Single-edged milling cutter for aluminum

A milling cutter and cutter head technology, which is applied in the field of single-edged aluminum milling cutters, can solve the problems of small chip removal space in the chip flute, easy generation of burrs at the cutting part of the workpiece plate, and difficult discharge of waste chips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

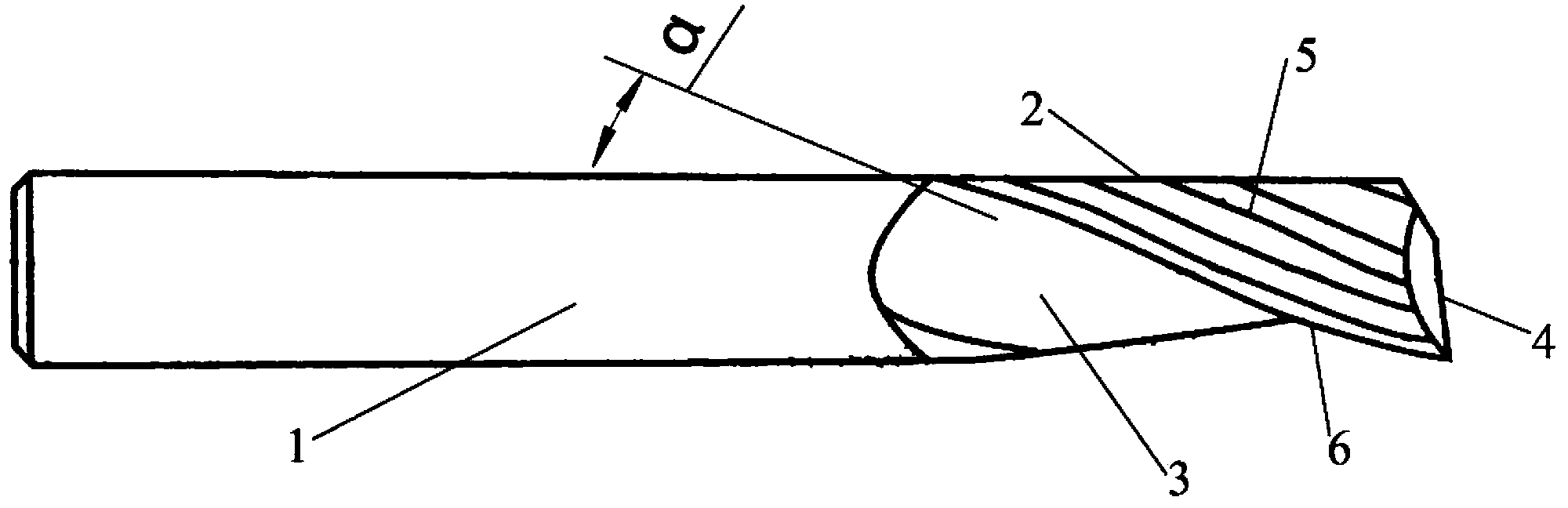

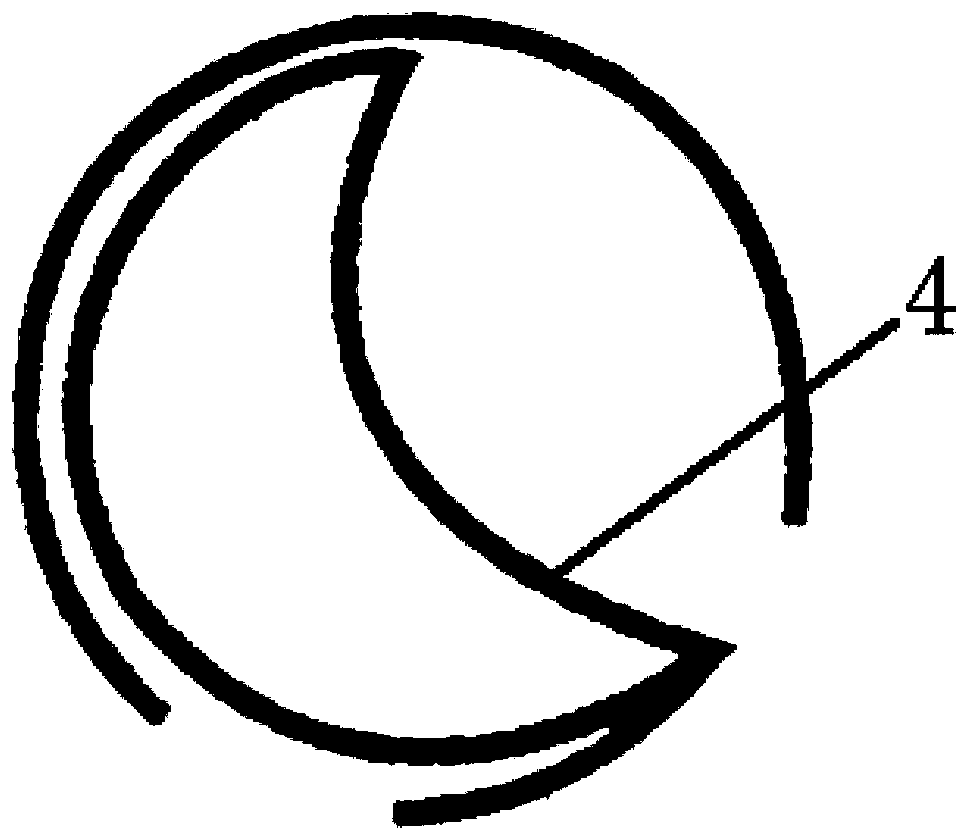

[0013] Depend on figure 1 It can be seen that the single-edge aluminum milling cutter of the present invention includes a cutter bar 1 and a cutter head 2, and a spiral chip flute 3 is arranged on the cutter head 2, and the helix angle α of the chip flute 3 is 25° or 35° , the flute 3 extends to the blade 4 at the tip of the cutter head 2 , the blade 4 is crescent-shaped, the outer wall of the cutter head 2 is provided with a back 5 , and the side of the cutter head 2 is provided with a side edge 6 . The surface of the cutter head 2 is provided with an aluminum nitride coating. The end of the cutter bar 1 is provided with a chamfer of 45°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com