Method for cleaning insulating oil sample bottle and utilized cleaning device

A technology for cleaning equipment and oil sample bottles, which is applied to cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. Consistent, high cleaning accuracy, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

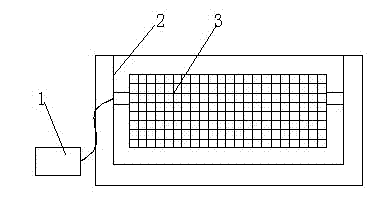

[0023] The present invention carries out according to the following steps:

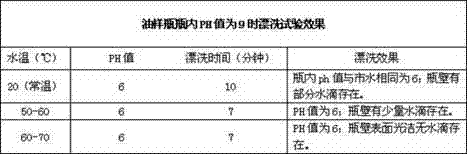

[0024] 1) Inject water into the cleaning tank 2 of the ultrasonic cleaning equipment, the temperature of the injected water is 18-22 degrees Celsius, and the pH value is 5.8-6.2;

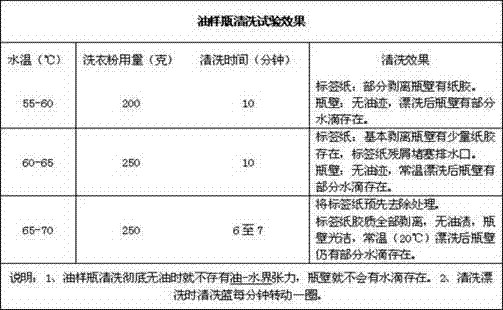

[0025] 2) Heat the water to 55-70 degrees Celsius, and the pH value is 6.8-7.2;

[0026] 3) Add washing powder into the cleaning tank 2 to make the pH value 9.8-10.2;

[0027] 4) Put the oil sample bottle to be cleaned into the cleaning basket 3 and place it in the cleaning tank 2, with the mouth of the bottle facing up at the beginning, Cleaning fluid Inject to expel the air in the bottle;

[0028] 5) Turn on the ultrasonic wave to clean the oil sample bottle for 6-10 minutes;

[0029] 6) Open the drain valve, discharge the cleaning liquid, and inject water to clean the cleaning tank 2 and the cleaning basket 3;

[0030] 7) Inject water into the cleaning tank 2 after cleaning, the water temperature of the injected wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com