Aluminum or aluminum alloy antibacterial material

An antibacterial material and aluminum alloy technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of high difficulty in sterilizing particles, incomplete filling, unsatisfactory actual control speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] An aluminum or aluminum alloy antibacterial material, the preparation process is as follows:

[0048] (1) Pretreatment: rough polishing - degreasing - washing - heat treatment - electropolishing:

[0049] The rough polishing is to use 600-mesh and 800-mesh water-grinding sandpaper to polish the surface of the aluminum material in sequence.

[0050] The degreasing is to use acetone solution to wash and soak.

[0051] Described thermal treatment is under inert condition, at 450 o C under high temperature treatment for 20min.

[0052] The electrolytic polishing is 50g / L phosphoric acid, 20g / L sulfuric acid, 3g / L glycerol, voltage 15V, time 2-5min, temperature 45 o c.

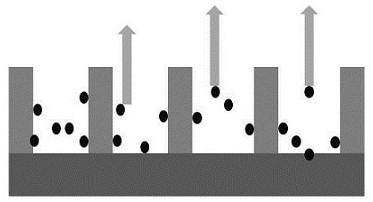

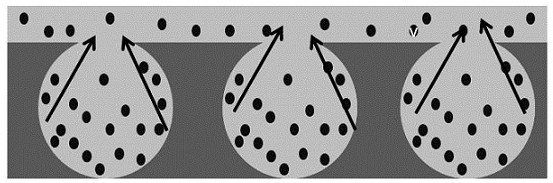

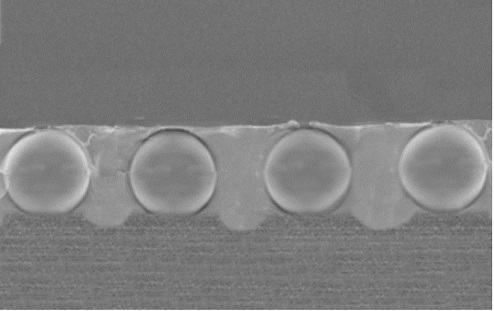

[0053] (2) Self-assemble monolayer PS pellets on the pretreated aluminum surface: Weigh 0.1g sodium dodecylsulfonate and 0.1g potassium persulfate and dissolve them in 70ml methanol and water solution, wherein the ratio of methanol is 10:2, keep the nitrogen atmosphere, magnetically stir for 30min, rais...

Embodiment 2

[0062] An aluminum or aluminum alloy antibacterial material, the preparation process is as follows:

[0063] (1) Pretreatment: rough polishing - degreasing - washing - heat treatment - electropolishing:

[0064] The rough polishing is to use 600-mesh and 800-mesh water-grinding sandpaper to polish the surface of the aluminum material in sequence.

[0065] The degreasing is to use acetone solution to wash and soak.

[0066] Described heat treatment is under inert condition, at 475 o C under high temperature treatment for 25min.

[0067] The electrolytic polishing is 50g / L phosphoric acid, 20g / L sulfuric acid, 3g / L glycerol, voltage 15V, time 3.5min, temperature 45 o c.

[0068] (2) Self-assemble monolayer PS pellets on the pretreated aluminum surface: Weigh 0.2g sodium dodecylsulfonate and 0.1g potassium persulfate and dissolve in 70ml methanol and water solution, wherein the ratio of methanol is 10:3.5, keep the nitrogen atmosphere, magnetically stir for 30min, raise the ...

Embodiment 3

[0077] An aluminum or aluminum alloy antibacterial material, the preparation process is as follows:

[0078] (1) Pretreatment: rough polishing - degreasing - washing - heat treatment - electropolishing:

[0079] The rough polishing is to use 600-mesh and 800-mesh water-grinding sandpaper to polish the surface of the aluminum material in sequence.

[0080] The degreasing is to use acetone solution to wash and soak.

[0081] Described heat treatment is under inert condition, at 500 o C under high temperature treatment for 30min.

[0082] The electrolytic polishing is 50g / L phosphoric acid, 20g / L sulfuric acid, 3g / L glycerin, voltage 15V, time 5min, temperature 45 o c.

[0083] (2) Self-assemble monolayer PS pellets on the pretreated aluminum surface: Weigh 0.3g of sodium dodecylsulfonate and 0.1g of potassium persulfate and dissolve them in 70ml of methanol and water solution, wherein the ratio of methanol is 10:5, keep the nitrogen atmosphere, magnetically stir for 30min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com