected with a first motor. According to the woodworking milling machine, the purpose of efficient dust removal can be achieved, the problem that an ordinary woodworking milling machine is poor in dust removal effect is solved, the situation that wood chips fly around in the machining process is avoided, and therefore workers can sweep and maintain the milling machine conveniently in the later period, the using effect is good, and the woodworking milling machine is worthy of wide popularization.

Owner:扬州市金阳光铸造有限公司

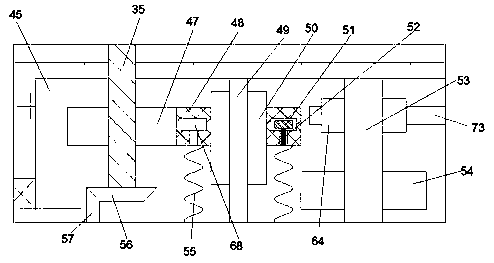

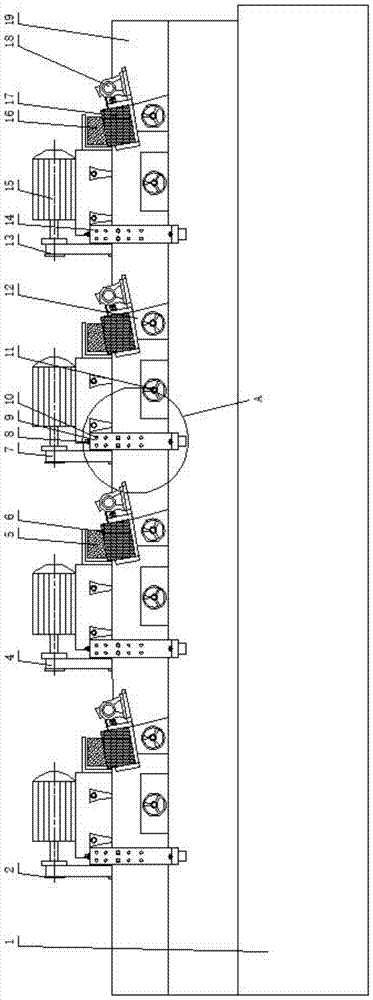

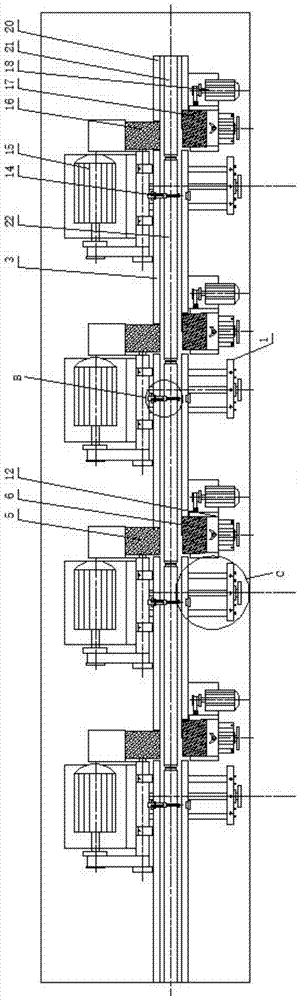

Steel rail fat edge milling device

PendingCN108515220AExtended service lifeIngenious structureWorkpiecesMilling equipment detailsVehicle frameMilling cutter

The invention discloses a steel rail fat edge milling device which comprises a frame, a working part and a supporting wheel, wherein the working part and the supporting wheel are separately mounted ontwo sides of the frame; the working part comprises a walking mechanism, a milling mechanism and a multi-guide wheel clamping mechanism; the walking mechanism and the supporting wheel are separately overlaid on two steel rails; the driving frame moves along the steel rails; the milling mechanism comprises a bottom plate, a milling cutter assembly and an adjusting assembly; the multi-guide wheel clamping mechanism clamps one steel rail and moves along the steel rails along with the frame; the bottom plate is slidably connected to the frame; the milling cutter assembly is mounted at the edge ofone side, facing the steel rails clamped by the multi-guide wheel clamping mechanism, of the bottom plate; and the adjusting assembly is used for adjusting the distance between the bottom plate and the steel rails clamped by the multi-guide wheel clamping mechanism and can fix the position of the bottom plate. The steel rail fat edge milling device disclosed by the invention is skillful in structure, high in degree of automation, more excellent in milling effect, high in milling speed, high in efficiency and longer in service life of a milling cutter. Compared with single-layered milling, reverse quake is smaller, and the structure is more stable.

Owner:CHANGZHOU HUAMING AUTOMATION TECH CO LTD +1

Milling machine for wrench opening

InactiveCN103394737AGuaranteed uptimeGood milling effectMilling equipment detailsDriving apparatusHydraulic cylinderFixed frame

The invention discloses a milling machine for a wrench opening. The milling machine comprises a transmission device, a fixing frame, a hydraulic cylinder, a wrench fixture and a work bench, wherein the transmission device comprises a motor and a knife shaft; the motor and the knife shaft are respectively fixed on the fixing frame through a bearing; the motor is transmittedly connected with one end of the knife shaft; the other end of the knife shaft is fixedly connected with an alloy milling cutter; the side wall of the fixing frame and the side wall of the work bench are slidingly connected by a sliding table; the hydraulic cylinder is disposed below the fixing frame; the wrench fixture is disposed in front of the milling cutter; the fixture comprises a pedestal, a support, a hydraulic piston disposed in the support and the fixing plate disposed on the top of the support; the hydraulic piston and the support are disposed at the top of the pedestal; a piston rod of the hydraulic piston penetrates through the fixing plate and protrudes out of the support; the top of the piston rod of the hydraulic piston is provided with a press block; the top surface of the fixing plate is provided with a lug; and the lug and the milling cutter form an included angle. The wrench opening milled by the machine is flat in surface, good in quality, high in work efficiency and convenient for use.

