A kind of porous titanium or titanium alloy with mixed material design optimization control drug release and preparation method thereof

An optimized control and titanium alloy technology, which is applied in the field of biomedical materials, can solve the problems of poor adhesion of osteoblasts, and achieve the effect of having binding force, facilitating cell proliferation, and enhancing osseointegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing porous titanium or titanium alloy with optimized mixed material design and controlled drug release, comprising the following steps:

[0034] Perform pulse laser processing on titanium or titanium alloy to obtain porous titanium or titanium alloy;

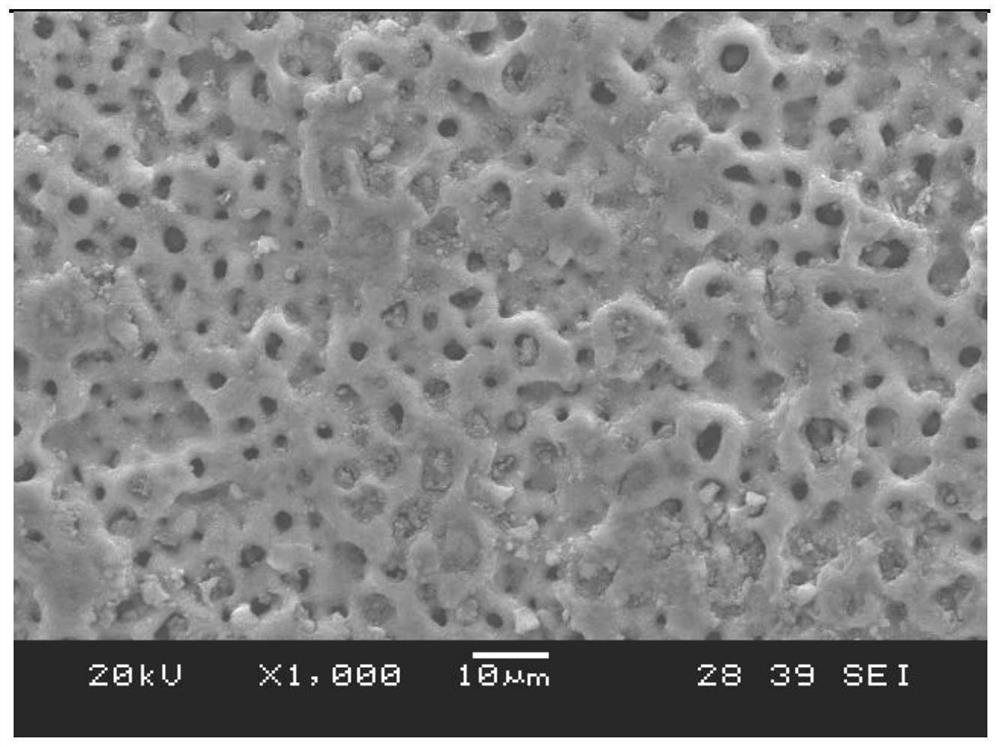

[0035] Performing micro-arc oxidation treatment on porous titanium or titanium alloy, forming a micro-arc oxidation layer on the surface of the porous titanium or titanium alloy to obtain modified porous titanium or titanium alloy;

