A multi-head moving gantry friction stir welding device

A friction stir welding, multi-head technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of surface oxidation of welding parts, undetectable welding temperature, remote welding parts, etc., and achieve diversified welding performance. , avoid welding defects, reduce the effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

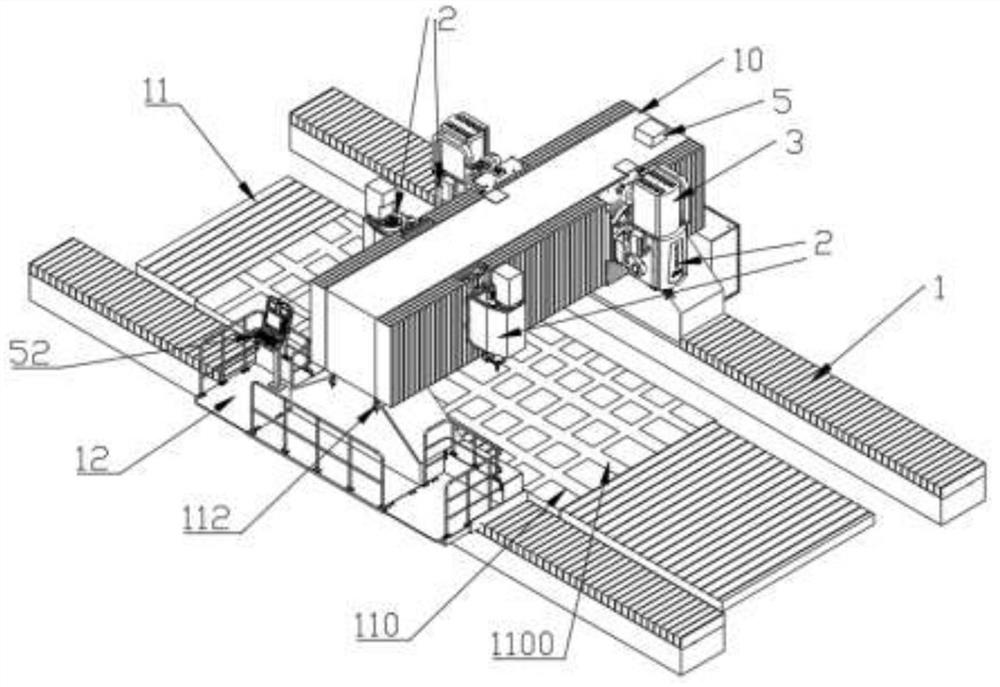

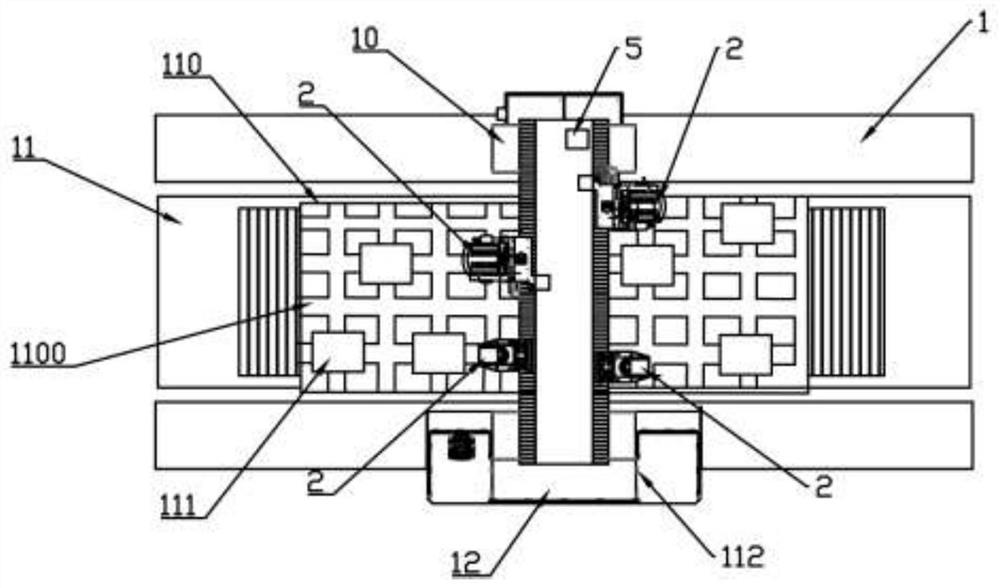

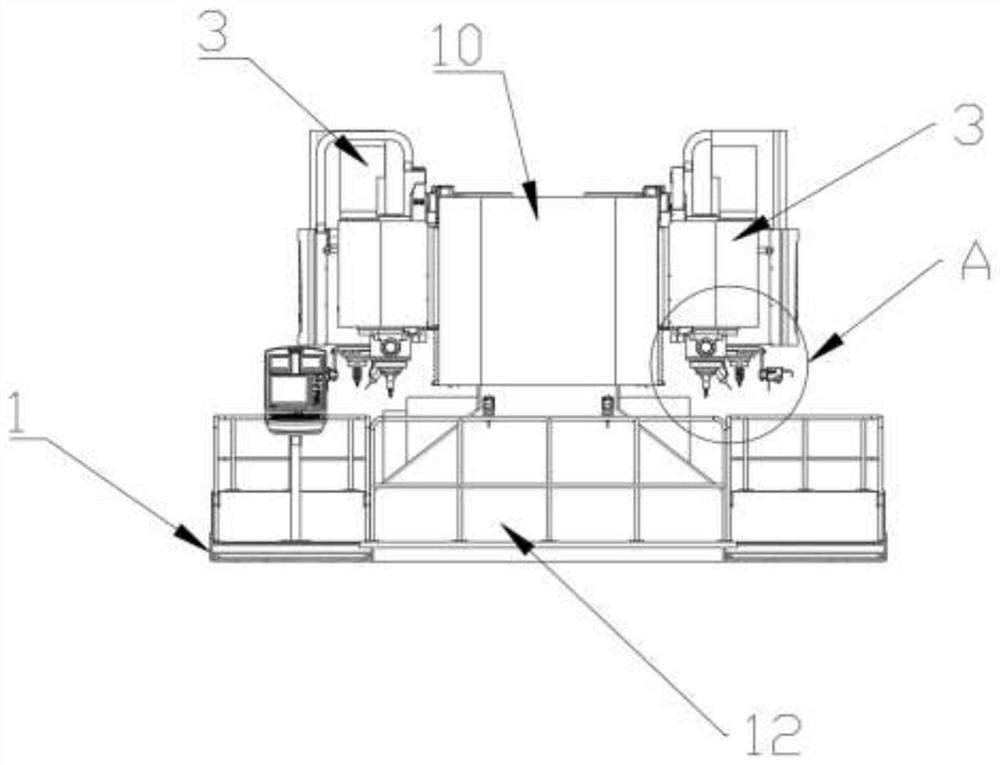

[0036] Example: such as figure 1 , 2 The shown multi-head moving gantry friction stir welding device mainly includes a base 1 arranged on the ground with a gantry 10 on the upper end and a workbench 11 located at the lower end of the gantry 10 along the width direction. Four welding heads 2 of different specifications on the front and rear sides of the beam of the gantry 10 and on the upper end of the workbench 11, the power system 3 that drives each welding head 2 to move, the welding measuring element 4, the intelligent control element 5, and various electrical components the power source to which the component is electrically connected;

[0037] Such as Figure 5 As shown, the workbench 11 is provided with a welding mobile plate 110 that can slide along the width direction of the workbench 11. The upper end of the welding mobile plate 110 is provided with a welding fixture 111 for fixing the weldment, and the upper end of the welding mobile plate 110 is provided with a me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com