Owner:湖南湘江工具制造有限公司

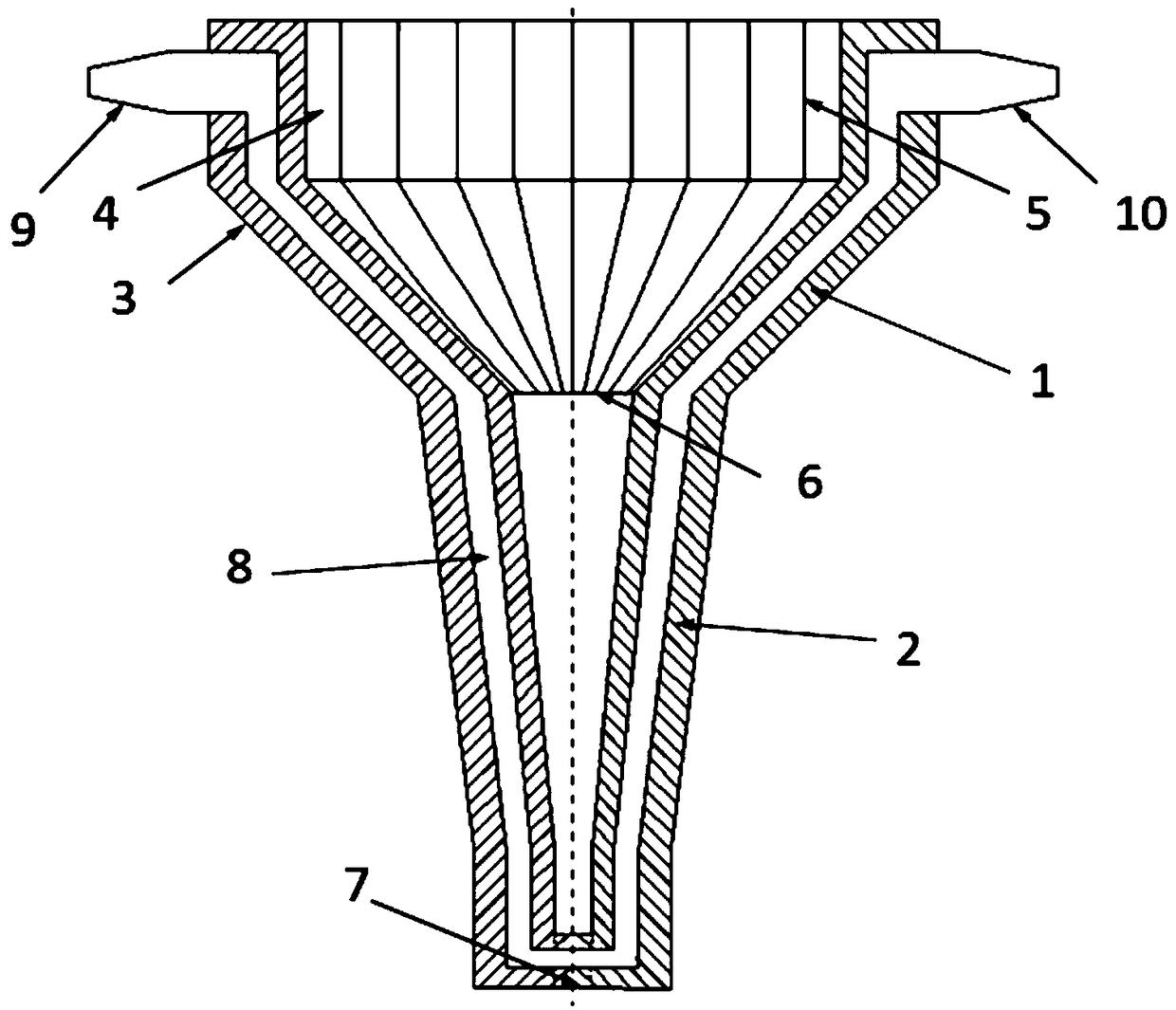

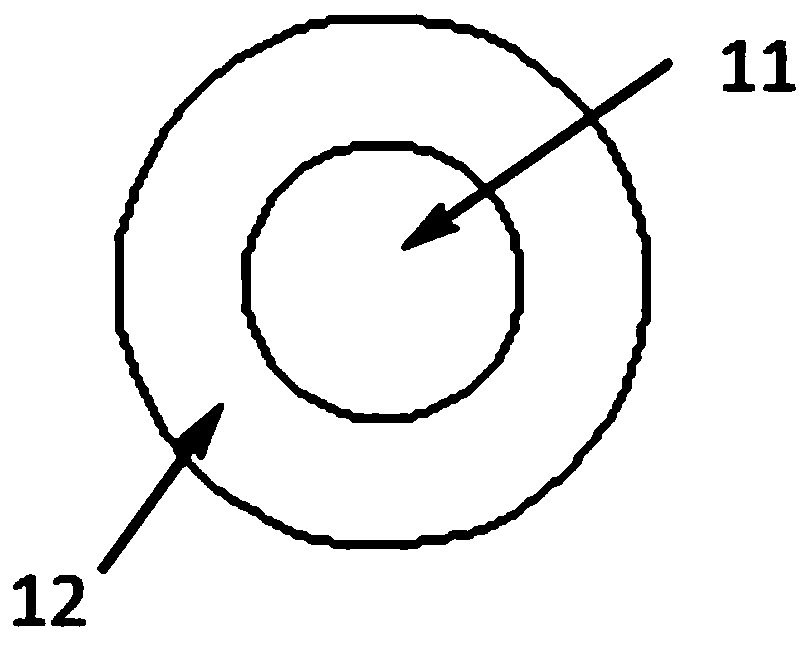

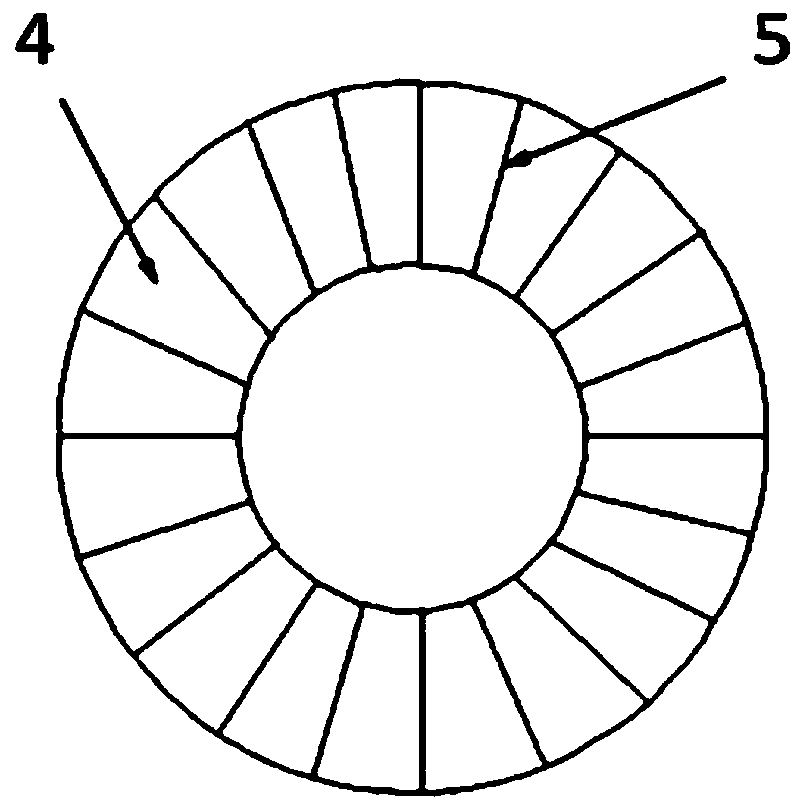

Water-cooling copper crucible device for atomization powdering

The invention belongs to the technical field of preparation of spherical metal powder through an atomization method, and particularly relates to a water-cooling copper crucible device for atomizationpowdering. The water-cooling copper crucible device is of an integrated structure, and comprises an upper crucible body and a lower leaking column; the crucible body comprises an outer side wall and crucible flaps; the crucible flaps are fixed to the inner side of the outer side wall, and a gap is formed between the crucible flaps and allows a magnetic line to penetrate through; the bottoms of thecrucible flaps are welded to the top end of the leaking column, and the inner diameter of the top end of the leaking column is equal to the minimum diameter of the bottoms of the crucible flaps; andthe upper part of the leaking column is of a design structure with the caliber being decreased stage by stage, and the lower part of the leaking column is of a straight-tube-shaped design structure. Amethod for decreasing the caliber of the leaking column stage by stage is adopted, thus heat conduction of the bottoms of solid materials is improved, the materials can be completely molten and smoothly flow down, the problem that a liquid flow cannot smoothly flow down, and consequently the leaking column is blocked is solved, and the lower part of the leaking column is designed into a straighttube shape, so that the powering effect is improved.

Owner:NANJING UNIV OF SCI & TECH +1

Steel pipe polishing and milling combination machine

InactiveCN105364497BReduce labor intensityImprove work efficiencyWork clamping meansOther manufacturing equipments/toolsEconomic benefitsEngineering

Owner:天津市聚永顺科技发展有限公司

A kind of inner surface milling processing equipment

ActiveCN110871287BReduce vibrationImprove machining accuracyFeeding apparatusMilling equipment detailsNumerical controlMilling cutter

