Electric contact net and storage battery set dual-power steel rail milling-grinding machine

A technology for rail milling and grinding car and battery pack, which is applied to tracks, track laying, track maintenance, etc., can solve the problems affecting rail milling and grinding effects, low pollution discharge, inability to meet, etc., and achieves high-precision measurement without interference and electricity. Convenience and highly recognized results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

[0050] Although the present invention has been described with reference to exemplary embodiments, it should be understood that the present invention is not limited to the specific embodiments described and shown in detail herein, and that it is possible for those skilled in the art to do so without departing from the scope defined by the claims. Personnel may make various changes to the exemplary embodiments described.

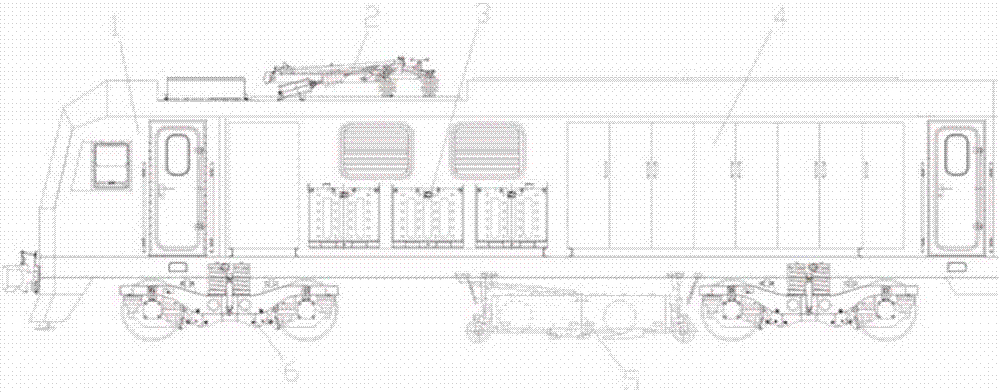

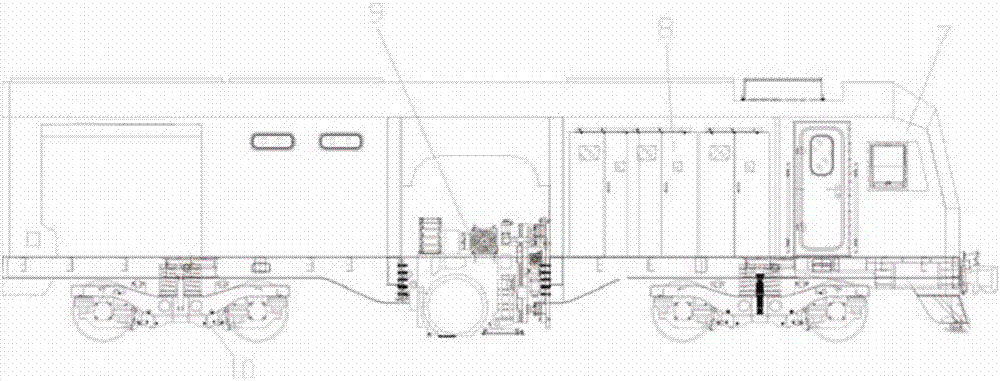

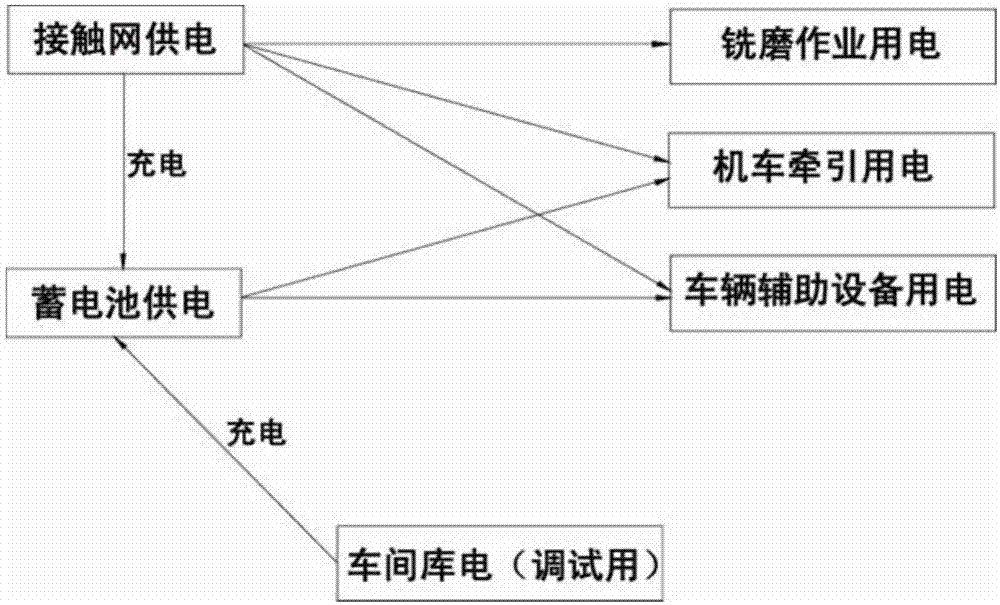

[0051] The present mainstream adopts the internal combustion engine as the driving power rail milling vehicle and has the disadvantages. The present invention provides a dual power rail milling vehicle with electric catenary and battery pack. Design thinking and key points of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com