Patents

Literature

55results about How to "Improve cleaning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

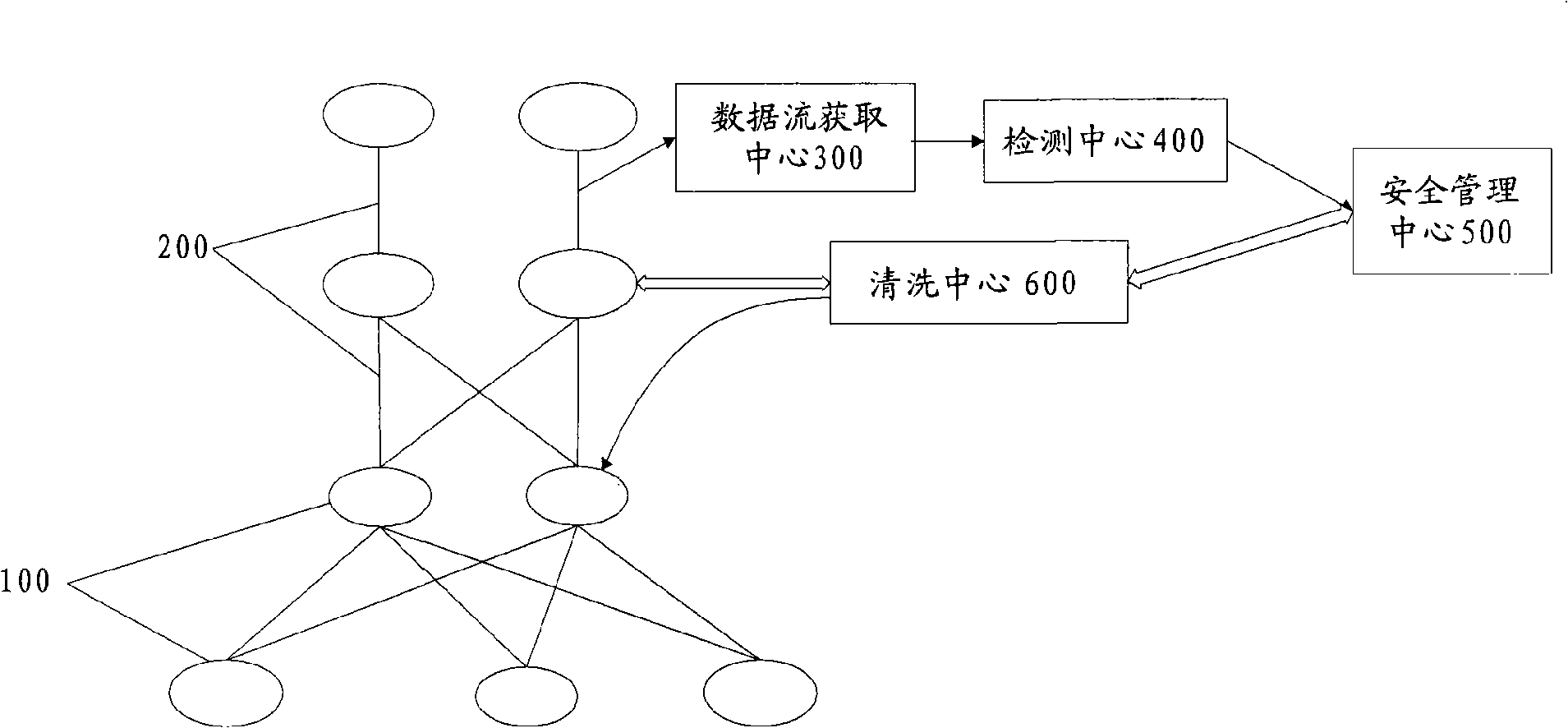

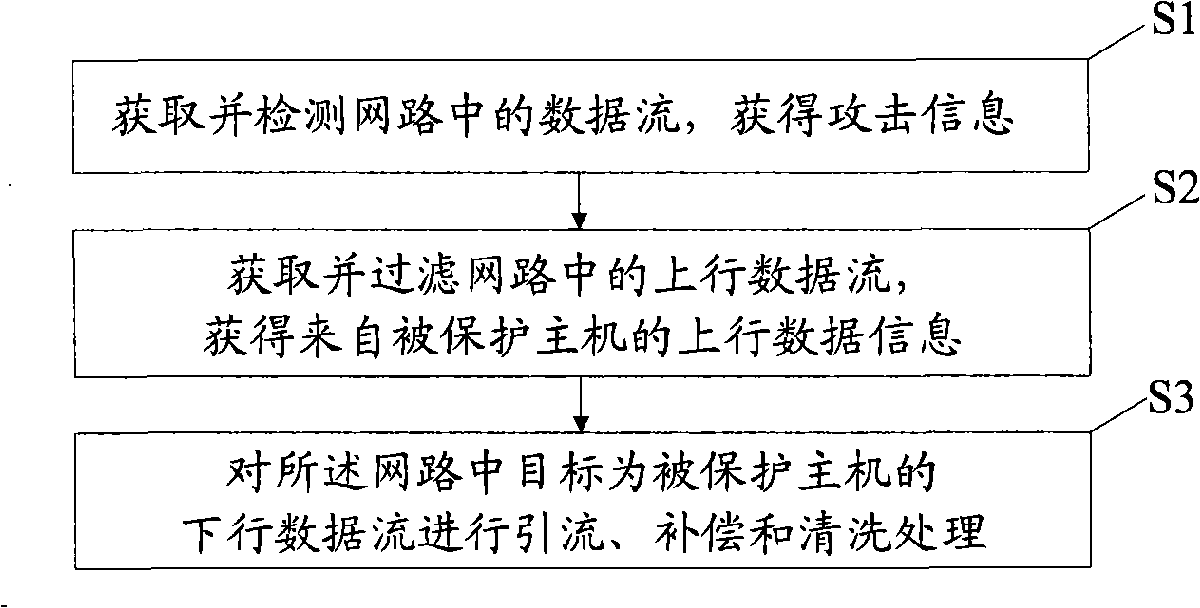

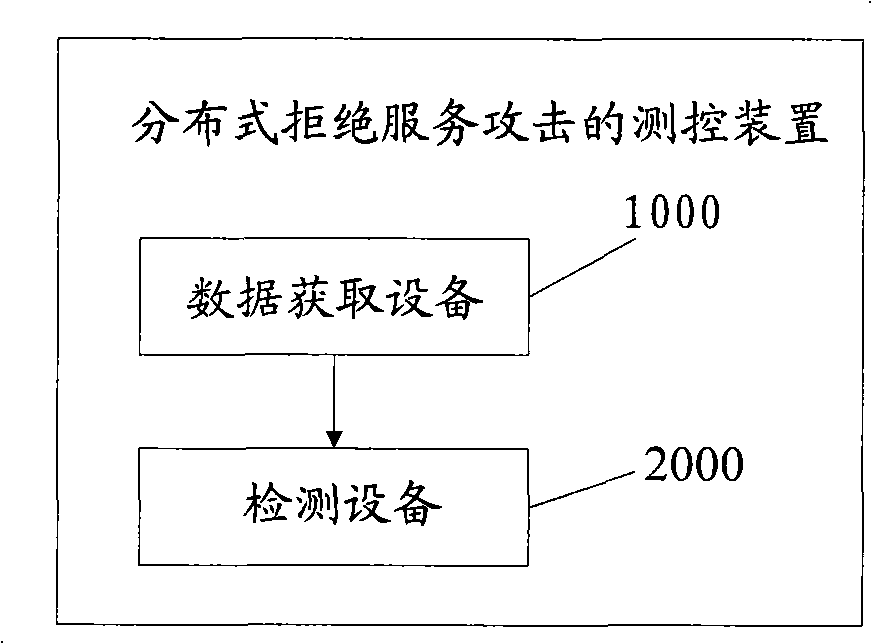

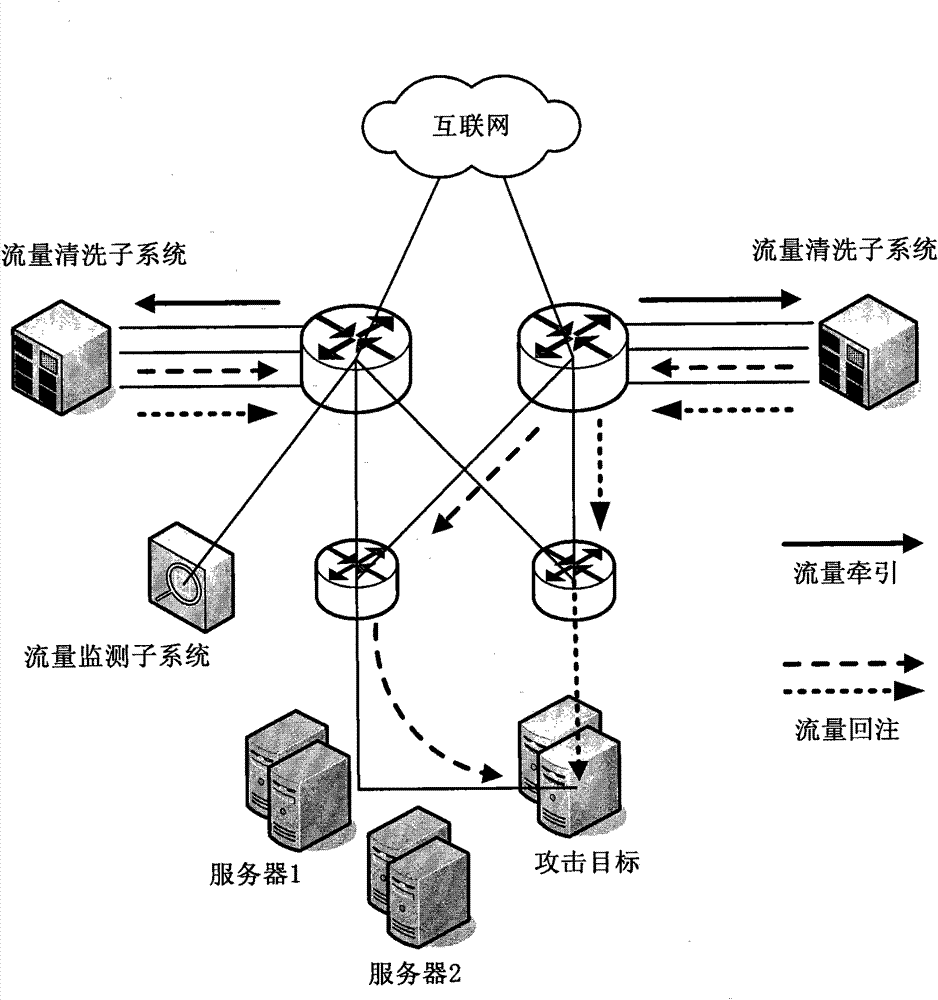

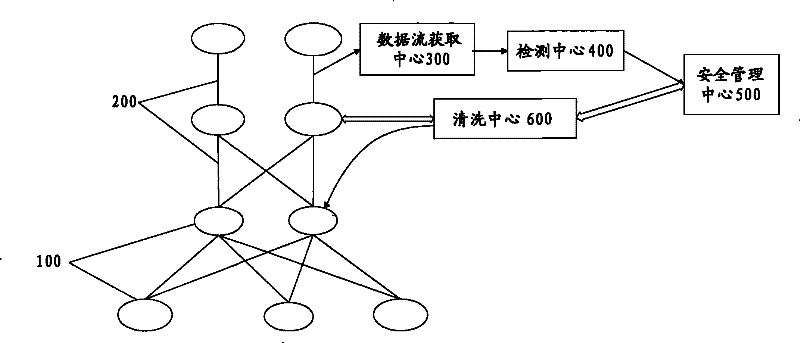

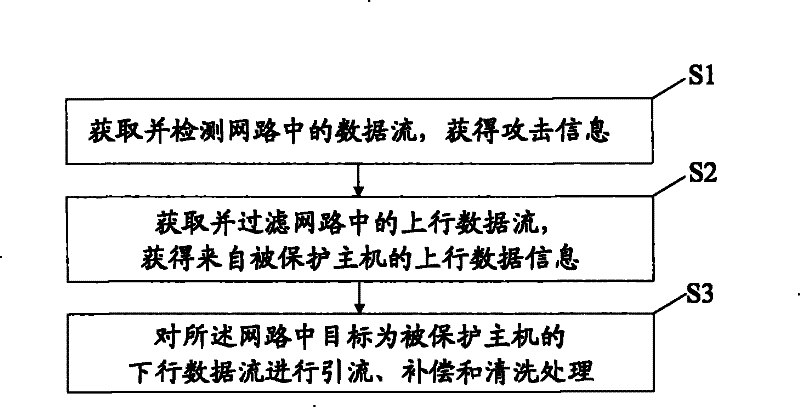

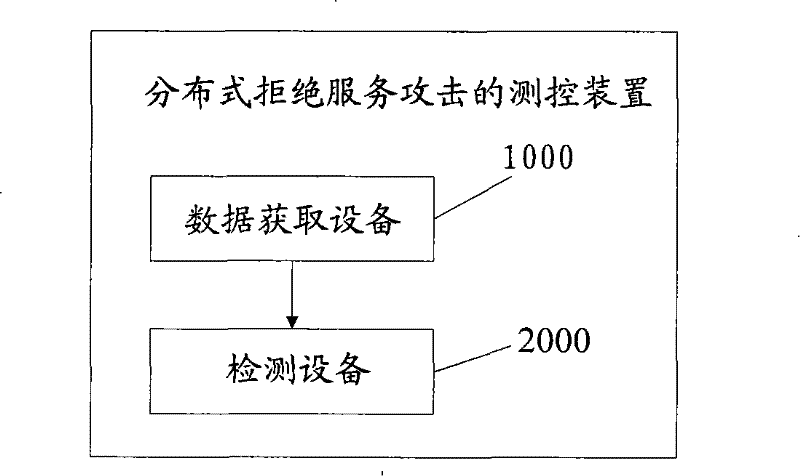

Distributed service attack refusing defense method, apparatus and system

The invention embodiment discloses a defense method, a device and a system for the DDos attack, which relate to the network technology and aim to solve the problem of low cleaning accuracy caused by the cleaning of the unidirectional data flow obtained by the network cleaning device found in the prior art. The defense method of the DDos attack in the invention embodiment includes that the data flow in the network is acquired and detected to obtain the attack information; the upstream data flow in the network is acquired and filtered to obtain the upstream data information of the protected host; the downstream data flow with the target of the protected host is processed with conduction, supplement and cleaning according to the attack information and the upstream data flow from the protected host. The invention embodiment also provides a measurement-control device, a cleaning device and a defense system for the DDos attack. The defense method, the device and the system for the DDos attack are applicable to the detection and defense of the DDos attack in the network technology.