Owner:昆山市拓川诚自动化设备有限公司

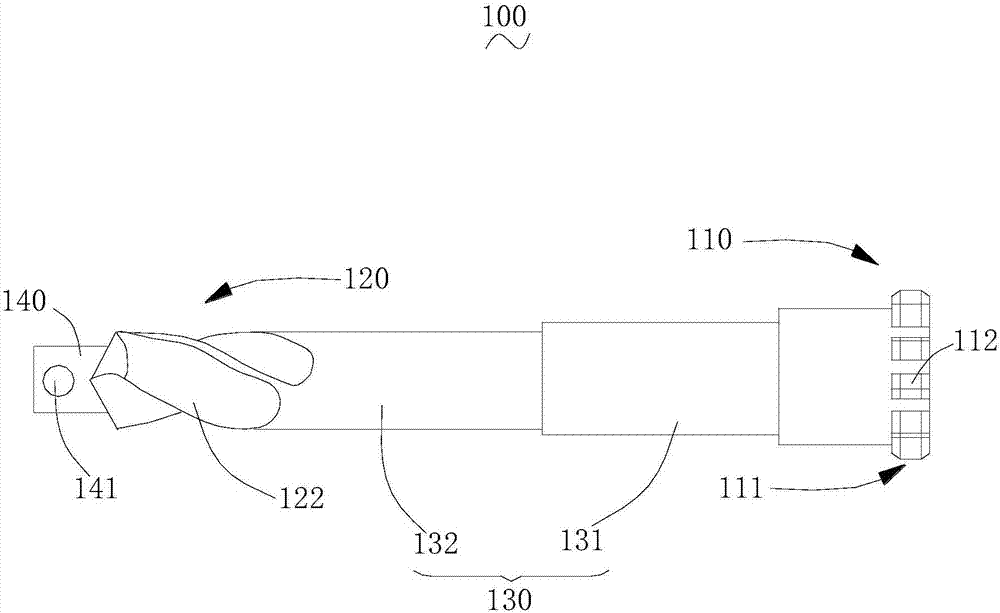

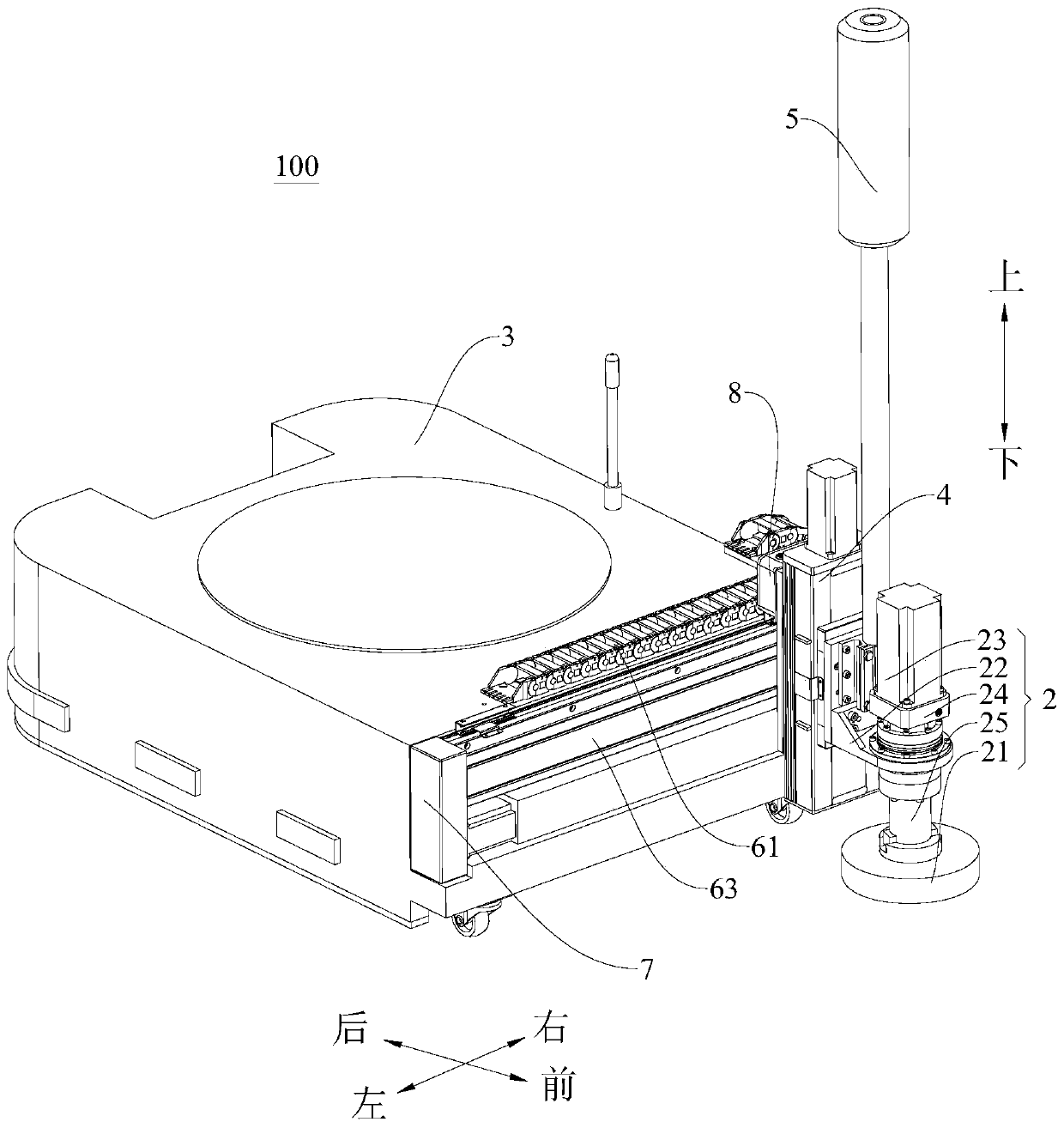

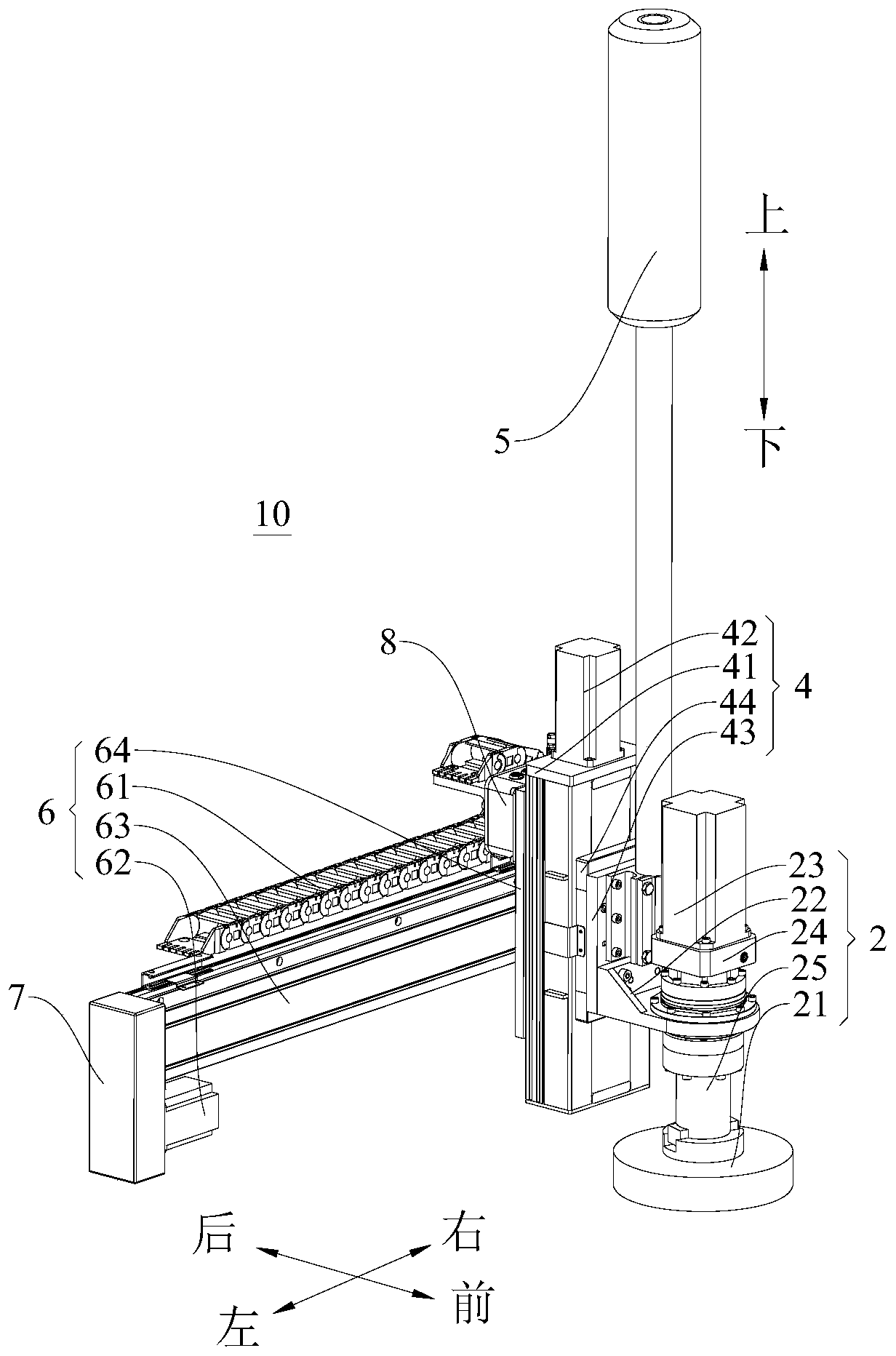

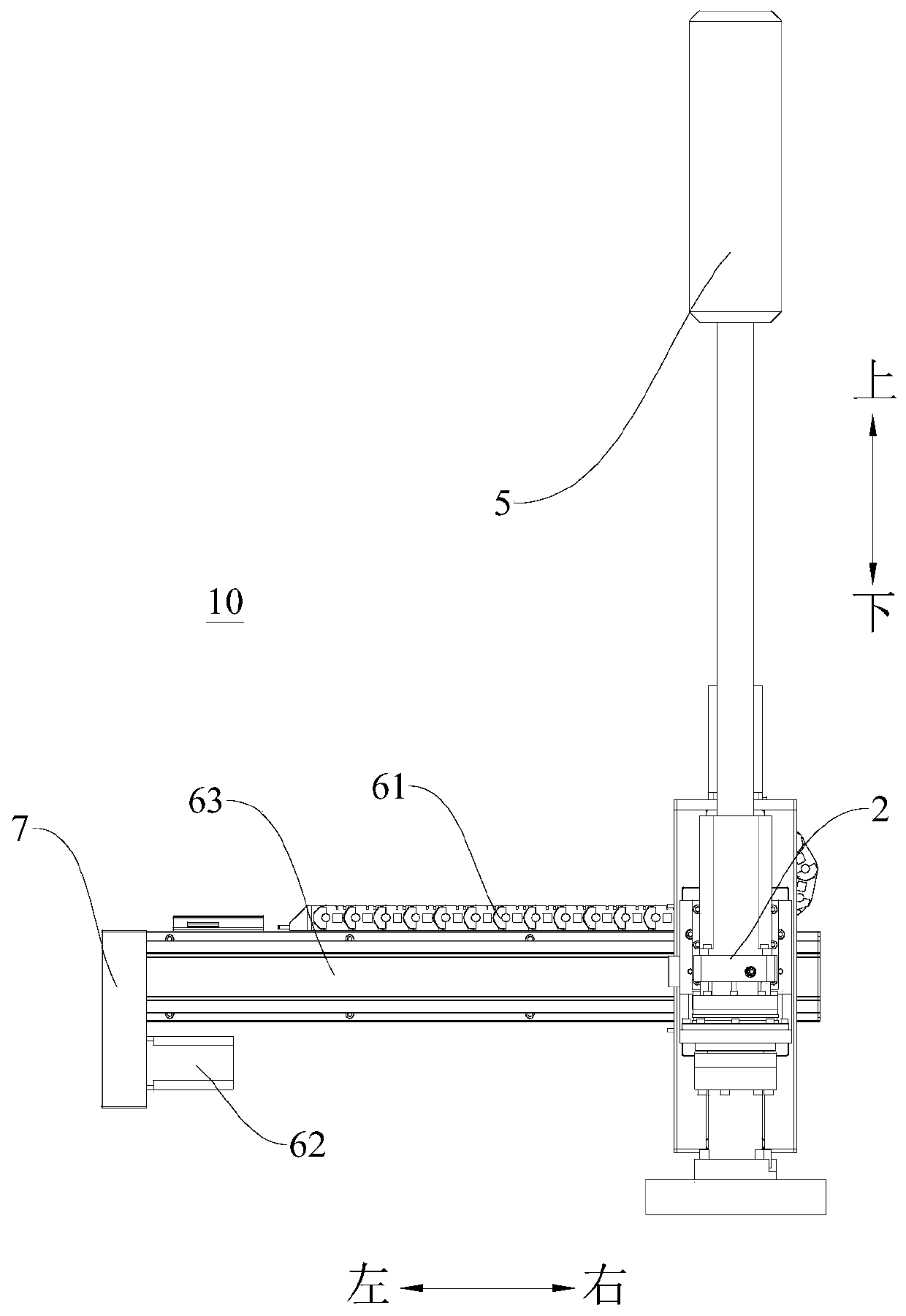

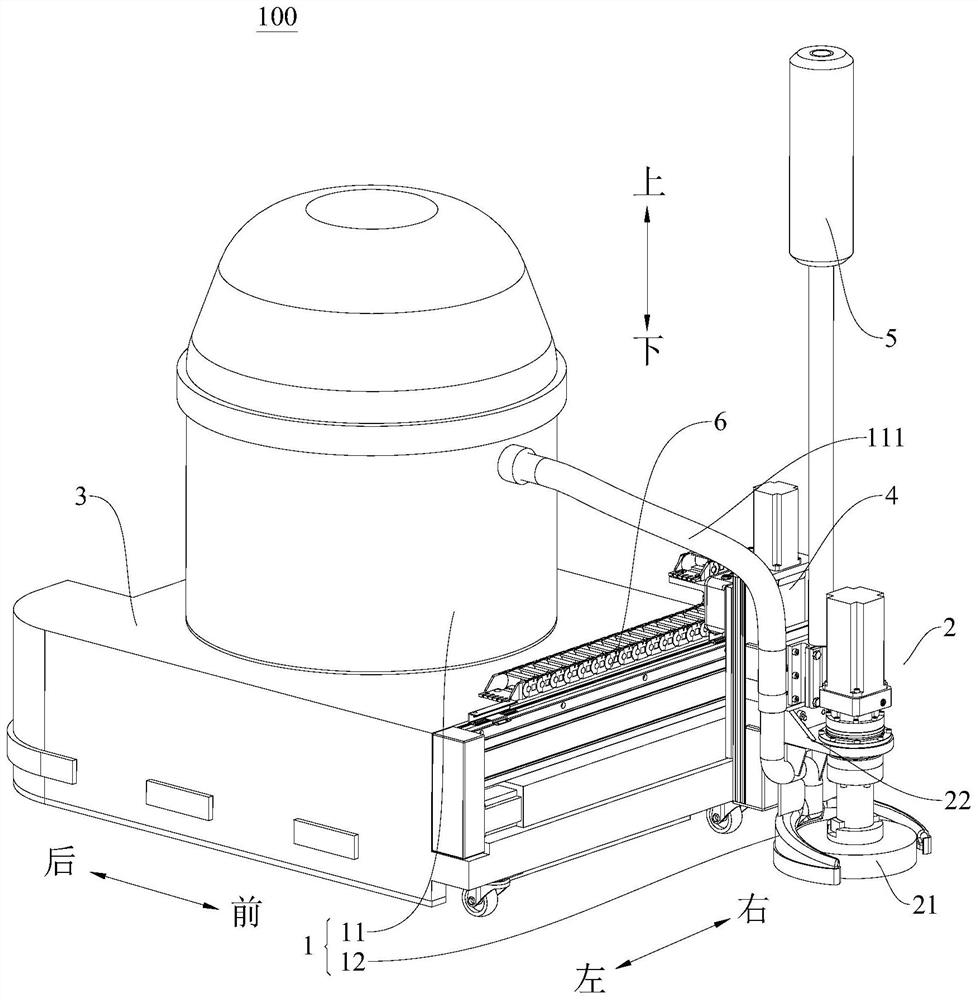

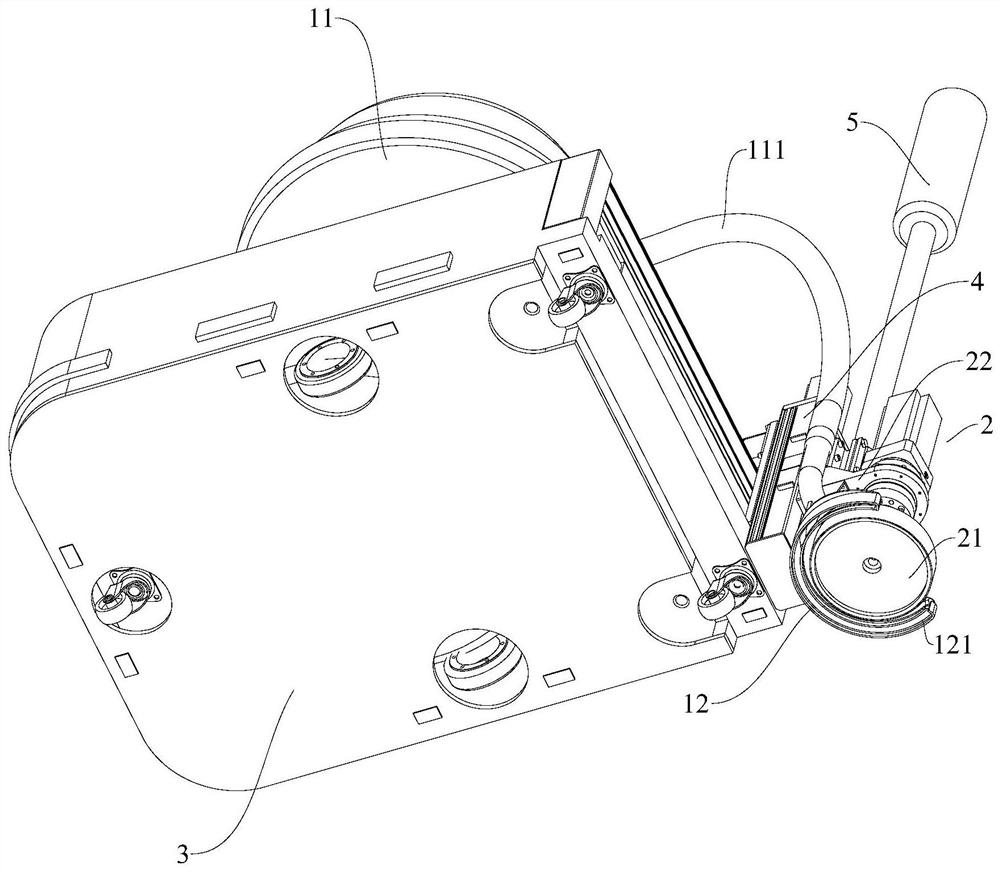

