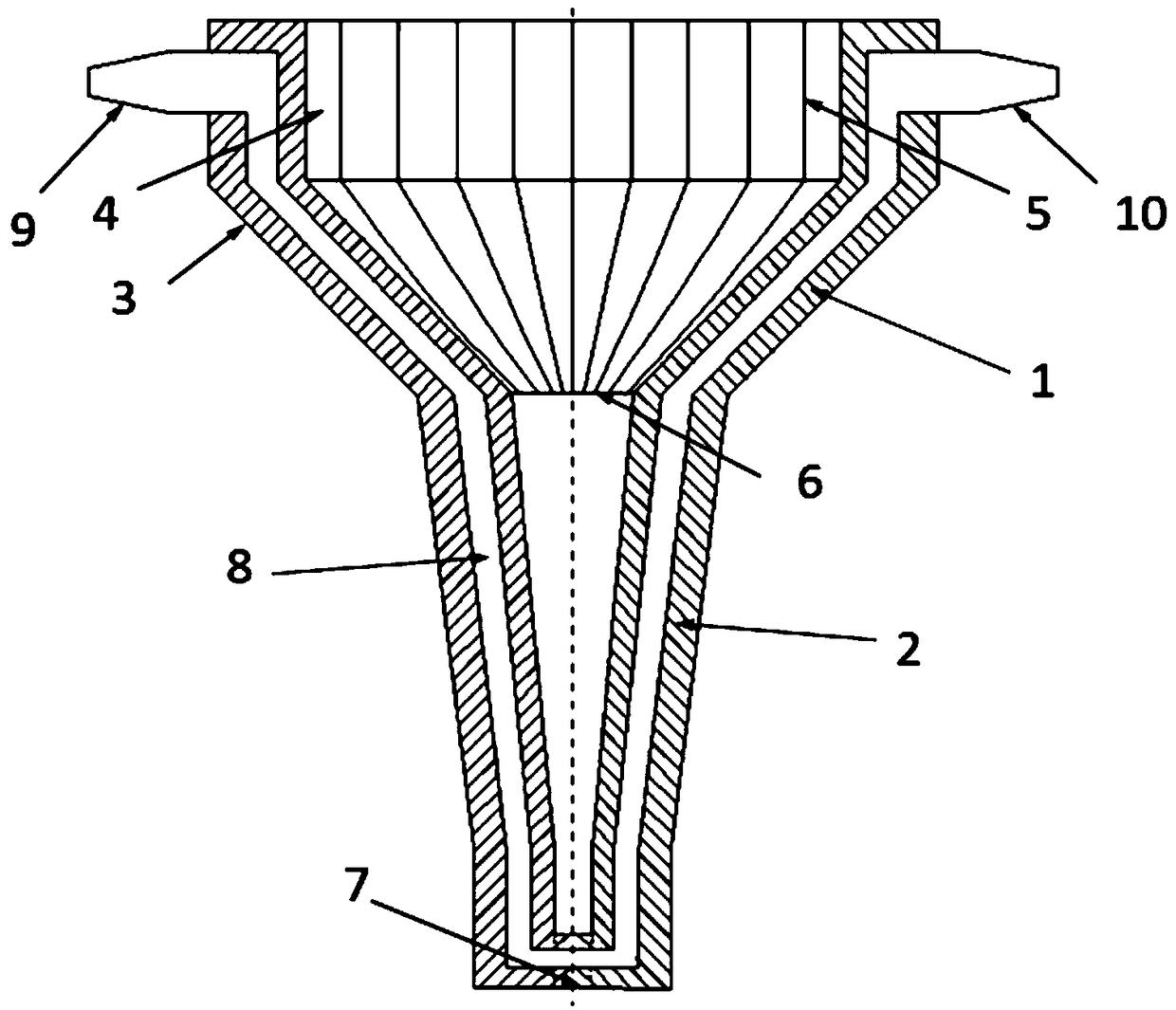

Water-cooling copper crucible device for atomization powdering

A water-cooled copper crucible and atomization powder-making technology, which is applied in the field of water-cooled copper crucible devices, can solve problems such as low atomization efficiency, clogged leakage, and atomization failure, and achieve the effects of improving smoothness, increasing heat sources, and increasing heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