Owner:CHENGDU HUAWEI TECH

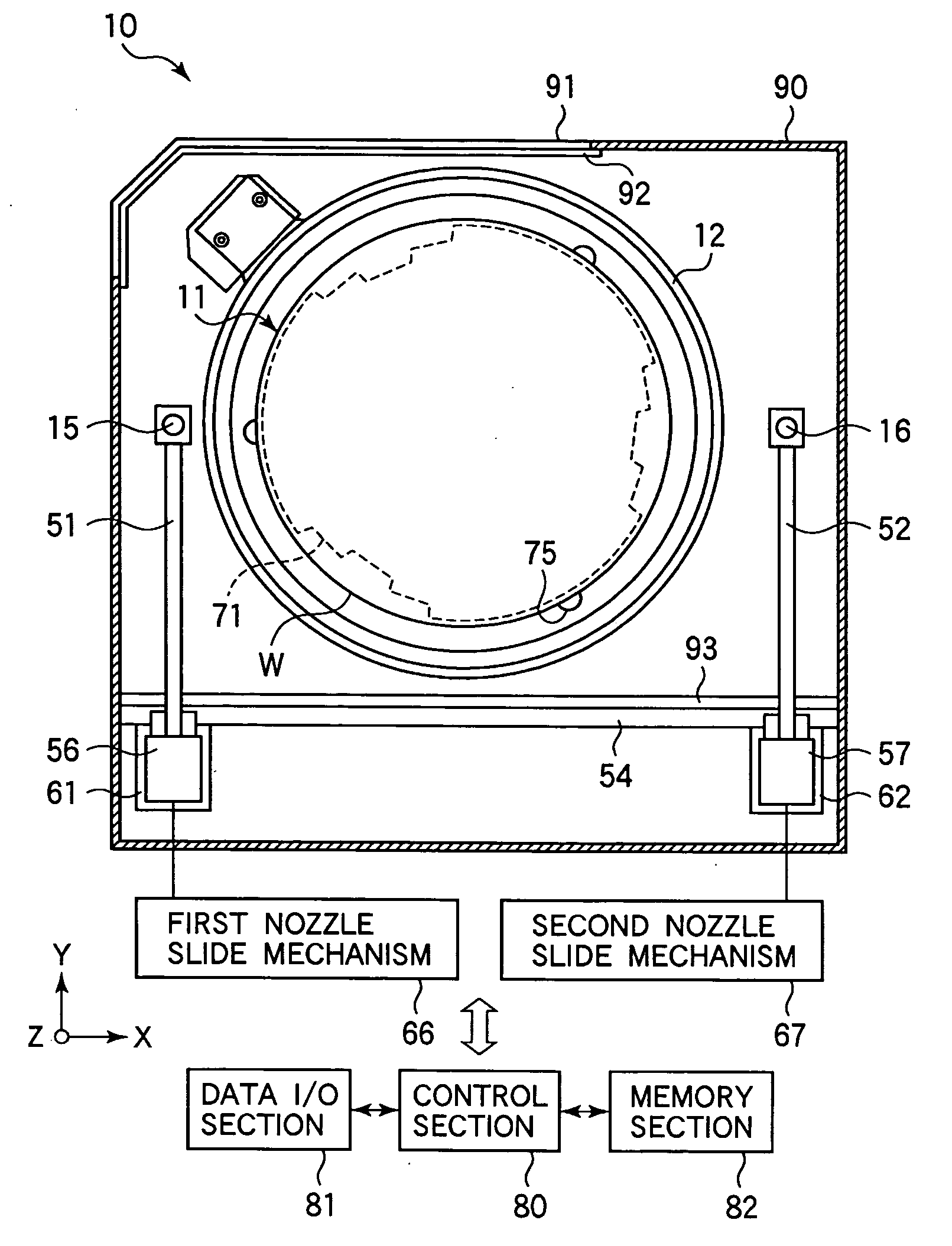

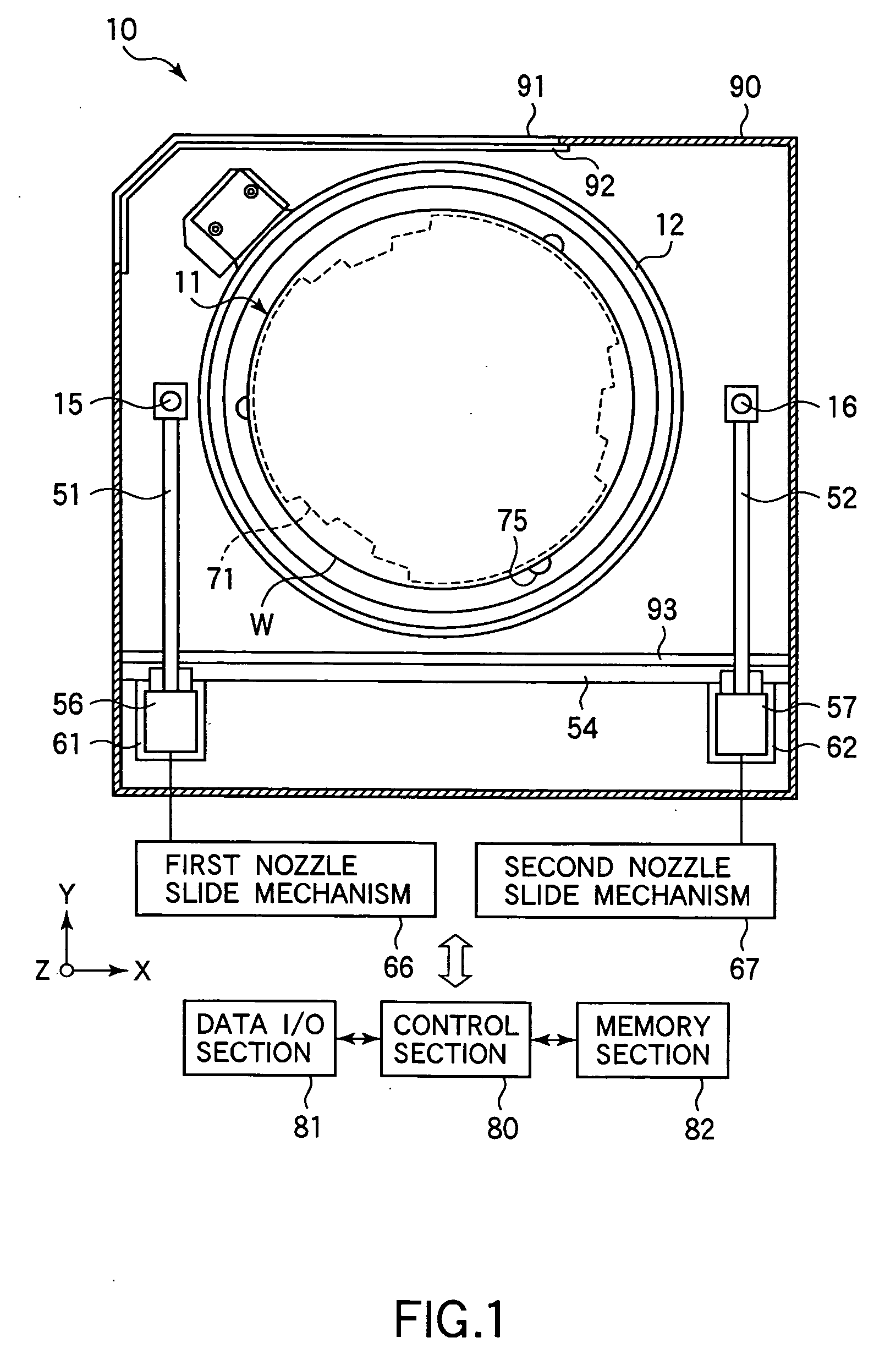

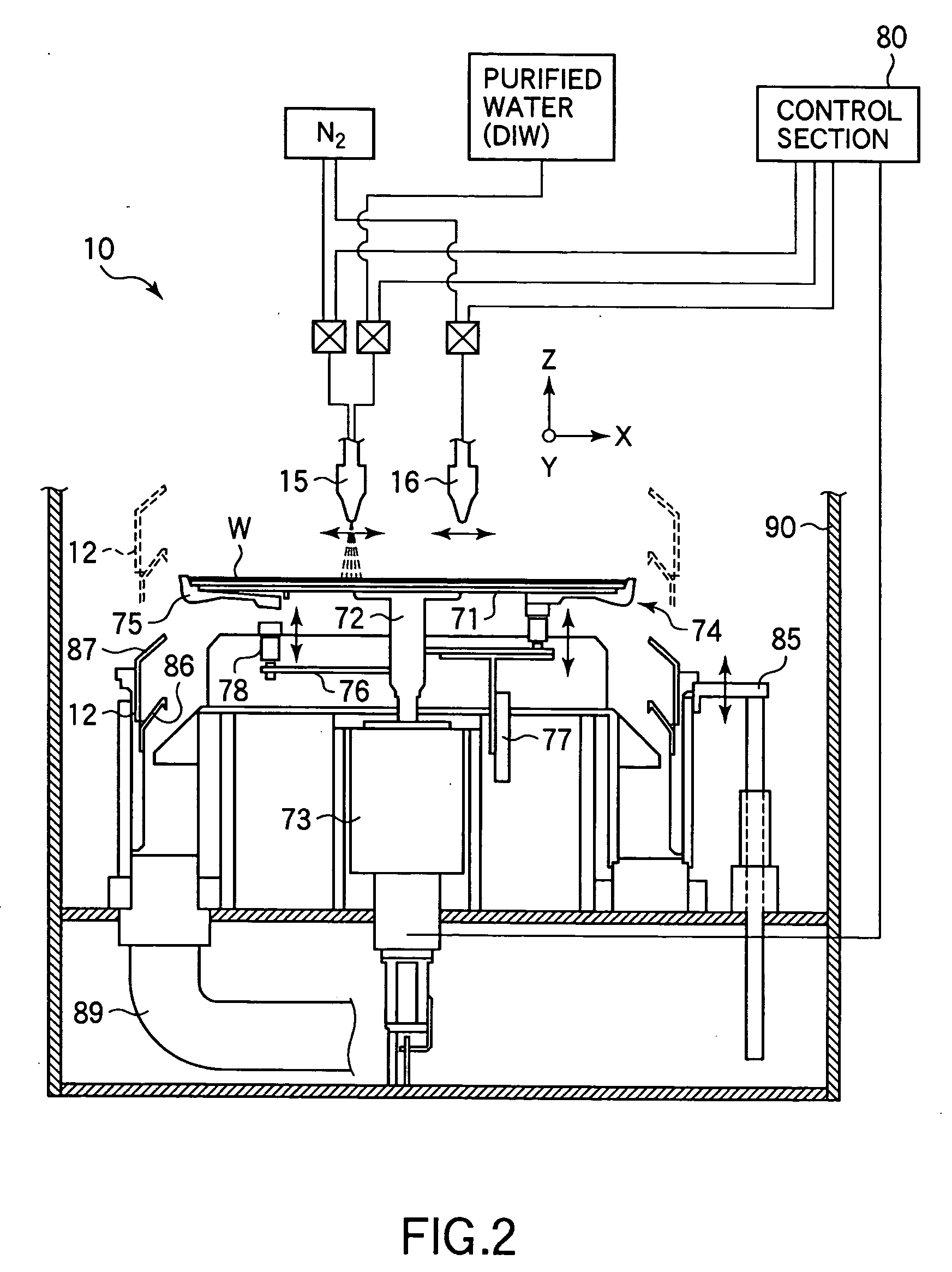

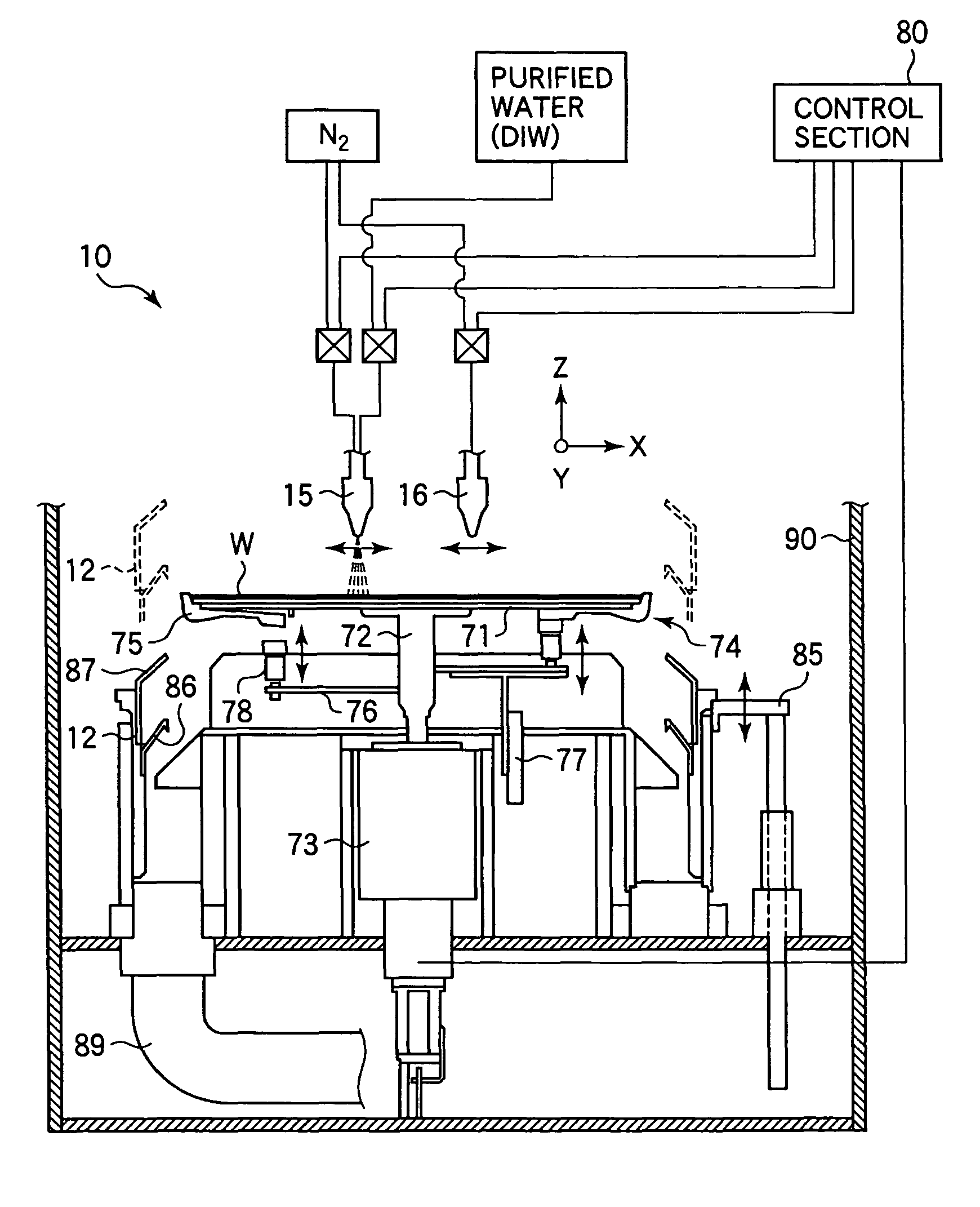

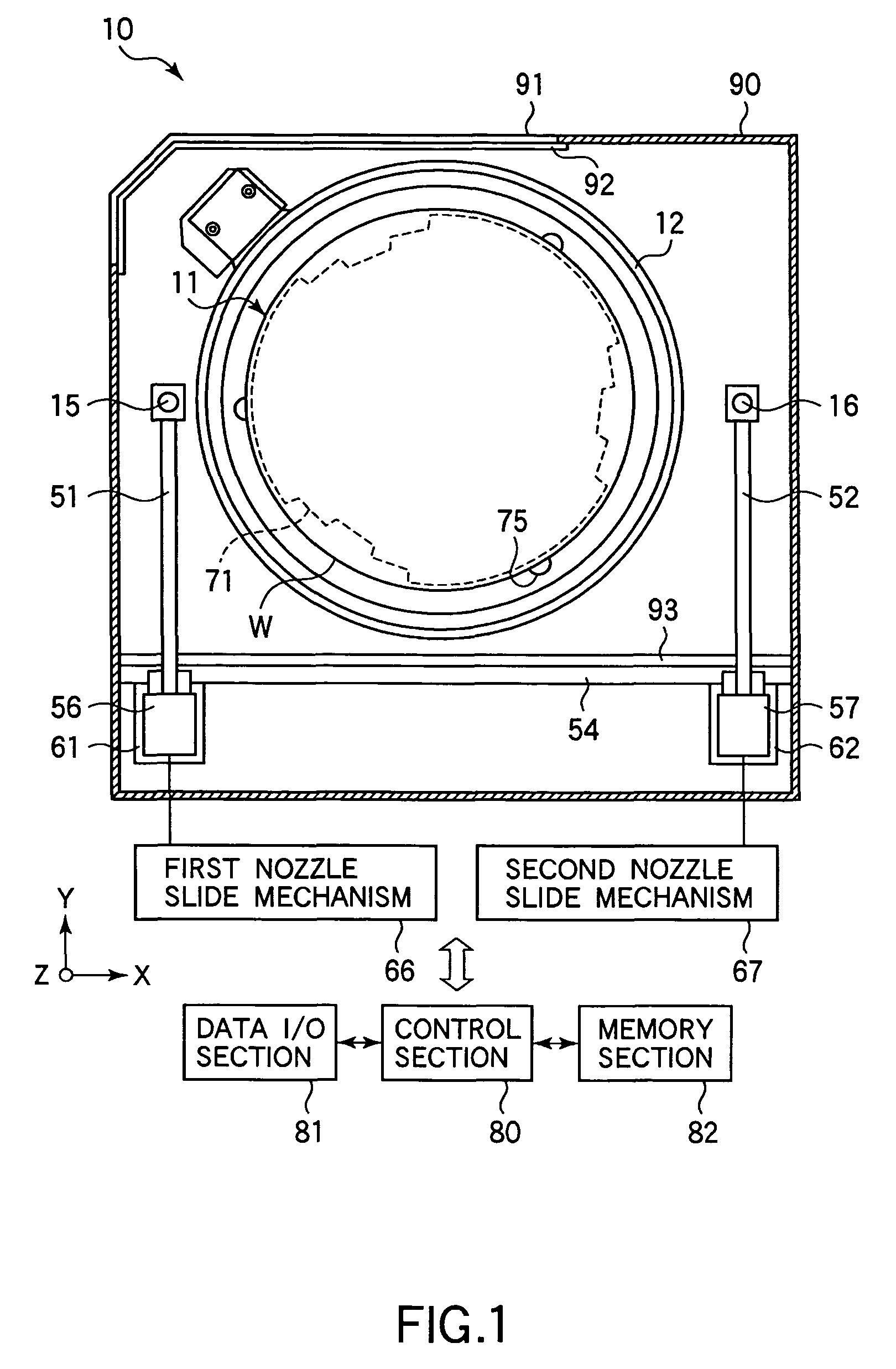

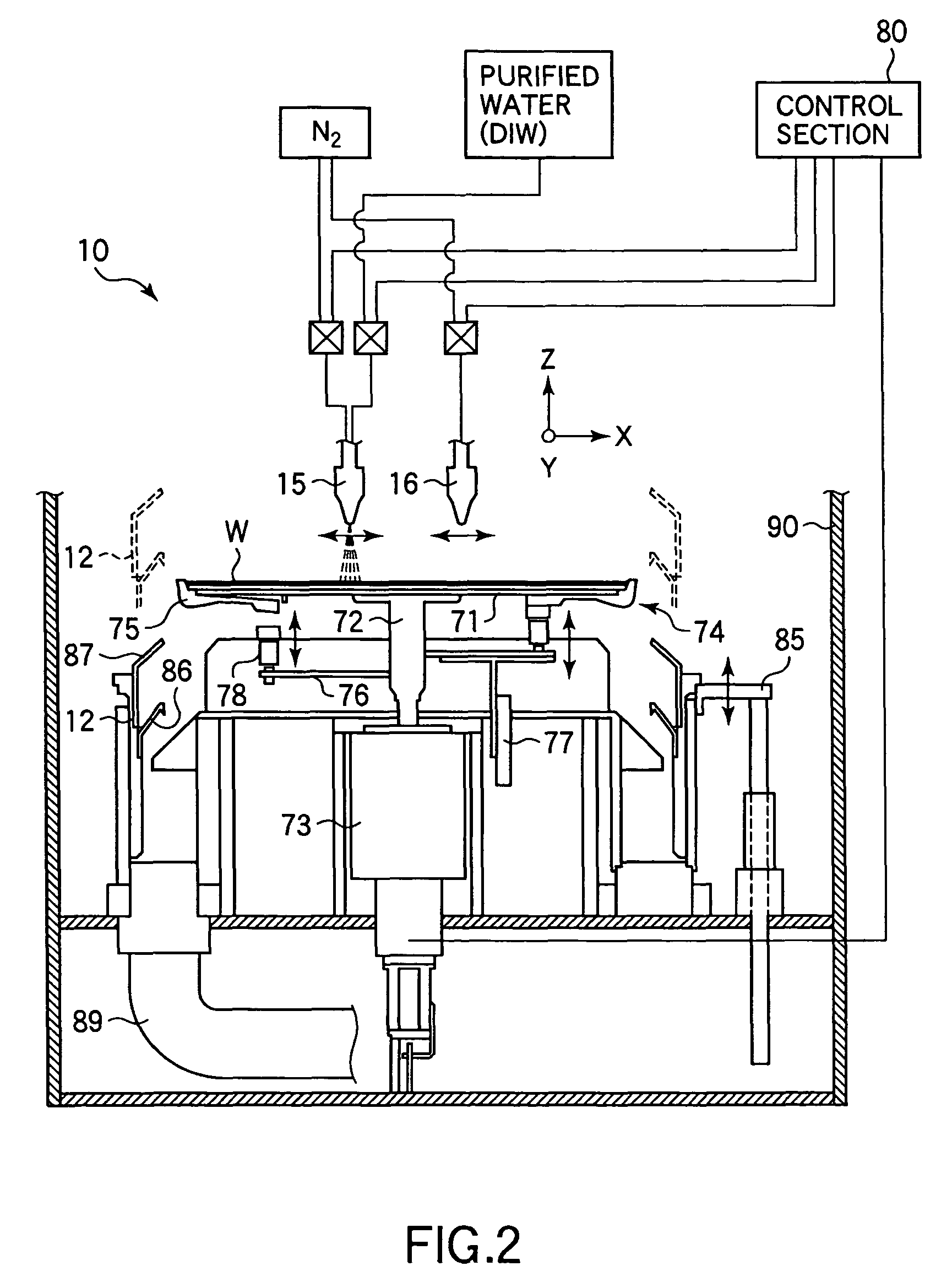

Substrate Cleaning Method and Computer Readable Storage Medium

ActiveUS20080041420A1Improve throughputSuppress static build-upSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringHigh pressure

A wafer W is processed by supplying a two-fluid, high pressure jet water, or mega-sonic water onto the wafer W, while rotating the wafer W in an essentially horizontal state. After supply of the cleaning fluid is stopped, the wafer W is dried by rotating the wafer W at a higher speed than that used in supplying the cleaning fluid. No rinsing process using purified water is performed in a period after stopping supply of the cleaning fluid and before rotating the substrate at the higher speed.

Owner:TOKYO ELECTRON LTD

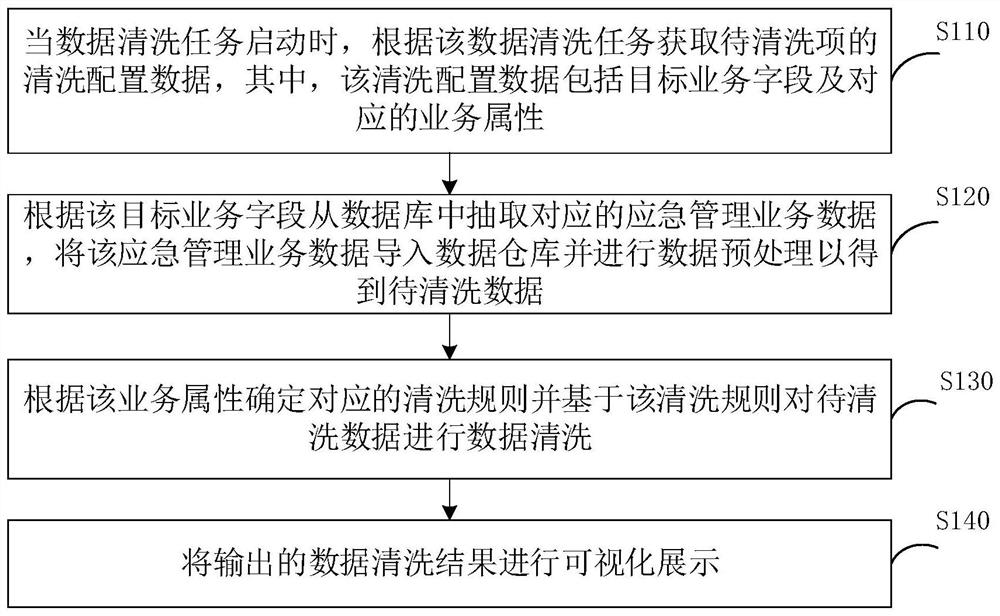

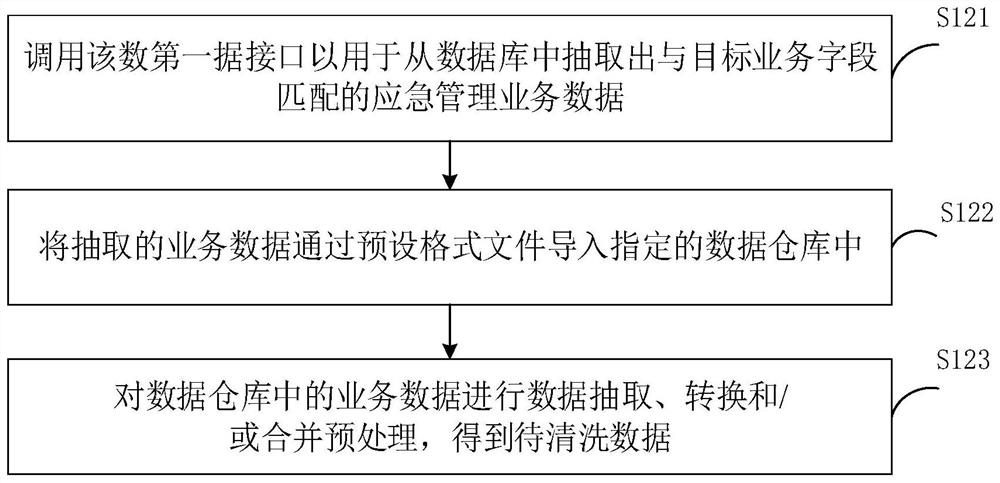

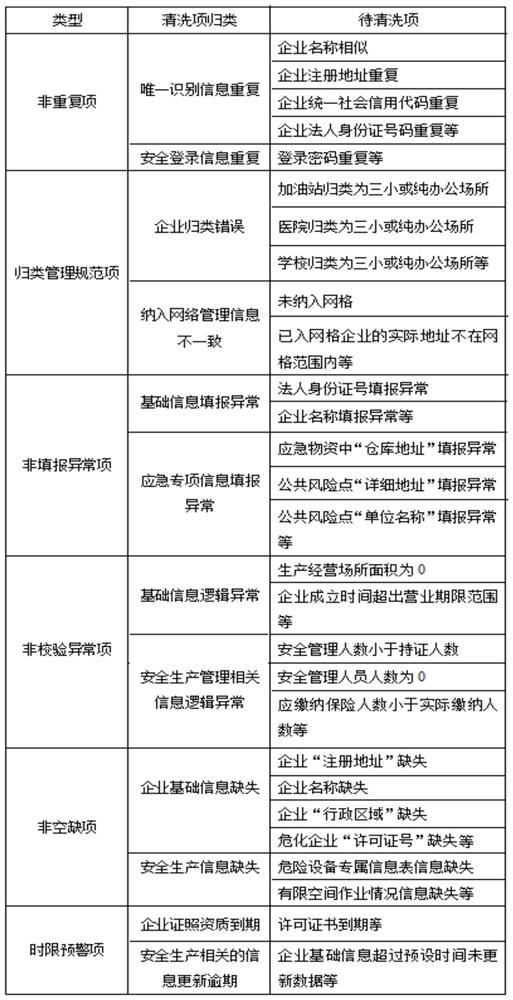

Emergency management service data cleaning method and system, terminal and readable storage medium

PendingCN111949647AImprove experienceRich and comprehensive cleaning contentDatabase distribution/replicationMulti-dimensional databasesData packData pre-processing

The embodiment of the invention provides an emergency management service data cleaning method and system, a terminal and a readable storage medium, and the method comprises the steps: obtaining the cleaning configuration data of a to-be-cleaned item when a data cleaning task is started, and enabling the cleaning configuration data to comprise a target service field and a corresponding service attribute; extracting corresponding emergency management service data from a database according to the target service field, importing the emergency management service data into a data warehouse, and performing data preprocessing to obtain to-be-cleaned data; determining a corresponding cleaning rule according to the service attribute and performing data cleaning on to-be-cleaned data; and outputtinga data cleaning result and carrying out visual display. According to the technical scheme, emergency management service requirements are combined, corresponding cleaning rules are set for data with different service attributes, the cleaning content is richer and more comprehensive, the cleaning accuracy is higher, display is carried out through a visual interface, and the user experience is improved.

Owner:深圳市安亿通科技发展有限公司

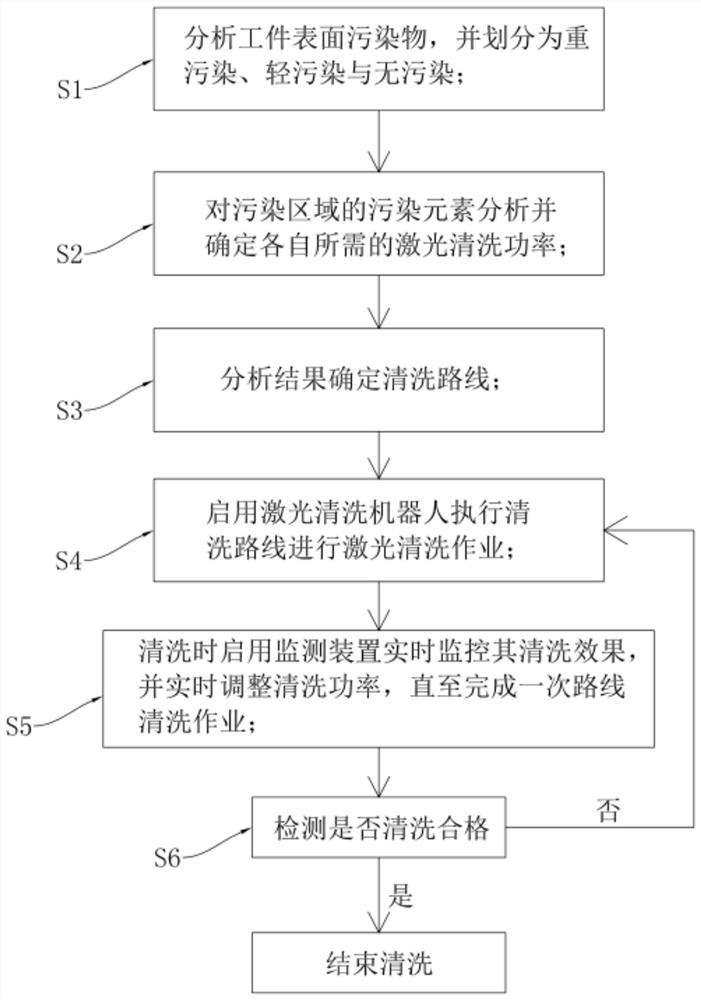

Intelligent cleaning method

ActiveCN112452947AEasy to analyzePrecision cleaningCleaning processes and apparatusReal time analysisControl signal

The invention discloses an intelligent cleaning method, and relates to the technical field of laser cleaning. The intelligent cleaning method is characterized by comprising the following steps of: S1,analyzing pollutants on the surface of a workpiece to be cleaned, and respectively dividing the pollutants into a heavily polluted area, a lightly polluted area and a pollution-free area; S2, analyzing the pollution elements of each polluted area and determining the laser cleaning power required by each polluted area; S3, determining a cleaning route for selective cleaning according to an analysis result; S4, sending a control signal of the cleaning route through a controller to a laser cleaning robot for execution, and monitoring the cleaning effect of the laser cleaning robot in real time through a monitoring device in the cleaning process; S5, analyzing the cleaning effect in real time and adjusting the cleaning power in real time through the controller; and S6, judging whether the cleaning is qualified or not through a cleaning effect detector, and if not, returning to the step S4 until the cleaning is qualified. Accurate cleaning can be achieved according to the cleaning route, the number of repeated cleaning times is reduced, and the effect of improving the cleaning precision and efficiency is achieved.

