Full-automatic character milling machine for aluminum caps

A fully automatic, word milling machine technology, applied in the mechanical field, can solve the problems of poor milling effect, small number of rotations of the milling shaft, etc., and achieve better milling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

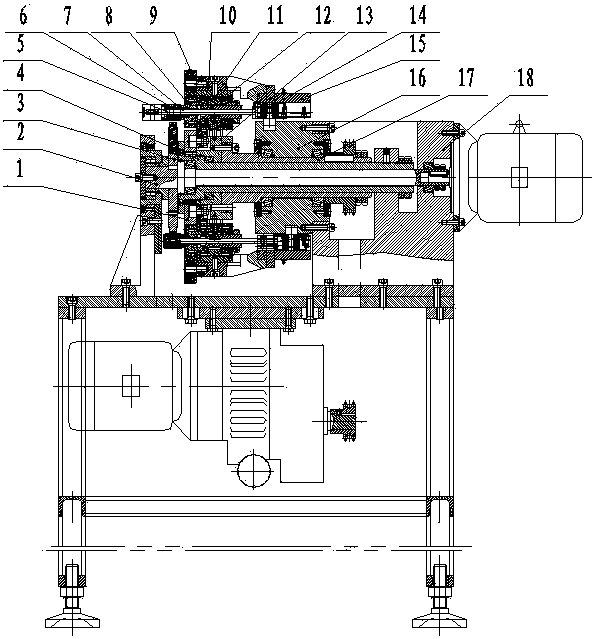

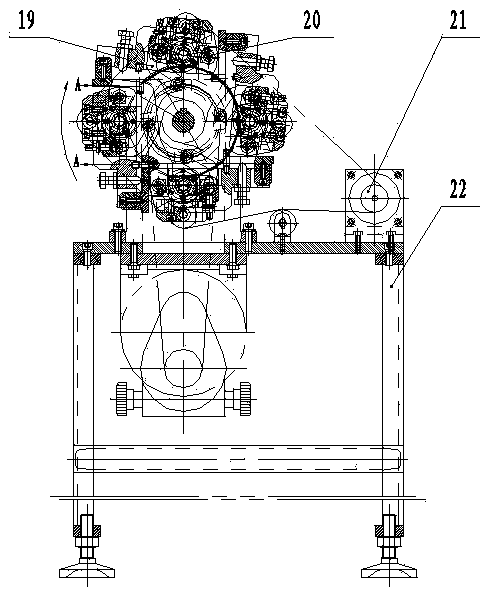

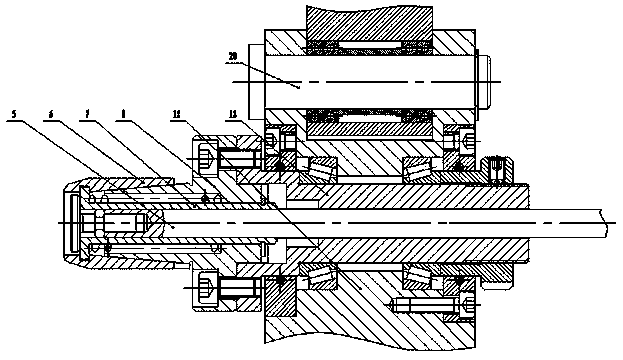

[0014] For better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings: the aluminum cover automatic milling machine includes a base 22, a forced motor 21 and a fixed seat B18 are arranged on the base 22, and a fixed shaft is provided on the fixed seat B18 4 and the uncapping cam 16, between the fixed shaft 4 and the uncapping cam 16, a rotating shaft 17 is provided through a bearing, the rotating shaft 17 is provided with a swivel 13, and the swivel 13 is provided with a swivel seat 11 by a revolving pin 20, on the swivel block 11 A fixed seat A10 and a pull block 19 are provided. The front end of the fixed seat A10 is equipped with a forced wheel 9, and the rear end is provided with a guide sleeve 15. The guide sleeve 15 is connected with the cover unloading cam 16. A slide block 14 is installed inside the guide sleeve 15, and the slide block 14 is provided with a push rod 5, and the rotary seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com