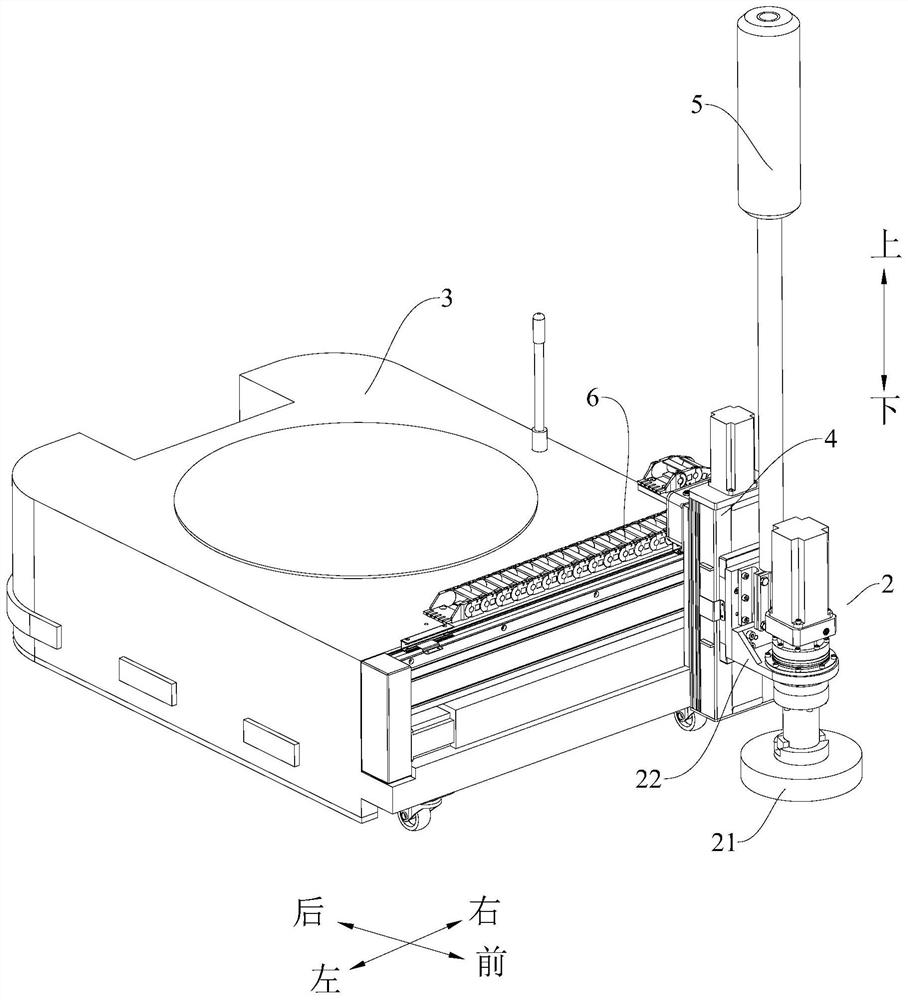

Milling device and milling robot provided with same

InactiveCN110424697AIncreased efficiency in milling and flattening operationsIncrease flexibilityBuilding constructionsAgricultural engineeringRobot

