Product coating method based on plastic or nylon products

A product, nylon technology, is applied in the coating field of plastic or nylon products, which can solve the problems of easy corrosion, large water plating pollution, and difficult water plating of ABS material, and achieve good decoration and improve cleaning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

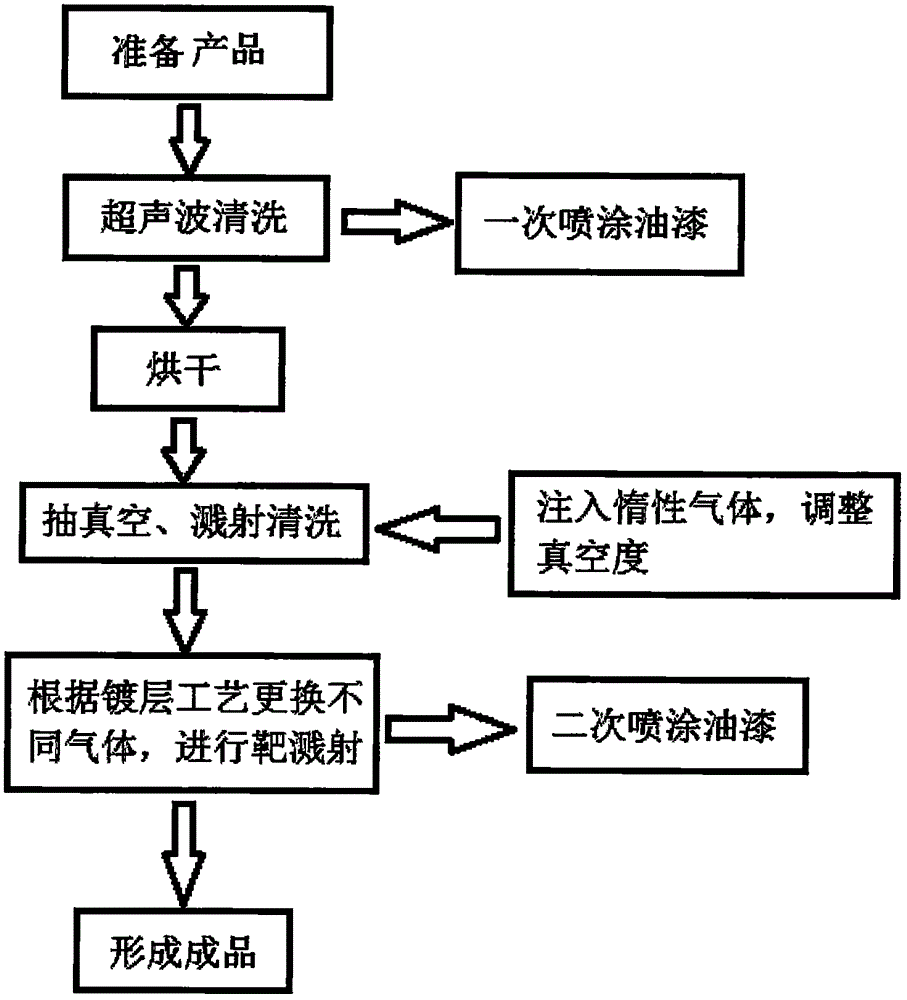

[0019] The present invention is further described below: a kind of product coating method based on plastics or nylon products, it comprises the steps:

[0020] A. Prepare the product, which is a plastic or nylon product, and perform ultrasonic degreasing cleaning, ultrasonic degreasing cleaning and ultrasonic pure water cleaning on the product respectively;

[0021] B. Dry the cleaned product and put it into the vacuum machine for coating;

[0022] C. Vacuum in the vacuum machine, and use DC magnetron sputtering or intermediate frequency magnetron sputtering or multi-arc magnetron sputtering for bombardment cleaning;

[0023] D. Change to the coating vacuum gas, and use the target material to sputter the product to form a coating.

[0024] In step A, first clean the substrate of the product to remove grease from the frame before coating. Among them, due to the irregular structure of the product, ultrasonic cleaning can effectively contact the depressions of the frame in multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com