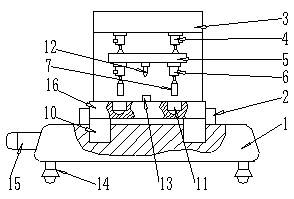

Valve pressing cap quick groove milling device

A slot milling device and fast technology, applied to milling machines, milling machine equipment, milling machine equipment details, etc., can solve problems such as low work efficiency, high product defective rate, product shaking, etc., to achieve high work efficiency, good slot milling effect, Reduce the effect of accidental injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

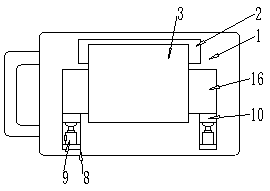

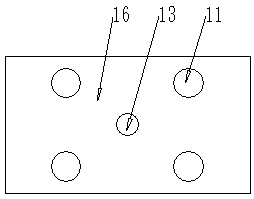

[0023] Embodiment: In the idle place of the device, place all the electrical components with matching drivers, and connect all the above-mentioned drivers, which refer to the power components, electrical components and the adapted power supply, through wires by those skilled in the art, For the specific connection method, please refer to the following working principle. The electrical connection between the electrical components is completed in sequence. The detailed connection method is a well-known technology in the field. The following mainly introduces the working principle and process, and does not discuss the electrical control. Instructions, the specific work is as follows: first put the valve pressure cap that needs to be milled into the storage slot, and then the second linear driver 9 can push the slider 10 to move, so that the slider 10 drives the mounting plate 16 to move, at this time The infrared transmitter 12 can transmit a signal, and then the infrared receiver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com