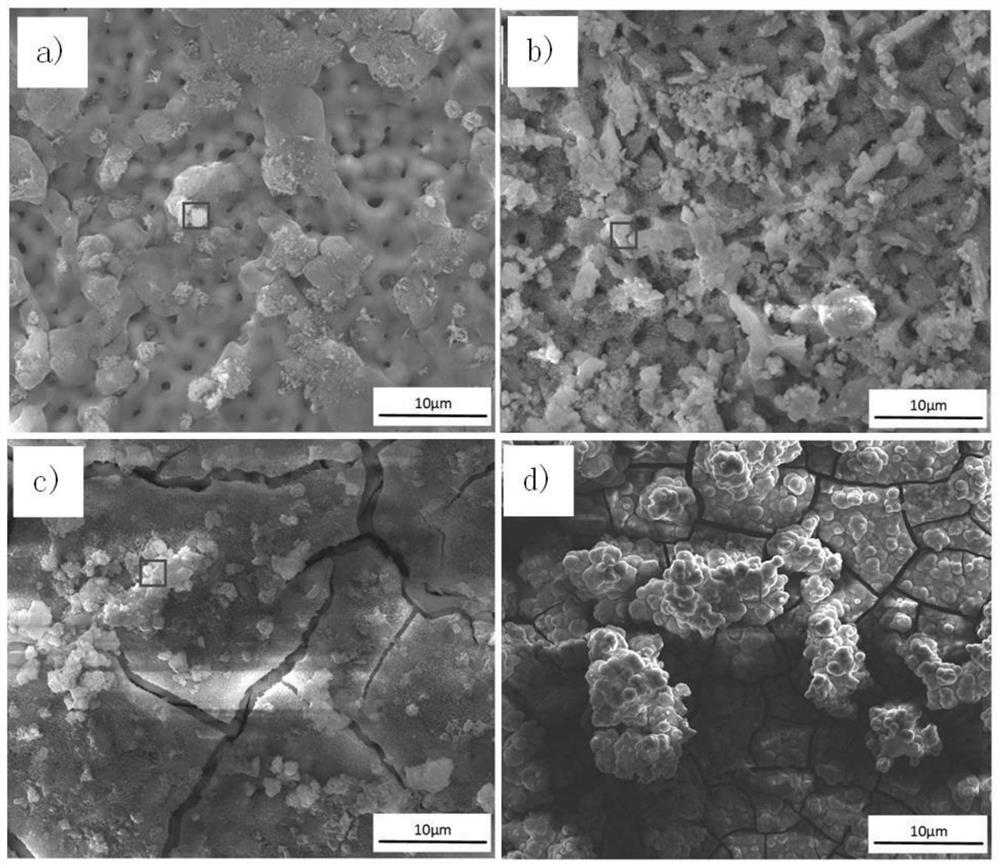

[0036] Soak the modified porous titanium or titanium alloy in the Chinese medicine slow-release solution, take it out and dry it, form a Chinese medicine slow-release layer on the surface of the modified porous titanium or titanium alloy, and obtain the porous titanium with optimized mixing design to control drug release or titanium alloy;

[0037] The traditional Chinese medicine slow-release liquid includes naringin, danshensu, berberine, polylacti...

Embodiment 1

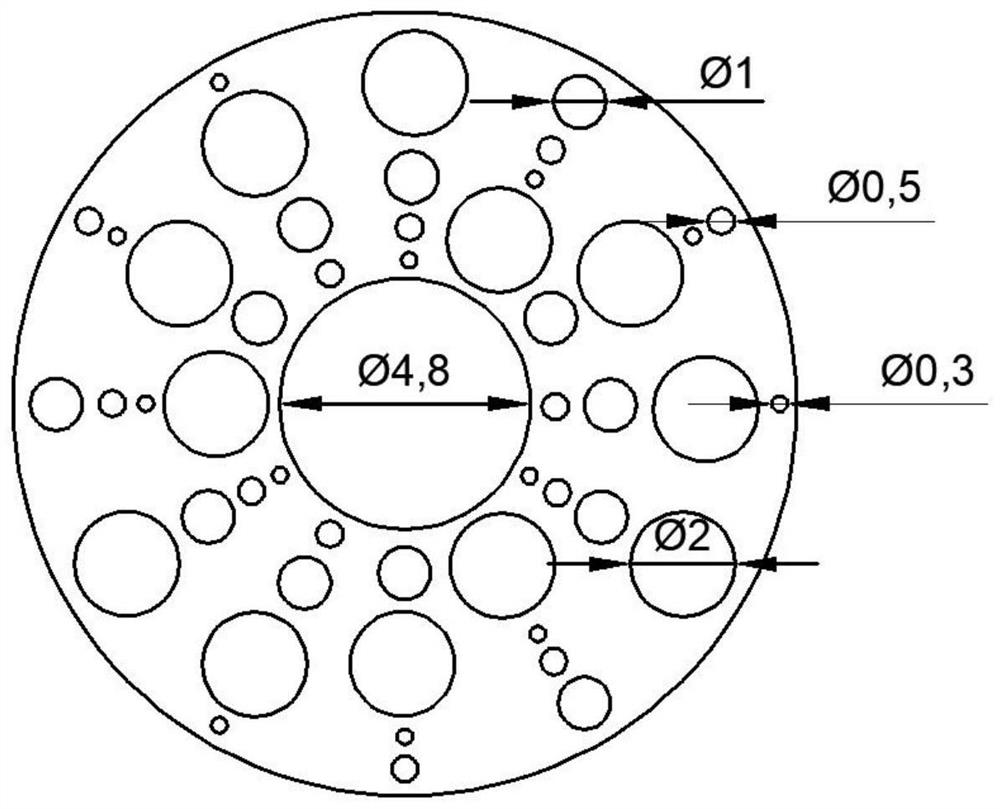

[0073] According to the structural parameters of the rabbit’s mandible, the aperture data of porous titanium or titanium alloy is designed (the porosity is 80%, and the apertures are 500 μm and 1000 μm respectively), and the geometric model and processing trajectory of porous titanium or titanium alloy are established according to the finite element software, and pulsed Laser processing to obtain porous titanium or titanium alloy; wherein, the working parameters of the pulse laser processing include: a solid-state laser with a wavelength of 900nm, a laser spot The output energy is 10J, the output power is 60W, the output voltage is 800V, the pulse width is 1ms, the frequency is 10Hz, and the water temperature is 25°C.

[0074] Perform micro-arc oxidation treatment on porous titanium or titanium alloy, form a micro-arc oxidation layer on the surface of the porous titanium or titanium alloy, and obtain modified porous titanium or titanium alloy; wherein, the working parameters o...

Embodiment 2

[0086] According to the structural parameters of natural bone, the pore diameter data of porous titanium or titanium alloy (the porosity is 65%, and the pore diameters are 500 μm, 750 μm and 1000 μm respectively), and the geometric model and processing trajectory of porous titanium or titanium alloy are established according to the finite element software. Pulse laser processing to obtain porous titanium or titanium alloy; wherein, the working parameters of the pulse laser processing include: a solid-state laser with a wavelength of 900nm, a laser spot The output energy is 10J, the output power is 60W, the output voltage is 800V, the pulse width is 1ms, the frequency is 10Hz, and the water temperature is 25°C.

[0087] Perform micro-arc oxidation treatment on porous titanium or titanium alloy, form a micro-arc oxidation layer on the surface of the porous titanium or titanium alloy, and obtain modified porous titanium or titanium alloy; wherein, the working parameters of the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com