The invention discloses a milling device and a milling robot provided with the same. The milling device comprises a rack, a milling module, a horizontal driving device and a vertical driving device. The milling module is used for milling the surface of a substrate. The horizontal driving device is arranged on the rack and can drive the milling module to move in the horizontal direction. The vertical driving device is arranged between the horizontal driving device and the milling module and can be driven by the horizontal driving device to move left and right. The vertical driving device is used for driving the milling module to move in the vertical direction. The milling device provided by the embodiment of the invention is good in flexibility, high in milling operation efficiency and goodin effect.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

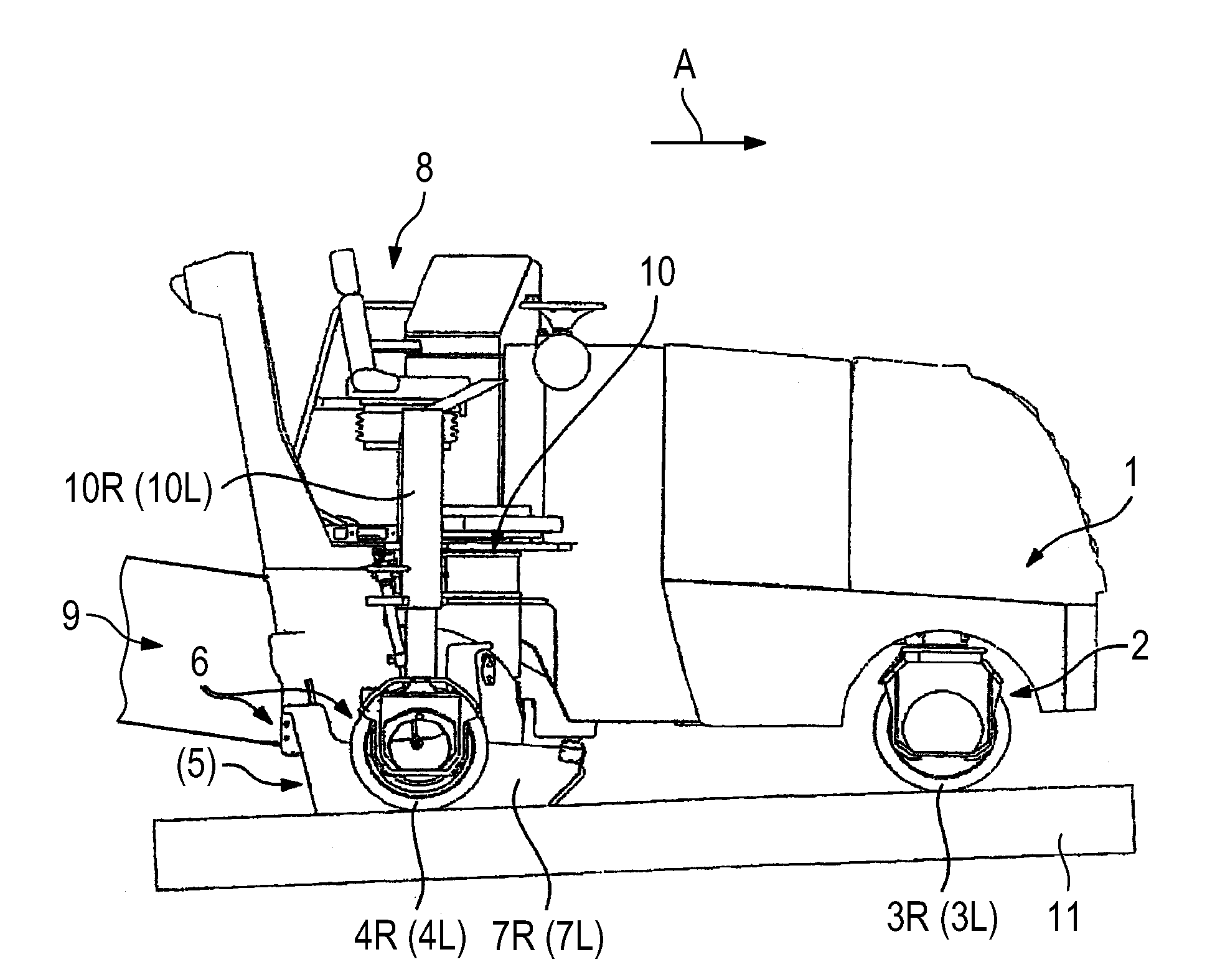

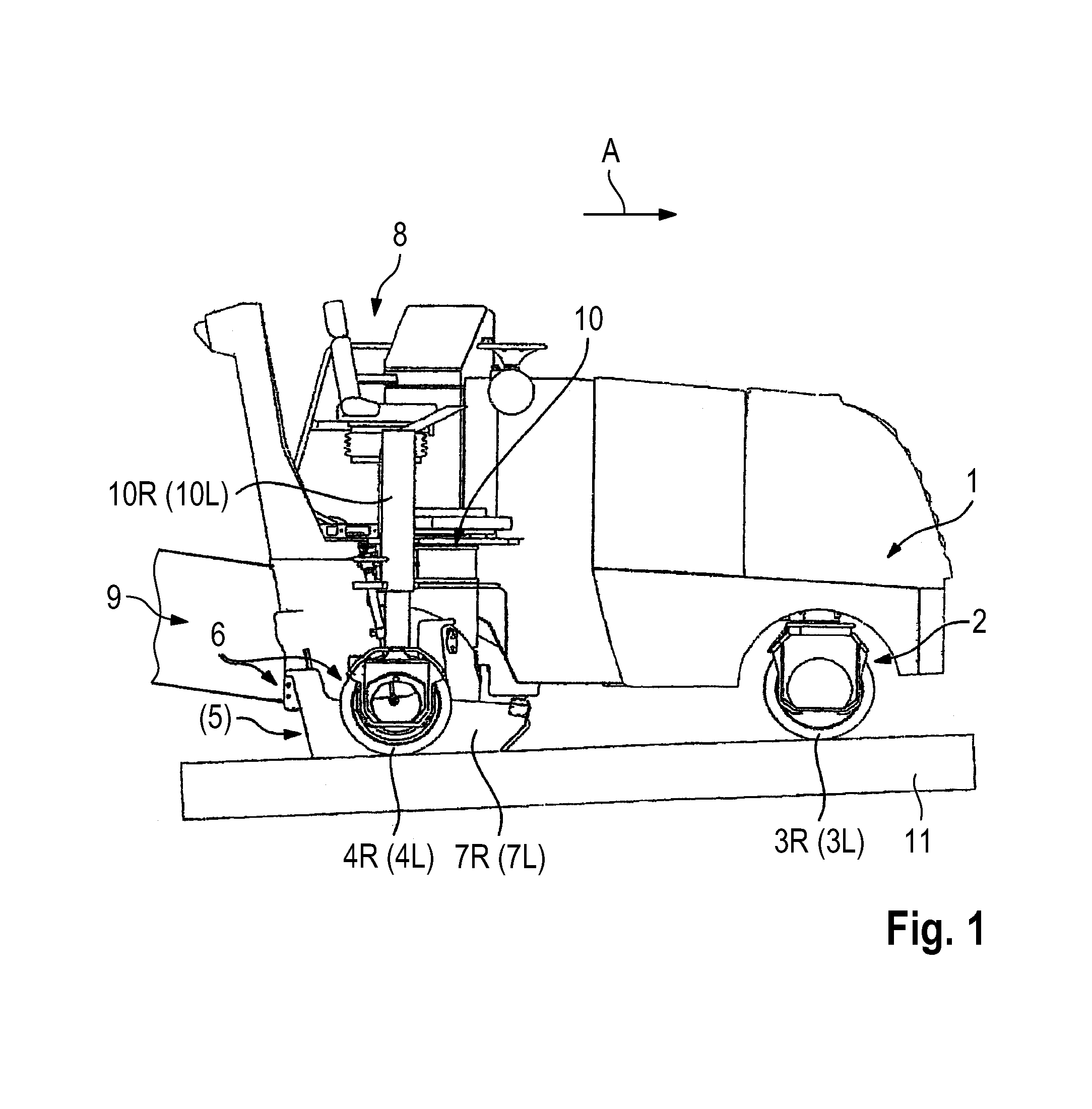

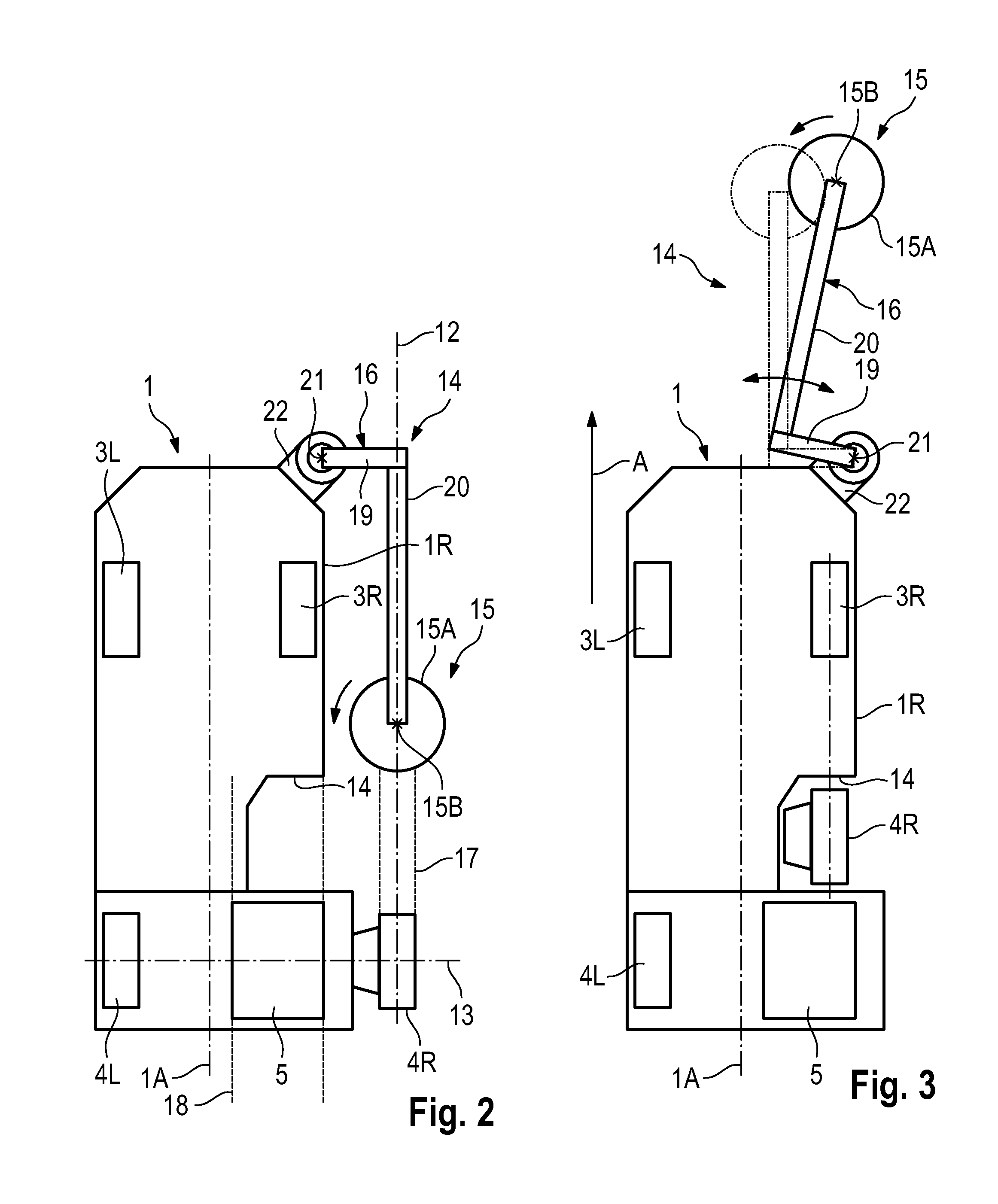

Self-Propelled Road Milling Machine

ActiveUS20160130772A1Good milling effectPromote resultsRoad cleaningRoads maintainenceTerrainRoad surface

The road milling machine according to the invention comprises a cleaning device which has a cleaning unit arranged in front of the work roller in the working direction. The cleaning unit ensures that the surface of the terrain over which the wheels or running gears travel is clear of material. As a result, an optimum milling result is always achieved. The invention takes effect in particular when using small millers which have at least one rear wheel or running gear which can be moved into an inner working position in relation to a longitudinal side of the machine frame and into an outer working position in relation to a longitudinal side of the machine frame. In this preferred embodiment, the cleaning device comprises a pivot device which is designed in such a way that the cleaning unit can be moved into an inner working position in relation to a longitudinal side of the machine frame and into an outer working position in relation to a longitudinal side of the machine frame. In the inner or outer working position, the cleaning unit is arranged on the same track as the rear wheel or running gear which can be moved into the inner or outer working position. This ensures that the track of the rear wheel or running gear is clear of milled material or other dirt, wherein the cleaning unit does not protrude too far beyond the rear wheel or running gear.