Owner:XIAMEN UNIV OF TECH

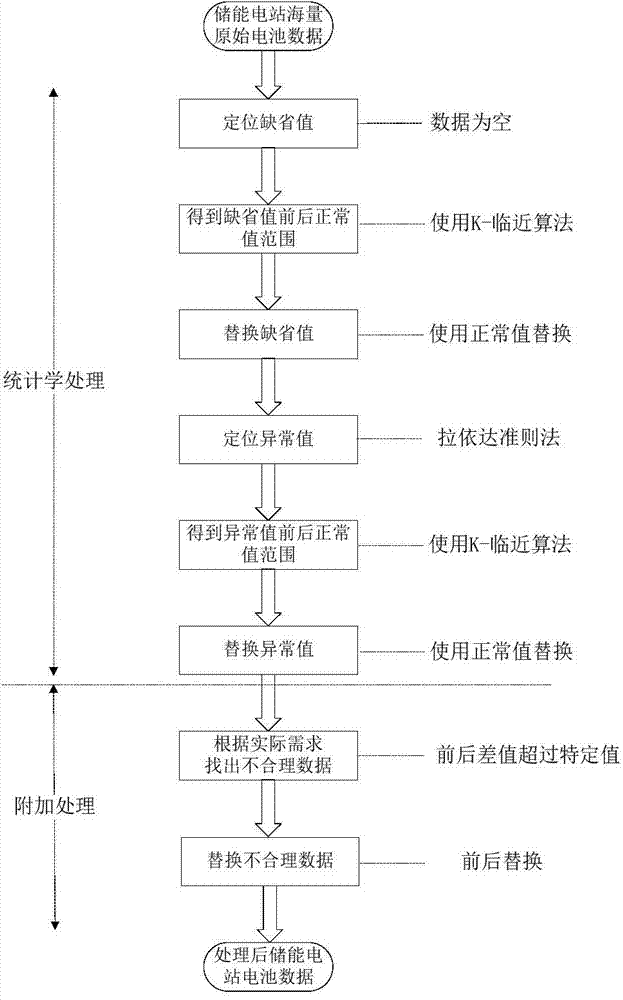

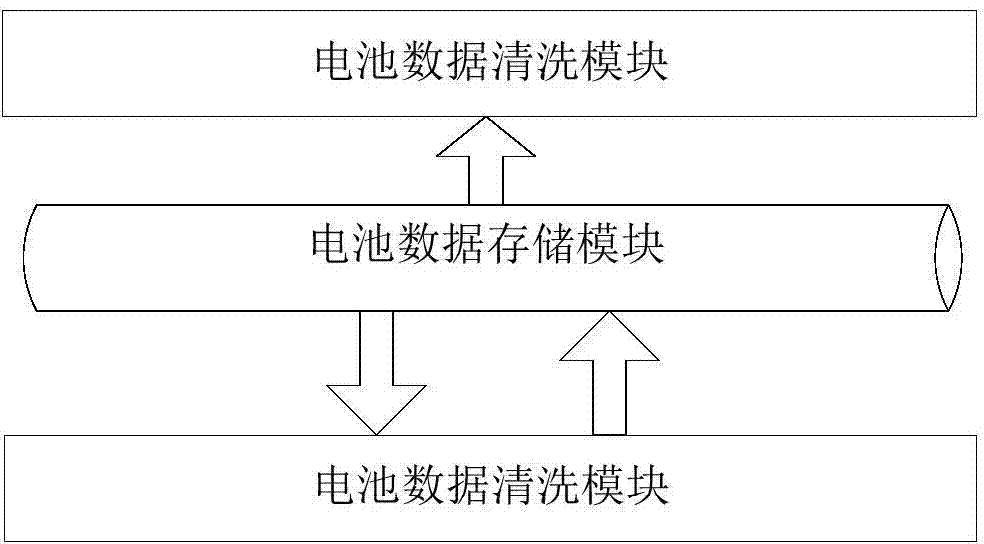

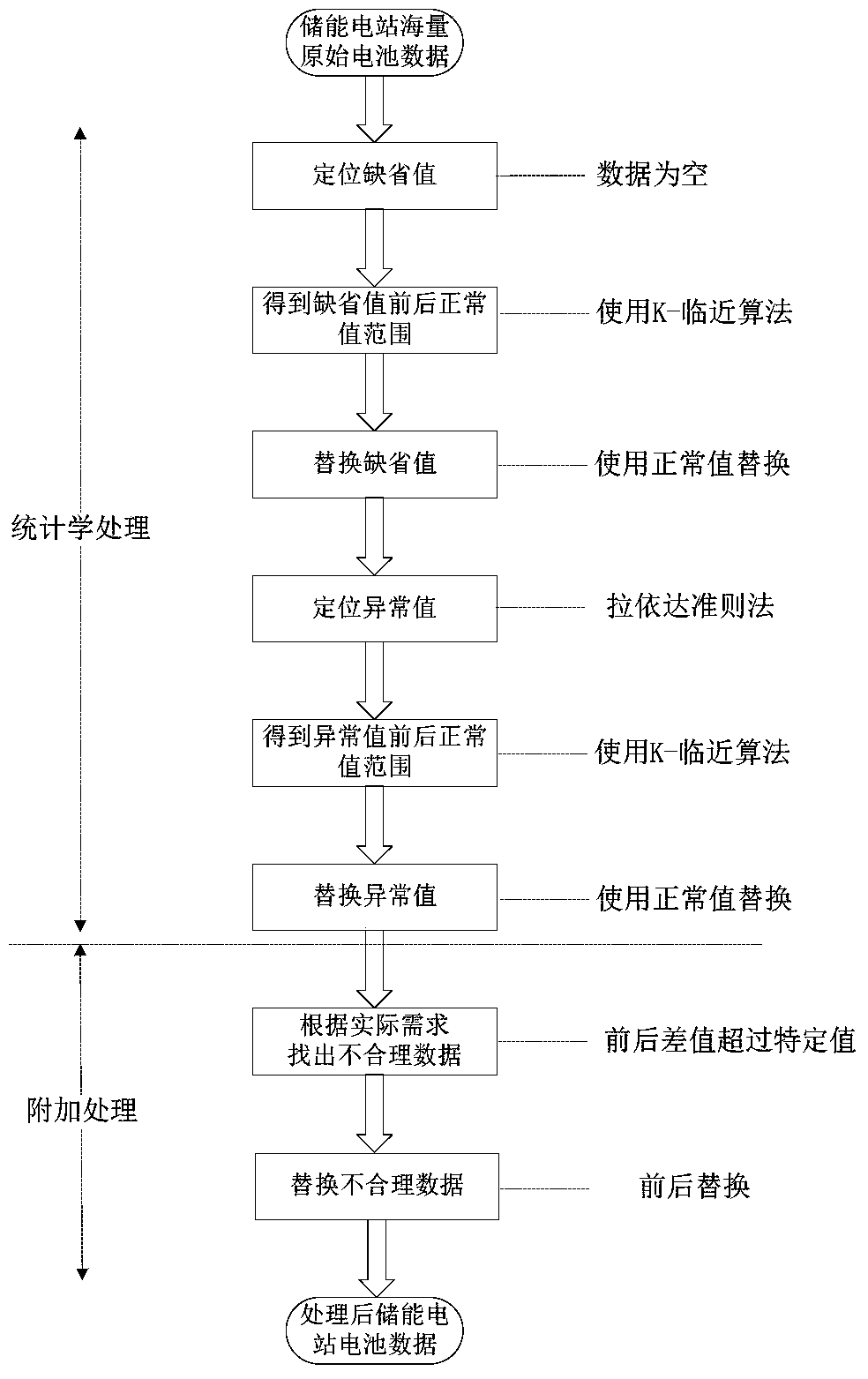

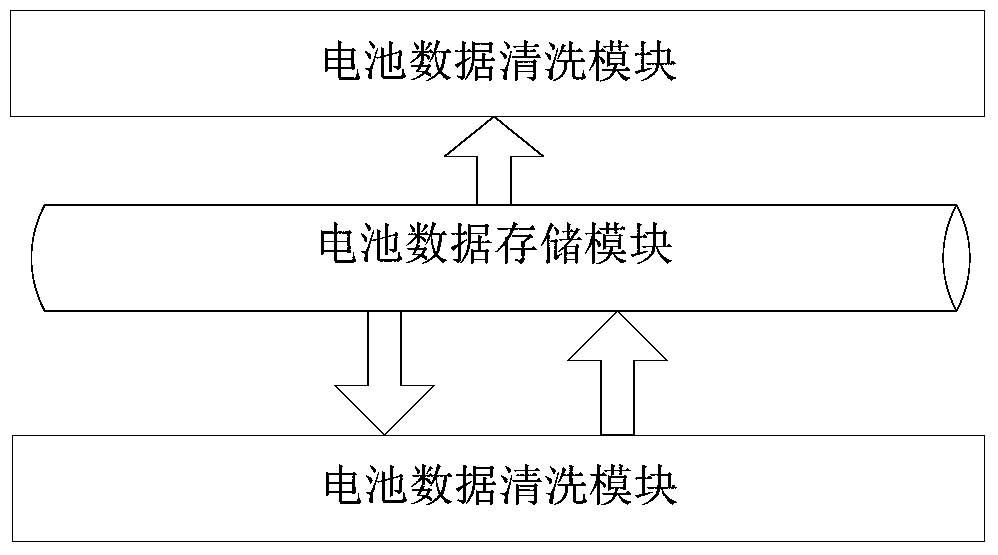

Method and system for cleaning mass data of energy storage power station

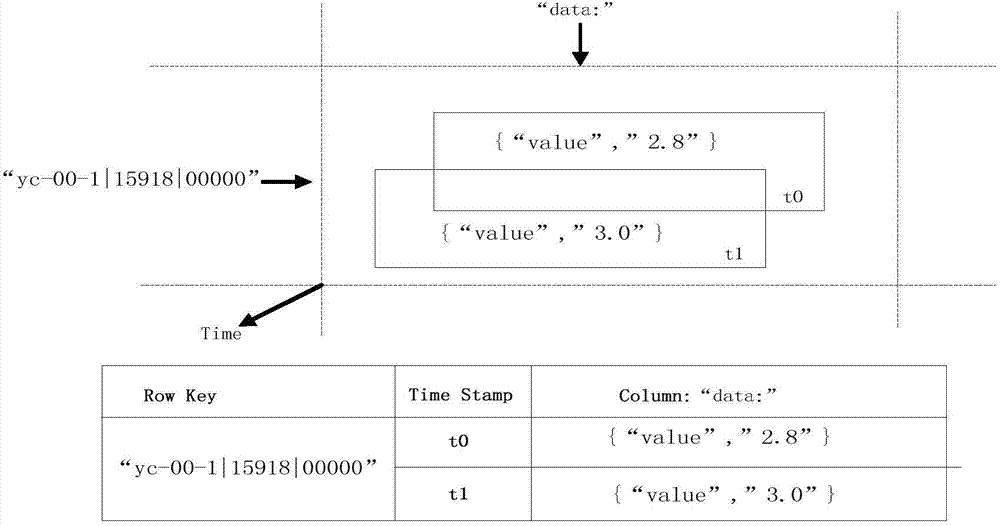

ActiveCN104750861AAchieve cleaningAchieving processing powerData processing applicationsEnergy efficient computingPower stationElectrical battery

The invention provides a method for cleaning mass data of an energy storage power station and a system for cleaning mass data of the energy storage power station. The method for cleaning mass data of the energy storage power station comprises the following steps: I, positioning and replacing default value of data concentration of the energy storage power station; II, positioning and replacing abnormal value of data concentration; III, determining unreasonable data from the data concentration obtained after replacing according to different types and characteristics of the energy storage battery data, and replacing it. The method and the system can clean the mass battery data, guarantee the mass data distribution processing requirement, realize the mass battery data optimization cleaning and pretreatment purposes of the energy storage power station after comprehensively considering about K neighbor algorithm, Pauta criterion method, distributed processing, and others; besides, the pretreatment and using effects of the mass data of the large-capacity battery energy storage power station are improved.

Owner:CHINA ELECTRIC POWER RES INST +4

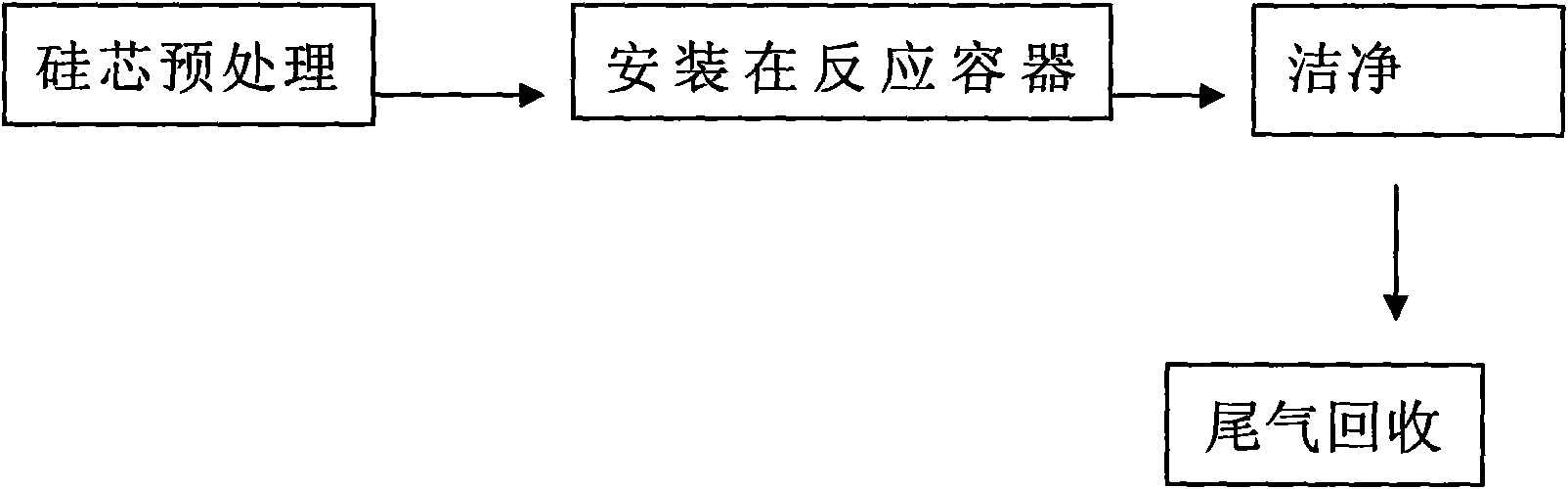

Silicon core cleaning technique

The invention discloses a silicon core cleaning technique, and relates to a processing technique of polysilicon, in particular to a method for cleaning silicone core. According to the technical schemeprovided by the invention, the silicon core cleaning technique comprises the following steps: a, silicon core pretreatment: firstly using anhydrous ethyl alcohol to wipe off the impurities on the surface of the silicon core, and then using acetone to wipe off oil stains on the surface of the silicon core; then putting the silicon core in an ultrasonic cleaning instrument for ultrasonic cleaning;and carrying out vacuum drying; b, cleaning: putting the cleaned silicon core in a closed reaction vessel, carrying out the following reaction under the temperature of 300 DEG C to 320 DEG C: Si+3HC-SiHCl3+H2; in the reaction process, introducing the mixed gas of hydrogen and hydrogen chloride into the reaction vessel; and c, repeated utilization of tail gas: adopting the reaction product of hydrogen trichloride and hydrogen as raw materials for preparing polysilicon, carrying out gas returning of the reaction product by a gas inlet pipe and a gas outlet pipe, and entering working section of reduction by a pipeline. The reaction product can be completely recovered, thus realizing zero emission of nitride and improving environment.

Owner:无锡中彩科技有限公司

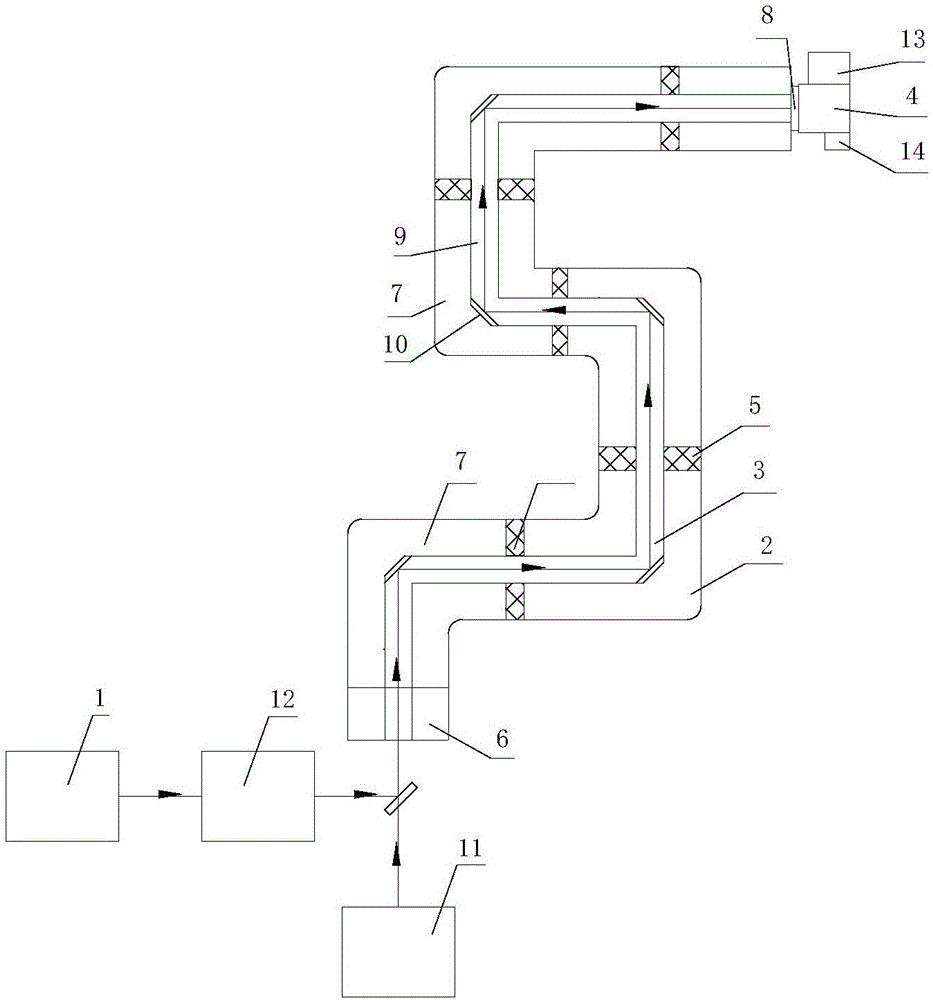

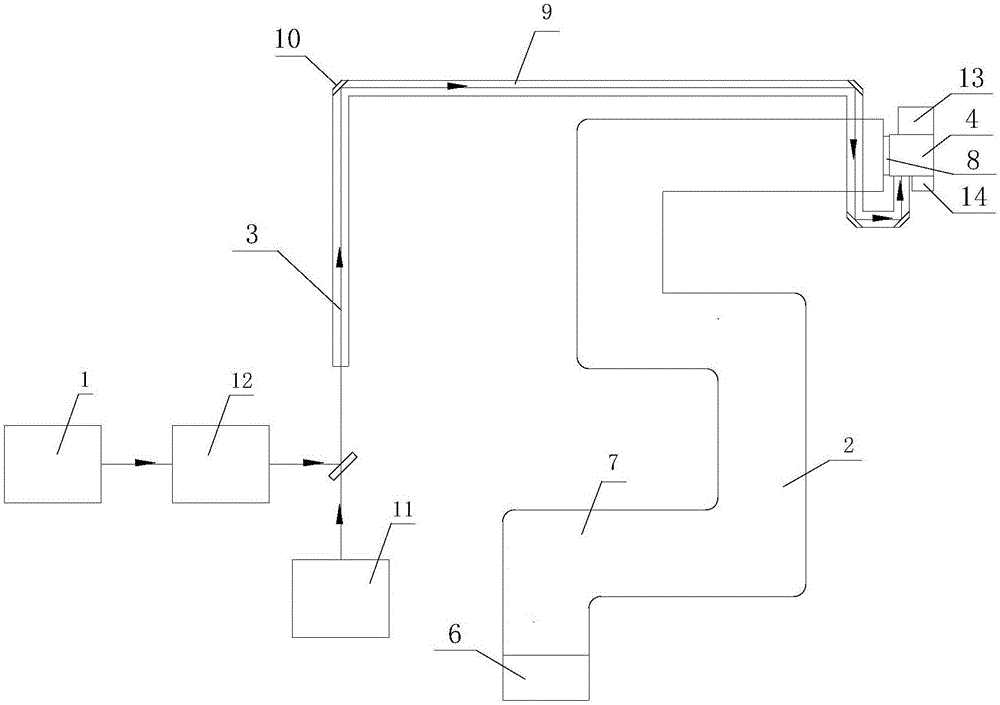

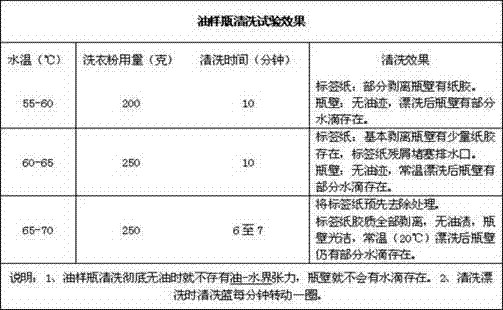

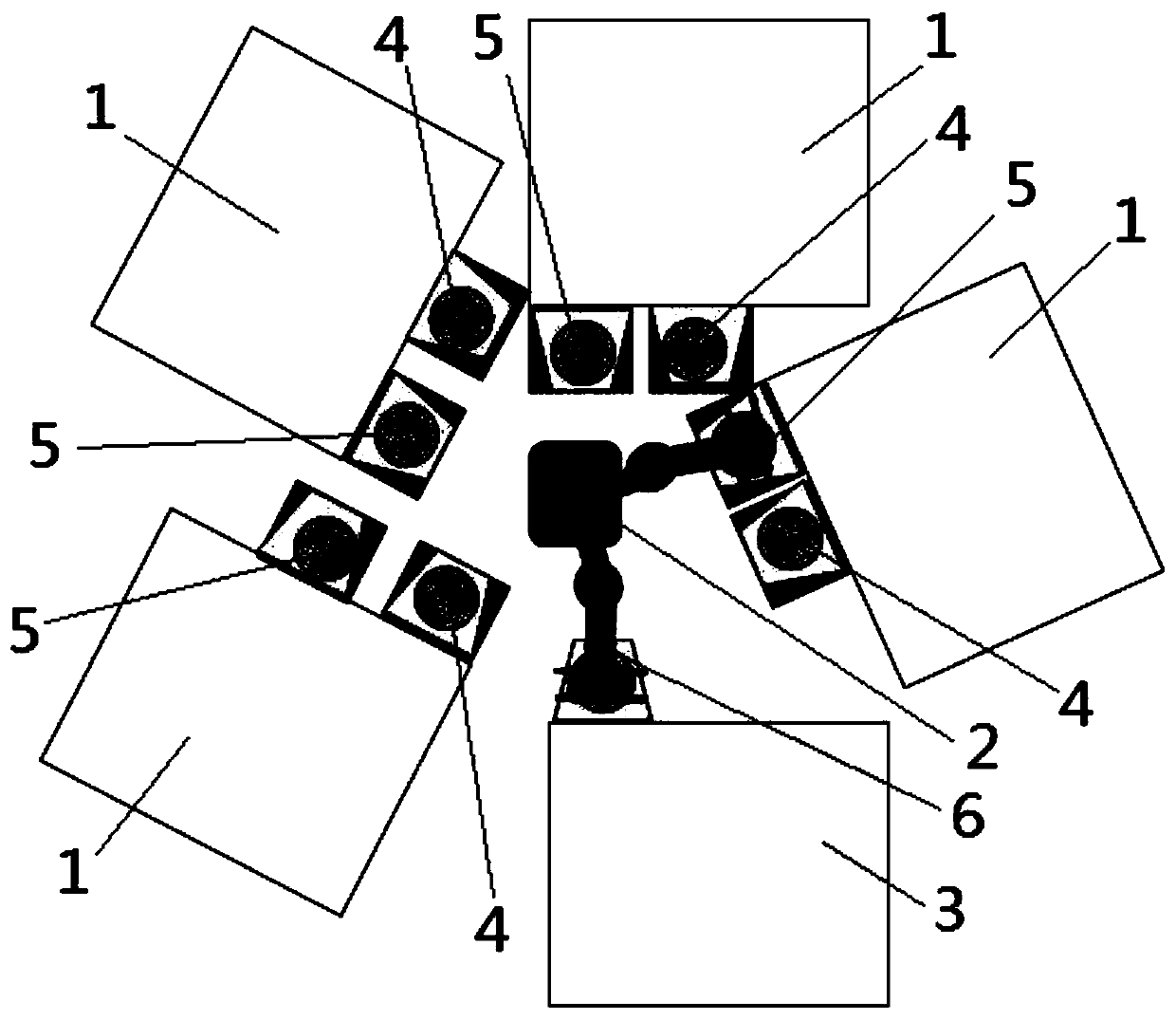

Laser cleaning device based on flexible optical path

PendingCN106733942AIncrease flexibilityImprove cleaning efficiencyCleaning using gasesAutomatic controlRobotic arm

The invention relates to a laser cleaning device based on a flexible optical path. The laser cleaning device comprises a laser, a mechanical arm, a light guide arm and a scanning mechanism, wherein the light guide arm is fixedly connected on the mechanical arm, and can move along with the mechanical arm; the laser is arranged close to one end of the light guide arm; the scanning mechanism is arranged close to the other end of the light guide arm; laser projected from the laser enters the light guide arm from an incident end of the light guide arm and enters the scanning mechanism after being projected from an emergent end of the light guide arm; the scanning mechanism can perform two-dimensional rotation; and the direction of laser entering the scanning mechanism is adjusted, laser penetrates through the scanning mechanism to scan a cleaning part, and cleaning is completed. According to the laser cleaning device, the mechanical arm and the light guide arm are combined, the light guide arm can freely rotate at all angles along with the mechanical arm, a traditional hard optical path is changed into the flexible optical path, flexibility of the device is greatly improved, and automatic control is facilitated.

Owner:WUHAN JINDUN LASER TECH CO LTD

Substrate cleaning method and computer readable storage medium

ActiveUS8147617B2Suppress static build-upImprove cleaning accuracySemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringAcoustic wave

A wafer W is processed by supplying a two-fluid, high pressure jet water, or mega-sonic water onto the wafer W, while rotating the wafer W in an essentially horizontal state. After supply of the cleaning fluid is stopped, the wafer W is dried by rotating the wafer W at a higher speed than that used in supplying the cleaning fluid. No rinsing process using purified water is performed in a period after stopping supply of the cleaning fluid and before rotating the substrate at the higher speed.

Owner:TOKYO ELECTRON LTD

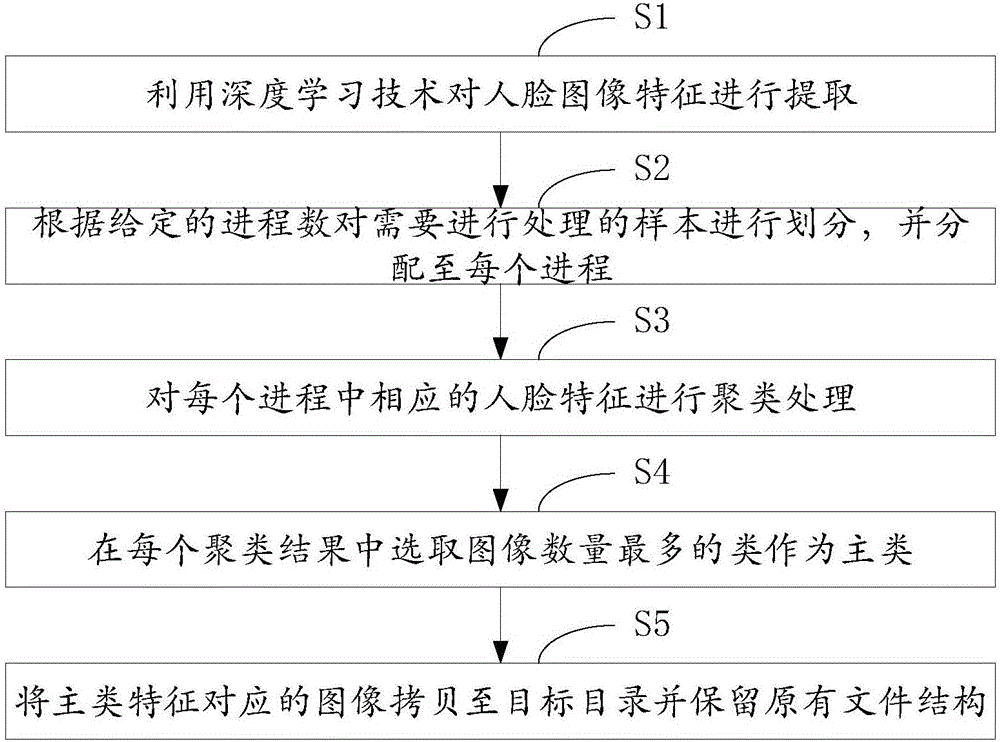

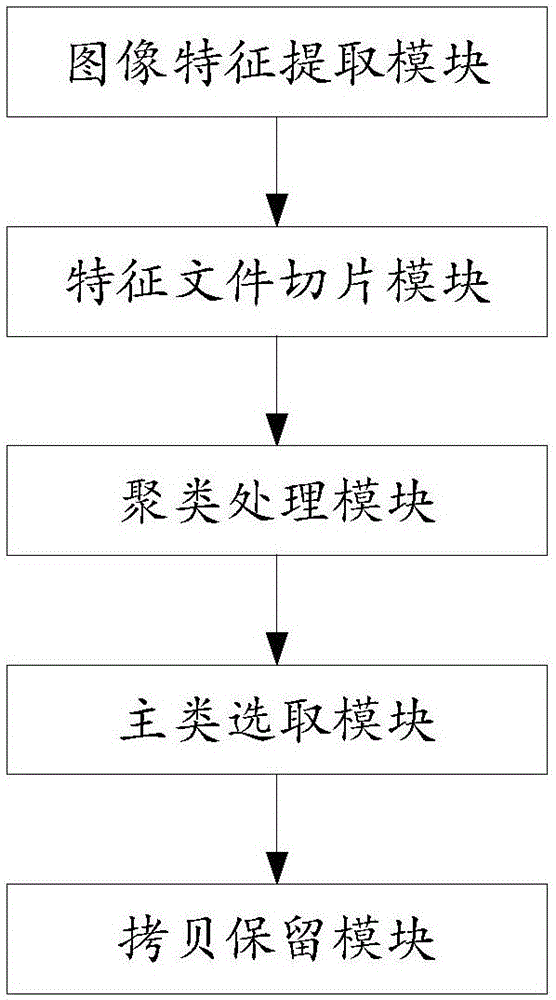

Facial sample cleaning method and system based on deep learning features

ActiveCN106650804AReduce feature dimensionGood identification effectCharacter and pattern recognitionPattern recognitionImaging Feature

The invention is applicable to the field of data mining and sample cleaning and provides a facial sample cleaning method and system based on deep learning features. The facial sample cleaning method comprises the steps that A, the deep learning technology is utilized to extract facial image features; B, a sample needing to be processed is partitioned according to a given process number, and the partitioned samples are allocated to all processes; C, corresponding facial features in each process are clustered; D, a class with most images is selected in each clustering result to serve as a main class; E, the image corresponding to the features of the main class is copied to a target directory, and an original file structure is reserved. The facial features extracted through deep learning are low in dimension and have very good identification capability; on the one hand, sample cleaning precision can be improved, and on the other hand, cleaning time can be saved; multiple processes are designed concurrently, the operational capability of hardware an be fully utilized, therefore, the efficiency of entire operation can be improved, and consumed time is shortened.