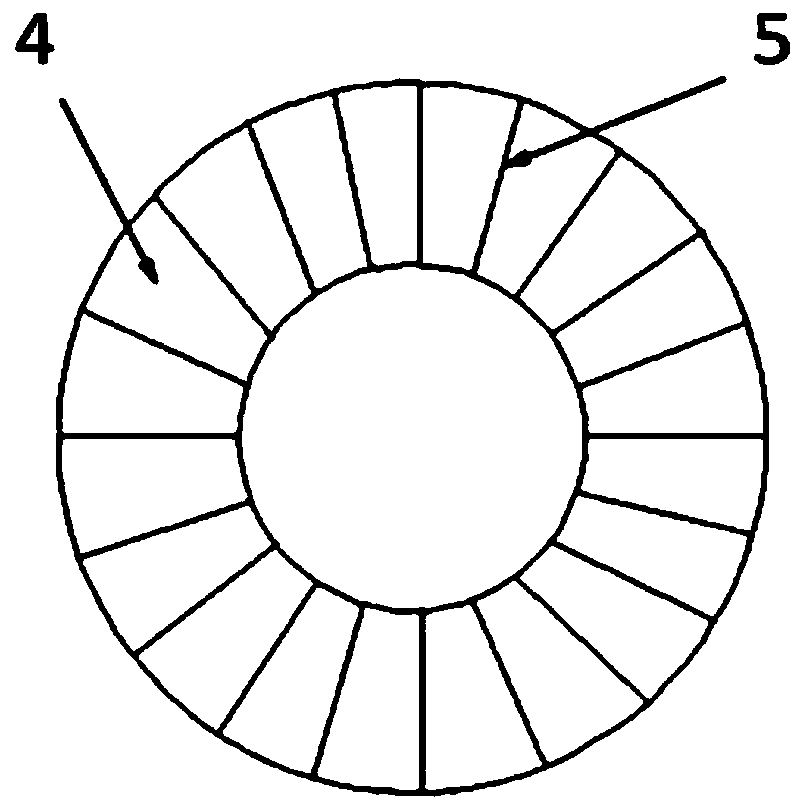

[0038] The product to be prepared in this embodiment is Ti6Al4V spherical powder. combine Figure 4 , the close-coupled gas atomization preparation method of Ti6Al4V spherical powder in this embodiment includes the following steps:

[0039] (1) Turn on the pump and compressor connected to the deionized water tank, the cooling water pressure should be kept between 0.1 and 0.2 MPa, and the outlet water temperature should be ≤20°C. When the deionized water circulates normally, put the Ti6Al4V alloy ingot into the water-cooled copper crucible, and vacuumize and pass in argon gas for gas protection, and the atomization chamber is also evacuated, and then pass in argon gas to make the atomization chamber The pressure is 800Pa;

[0040] (2) Turn on the power and increase the current step by step. When the current value reaches 250A, open the argon valve connected to the tightly coupled nozzle, and adjust the argon pressure of the tightly coupled nozzle 13 to 4Mpa. After waiting for...

Embodiment 2

[0044] The product to be prepared in this embodiment is Ti48Al2Cr2Nb spherical powder. combine Figure 4, the close-coupled gas atomization preparation method of Ti48Al2Cr2Nb spherical powder in this embodiment includes the following steps:

[0045] (1) Turn on the pump and compressor connected to the deionized water tank, the cooling water pressure should be kept between 0.1 and 0.2 MPa, and the outlet water temperature should be ≤20°C. When the deionized water circulates normally, put the Ti48Al2Cr2Nb alloy ingot into the water-cooled copper crucible, and evacuate and pass in argon gas for gas protection, and the atomization chamber is also evacuated, and then pass in argon gas to make the atomization chamber The pressure is 800Pa;

[0046] (2) Turn on the power and increase the current step by step. When the current value reaches 250A, open the argon valve connected to the tightly coupled nozzle, and adjust the argon pressure of the tightly coupled nozzle to 4Mpa. After w...

Embodiment 3

[0050] The product to be prepared in this embodiment is pure Ti spherical powder. combine Figure 4 , the close-coupled gas atomization preparation method of pure Ti spherical powder in this embodiment comprises the following steps:

[0051] (1) Turn on the pump and compressor connected to the deionized water tank, the cooling water pressure should be kept between 0.1 and 0.2 MPa, and the outlet water temperature should be ≤20°C. When the deionized water circulates normally, put the high-purity titanium sponge into the water-cooled copper crucible, and then vacuumize and pass in argon gas for gas protection. The pressure is 800Pa;

[0052] (2) Turn on the power and increase the current step by step. When the current value reaches 250A, open the argon valve connected to the tightly coupled nozzle, and adjust the argon pressure of the tightly coupled nozzle to 4Mpa. After waiting for 5-8s, the current value increases. up to 300~350A;

[0053] (3) When the molten pure Ti allo...

PUM

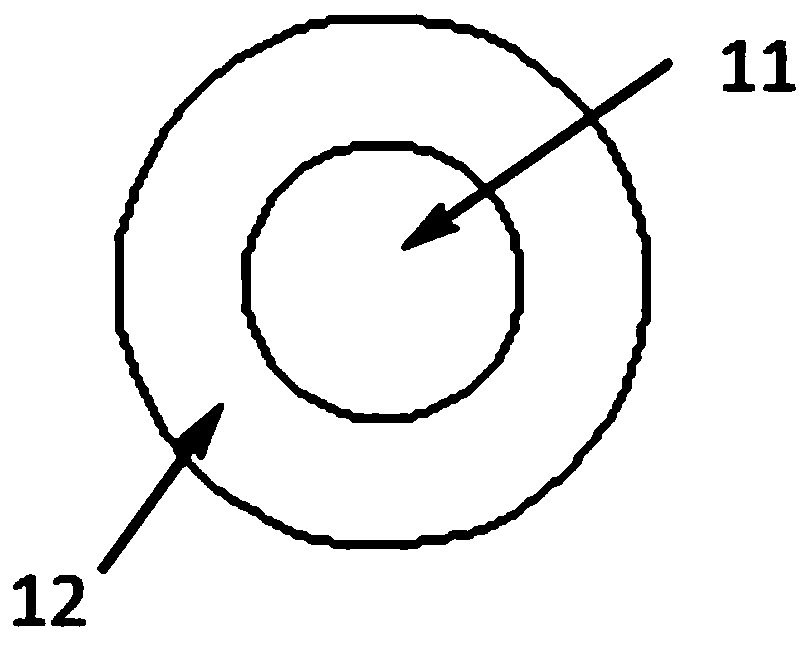

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Inner circle diameter | aaaaa | aaaaa |

| Outer circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com