Owner:WIRTGEN GMBH

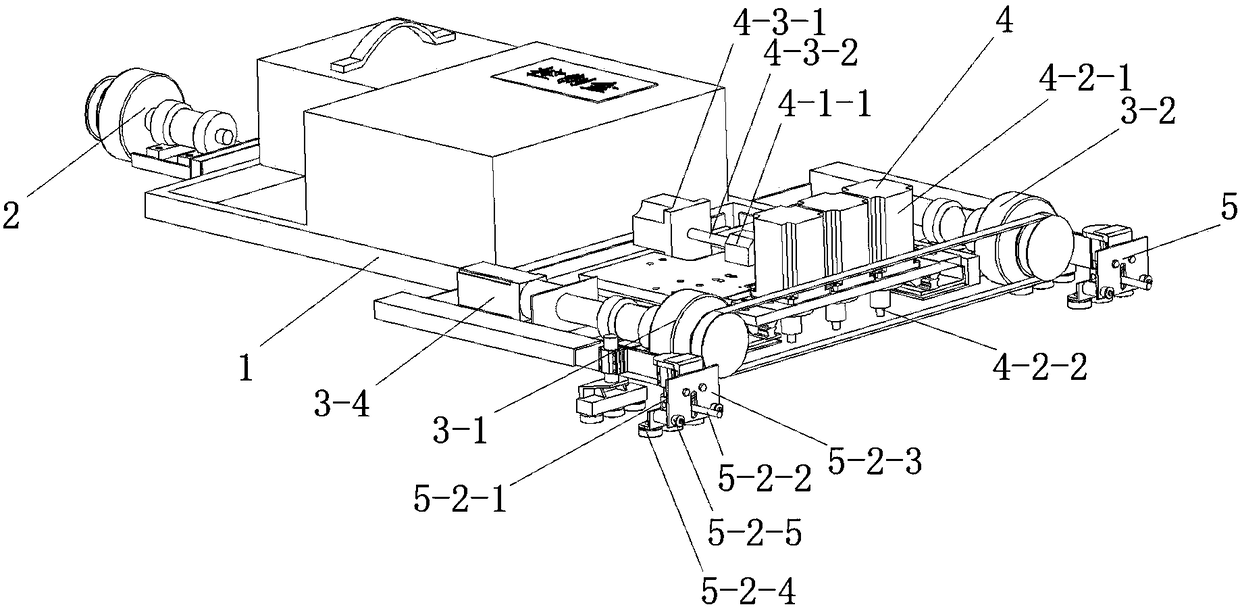

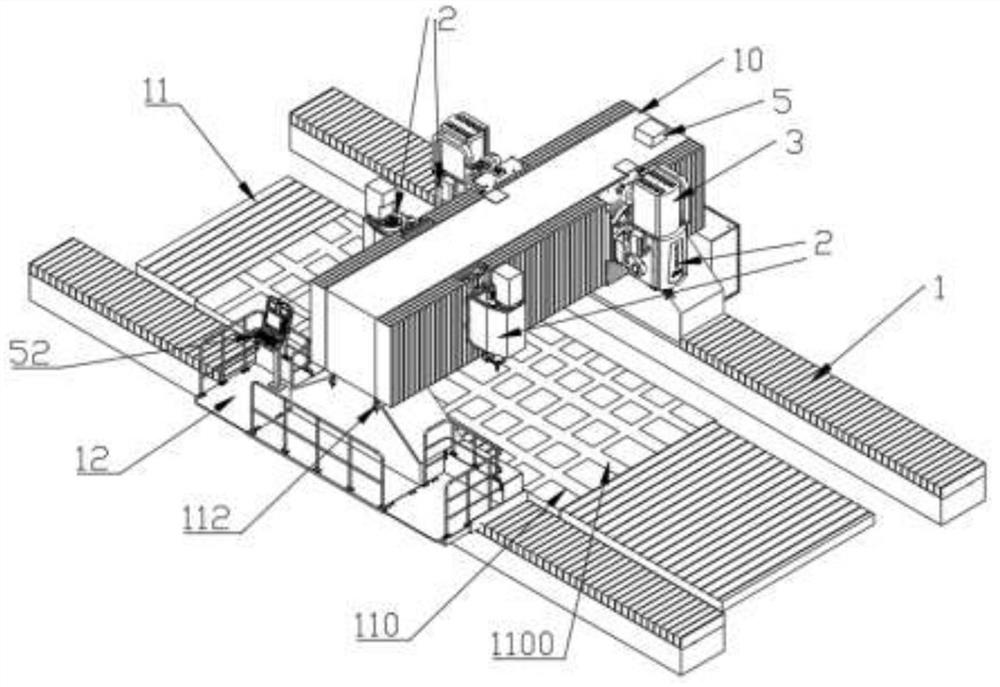

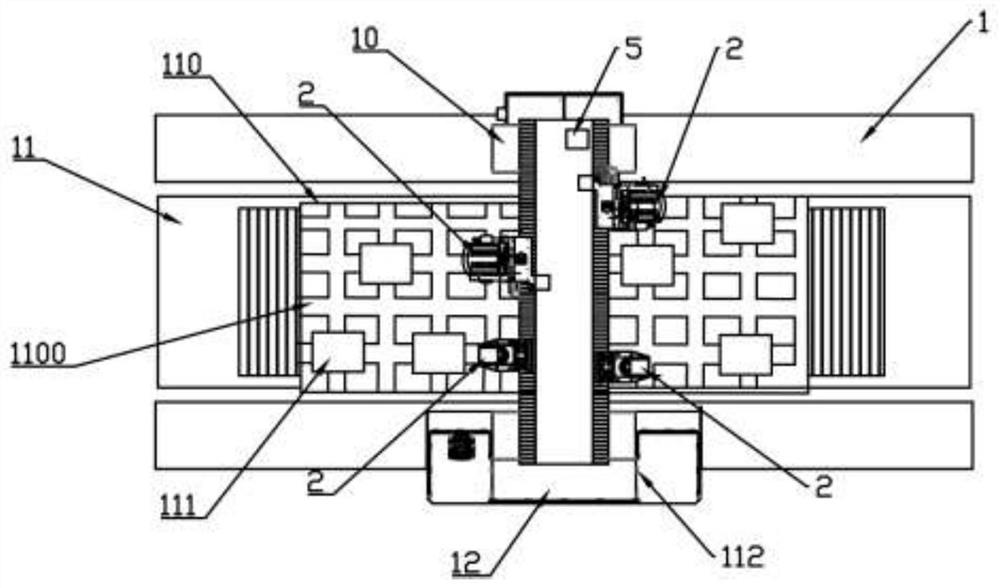

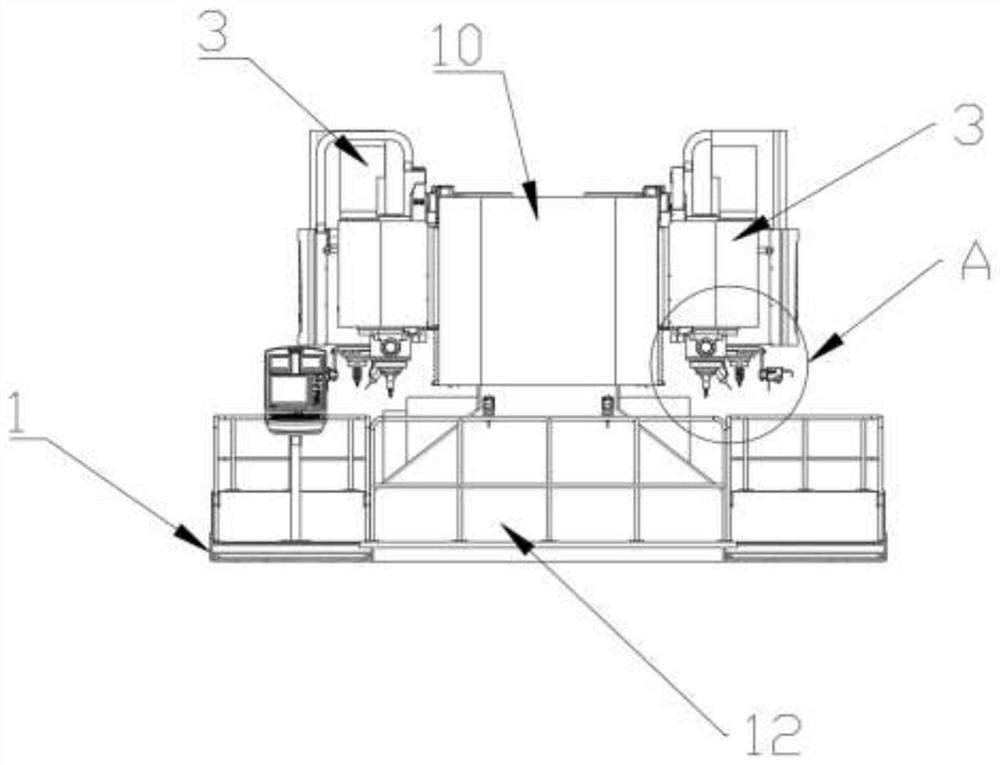

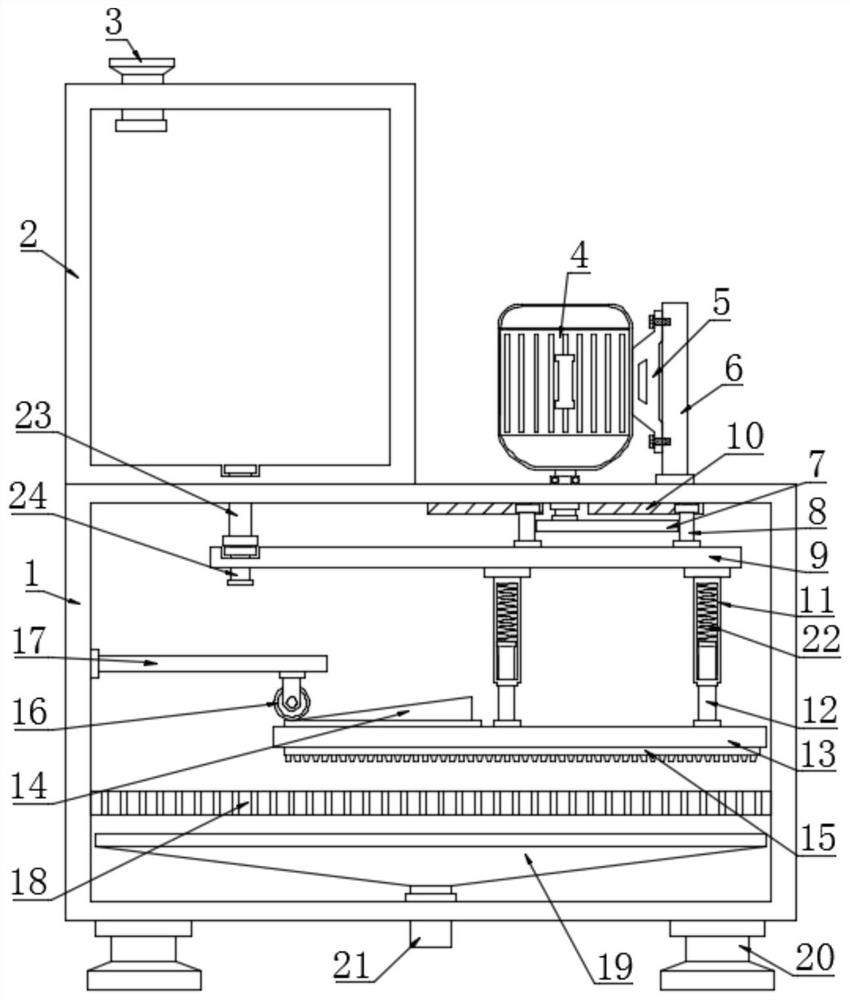

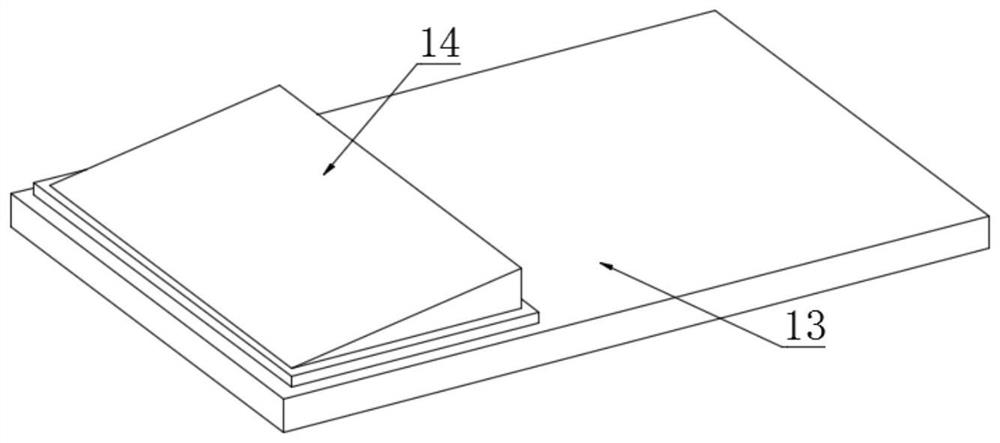

A multi-head moving gantry friction stir welding device

ActiveCN111843179BHave the characteristics of diversificationDiversified weldabilityNon-electric welding apparatusFriction weldingElectrical connection

The invention discloses a multi-head movable gantry friction stir welding device, which belongs to the technical field of friction stir welding equipment. The device mainly includes a base set on the ground with a gantry frame at the upper end and a workbench directly below the gantry frame at the upper end along the width direction, a welding head, a power system, a welding measuring element, an intelligent control element, and various electrical components. The power supply for the electrical connection of the components; the invention integrates multiple friction stir welding welding heads into one bed friction stir welding equipment. This equipment has diversified characteristics and can meet various needs at the same time, and the welding performance is diversified and far superior. Compared with the traditional friction stir welding, it realizes the welding of various complex parts with one equipment; the weldment is adsorbed on the upper ends of multiple T-shaped sliding adsorption blocks through the electromagnetic adsorption plate, and each T-shaped sliding adsorption block is driven by the motor to slide in the positioning sliding groove , so as to complete the automatic adjustment of the position of the weldment, the structure is simple, the operation is convenient, and the workload of the staff is reduced.