Owner:SHENZHEN INTELLIFUSION TECHNOLOGIES CO LTD

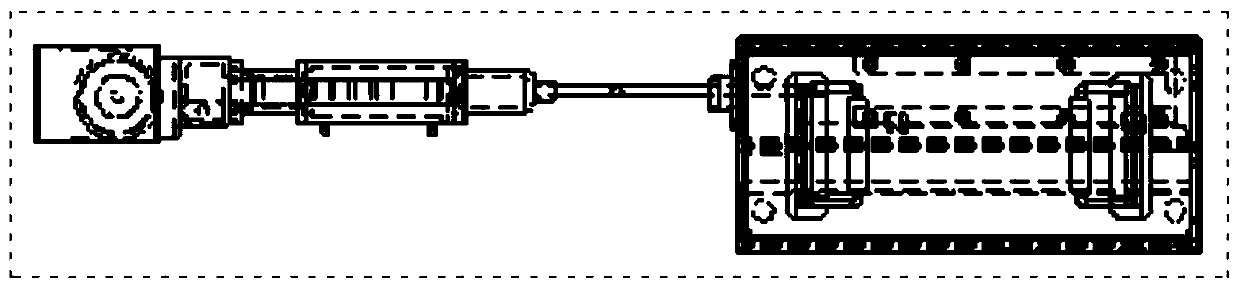

Double-wavelength composite beam shaping handheld type self-adaptive laser cleaning device

ActiveCN107309221AClean up thoroughlyDamage reduction propertiesCleaning processes and apparatusOptical elementsHand heldWavelength

The invention provides a double-wavelength composite beam shaping handheld type self-adaptive laser cleaning device comprising a laser device, a transmission optical fiber, a lifting focusing assembly, a laser distance measuring sensor, a galvanometer scanning system, a lifting guide electric drive assembly and a double-wavelength composite shaping system. The galvanometer scanning system is used for focusing an incident laser beam to the surface of a workpiece and enables the laser beam to conduct scanning motion on the surface of the workpiece along a set path. The lifting focusing assembly is arranged on the lower side of a laser beam emergence end of the galvanometer scanning system. The laser distance measuring sensor is fixedly installed on the side face of the galvanometer scanning system. The input end of the double-wavelength composite shaping system and the laser device are connected through the transmission optical fiber. The double-wavelength composite shaping system outputs a double-wavelength composite shaping beam after internal optical transformation. The output end of the double-wavelength composite shaping system is fixedly connected with the laser beam incident end of the galvanometer scanning system. The double-wavelength composite beam shaping handheld type self-adaptive laser cleaning device can greatly improve the uniformity and fineness degree of cleaning and greatly improve the cleaning quality.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

