Silicon core cleaning technique

A silicon core, clean technology, applied in the direction of crystal growth, post-processing details, post-processing, etc., can solve the problems of producing a large amount of nitrogen oxides, harming operators, affecting the environment, etc., to achieve cost saving, high cleaning accuracy, and cleaning effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

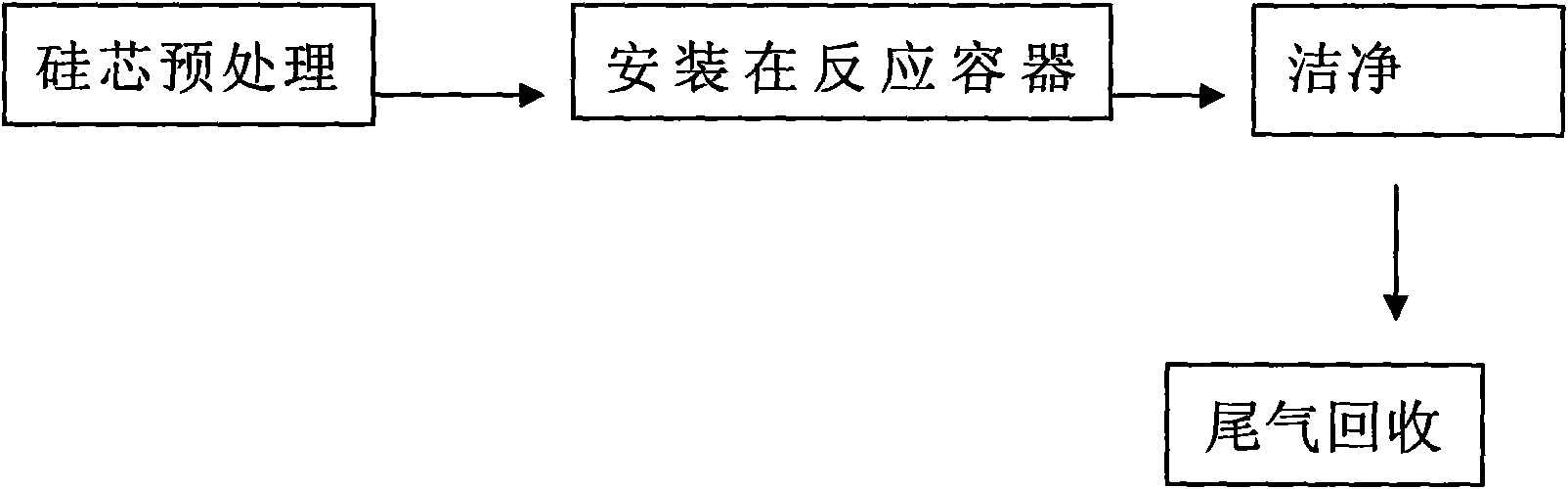

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0017] a. Silicon core pretreatment: select a silicon core with a length of 2000 mm to 2600 mm and a thickness of 8 to 12 mm. First, use a soft object to dip a small amount (preferably wet gauze) of absolute ethanol to wipe off the impurities on the surface of the silicon core. Acetone wipes off the oil on the surface of the silicon core, and then puts the silicon core in an ultrasonic cleaning device for ultrasonic cleaning and drying;

[0018] b. Cleaning: Install the silicon core graphite fixture vertically in a closed reaction vessel, and the following reaction occurs at a temperature of 300-320°C: Si+3HCl→SiHCl 3 +H 2 , while corroding the surface layer of the silicon core, remove the oxide layer and metal impurities on the surface of the silicon core;

[0019] In the above reaction process, the mixed gas of hydrogen and hydrogen chloride is passed into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com