Owner:BEIJING FSW TECH

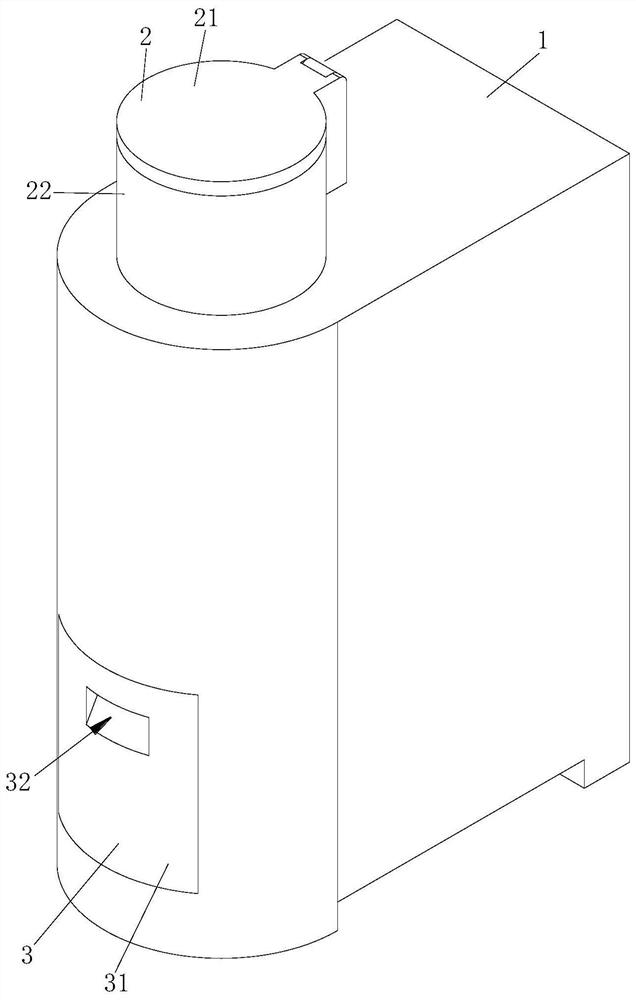

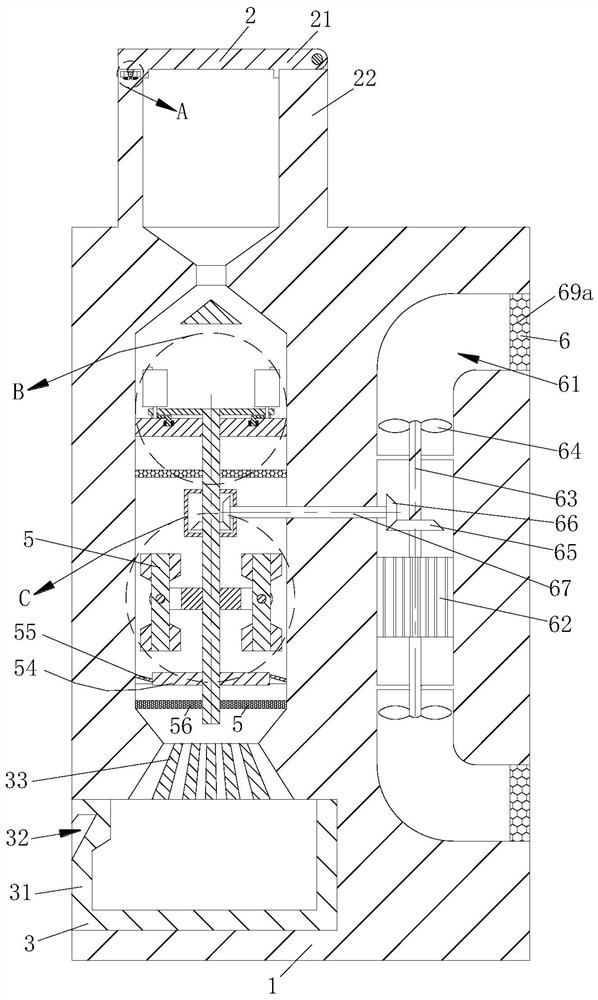

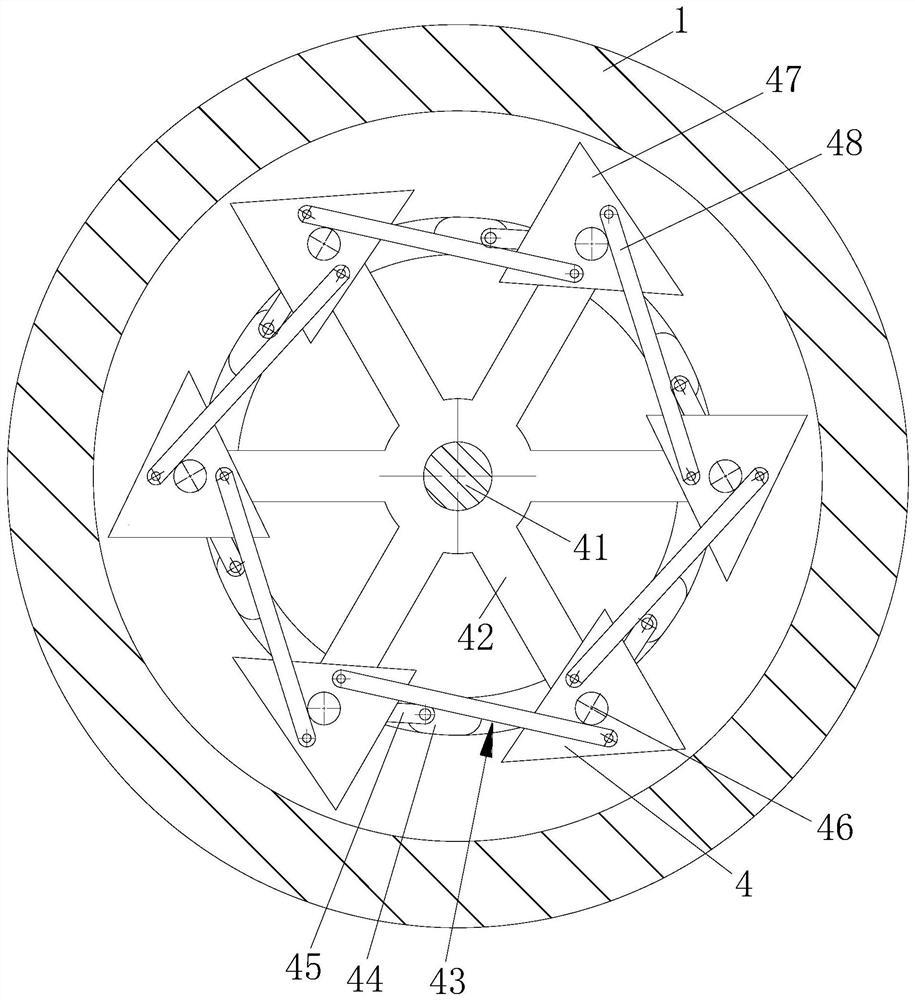

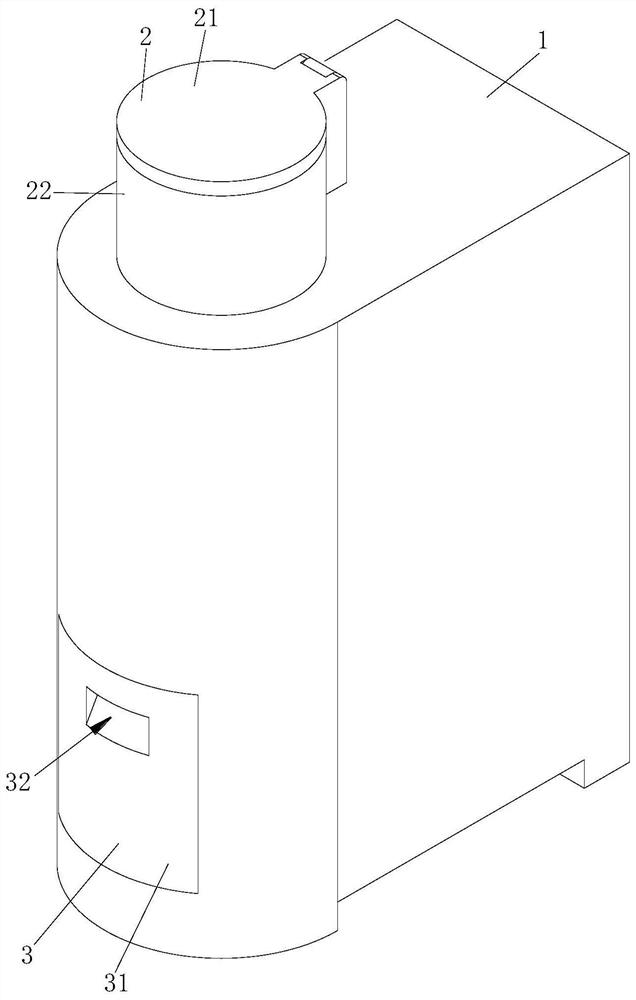

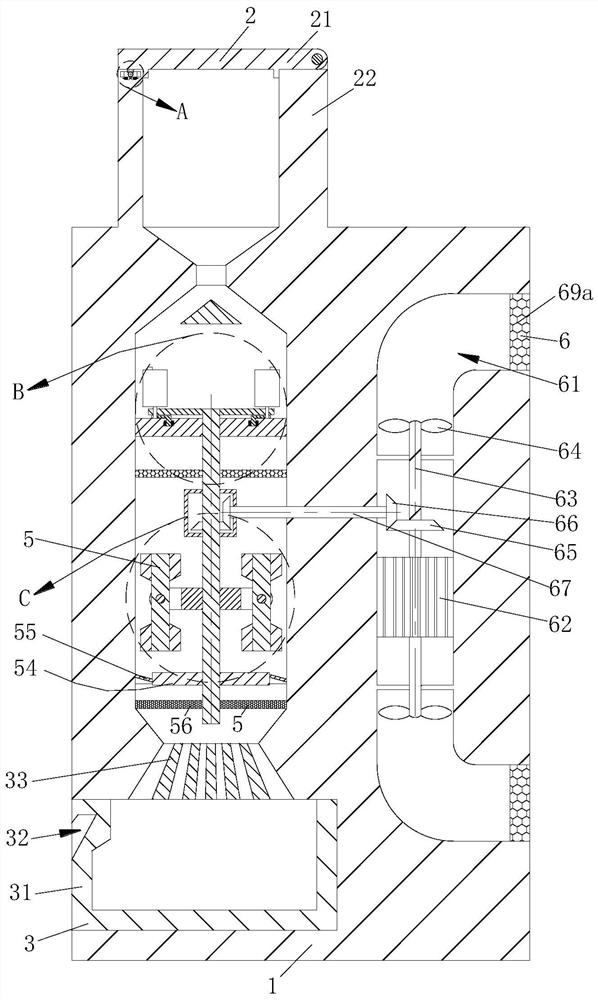

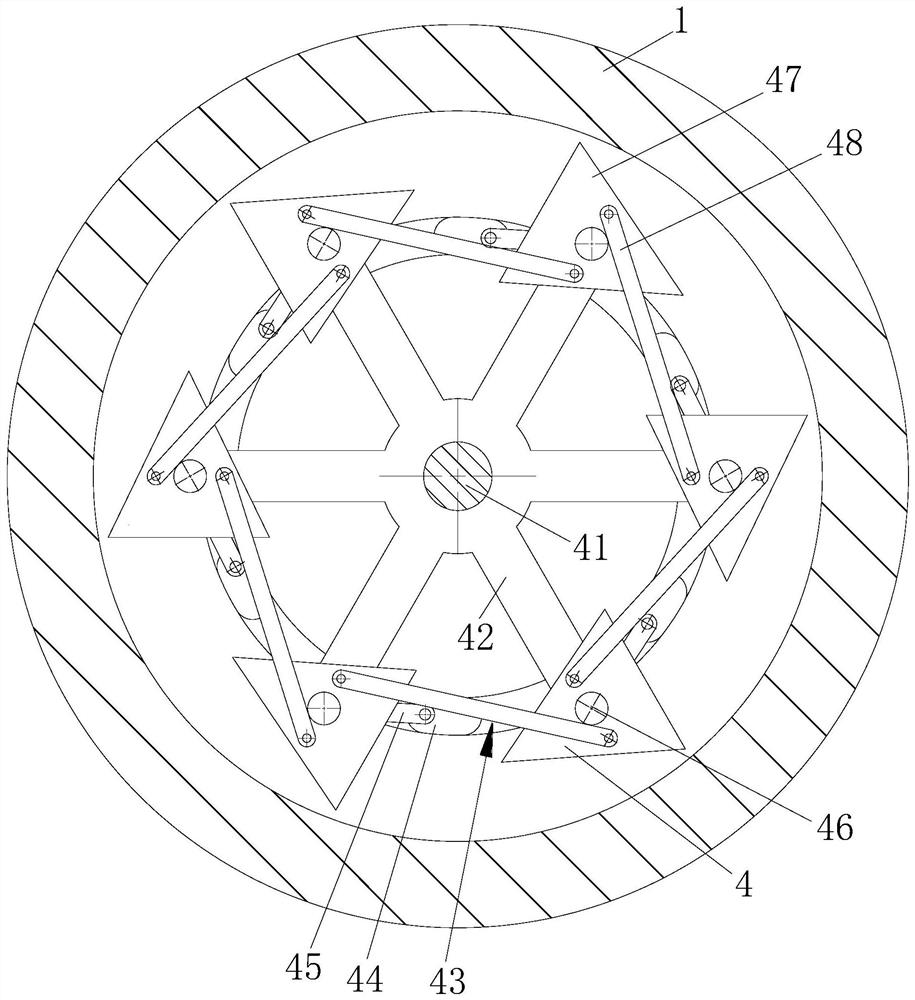

Coffee beverage raw material grinding device

The invention relates to the field of coffee grinding devices, in particular to a coffee beverage raw material grinding device which comprises a main body, a containing mechanism, a storage mechanism,a coarse grinding mechanism, a fine grinding mechanism and a power mechanism. Coffee beans can be conveniently placed in a containing container through the arrangement of the containing mechanism, and the fixed containing capacity corresponds to the storage capacity of the storage mechanism, so that the overflow risk caused by too many manufactured finished products is avoided; large-particle coffee beans can be conveniently smashed through the arrangement of the coarse grinding mechanism, so that conditions are provided for follow-up fine grinding of the fine grinding mechanism; through thearrangement of the fine grinding mechanism, semi-finished coffee bean particles can be conveniently ground, so that the powder making effect is further improved; through the arrangement of the storagemechanism, powder can be conveniently and evenly stored in the storage unit, so that the phenomenon that the storage space is insufficient due to the fact that the middle is stacked too high is avoided; and through the arrangement of the power mechanism, power can be conveniently provided for the rough grinding mechanism and the fine grinding mechanism, and heat dissipation can be conducted on the power component of the mechanism at the same time.

Owner:正大(海南)兴隆咖啡产业开发有限公司

Raw material grinding device for coffee beverage

ActiveCN112386128BEasy to placeEasily brokenCoffee millsSpice millsProcess engineeringIndustrial engineering

The invention relates to the field of coffee grinding devices, in particular to a raw material grinding device for coffee beverages, which includes a main body, a holding mechanism, a storage mechanism, a rough grinding mechanism, a fine grinding mechanism and a power mechanism; The coffee beans are placed in the holding container, and the fixed holding capacity corresponds to the storage capacity of the storage mechanism, so as to avoid the risk of overflow caused by too many finished products, and it is convenient to crush the large-grained coffee beans through the setting of the coarse grinding mechanism , to provide conditions for the follow-up fine grinding mechanism, through the setting of the fine grinding mechanism, it is convenient to grind the semi-finished coffee bean particles, and further improve the milling effect, through the setting of the storage mechanism, it is convenient to store the powder evenly in the storage unit The interior of the machine avoids the phenomenon of insufficient storage space caused by excessive accumulation in the middle. The setting of the power mechanism is convenient for providing power for the rough grinding mechanism and the fine grinding mechanism, and can simultaneously dissipate heat for its own power components.