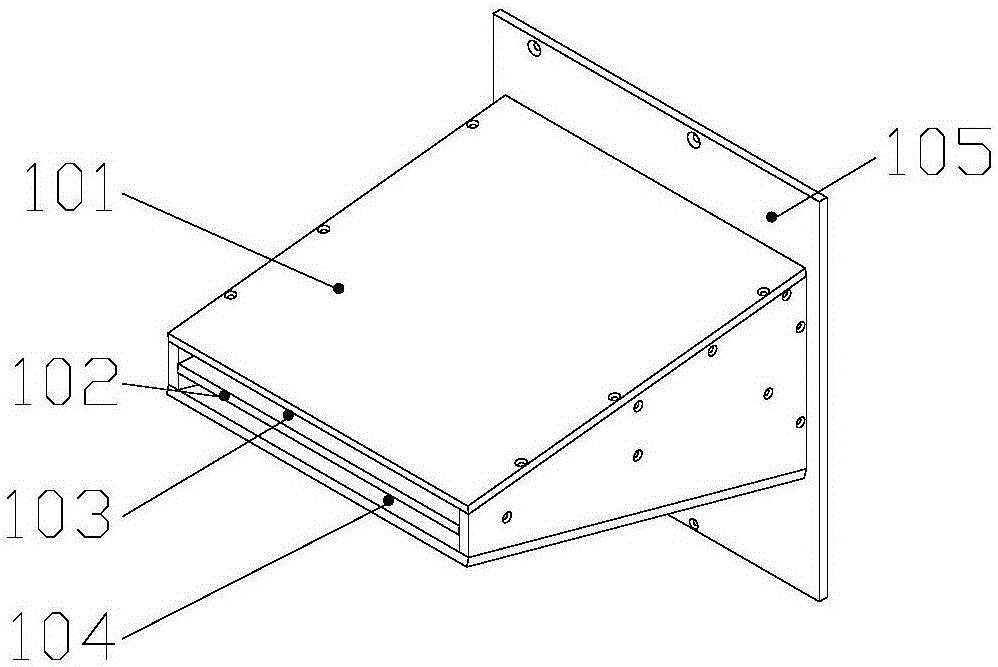

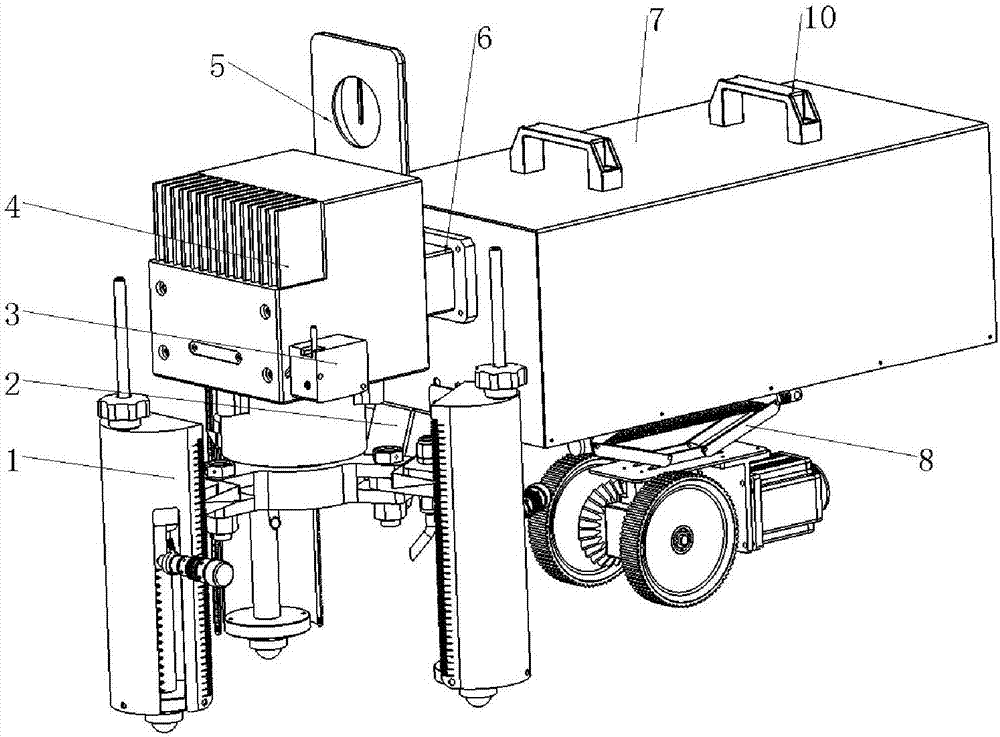

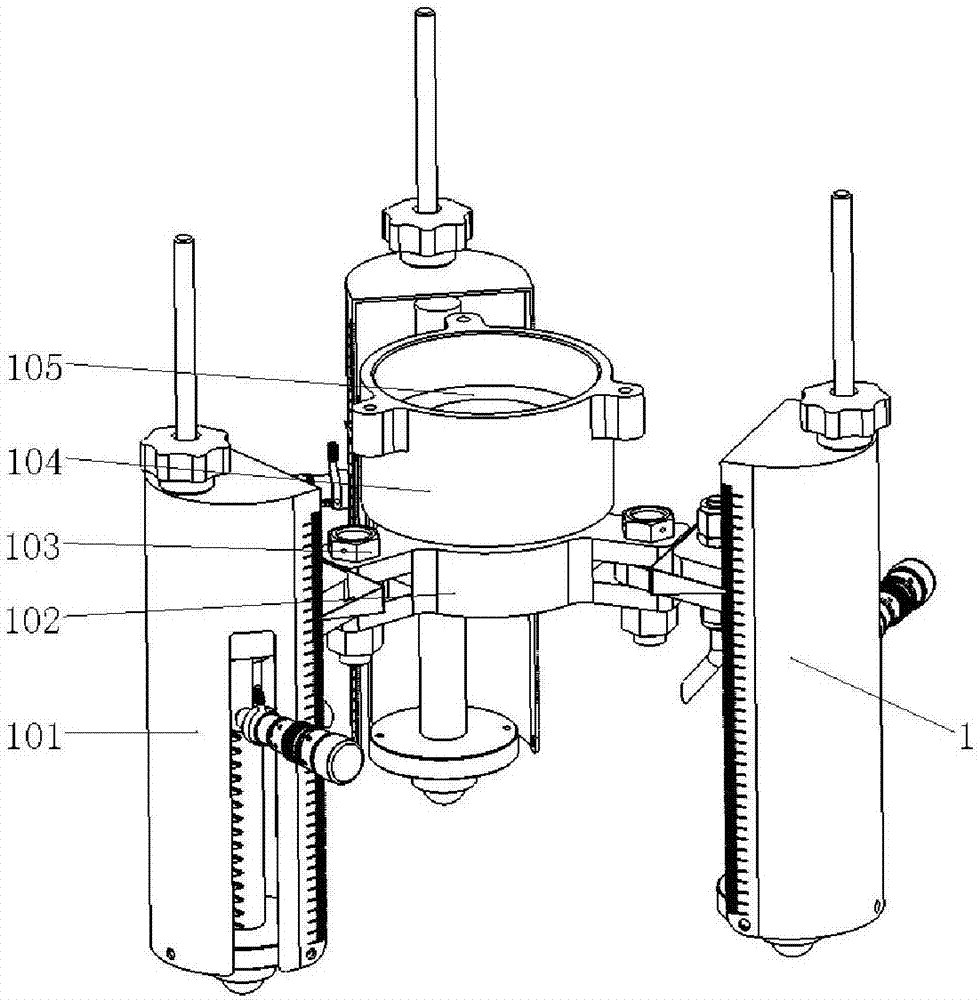

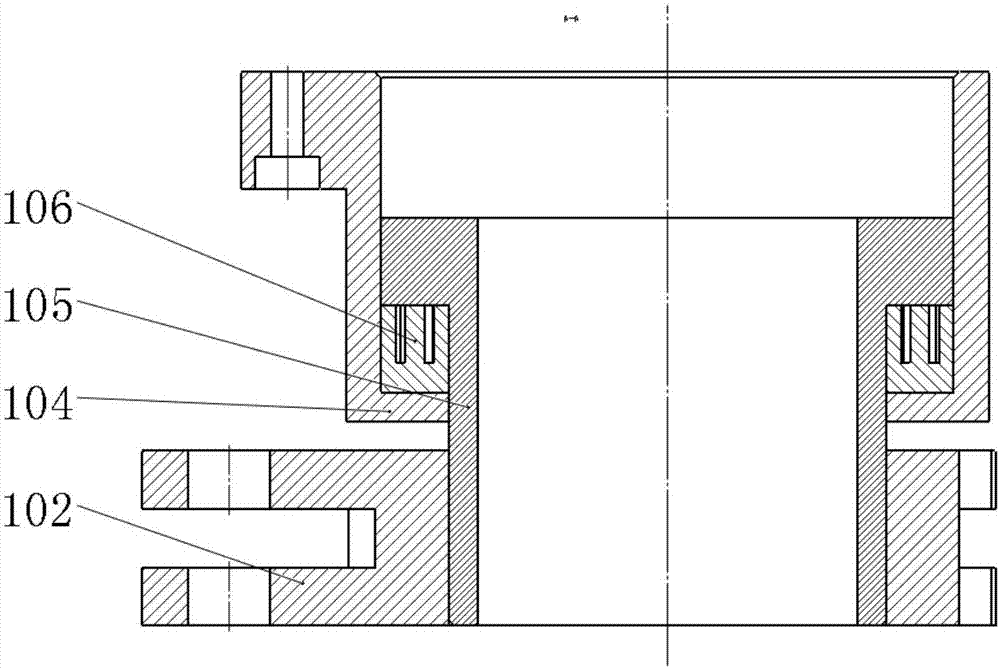

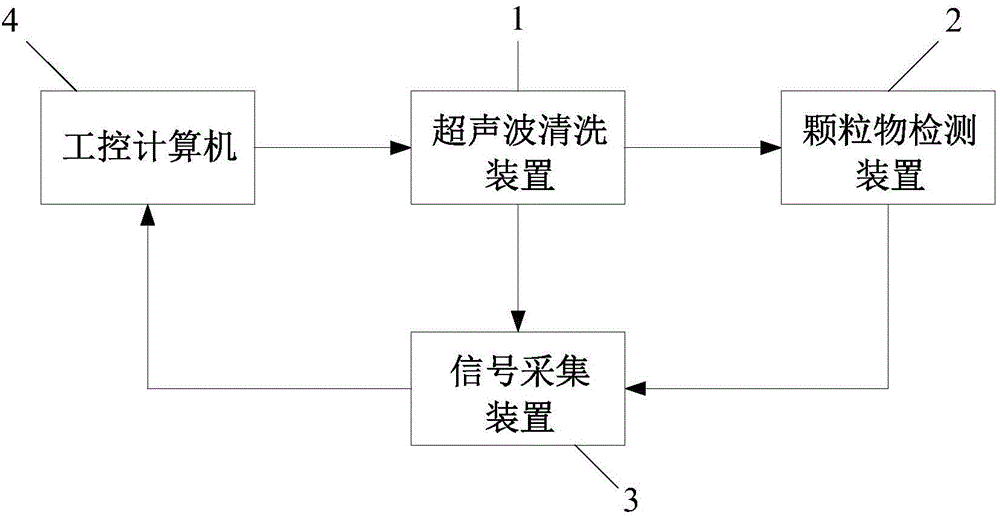

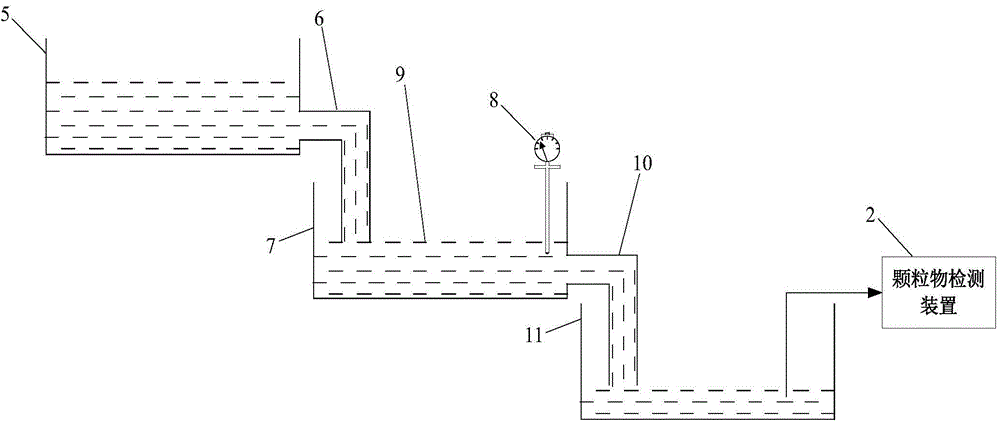

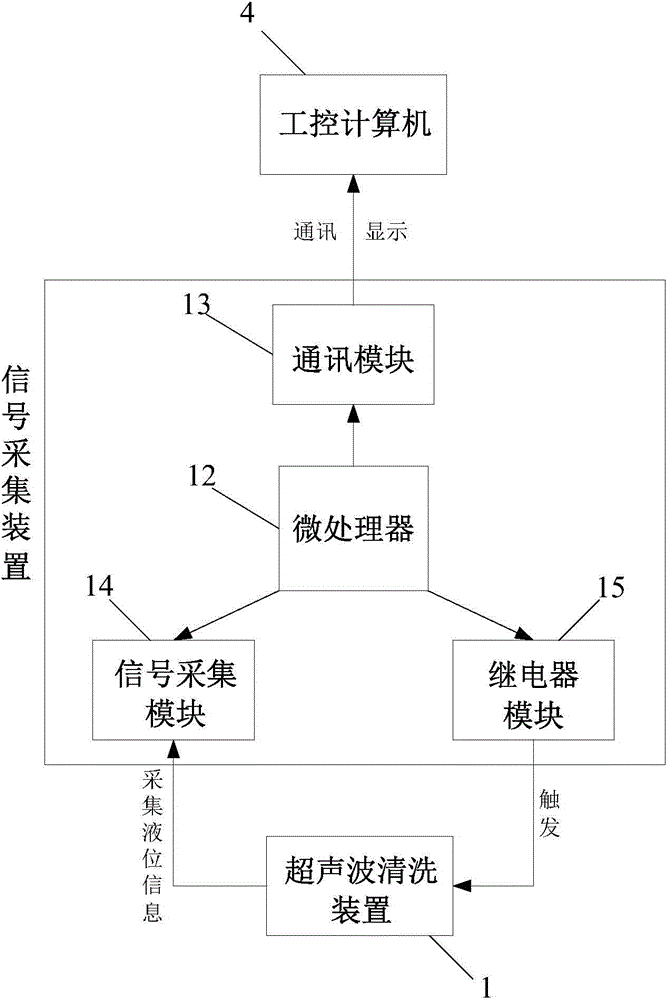

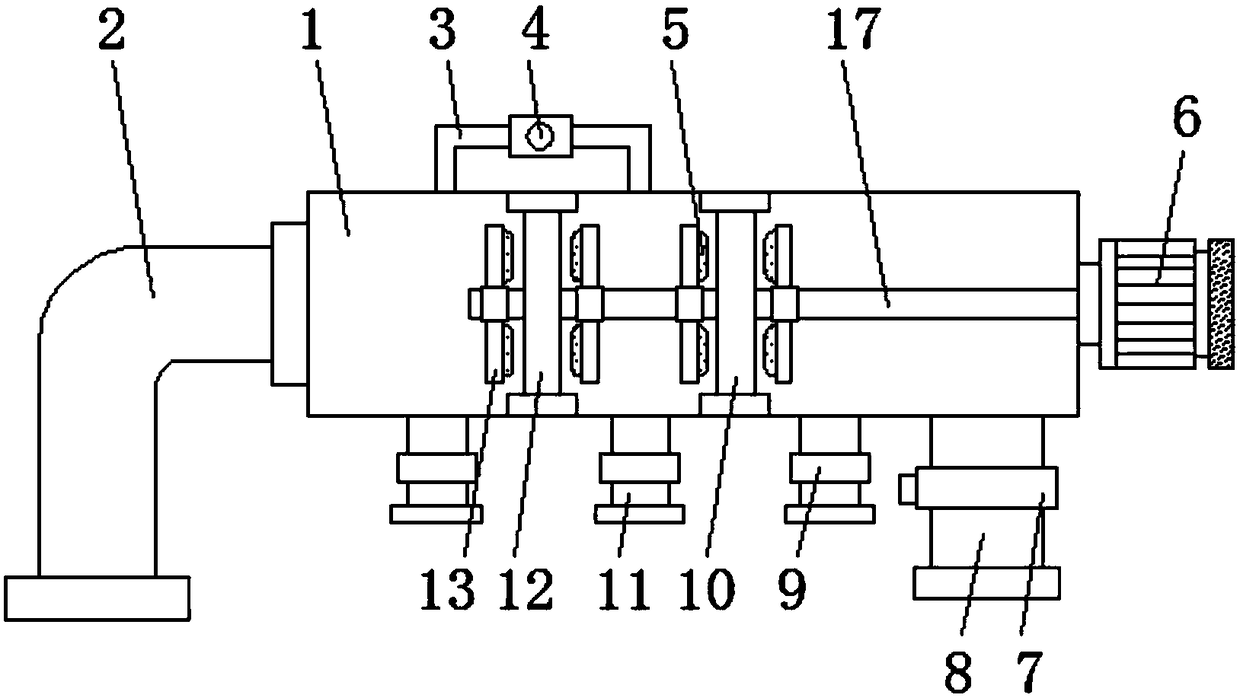

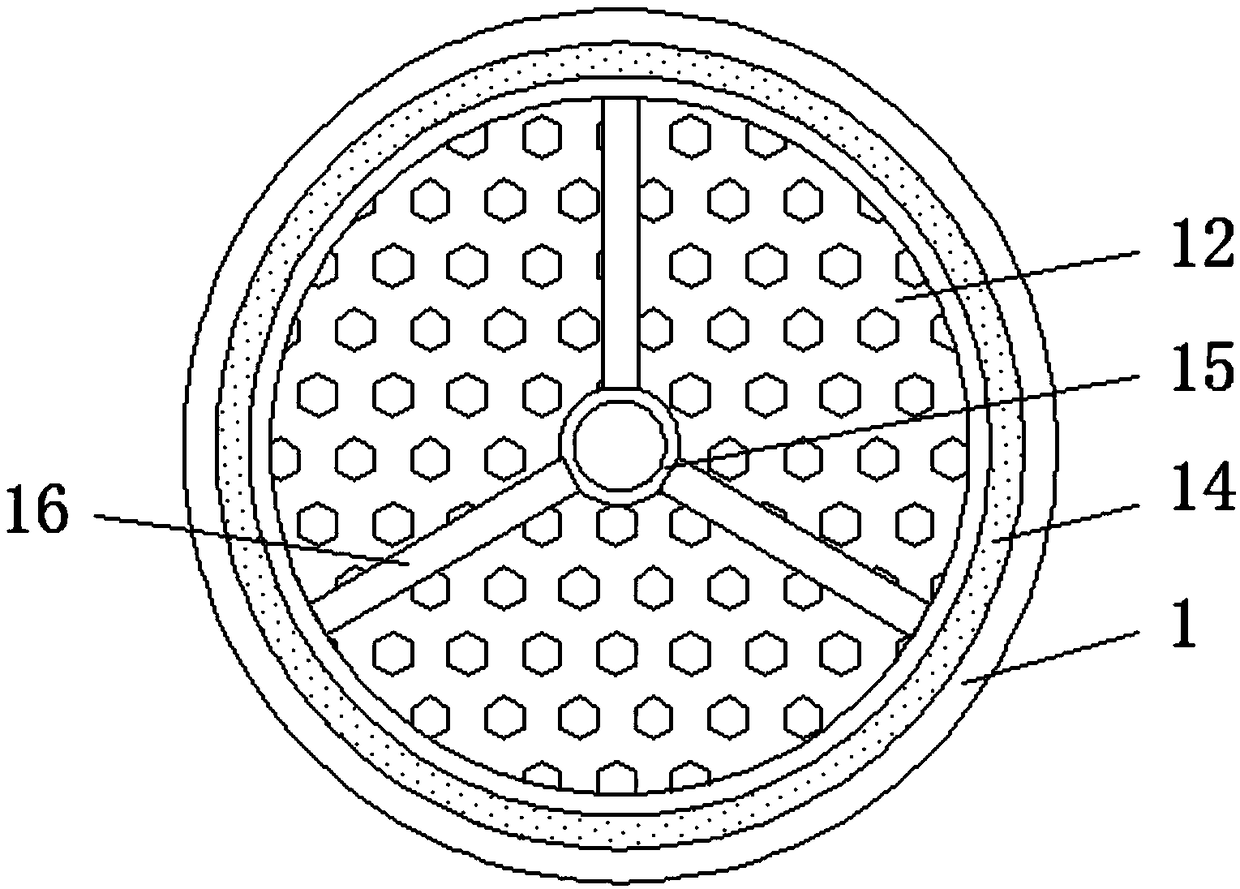

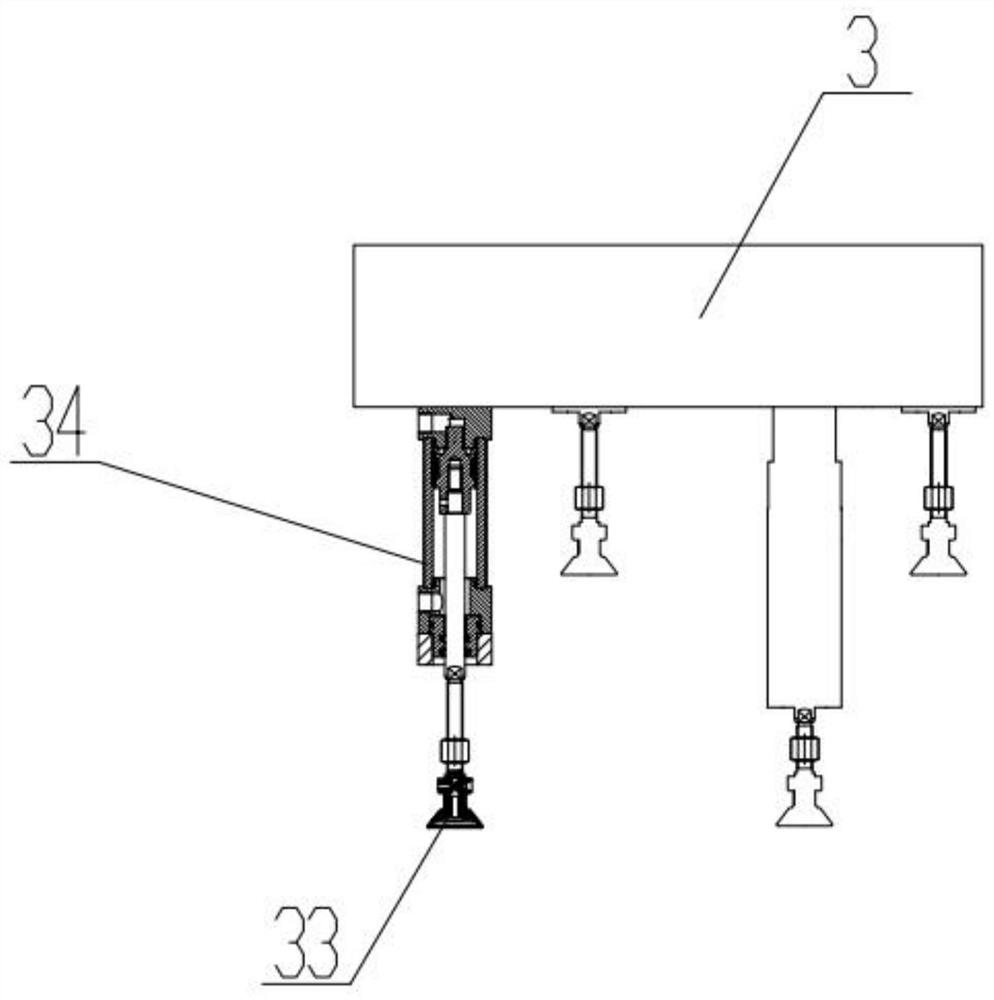

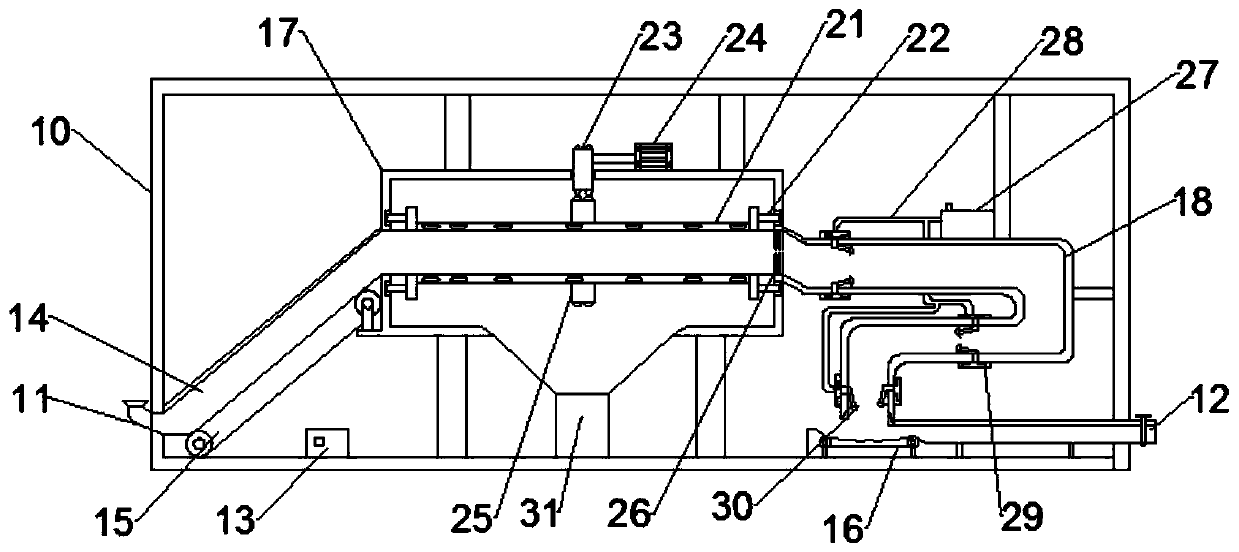

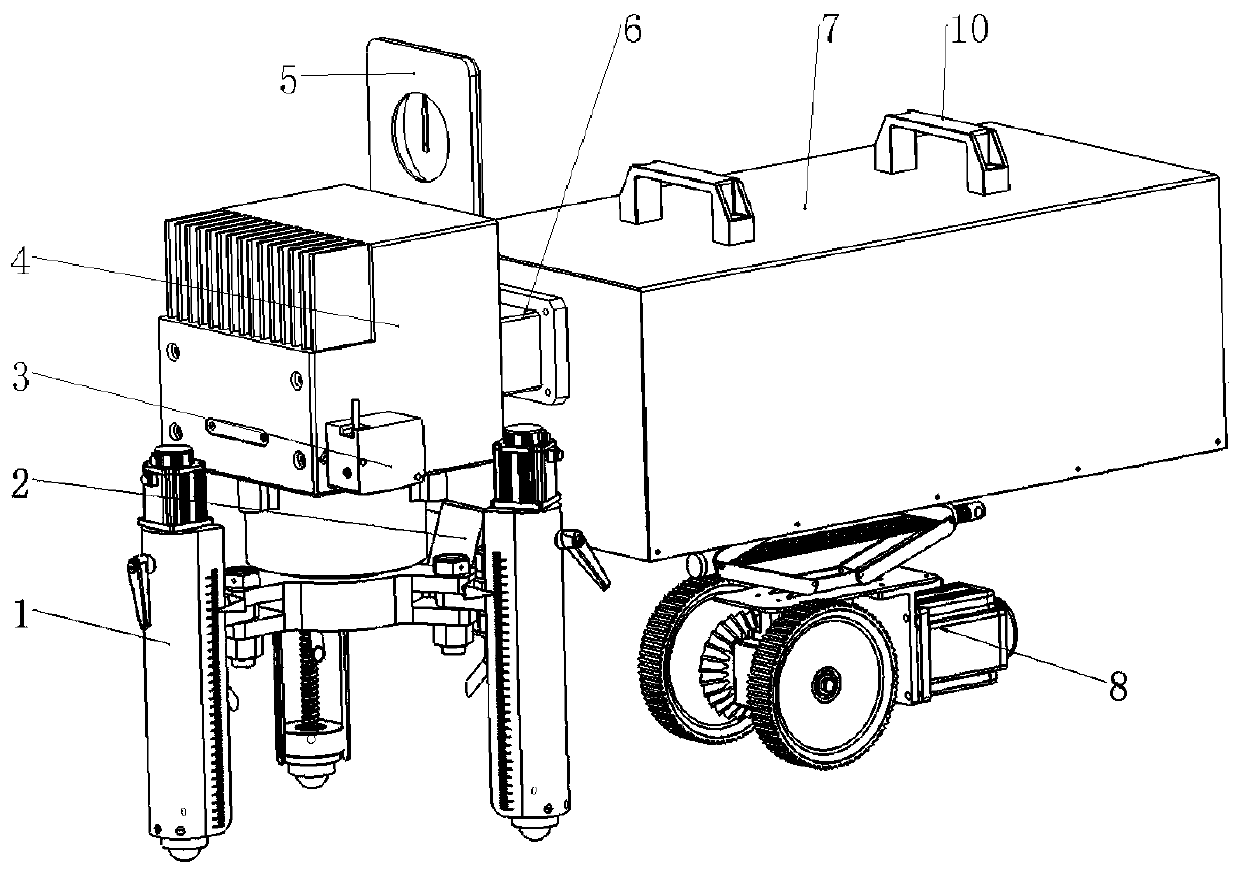

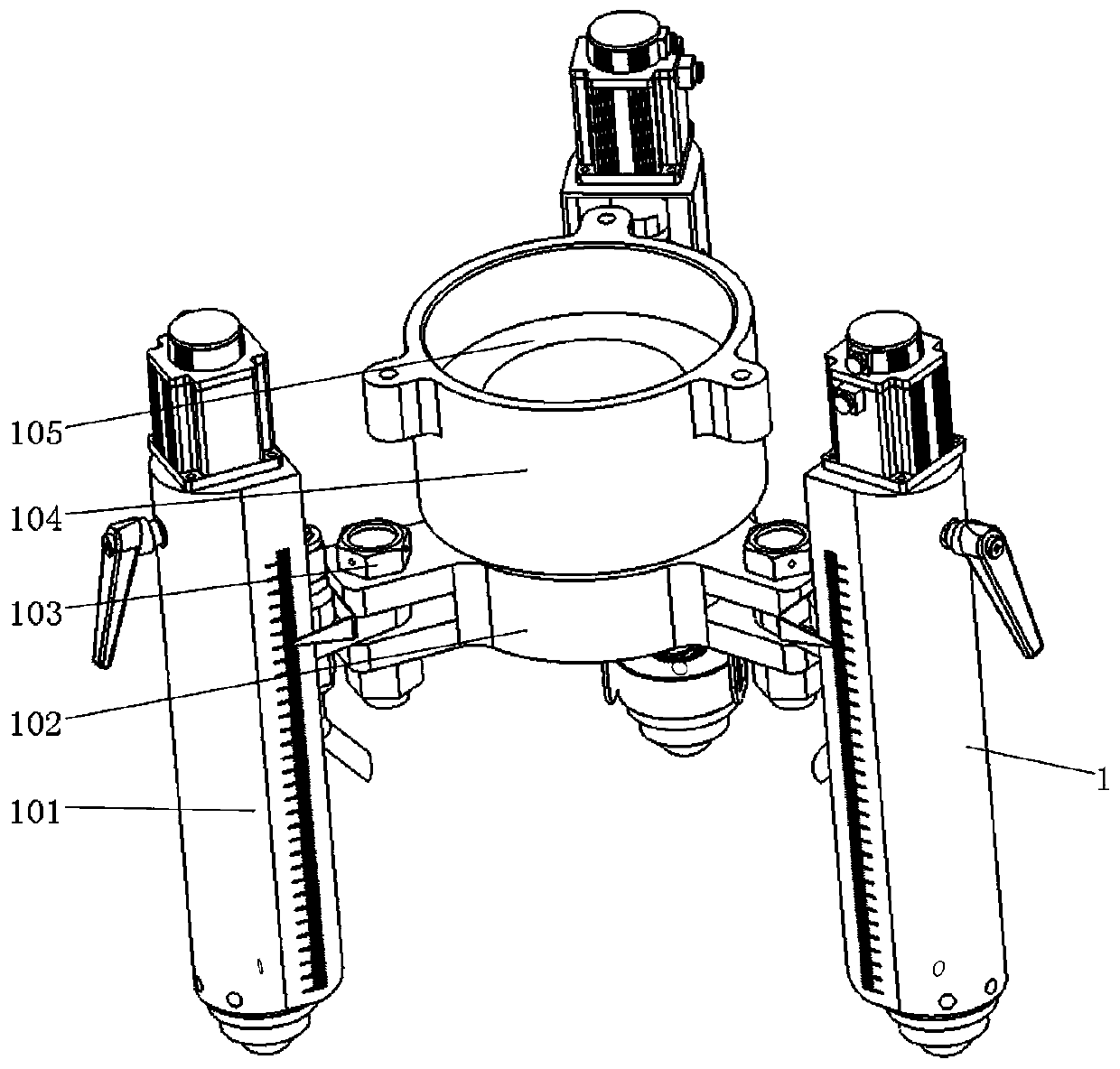

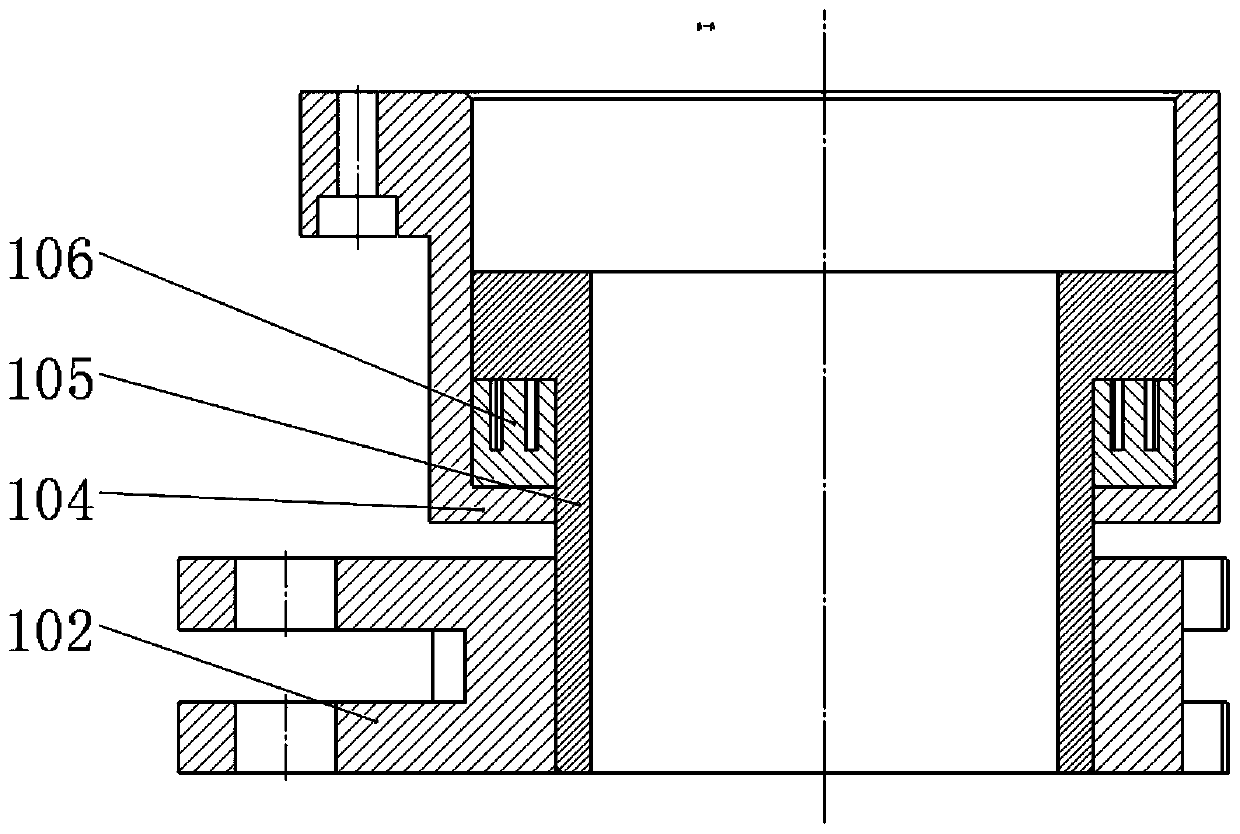

Automatic detection and cleaning system of redundant substance of liquid rocket engine pipeline

ActiveCN104588362AImprove cleaning efficiencyImprove cleaning accuracyParticle size analysisParticle suspension analysisParticulatesControl signal

The invention provides an automatic detection and cleaning system of a redundant substance of a liquid rocket engine pipeline. The system mainly comprises an ultrasonic cleaning device, a particulate matter detection device, a signal acqusition device and an industrial control computer, wherein the ultrasonic cleaning device comprises a liquid holding tank, a liquid inlet pipe, a cleaning tank, a liquid level meter, an ultrasonic generator, a drainage pipe and a liquid collection tank; the cleaning tank is communicated with the liquid holding tank through the liquid inlet pipe and is communicated with the liquid collection tank through the drainage pipe; the liquid level meter and the ultrasonic generator are positioned in the cleaning tank; the particulate matter detection device is communicated with the liquid collection tank; the signal acqusition device comprises a microprocessor, a communication module, a signal acqusition module and a relay module; the industrial control computer is used for transmitting a turn-on and turn-off control signal to the microprocessor through the communication module and receiving and displaying liquid level information and particle matter information.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

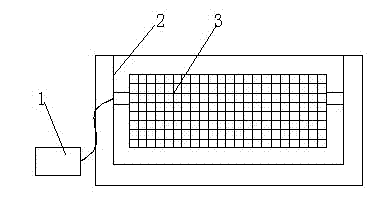

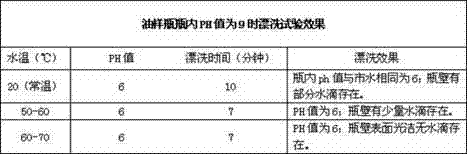

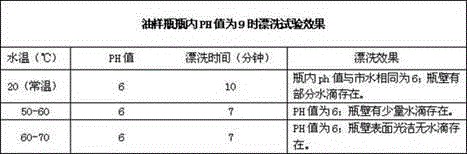

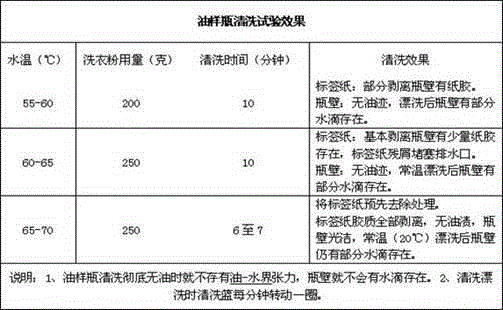

Method for cleaning insulating oil sample bottle and utilized cleaning device

The invention relates to a method for cleaning an insulating oil sample bottle and a utilized cleaning device. The insulating oil sample bottle cleaning method comprises the steps of (1) ultrasonic decontamination: before work, preheating water to a suitable temperature firstly, adding laundry powder, placing an oil sample bottle in a cleaning basket which is then placed in a cleaning tank, rotating the cleaning basket to enable the oil sample bottle to be filled with a cleaning solution, and starting a decontamination ultrasonic generator for the decontamination; and (2) ultrasonic rinse: opening a blowdown valve after the decontamination cleaning is finished, cleaning the cleaning tank appropriately after the cleaning solution is discharged completely, closing the valve, opening a water inlet valve, opening the ultrasonic generator, heating the water to a suitable temperature, placing the oil sample bottle into the water for rinse, and after the oil sample bottle is rinsed cleanly, taking the bottle out of a vessel and performing draining separation. The method for cleaning the insulating oil sample bottle and the utilized cleaning device have the advantages as follows: (1) the cleaning speed is high, the cleaning effect is good, the cleanliness is high, and the damage to the surface of a workpiece is prevented; (2) hands of a worker are not contacted with the cleaning solution, and deep holes, thin seams and hidden positions of the workpiece can also be cleaned up safely and reliably; and (3), the cleaning precision is high, and tiny stain particles can be cleaned powerfully.

Owner:JIANGSU ELECTRIC POWER COMPANY YANGZHOU POWER +2

Silicon wafer CMP post-processing equipment and processing flow

ActiveCN109860085AImprove cleaning accuracyIncrease production capacitySemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringSilicon

The invention relates to silicon wafer CMP post-processing equipment and a processing flow. The silicon wafer CMP post-processing equipment comprises an ozone water tank and a pure water flushing tank, wherein the ozone water tank and the pure water flushing tank are located at the rear ends of a plurality of CMP processing devices; a mechanical arm; a CMP post-cleaning device, wherein a water tank for placing a silicon wafer storage box is arranged at the front end of the CMP post-cleaning device. The processing method comprises the following steps: 1, processing silicon wafers by the CMP processing devices, and putting the silicon wafers into the silicon wafer storage box located in the ozone water tank of the CMP processing devices; 2, putting the silicon wafer storage box at the firststep in the pure water flushing tank for flushing; 3, delivering the silicon wafer storage box in the pure water flushing tank at the rear ends of the CMP processing devices to the water tank at the front end of the CMP post-cleaning device through the mechanical arm; 4, cleaning the silicon wafers in the silicon wafer storage box in the water tank one by one by the CMP post-cleaning device by using a CMP post-cleaning process. The method has the following advantages: (1) the silicon wafers are in a wet state in the whole process, and the cleaning precision of the silicon wafers is high; (2) the cleaning process effect of the silicon wafers after CMP is good.

Owner:若名芯半导体科技(苏州)有限公司

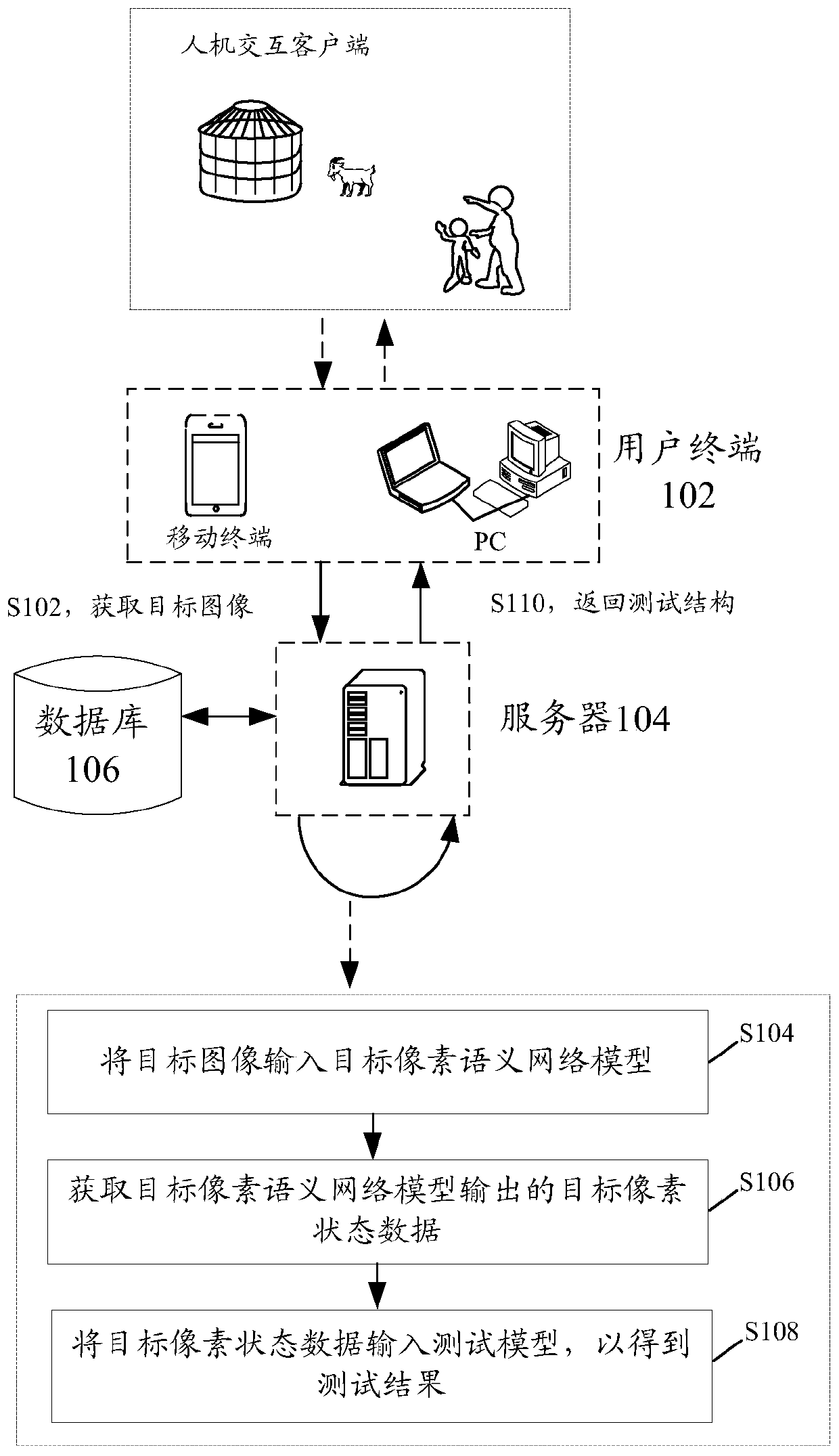

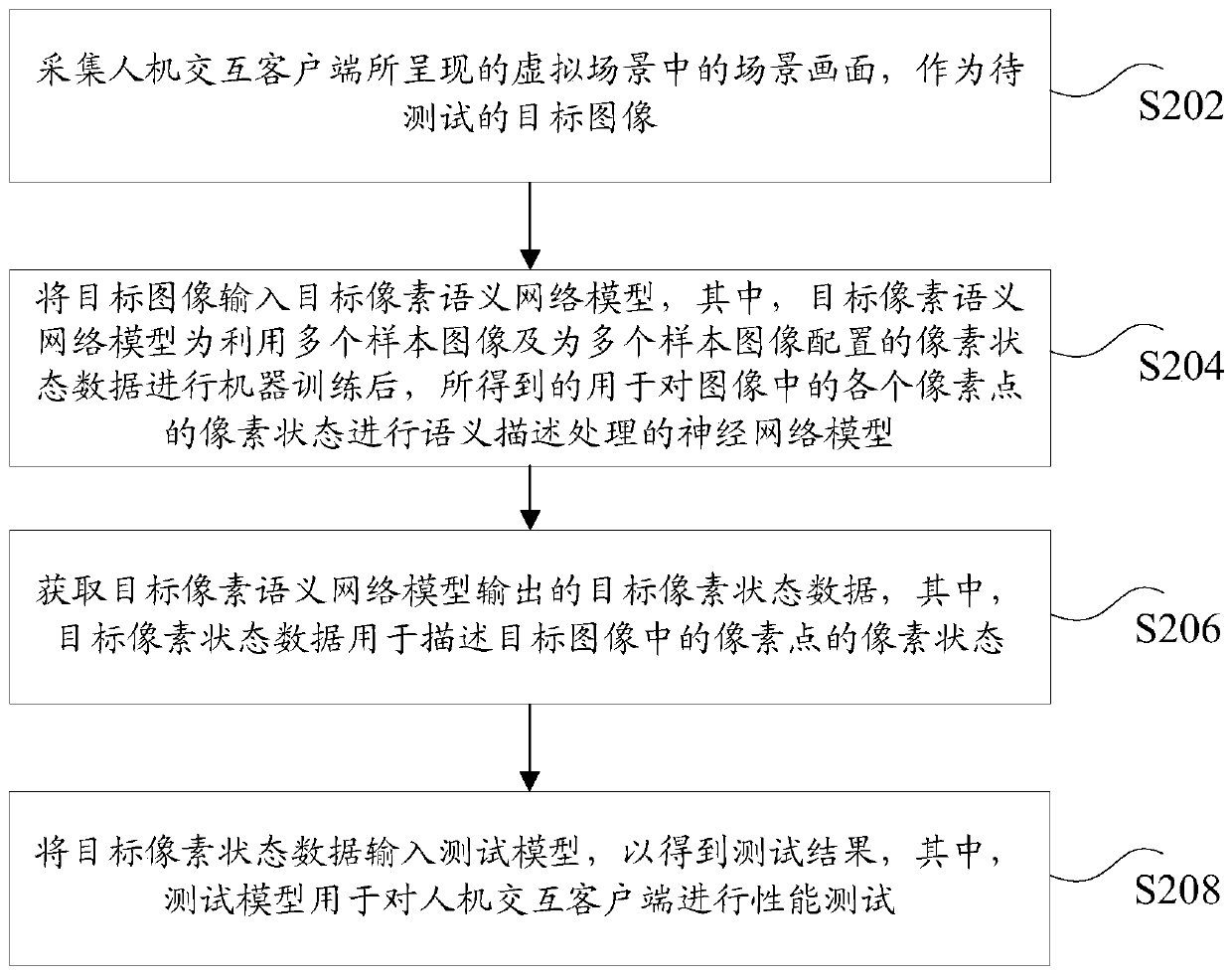

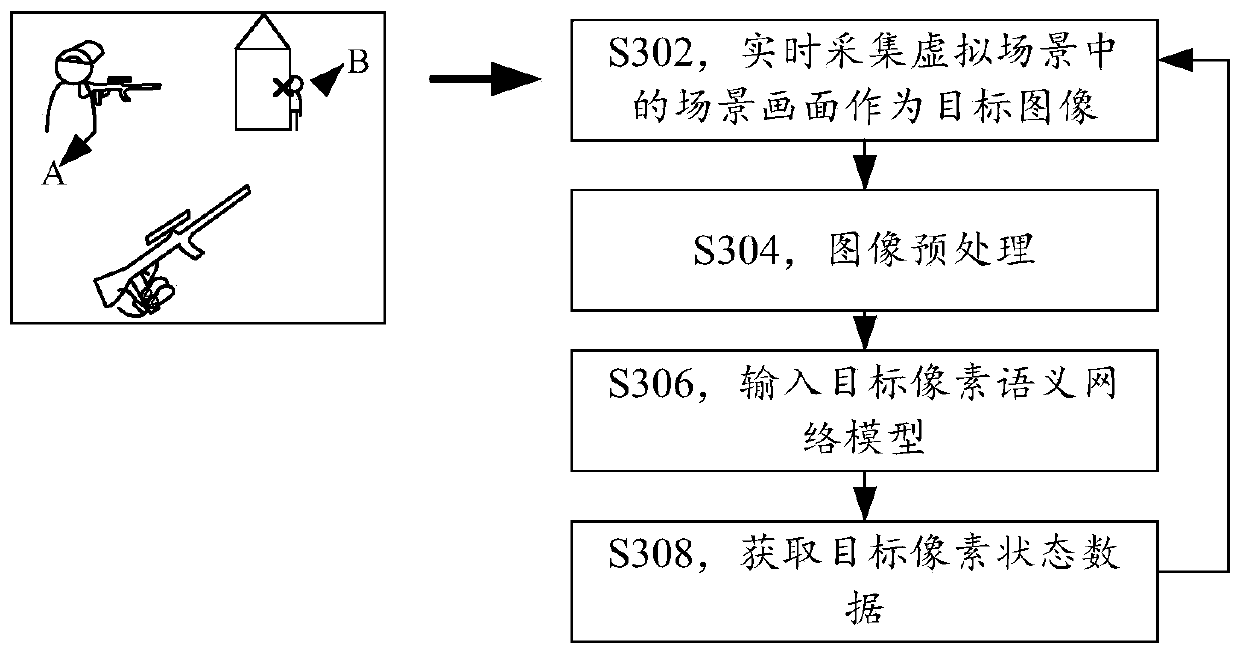

Image testing method and device, storage medium and electronic device

PendingCN110163201AImprove cleaning accuracyFix technical issues with lower accuracyCharacter and pattern recognitionComputer graphics (images)Sample image

The invention discloses an image testing method and device, a storage medium and an electronic device. The method comprises the following steps: acquiring a scene picture in a virtual scene presentedby a human-computer interaction client as a target image to be tested; inputting the target image into a target pixel semantic network model, wherein the target pixel semantic network model is a neural network model used for conducting semantic description processing on pixel states of all pixel points in the image and obtained after machine training is conducted through multiple sample images andpixel state data configured for the multiple sample images; acquiring target pixel state data output by the target pixel semantic network model; and inputting the target pixel state data into a testmodel to obtain a test result, the test model being used for performing a performance test on the human-computer interaction client. The technical problem that the test result is low in accuracy afterthe image test method provided by the related technology is adopted is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

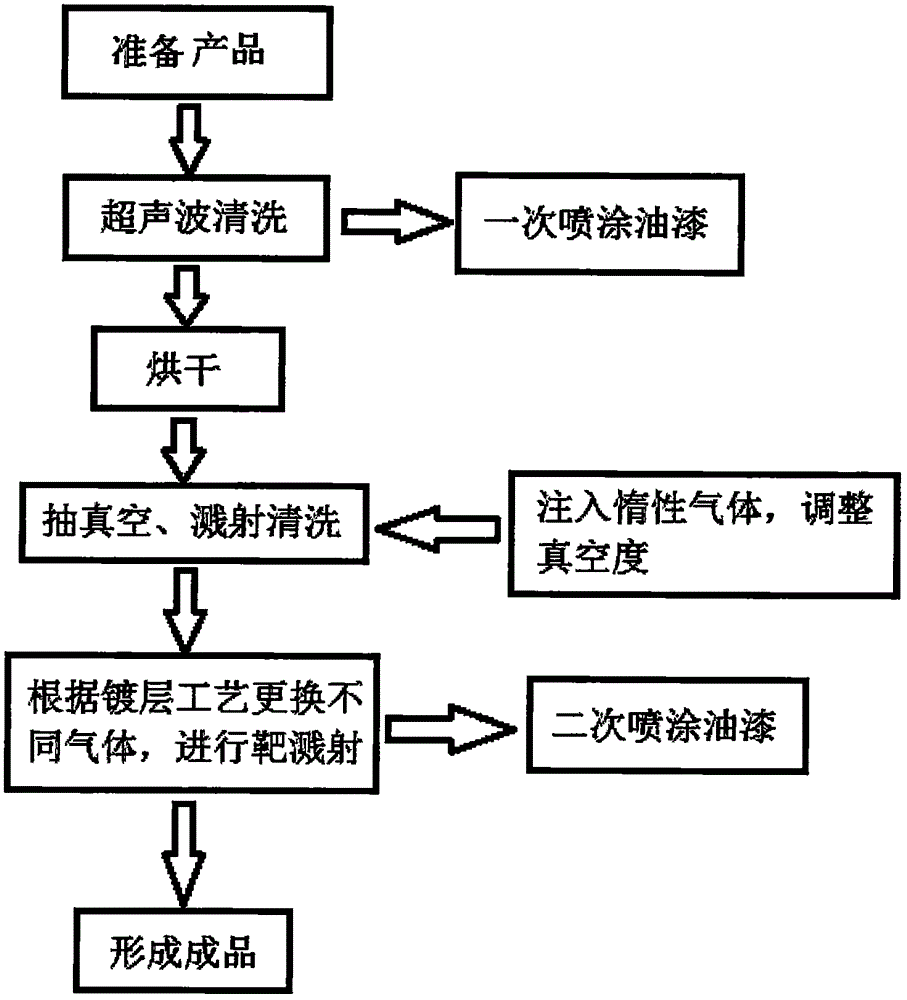

Product coating method based on plastic or nylon products

InactiveCN106521410AModerate bindingImprove the decorative effectVacuum evaporation coatingSputtering coatingSputteringMegasonic cleaning

The invention discloses a coating method for products, including glasses, based on plastic or nylon products. The coating method includes the following steps that the products are prepared and subjected to ultrasonic degreasing cleaning, ultrasonic deoiling cleaning and ultrasonic pure water cleaning; the cleaned products are dried and placed into a vacuum machine for film coating; the interior of the vacuum machine is vacuumized, and bombardment cleaning is carried out through direct current magnetron sputtering or medium-frequency magnetron sputtering or multi-arc magnetron sputtering; and reaction gas required for coating forming is added according to needs, and a target is used for conducting target sputtering on the products to form coatings. According to the coating method, ultrasonic cleaning is additionally adopted, the products are treated before being coated, balanced contact at multiple angles can be achieved, and cleaning precision is improved; multiple types of magnetron sputtering are adopted for bombardment cleaning, the surfaces of the products can be effectively cleaned before coating, and thus the products can be combined with the coatings more effectively; and in the coating environment, inert gas is injected continuously to control the vacuum degree and add the gas required for coating, and thus the required coating effect of the coatings is achieved.

Owner:温州市瓯海瞿溪兴悦真空镀膜厂

Underwater laser cleaning device for ship

The invention relates to the field of laser cleaning equipment, in particular to an underwater laser cleaning device for ship. The device is arranged for ship cleaning, can directly conduct laser cleaning on the bottom of a ship located in water and is high in automation degree. The ship underwater laser cleaning device comprises two floating devices, two lifting devices and a cleaning base, the upper ends of the lifting devices are connected with the floating devices, the cleaning base is arranged between the two lifting devices and connected with the lower ends of the lifting devices, and the floating devices are provided with laser generators. The cleaning base is provided with a laser head, and the laser generator is connected with the laser head through an optical fiber. The floatingdevices directly float on the water surface, the cleaning base is suspended in water through the lifting device,s and laser cleaning can be directly conducted on the bottom of a ship.

Owner:JINAN SENFENG TECH CO LTD

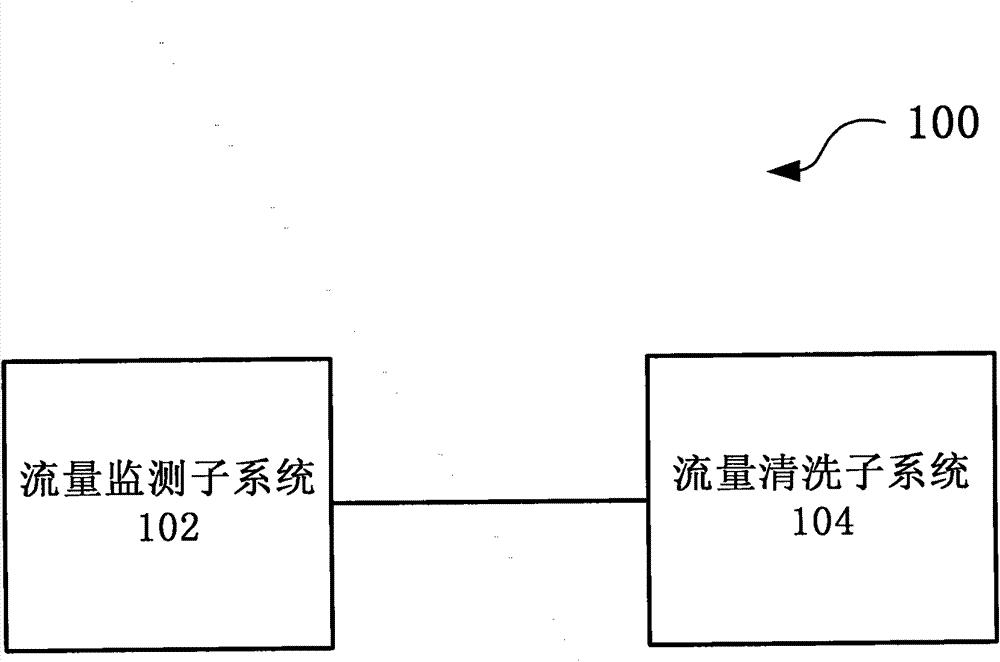

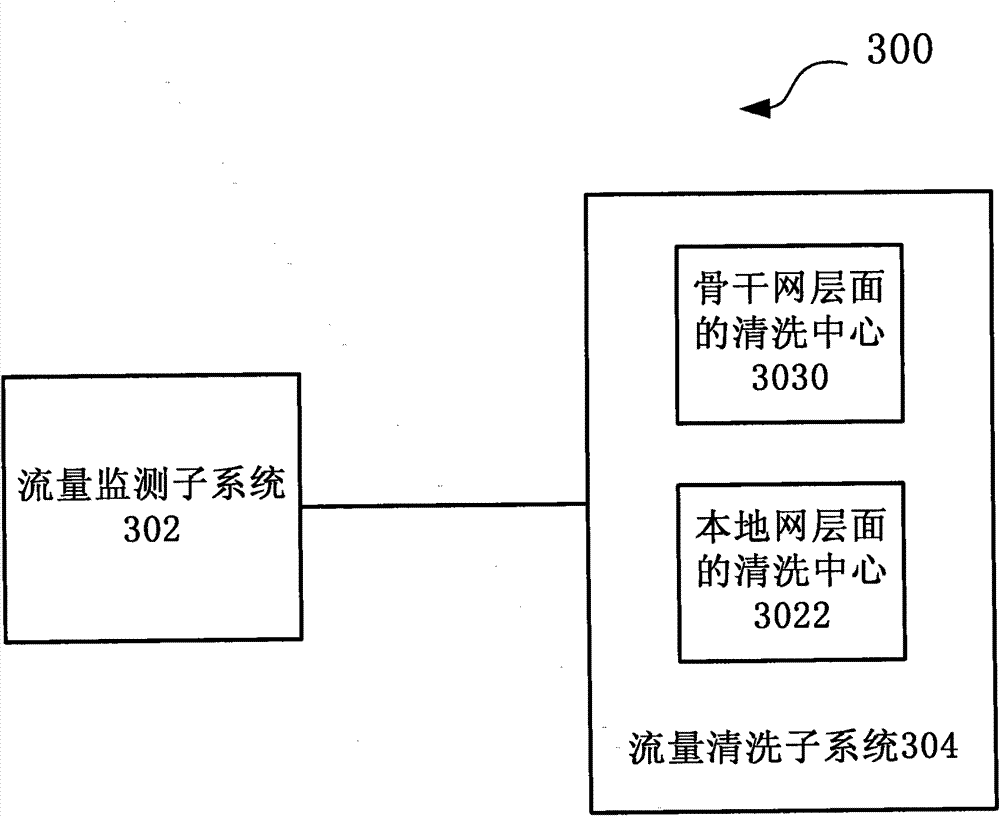

Large-scale DDoS (Distributed Denial of Service) attack defense system and method based on two-level linkage mechanism

ActiveCN101924764BSolve the accuracy problemLower deployment costsTransmissionAlarm messageDdos defense

The invention discloses large-scale DDoS (Distributed Denial of Service) attack defense system and method based on a two-level linkage mechanism. The method comprises the following steps of: monitoring the flow of a total network by a flow monitoring subsystem in real time, and searching and confirming a DDoS attack behavior; sending an alarm message for triggering a cleaning operation to a flow cleaning subsystem, and guiding the abnormal flow of the DDoS attach behavior to the flow cleaning subsystem; receiving the abnormal flow guided by the flow monitoring subsystem by the flow cleaning subsystem, cleaning the abnormal flow according to the cleaning operation triggered by the alarm message, (wherein the flow cleaning subsystem adopts the two-level architecture of a backbone network plus a local network defense system, and the two levels of cleaning system work cooperatively and clean synchronously), and injecting the cleaned cleaning flow back to a target customer network. The large-scale DDoS attack defense system and method based on the two-level linkage mechanism solve the problems of cleaning capacity, cleaning precision, and the like existing in the traditional DDoS defense technology; and on the basis of reducing the deployment cost of service scale, the large-scale DDoS attach defense capability of the total network is greatly improved, and the cleaning precision ofthe attack flow is increased.

Owner:CHINA TELECOM CORP LTD

Water power generation pipeline water filtering device

InactiveCN109289271AComprehensive cleaningGuaranteed cleanlinessStationary filtering element filtersWater filterDifferential pressure

The invention discloses a water power generation pipeline water filtering device, which comprises a filter tank. One end of the filter tank is connected with an inlet pipe, and a coarse filter net anda fine filter net are arranged inside the filter tank. A waterproof bearing seat is arranged at the center of both the coarse filter net and the fine filter net. A control line is fixed at the top ofthe filter tank. The control line is equipped with a differential pressure switch. Three blow-off pipes are arranged at the bottom of the filter tank. A Y-160M 2-2 motor is fixed at the other end ofthe filter tank. An output end of the Y-160M 2-2 motor is connected with a rotating spindle, one end of which penetrates through the two waterproof bearing seats. Four triangular stirring rods are fixed at one end of the rotating spindle. According to the invention, a protective cover wraps the rotating spindle and a grinding head, and residues generated by processed metal tableware are collectedby the protective cover. The splash of the residues is also avoided, the use safety of workers is ensured, and the polishing device is cleaner.

Owner:合肥先杰新能源科技有限公司

Method for cleaning insulating oil sample bottle and utilized cleaning device

The invention relates to a method for cleaning an insulating oil sample bottle and a utilized cleaning device. The insulating oil sample bottle cleaning method comprises the steps of (1) ultrasonic decontamination: before work, preheating water to a suitable temperature firstly, adding laundry powder, placing an oil sample bottle in a cleaning basket which is then placed in a cleaning tank, rotating the cleaning basket to enable the oil sample bottle to be filled with a cleaning solution, and starting a decontamination ultrasonic generator for the decontamination; and (2) ultrasonic rinse: opening a blowdown valve after the decontamination cleaning is finished, cleaning the cleaning tank appropriately after the cleaning solution is discharged completely, closing the valve, opening a water inlet valve, opening the ultrasonic generator, heating the water to a suitable temperature, placing the oil sample bottle into the water for rinse, and after the oil sample bottle is rinsed cleanly, taking the bottle out of a vessel and performing draining separation. The method for cleaning the insulating oil sample bottle and the utilized cleaning device have the advantages as follows: (1) the cleaning speed is high, the cleaning effect is good, the cleanliness is high, and the damage to the surface of a workpiece is prevented; (2) hands of a worker are not contacted with the cleaning solution, and deep holes, thin seams and hidden positions of the workpiece can also be cleaned up safely and reliably; and (3), the cleaning precision is high, and tiny stain particles can be cleaned powerfully.

Owner:JIANGSU ELECTRIC POWER COMPANY YANGZHOU POWER +2

Ship underwater laser cleaning device

The invention relates to the field of laser cleaning equipment, in particular to an underwater laser cleaning device for ships, which is designed for cleaning ships and can directly perform laser cleaning on the bottom of ships in water, with a high degree of automation. The underwater laser cleaning device for ships includes a floating device, a lifting device and a cleaning base. Both the floating device and the lifting device are two. The upper end of the lifting device is connected to the floating device. The lower end is connected, the floating device is provided with a laser generator, and the cleaning base is provided with a laser head, and the laser generator and the laser head are connected through an optical fiber. The floating device floats directly on the water surface, and the cleaning base is suspended in the water through the lifting device, which can directly perform laser cleaning on the bottom of the ship.

Owner:JINAN SENFENG TECH CO LTD

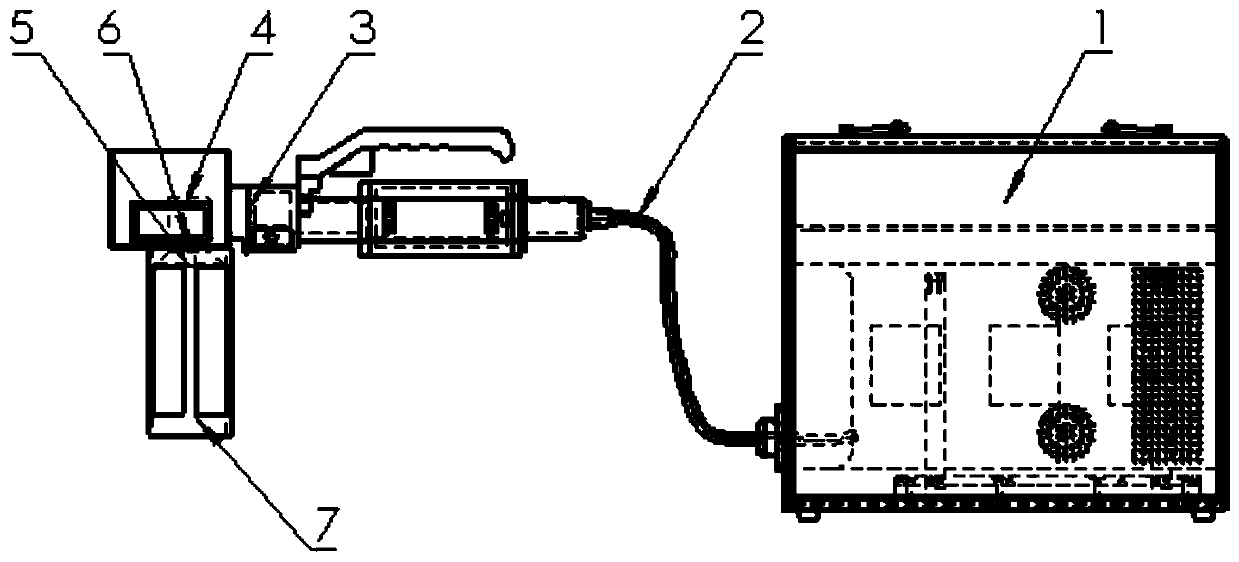

Handheld type laser cleaning machine and contaminant removing method

PendingCN110125097AAvoid secondary pollutionImprove cleaning accuracyCleaning processes and apparatusTime efficientHand held

The invention belongs to the technical field of steel rust removing devices and discloses a handheld type laser cleaning machine and a contaminant removing method. Laser parameters are adjusted, the energy density of plasmas is controlled to be higher than a first threshold value and lower than a second threshold value, and a contaminated layer or an oxide layer is removed; a second threshold value about the plasmas exists; according to the surface contamination degree of the contaminated layer, the number of times of pulse is selected to clean the surface of the contaminated layer. The handheld type laser cleaning machine is free of grinding, adopts noncontact type cleaning and avoids secondary pollution; the handheld type laser cleaning machine is high in cleaning precision, high in controllability, free of consumables and high in environmental protection performance; due to the handheld type, operation and control are easy, and the handheld type laser cleaning machine can operate just by being electrified; the handheld type laser cleaning machine is high in cleaning efficiency, saves time, stable in system and long in service life; the handheld type laser cleaning machine does not influence the steel, and even surface characters, bolts and other corners can be cleaned up; by means of switching through a functional button on a laser generator, the handheld type laser cleaningmachine can be converted to achieve the function of cutting thin plates.

Owner:HUANGSHI BOKONG AUTOMATION TECH CO LTD

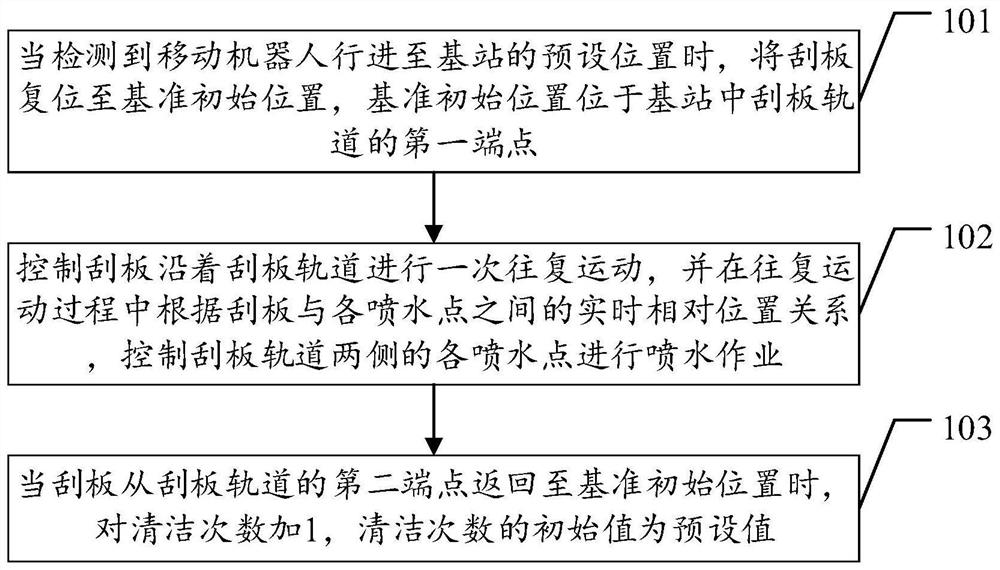

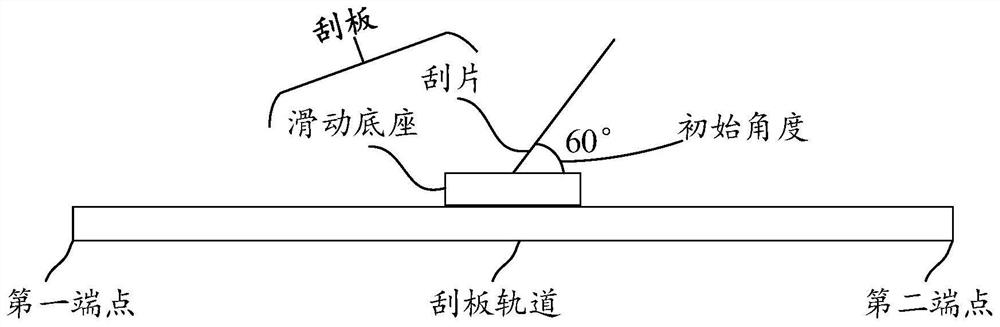

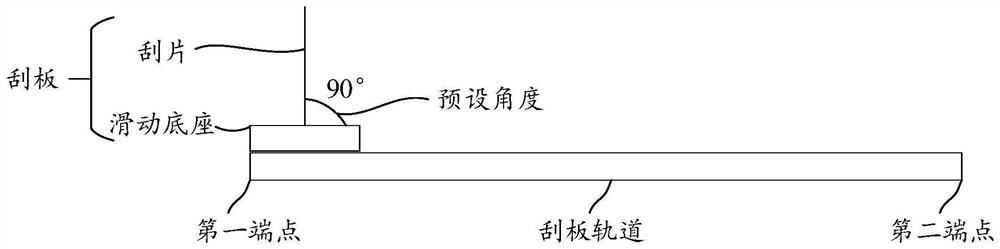

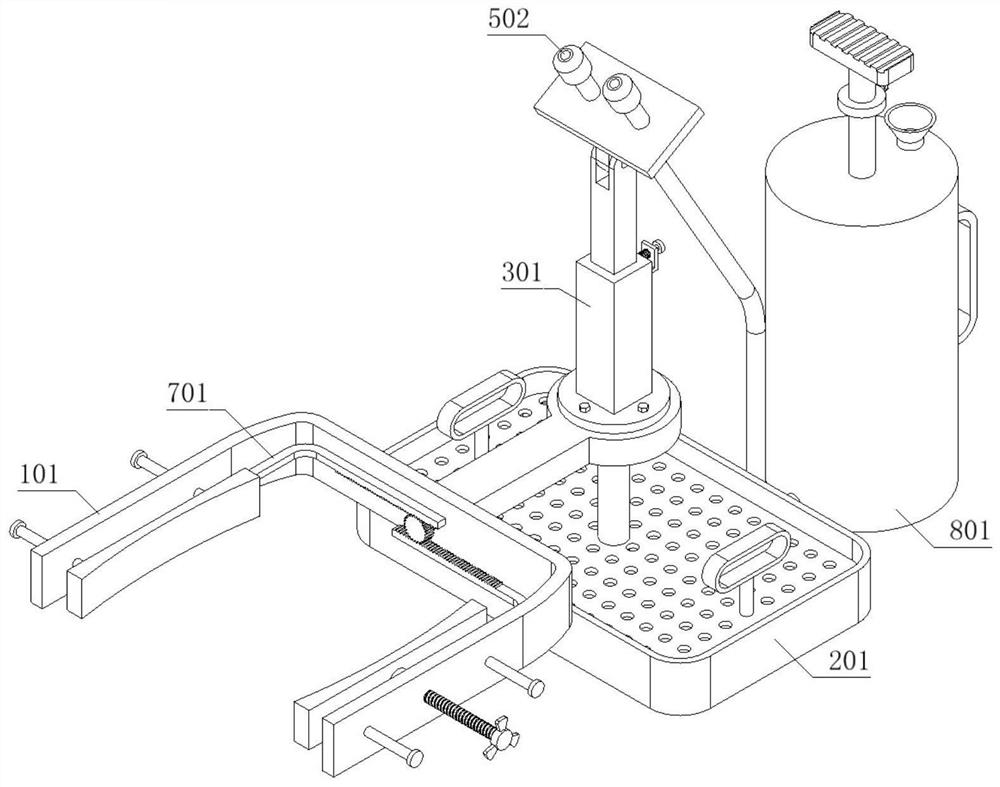

Cleaning control method, device and system and storage medium

ActiveCN112971646AImprove cleaning accuracyReduce wasteCarpet cleanersFloor cleanersMobile robotReciprocating motion

The invention relates to the technical field of smart home, and discloses a cleaning control method, device and system and a storage medium, which are used for controlling each water spraying point to perform water spraying operation according to a real-time relative position relationship between a scraper blade and each water spraying point, improving the cleaning accuracy and reducing the waste of water resources. The cleaning control method comprises the steps that when it is detected that a mobile robot advances to a preset position of a base station, the scraper blade is reset to a reference initial position, and the reference initial position is located at a first end point of a scraper blade track in the base station; the scraper blade is controlled to reciprocate once along the scraper blade track, and the water spraying points on the two sides of the scraper blade track are controlled to spray water according to the real-time relative position relation between the scraper blade and the water spraying points in the reciprocating process; and when the scraper blade returns to the reference initial position from the second end point of the scraper track, 1 is added to the cleaning times, and the initial value of the cleaning times is a preset value.