Owner:正大(海南)兴隆咖啡产业开发有限公司

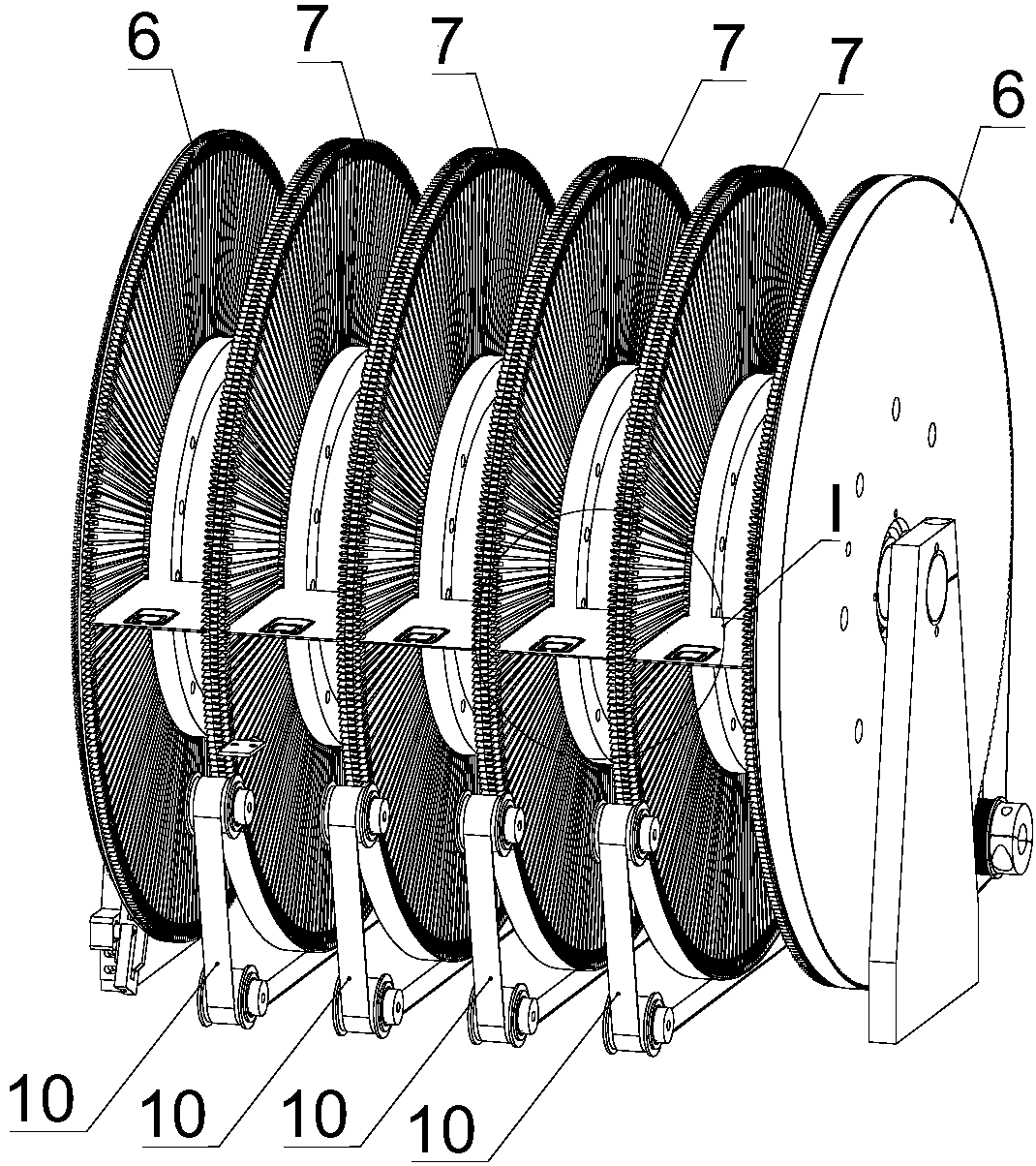

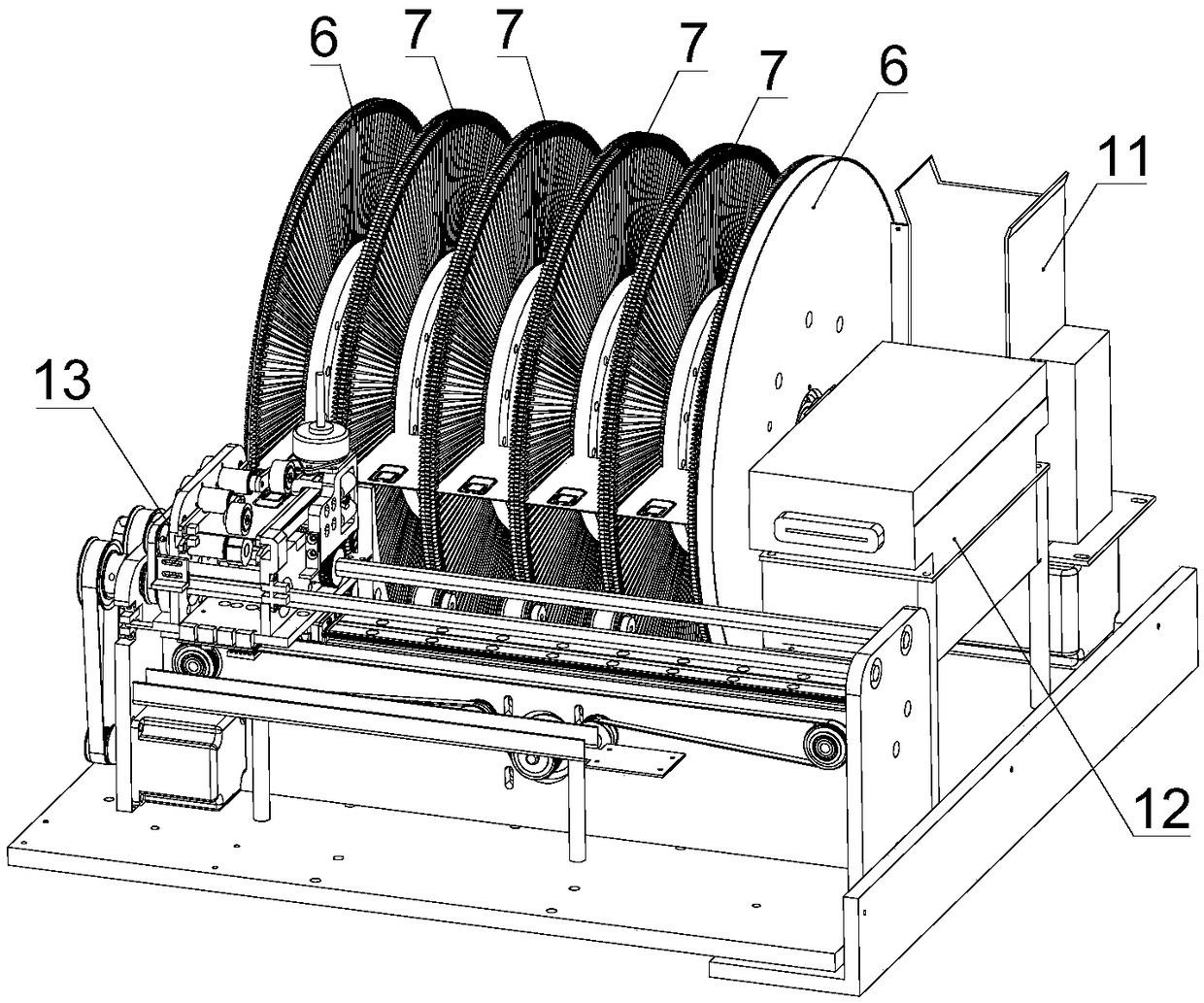

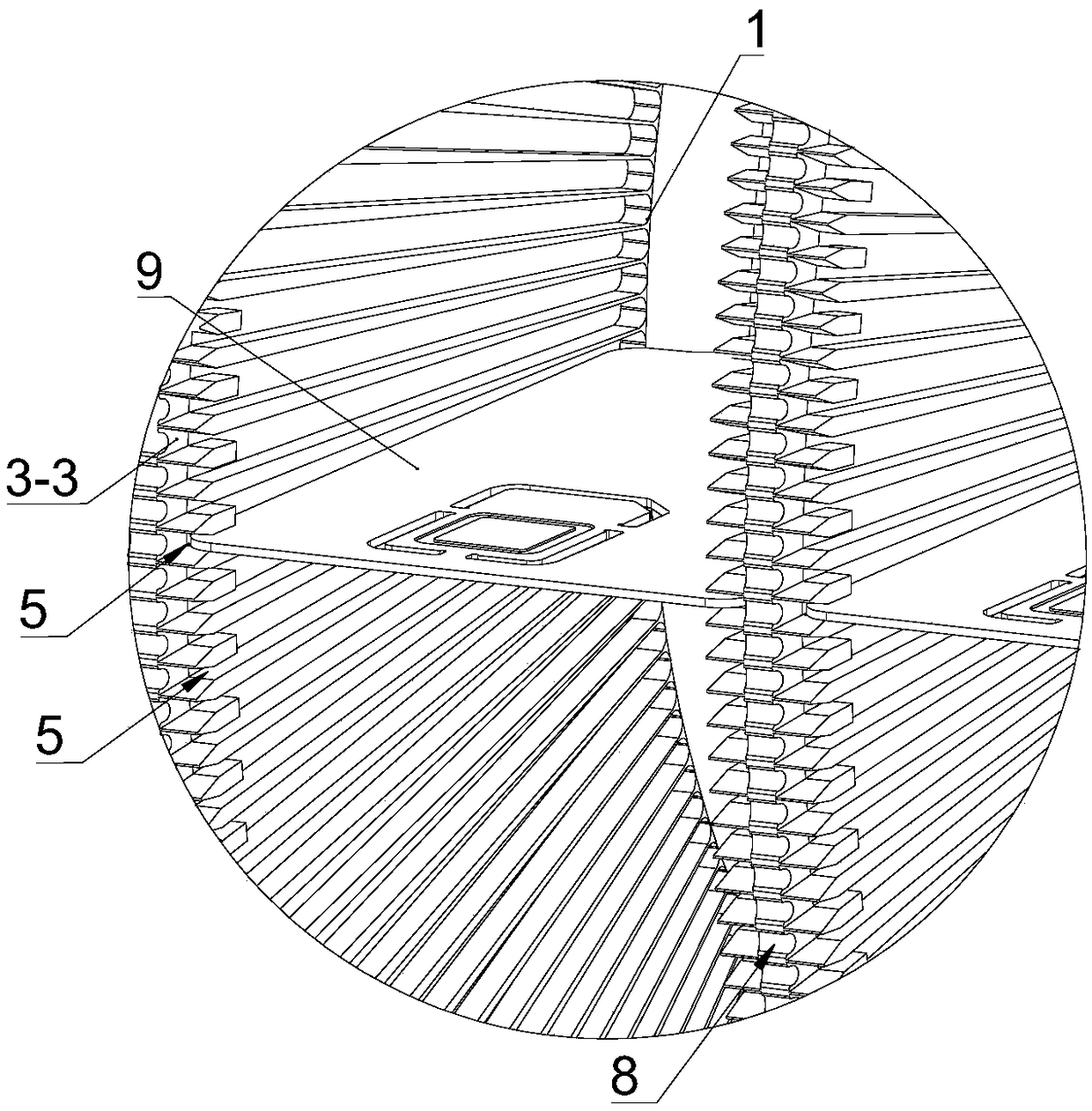

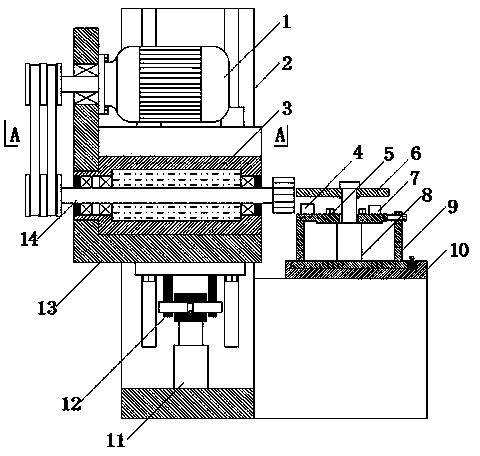

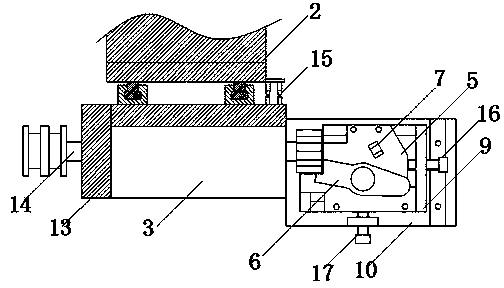

Full-automatic character milling machine for aluminum caps

ActiveCN103846479AIncrease the number of revolutionsGood milling effectMilling equipment detailsMetal working apparatusMilling cutterCam

The invention provides a full-automatic character milling machine for aluminum caps. The full-automatic character milling machine comprises a base on which a forcing motor and a fixed seat B are arranged, wherein a fixed shaft and a cap detaching cam are arranged on the fixed seat B, the fixed shaft is provided with a character milling cam and a milling cutter main shaft, the milling cutter main shaft is connected with the fixed seat B and provided with a milling cuter, a rotating shaft is arranged between the fixed shaft and the cap detaching cam by a bearing, a rotating body on the rotating shaft is provided with a rotating seat by a rotating shaft, a fixed seat A and a pull block are arranged on the rotating seat, the front end of the fixed seat A is provided with a forcing wheel, the rear end of the fixed seat A is provided with a guide sleeve, the guide sleeve is connected with the cap detaching cam, a slider is arranged in the guide sleeve and provided with an ejecting rod, the rotating seat is internally provided with a taper seat shaft by a bearing, the taper seat shaft is provided with a taper seat, the taper seat is provided with an expansion sleeve, a spring is arranged between the expansion sleeve and the taper seat, the taper seat is internally provided with a limit rod, the big end of the limit rod is sleeved inside the clamping opening in the expansion sleeve, and the front end of the ejecting rod penetrates through the limit rod. The number of rotations of a milling shaft is increased by five times and the milling effect is excellent.

Owner:LIPENG PACKING YANTAI CITY

milling robot

ActiveCN110394904BGood milling effectImprove reliabilityBuilding constructionsManipulatorMilling cutterEngineering

The invention discloses a milling robot. The milling robot includes a dust suction device and a milling device. The dust suction device includes a dust suction body and an arc-shaped suction cup connected with the dust suction body. The dust suction port communicated with the main body and the arc-shaped suction cup define an installation space with an open side, and the milling device includes a milling cutter, which is rotatably arranged in the installation space. According to the milling robot of the embodiment of the present invention, by setting an arc-shaped suction cup on the dust suction device and making part of the milling cutter protrude from the opening, the milling cutter can first contact the uneven area on the surface of the substrate, which can not only better Milling and leveling the surface of the substrate can also protect the arc-shaped suction cup, which can prevent the arc-shaped suction cup from colliding or wearing after first contacting the uneven substrate surface, thus affecting the dust collection effect of the dust collection device, high reliability and practical Strong.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

A pharmaceutical and chemical raw material powder making device

The invention discloses a pharmaceutical chemical raw material powder milling device. A driving motor is fixedly mounted on the right side of the upper part of a device shell, the lower part of the driving motor is rotatably connected with an output shaft, and the lower end of the output shaft is fixedly connected with an eccentric wheel. The two sides of the eccentric wheel are correspondingly attached to vertical rods, the lower ends of the vertical rods are fixedly connected with a top plate, and the upper ends of the vertical rods are slidably connected with guiding grooves. The two sidesof the lower surface of the top plate are correspondingly and fixedly connected with the upper ends of elastic devices, and the lower ends of the elastic devices are fixedly connected with a movable plate. The lower surface of the movable plate is fixedly connected with a wear-resistant tooth plate, and the left side of the upper surface of the movable plate is fixedly connected with a wedge-shaped slope. The upper part of the wedge-shaped slope is attached to a roller. The pharmaceutical chemical raw material powder milling device adopts the output shaft of the motor to drive the eccentric wheel to rotate, thereby driving the vertical rods and the top plates to reciprocate left and right, the top plate intermittently blocks a through tube to achieve the function of intermittent material falling, the top plate further drives the movable plate to move left and right, and the movable plate drives the wear-resistant tooth plate to move up and down while moving left and right to perform bidirectional grinding and crushing on materials on a filter plate under the action of the roller, the wedge-shaped slope and the elastic devices.

Owner:美亚药业海安有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com