Owner:SHENZHEN SILVER STAR INTELLIGENT TECH CO LTD

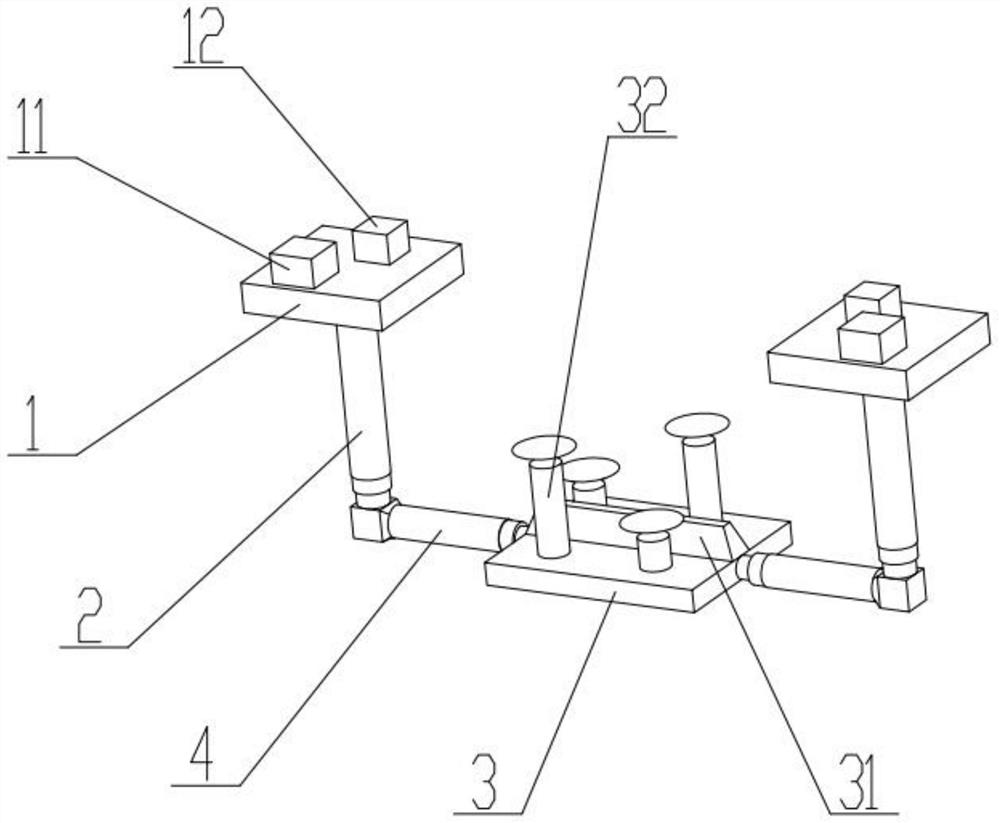

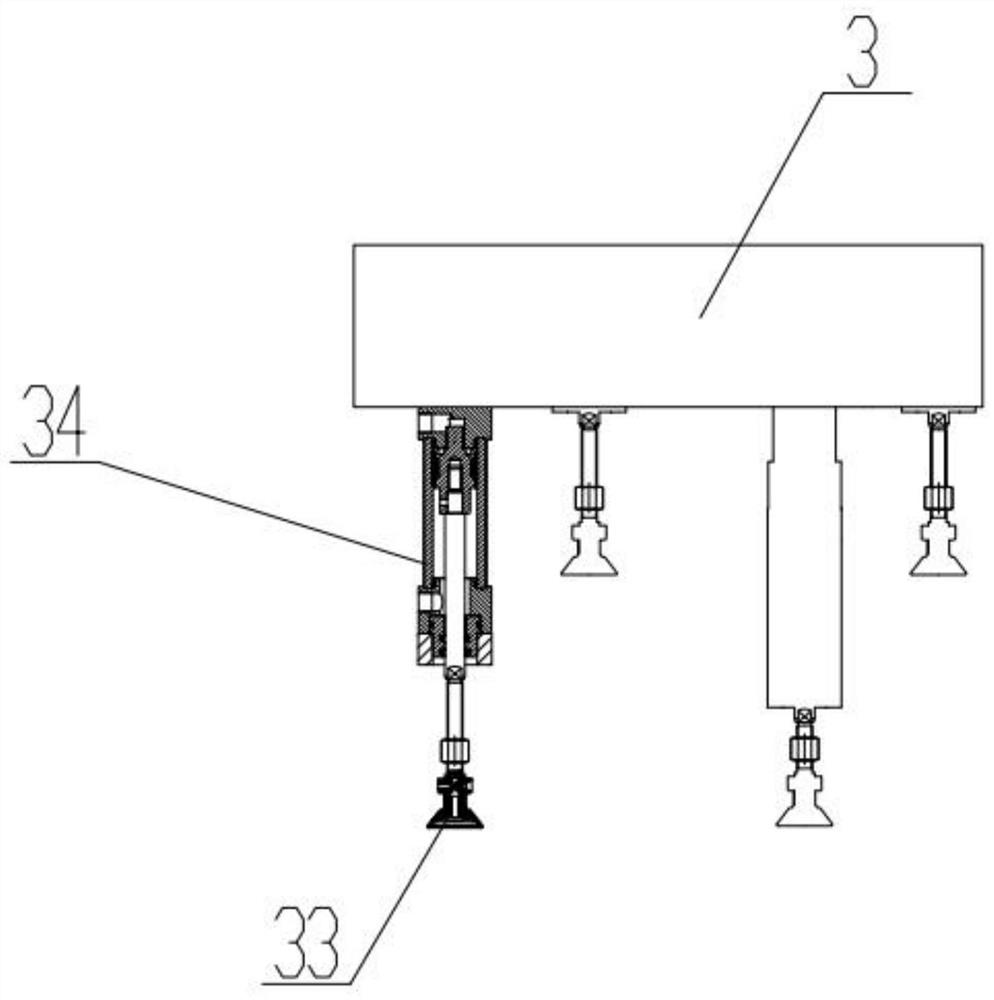

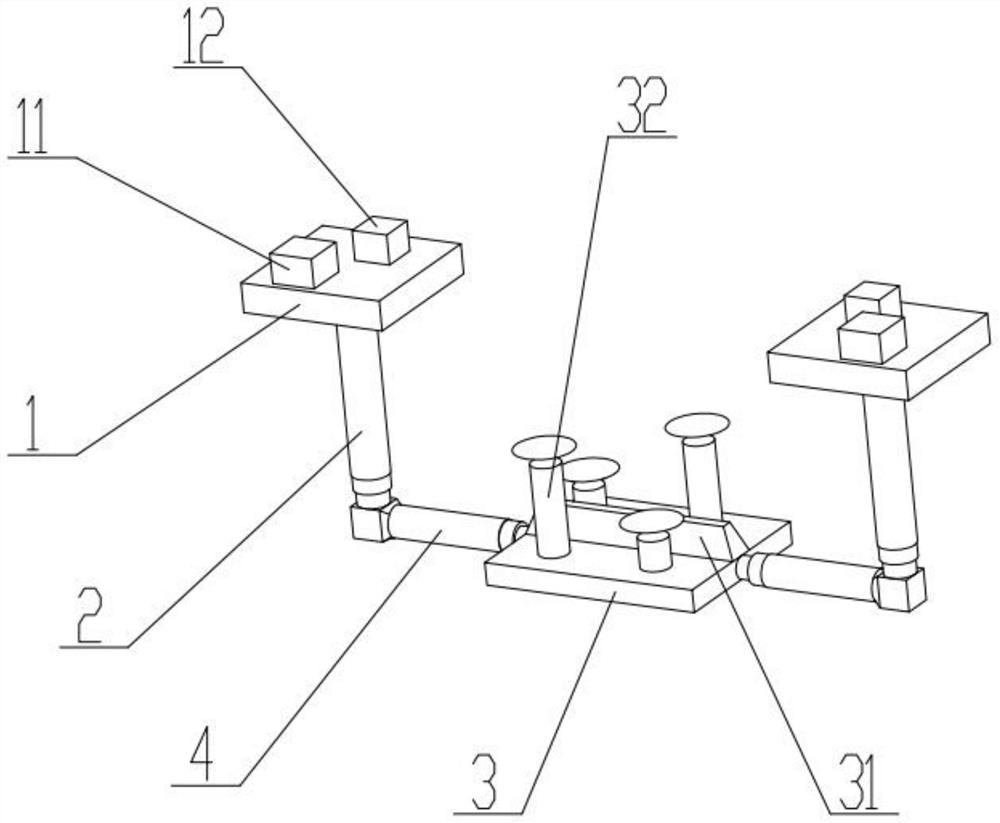

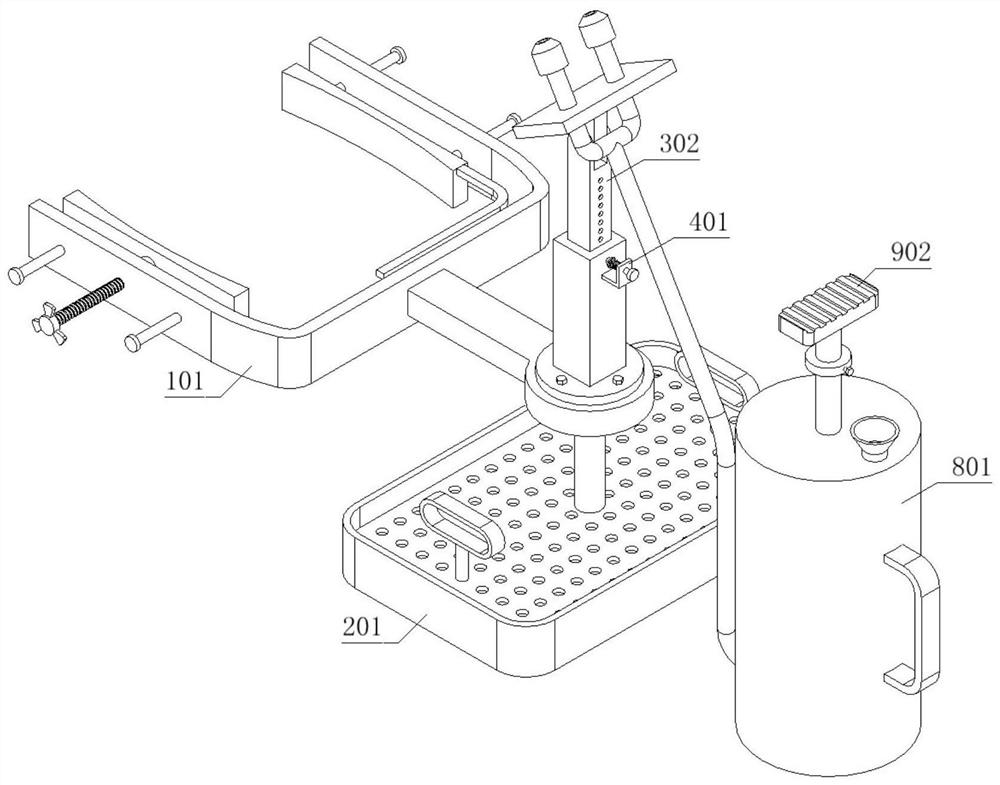

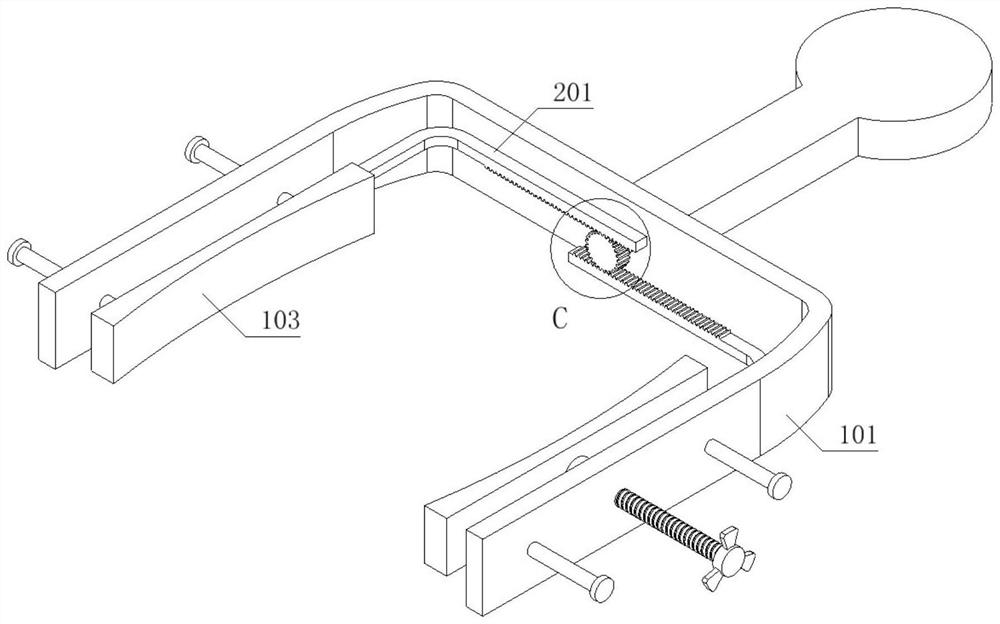

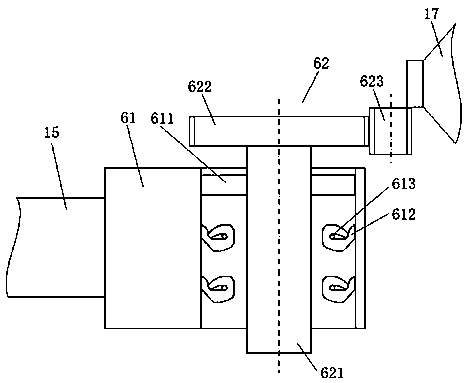

Portable nasal irrigator and sprayer fixing device thereof

ActiveCN114145984AAccurately control the amount of liquidEasy to fixEnemata/irrigatorsMedical devicesApparatus instrumentsElectrical and Electronics engineering

The invention provides a portable nasal irrigator and a nozzle fixator thereof, and relates to the technical field of medical instruments. A collecting device is mounted at the bottom of the mounting assembly, a connecting device is mounted on the mounting assembly, an adjusting mechanism is mounted at the top of the mounting assembly, and a limiting device is mounted on the adjusting mechanism; the cleaning assembly is mounted at the top of the adjusting mechanism, and a fixing device is mounted on the adjusting mechanism; the storage device is arranged on the right side of the mounting assembly, and a pressurizing assembly is mounted in the storage device; waste generated during cleaning can be automatically collected, meanwhile, impurities and waste liquid in the waste can be automatically separated, and medical staff can conveniently and accurately control the liquid outlet amount of the two spray heads; the problems that waste generated in the cleaning process cannot be automatically collected, and it is inconvenient for medical staff to accurately control the liquid outlet amount of a spray head are solved.

Owner:JIANGSU AIAIJIA HEALTH TECH CO LTD

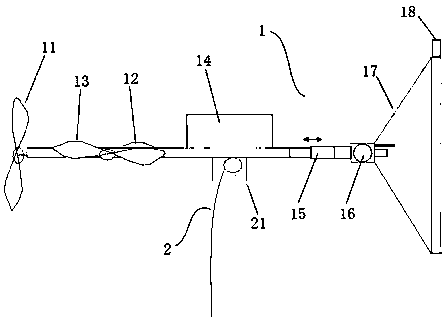

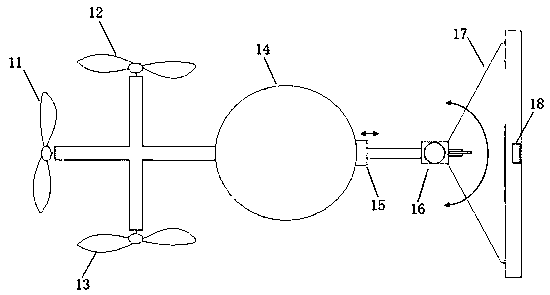

Glass cleaning robot and cleaning method

PendingCN111374587ALong blanking timeReduce weightAircraft componentsAutomatic obstacle detectionControl signalUncrewed vehicle

The invention discloses a glass cleaning robot and a cleaning method and belongs to the field of unmanned aerial vehicle control. The cleaning robot comprises an unmanned aerial vehicle, a mooring rope and a ground trolley; the unmanned aerial vehicle comprises a cleaning reaction force adjusting device, a telescopic long rod device, a steering device and the like; the telescopic long rod device comprises a telescopic adjustable long rod and is used for driving the cleaning device to move back and forth along with the telescopic adjustment of the long rod; the steering device comprises a fixing base and a rotating body and is used for driving the cleaning device to rotate leftwards and rightwards along with rotating adjustment of the rotating body; the cleaning reaction force adjusting device is connected with the other end of the telescopic long rod device and used for generating a pair of reaction forces acting on the unmanned aerial vehicle when the cleaning device sprays liquid; the mooring rope is used for conveying power supply power of the unmanned aerial vehicle, transmitting a control signal and conveying cleaning water and cleaning liquid for cleaning; the ground trolleyis used for generating the control signal and storing the cleaning liquid. The glass cleaning robot of the invention has the advantages of low power and wide application range.

Owner:BEIJING HUALANDE TECH CONSULTING SERVICE CO LTD

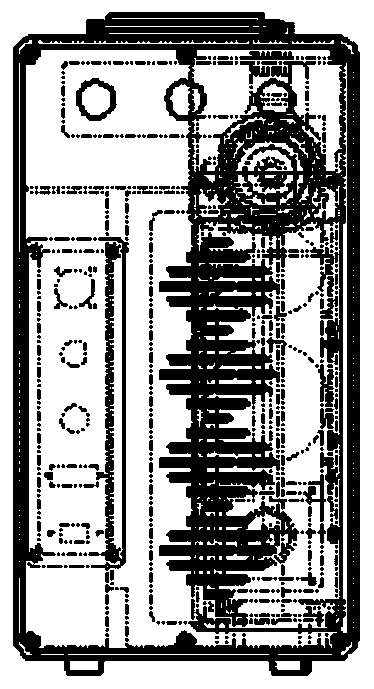

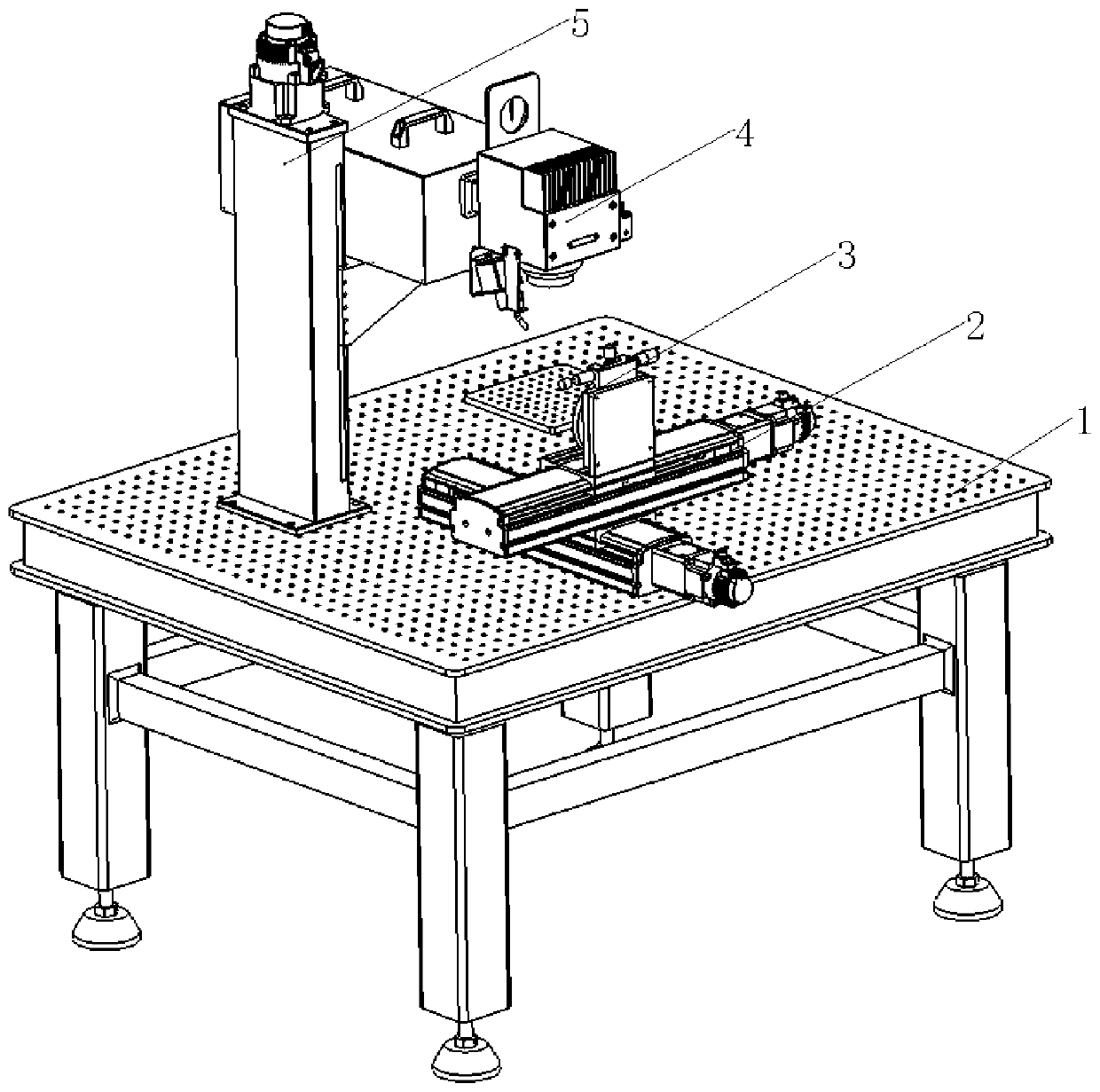

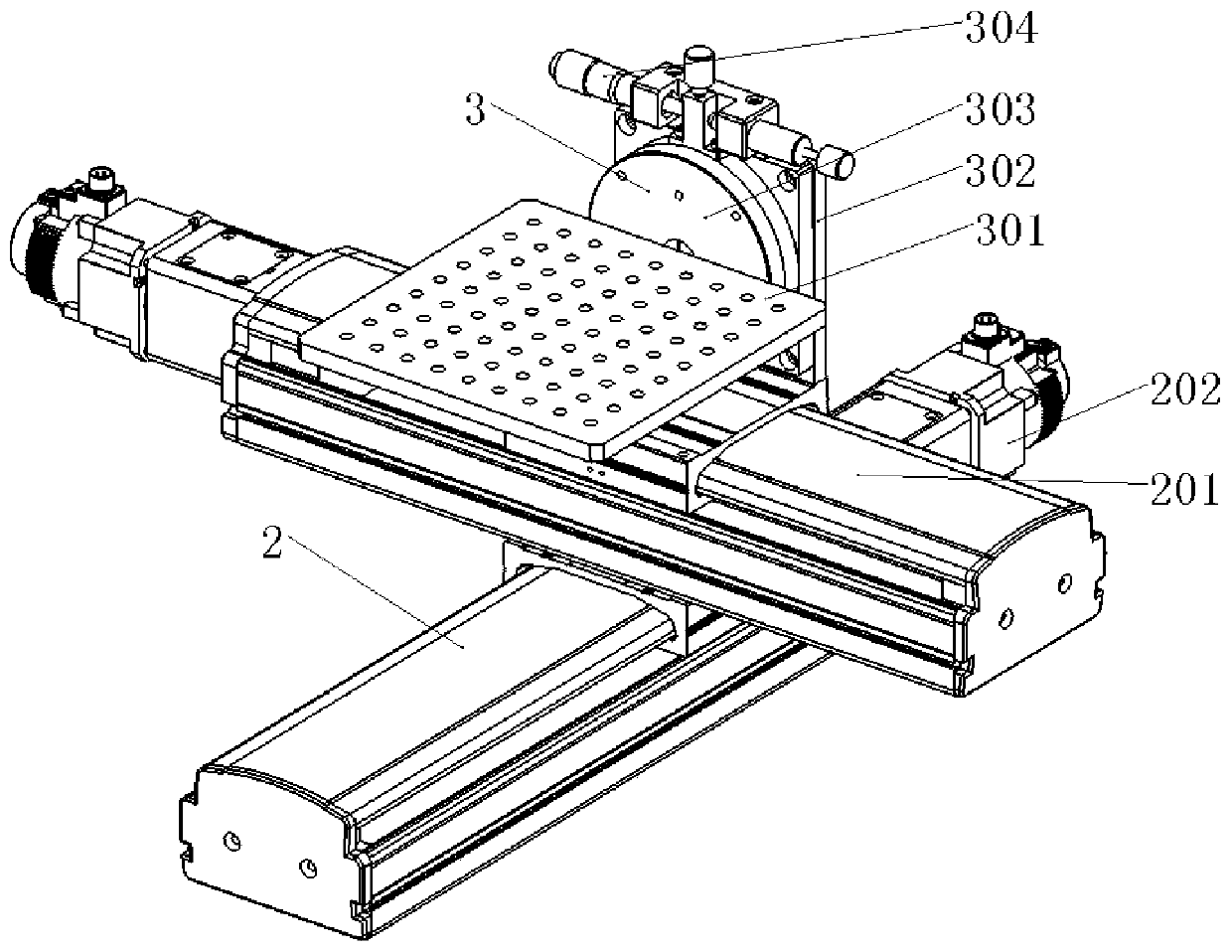

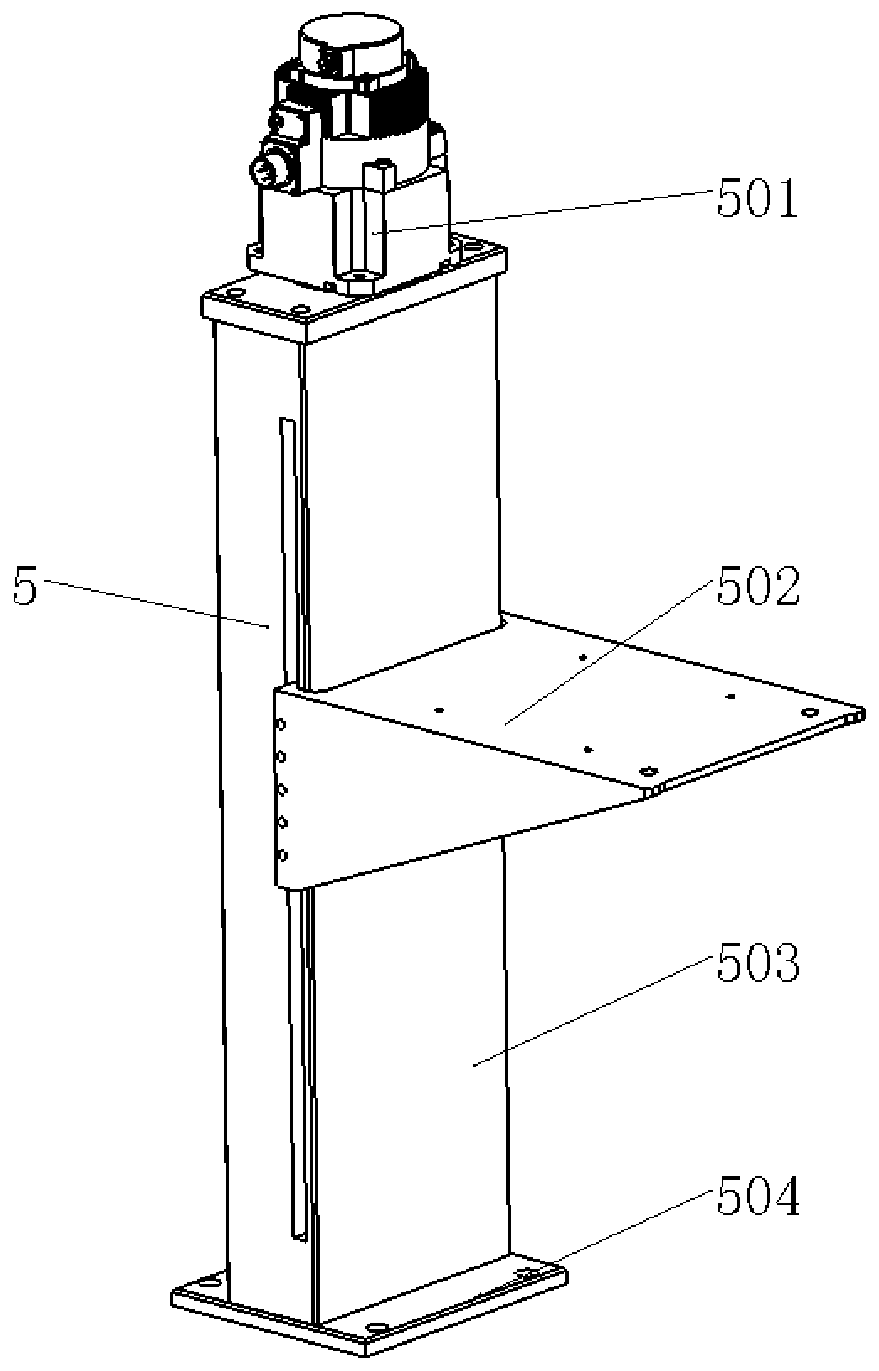

A desktop laser precision cleaning device with dual-wavelength composite energy distribution

InactiveCN107297365BWash thoroughlyDamage reduction propertiesCleaning processes and apparatusLaser beam welding apparatusLaser rangingGalvanometer

The invention provides a bench-type laser precision washing device with dual-wavelength composite energy distribution, comprising a workbench, an X-Y electric module, a turntable component, a laser washing component, and a Z-directional lifting bench; the X-Y electric module is fixedly mounted on the workbench, the turntable component is mounted on the X-Y electric module, the Z-directional lifting bench is mounted on the workbench, and the laser washing component is mounted on a lifting plate of the Z-directional lifting bench; the laser washing component includes a laser, a transmission fiber, a blow nozzle, a laser ranging sensor, a galvanometer scanning system and a dual-wavelength composite reshaping system; a laser beam emitted by the laser is transmitted by the transmission fiber and enters the dual-wavelength composite reshaping system; the dual-wavelength composite reshaping system outputs a dual-wavelength composite reshaped beam that passes through the galvanometer scanning system and is focused on the surface of material. The bench-type laser precision washing device has the advantages that washing uniformity and fineness are improved, damage to material matrix is effectively decreased via circular spacing, and washing quality is greatly improved.

Owner:山东微壹信息技术有限公司

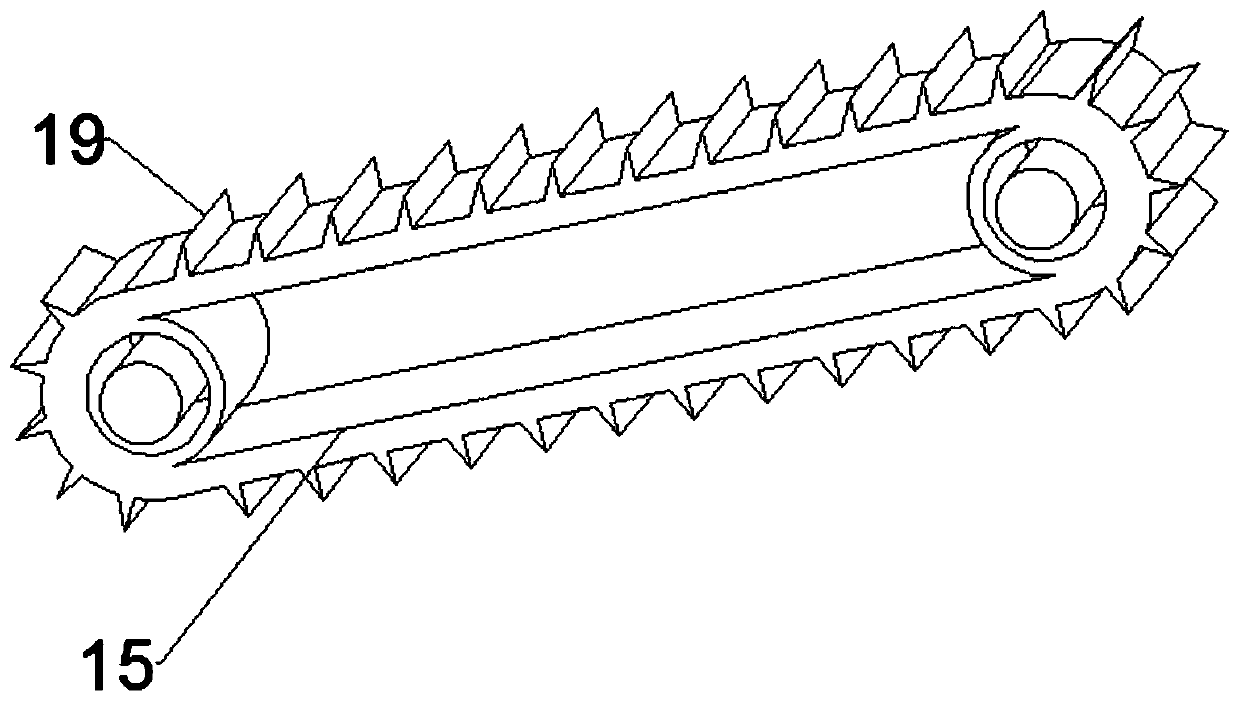

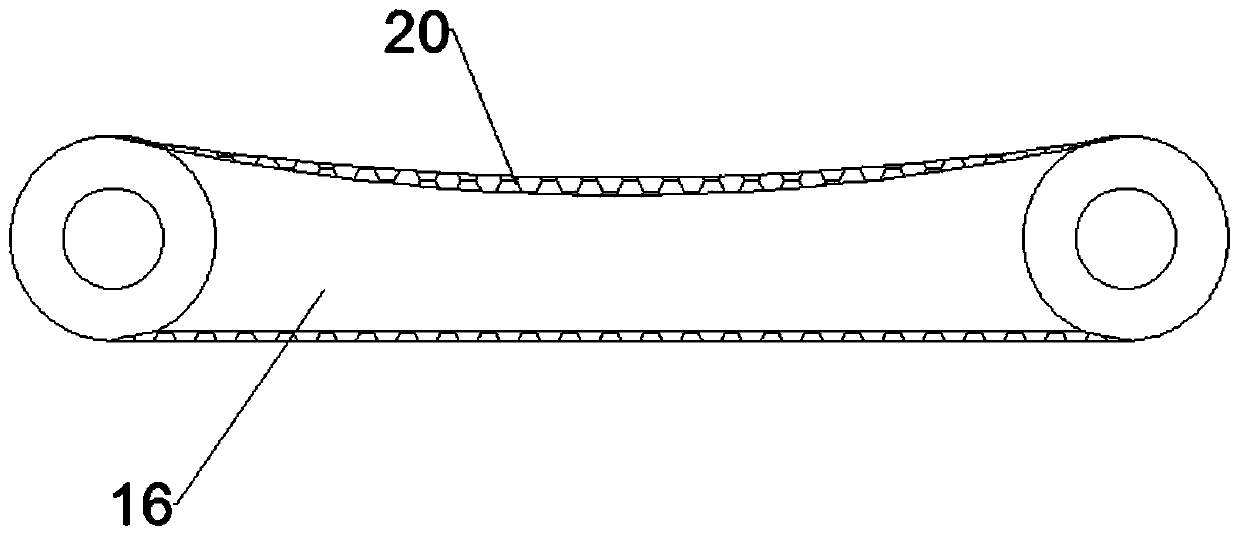

Potato washing device

The present invention relates to the technical field of modern agricultural machinery industry and discloses a potato washing device. The potato washing device comprises a box body, a material inlet,a material outlet, a power box, a water tank and a water conveying pipe; a left side of an inside of the box body is provided with a transverse mud removing cylinder, a right side of the mud removingcylinder is provided with a flushing pipeline, a bottom end of the material inlet communicates with a material conveying pipeline, a rear end of the material conveying pipeline communicates with a center of a left side of the mud removing cylinder, a group of rotary cylinders which are coaxial with the mud removing cylinder are arranged in the mud removing cylinder, a right end part of the mud removing cylinder communicates with the flushing pipeline downwards, two groups of water spray heads are arranged in the front end, middle end and rear end of the flushing pipeline, outer ends of the water spray heads communicate with a booster pump, and the booster pump communicates with a water tank fixed on an upper surface of the flushing pipeline through a water conveying pipe; and a second conveying belt is arranged right below the rear end of the flushing pipeline. Advantages are as follows: the potato washing device is high in washing precision, conducts continuous transportation and washing, and is suitable for large-scale potato washing and use.

Owner:陆璨

Distributed service attack refusing defense method, apparatus and system

The invention embodiment discloses a defense method, a device and a system for the DDos attack, which relate to the network technology and aim to solve the problem of low cleaning accuracy caused by the cleaning of the unidirectional data flow obtained by the network cleaning device found in the prior art. The defense method of the DDos attack in the invention embodiment includes that the data flow in the network is acquired and detected to obtain the attack information; the upstream data flow in the network is acquired and filtered to obtain the upstream data information of the protected host; the downstream data flow with the target of the protected host is processed with conduction, supplement and cleaning according to the attack information and the upstream data flow from the protected host. The invention embodiment also provides a measurement-control device, a cleaning device and a defense system for the DDos attack. The defense method, the device and the system for the DDos attack are applicable to the detection and defense of the DDos attack in the network technology.

Owner:CHENGDU HUAWEI TECH

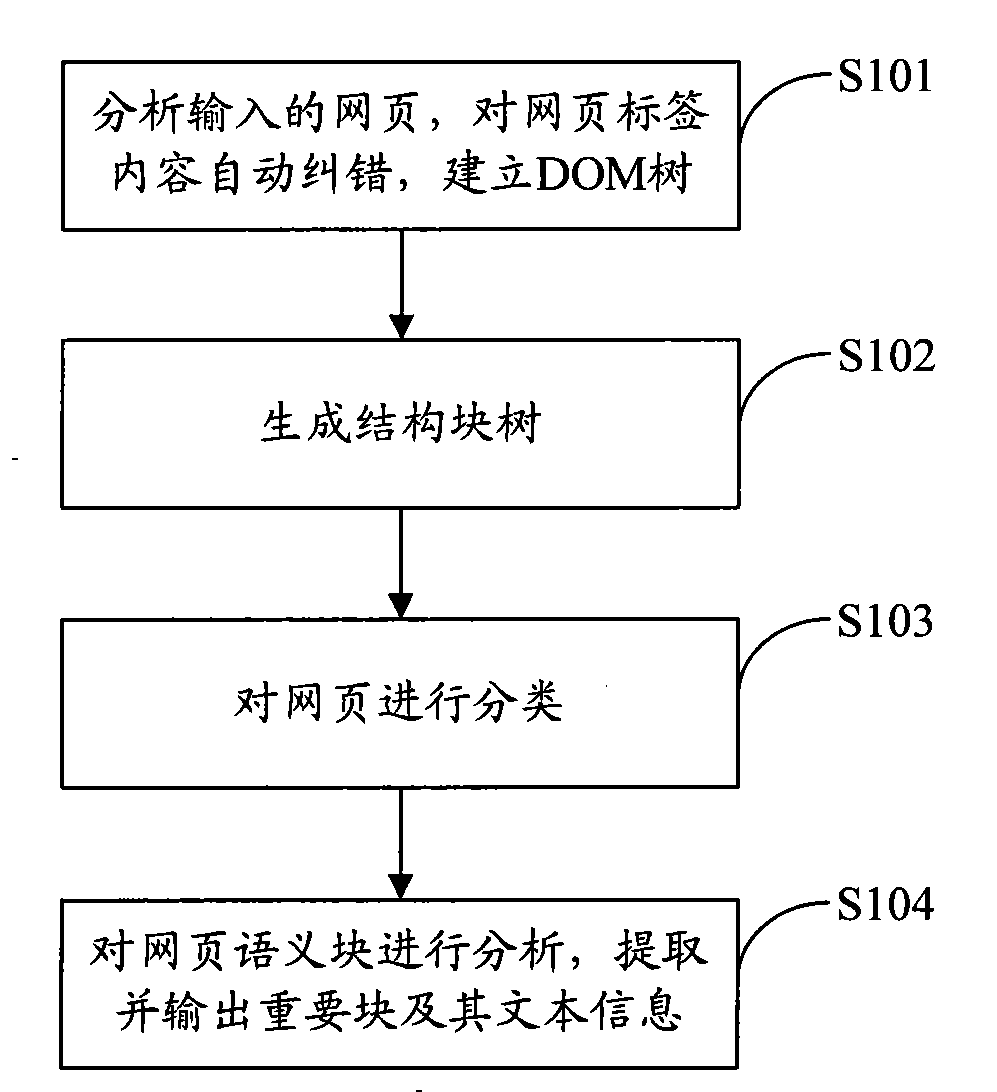

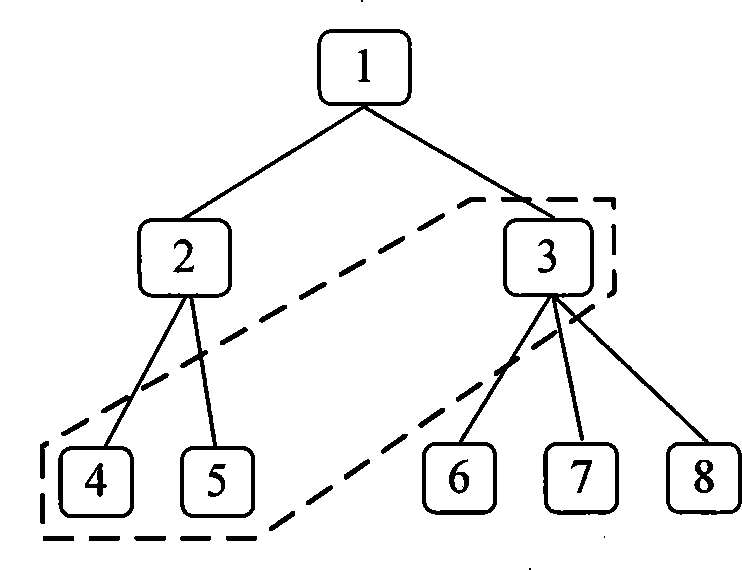

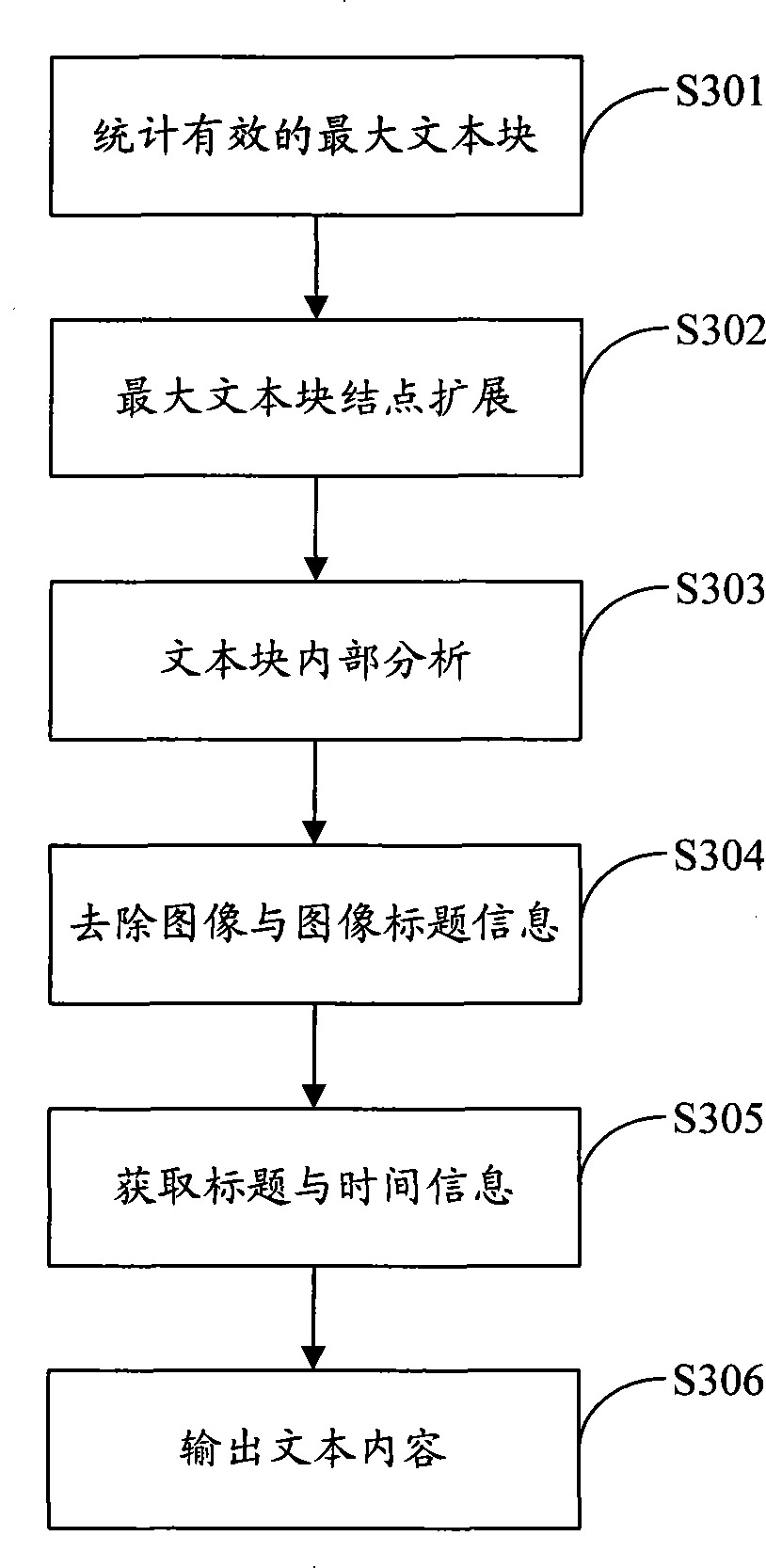

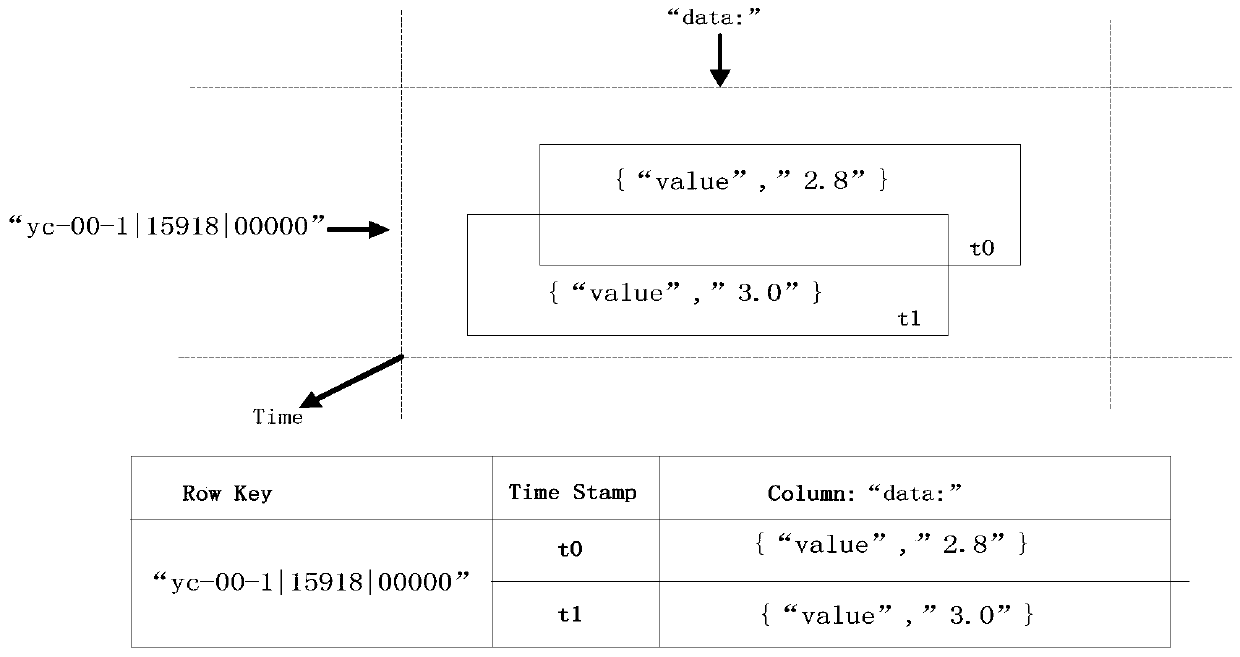

Equipment, system and method for cleaning internet web page

ActiveCN101251855BEfficient extractionAchieve cleaningSpecial data processing applicationsInformation processingEngineering

Owner:SHENZHEN TENCENT COMP SYST CO LTD

A method and system for cleaning mass data of an energy storage power station

ActiveCN104750861BAchieve cleaningAchieving processing powerData processing applicationsEnergy efficient computingPower stationData set

The present invention provides a method and system for cleaning mass data of an energy storage power station, the method comprising the following steps: I, locating and replacing the default value in the data set of the energy storage power station; II, locating and replacing the abnormal value in the data set; III. According to the characteristics of different categories of the energy storage battery data, determine unreasonable data in the data set obtained after replacement, and replace them. The method and system of the present invention can not only realize the cleaning of massive battery data, but also ensure the distributed processing requirements of massive data, and realize the optimal cleaning of massive battery data of energy storage power stations with comprehensive consideration of K-nearest neighbor algorithm, Raida criterion method, distributed processing, etc. The purpose of preprocessing is to improve the effect of preprocessing and utilization of massive data of large-capacity battery energy storage power stations.

Owner:CHINA ELECTRIC POWER RES INST +4

A handheld self-adaptive laser cleaning device with self-converting dual-wavelength laser beams

ActiveCN107321717BDamage reduction propertiesClean up thoroughlyCleaning processes and apparatusLaser rangingGalvanometer

The invention provides a hand-held adaptive laser cleaning device capable of self-changing double-wavelength laser beams. The hand-held adaptive laser cleaning device comprises a laser, a transmission fiber, a lifting focusing assembly, a laser ranging sensor, a galvanometer scanning system, a lifting guide electric driving assembly and a double-wavelength laser beam composite system. The galvanometer scanning system is used for focusing the incident laser beams on the surface of a workpiece, and enabling the laser beams to make scanning movement on the surface of the workpiece according to the set track. The lifting focusing assembly is arranged below the laser beam emitting end of the galvanometer scanning system. The input end of the double-wavelength laser beam composite system and the laser are connected through the transmission fiber, the double-wavelength laser beams are output after internal optical transformation, and the output end of the double-wavelength laser beam composite system is fixedly connected with the laser beam incident end of the galvanometer scanning system. According to the hand-held adaptive laser cleaning device, the two laser beams with the different wavelengths act on the surface of the material simultaneously so that composite pollutants of various components can be completely removed simultaneously, and the cleaning quality is greatly improved.

Owner:山东承坤信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com